Process for preparing rigid polyurethane foams

A technology of rigid polyurethane and foamed plastics, applied in the field of foamed plastics, can solve the problems of reducing the thermal conductivity of cyclopentane, obvious greenhouse effect, etc., and achieve the effects of solving volatile, reducing thermal conductivity and improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

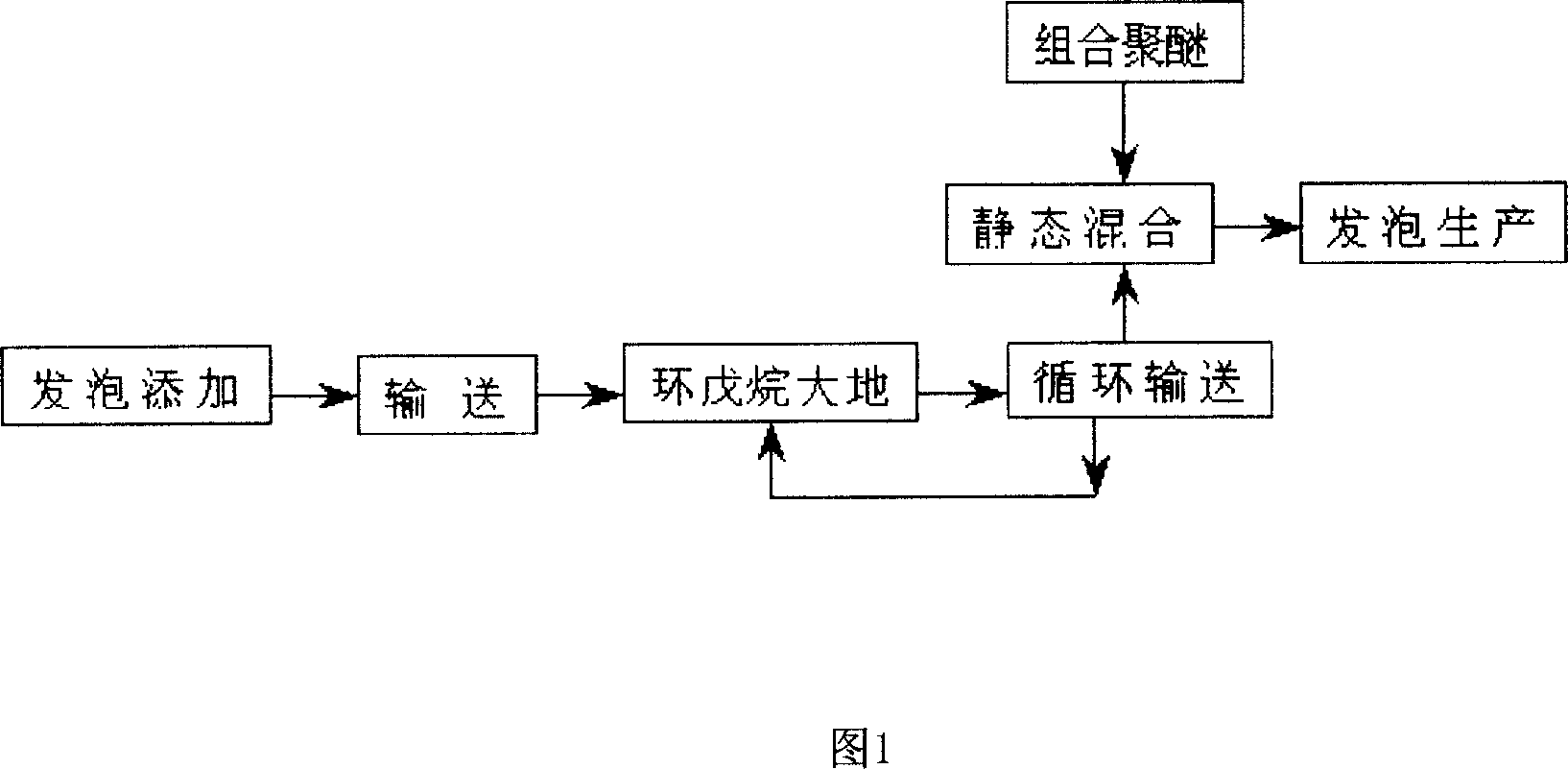

Image

Examples

Embodiment Construction

[0016] The production method of rigid polyurethane foam of the present invention uses polyisocyanate, combined polyether, foaming agent and novel foaming additive as raw materials. Combined polyether includes polyol, water, catalyst, stabilizer, etc. The main component of combined polyether is a variety of monomeric polyethers with a functionality of 3 to 8 and a molecular weight below 1300. Commonly used monomeric polyethers contain several of the following Monomer polyether: amine ether, glycerol polyether, sucrose polyether, mannitol polyether, sorbitan polyether, glycerol sucrose polyether, xylidine polyether, polyester polyether, etc. The catalyst is various amine catalysts or trimer catalysts. The foaming agent can be HCFC-141b, HFC-245fa, cyclopentane, and cyclo / isopentane. The new foaming additive is an organic fluorine compound, such as the FA-188 foaming additive of 3M Company, which has ODP =0, GWP value<100, the advantage of environmental protection is good, adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com