Anode material, anode and battery

A negative electrode material and negative electrode technology, applied in the direction of secondary batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of reduced energy density, large oxide ratio, thick film thickness, etc., to prevent the reduction of volumetric energy density, high Effect of capacity, smooth insertion and withdrawal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0023] The anode material according to the first embodiment of the present invention includes an active portion containing at least one of silicon and tin as constituent elements and a covering portion of a metal oxide arranged on a part of the surface of the active portion. It is because silicon and tin have a high ability to insert and extract lithium, and high energy density can be obtained. Also, because the chemical stability of the negative electrode material can be improved when the covering portion is included. In addition, since the negative electrode material has an exposed portion in which no covering portion is arranged on a part of the surface of the active portion, lithium or the like can be inserted and extracted smoothly.

[0024] Examples of the above active portion include a simple substance, alloy or compound of silicon, a simple substance, alloy or compound of tin, and a material containing one or two or more phases at least partially containing them. The ...

no. 2 approach

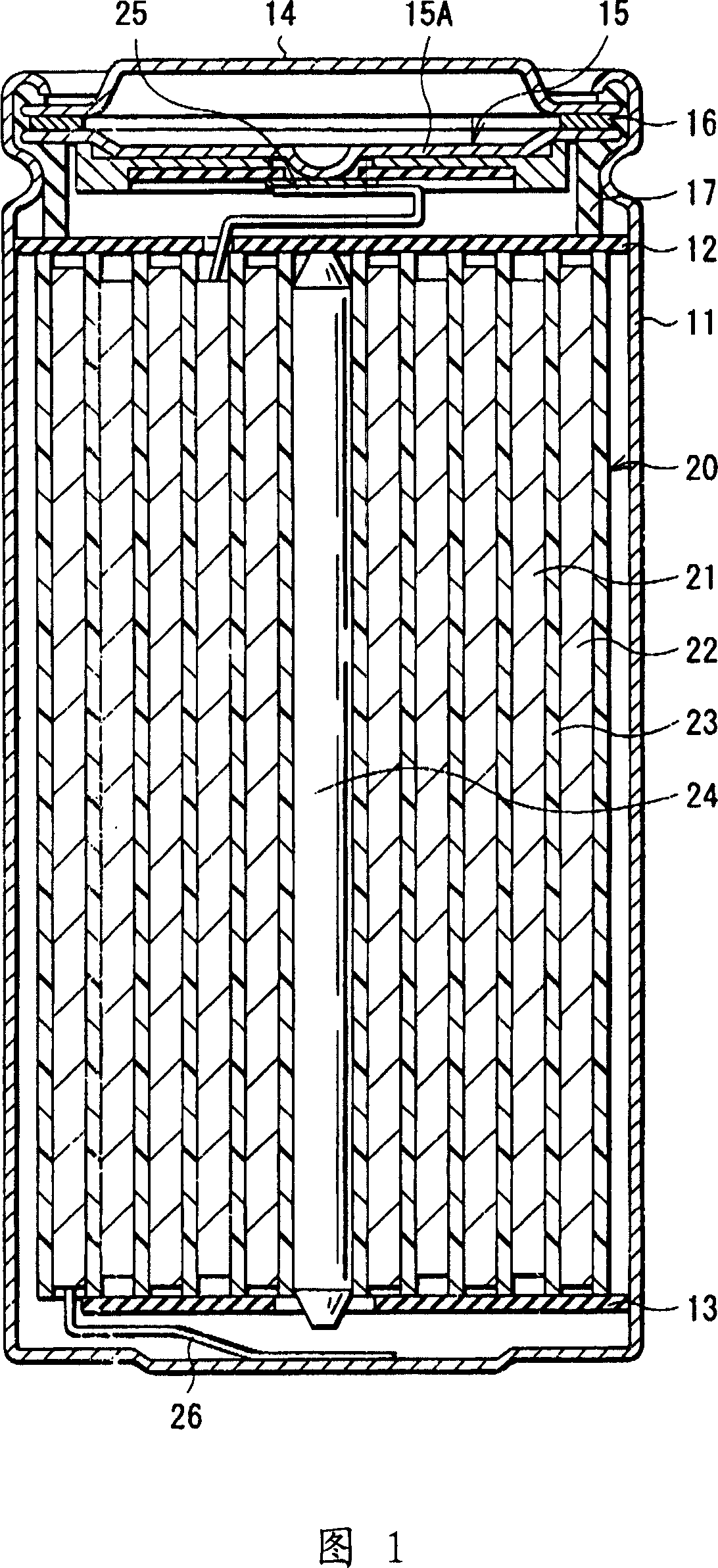

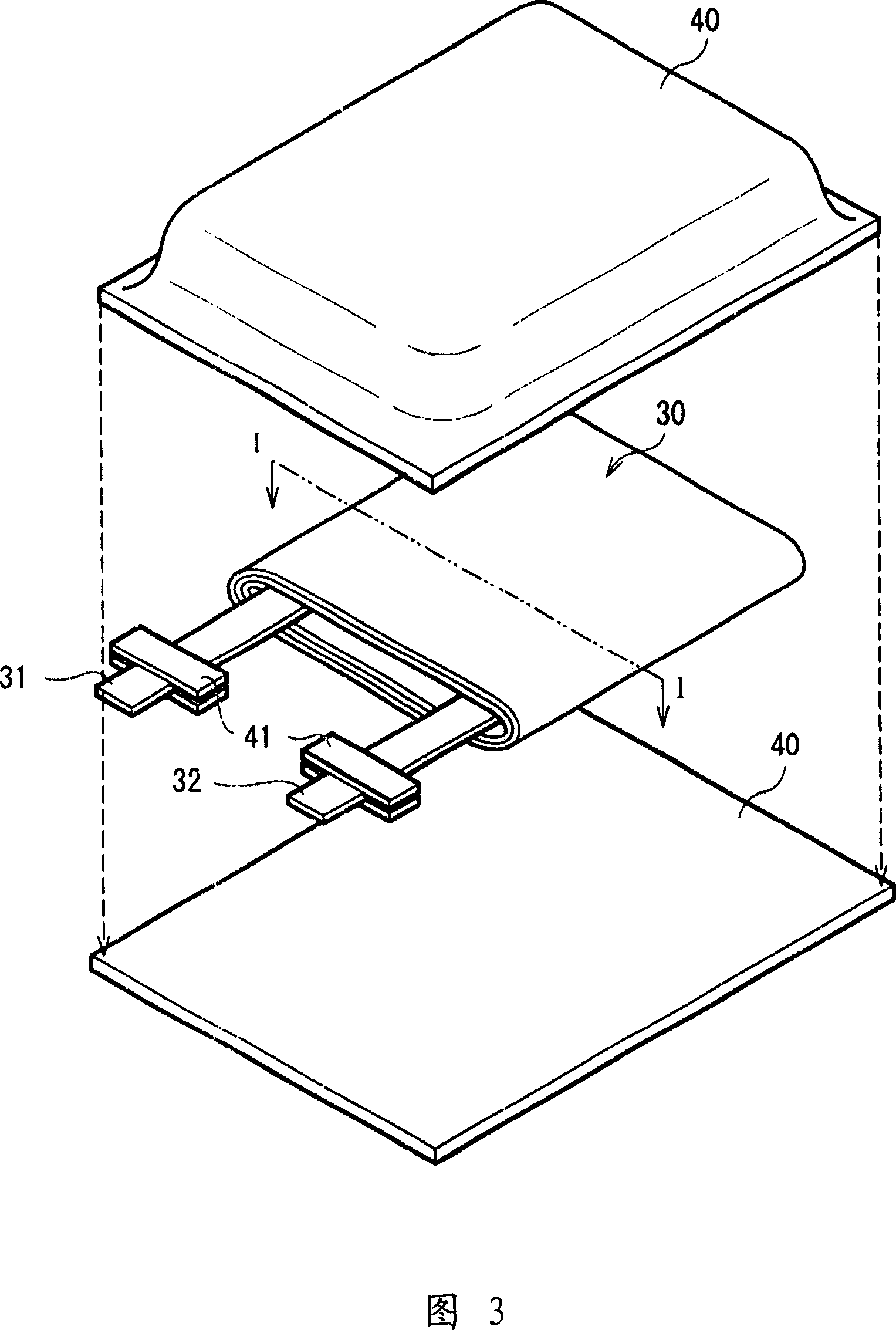

[0074] The secondary battery according to the second embodiment of the present invention has the same structure, function and effect as the first embodiment except that the structures of the negative electrodes 22 and 34 are different, so the secondary battery can be manufactured in the same manner. Therefore, in this embodiment, referring to FIGS. 1 , 2 , 3 and 4 , the same components are denoted by the same numerals as those in the first embodiment, and no further description will be given.

