Beta-type silicon carbide whisker reinforcement method

A silicon carbide whisker and reinforcement treatment technology, which is applied to improve the performance and expand the application field of photosensitive resin-based composite materials, and can solve the problems of insufficient strength and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

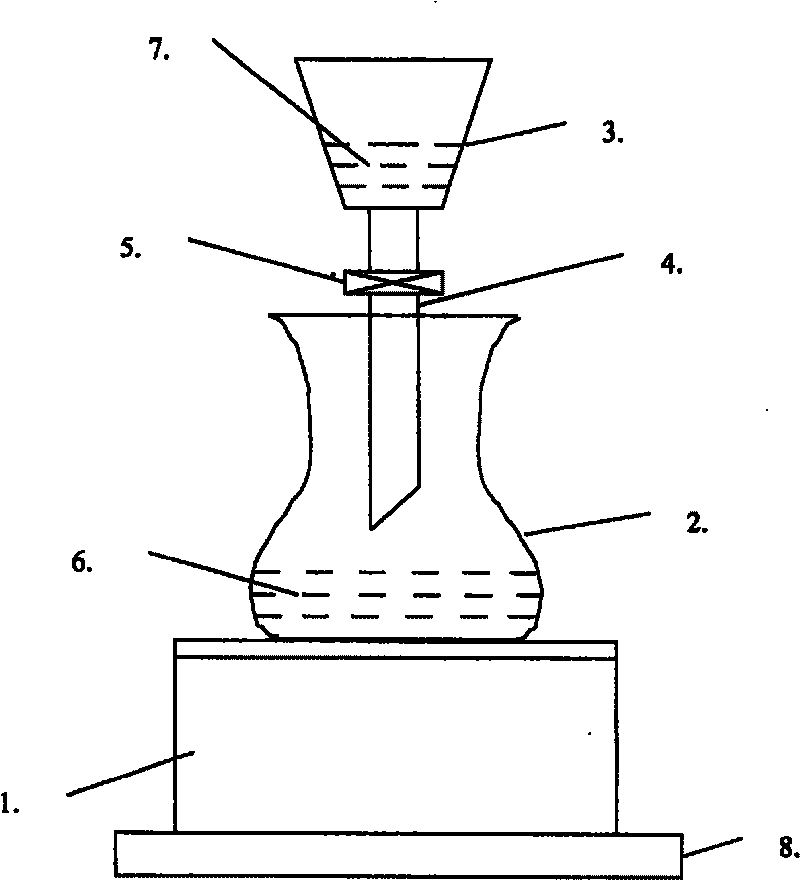

[0075] The present invention will be further described below in conjunction with accompanying drawing:

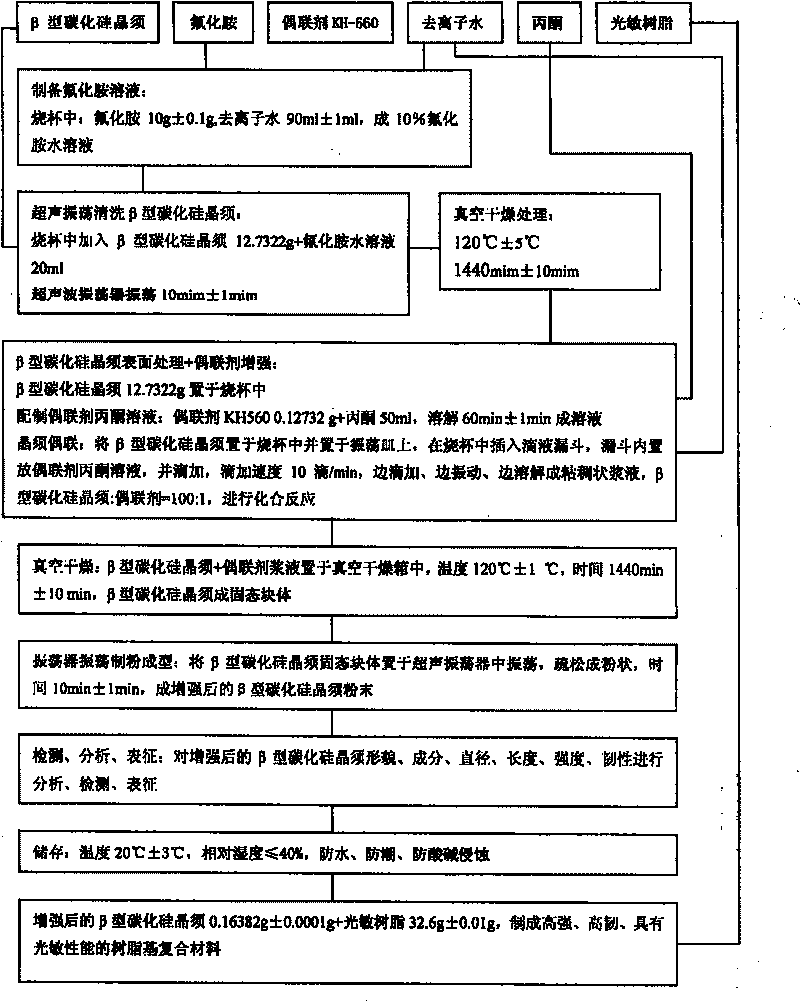

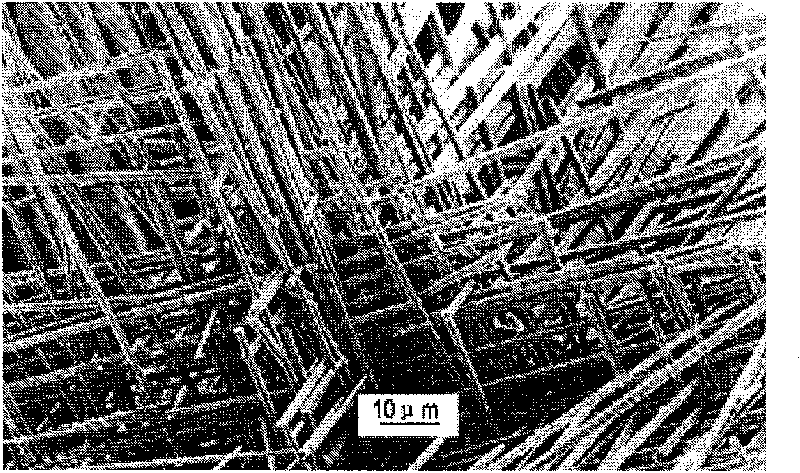

[0076] Figure 1 It shows the process flow chart of the enhanced treatment method of β-type silicon carbide whiskers and photosensitive resin, which must be strictly followed by the process flow and process parameters, and operated in sequence. First, the enhanced treatment of β-type silicon carbide whiskers is performed, and then matched with the photosensitive resin , mixed to make a composite material with high strength, high toughness and photosensitive properties.

[0077] The required chemical substances and materials should be strictly selected, and the precision and purity should be controlled, and no impurities should be involved to prevent side reactions, so as not to affect the physical properties of β-type silicon carbide whiskers after enhancement.

[0078] The chemical substances used in the enhanced modification treatment method should be strictly weighed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com