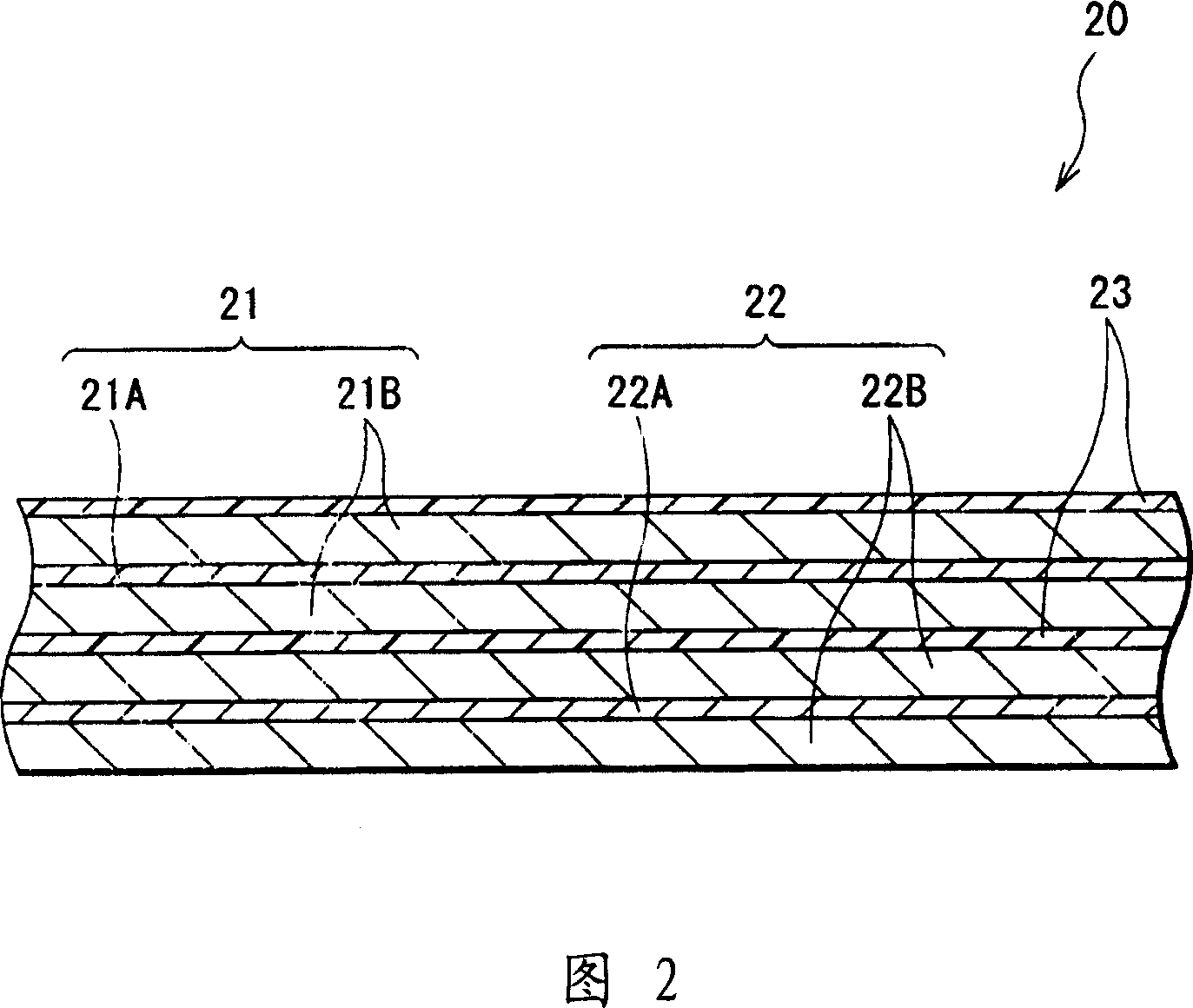

[0075] As in the case of the first embodiment, the negative electrodes 22 and 34 have a structure in which the negative electrode active material layers 22B and 34B are arranged on both faces of the negative electrode current collectors 22A and 34A, respectively, and the negative electrode active material layers 22B and 34B each include a negative electrode material, The negative electrode material includes an active part comprising at least one constituent element of silicon and tin and...

Embodiment 1-1 to 1-8

[0081] A coin-type secondary battery shown in FIG. 5 was formed. The two electrodes are formed by laminating the positive electrode 51 and the negative electrode 52 with the separator 53 impregnated with the electrolytic solution to form a laminate, sandwiching the laminate between the package case 54 and the package cover 55 , and then gap filling by the gasket 56. secondary battery.

[0082] First, after an active portion was formed on the anode current collector 52A formed of a copper foil having a thickness of 10 μm by an electron beam evaporation method, the anode current collector 52A was punched into a sheet having a diameter of 16 mm.

[0083] Then, in Examples 1-1 to 1-5, the negative electrode current collector 52A on which silicon was deposited was immersed in a solution obtained by dissolving boric acid as a fluorine anion trapping agent in hexafluorotitanic acid as a fluorine metal complex. In a solvent formed in ammonium to deposit titanium oxide (TiO 2 ), thereb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com