High-temperature-resistant optical film doped with stabilized zirconia and method for preparing same

A technology for stabilizing zirconia and optical films, applied in optics, optical components, ion implantation coating, etc., can solve problems such as invisible optical films, and achieve the effect of high brightness and improved resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

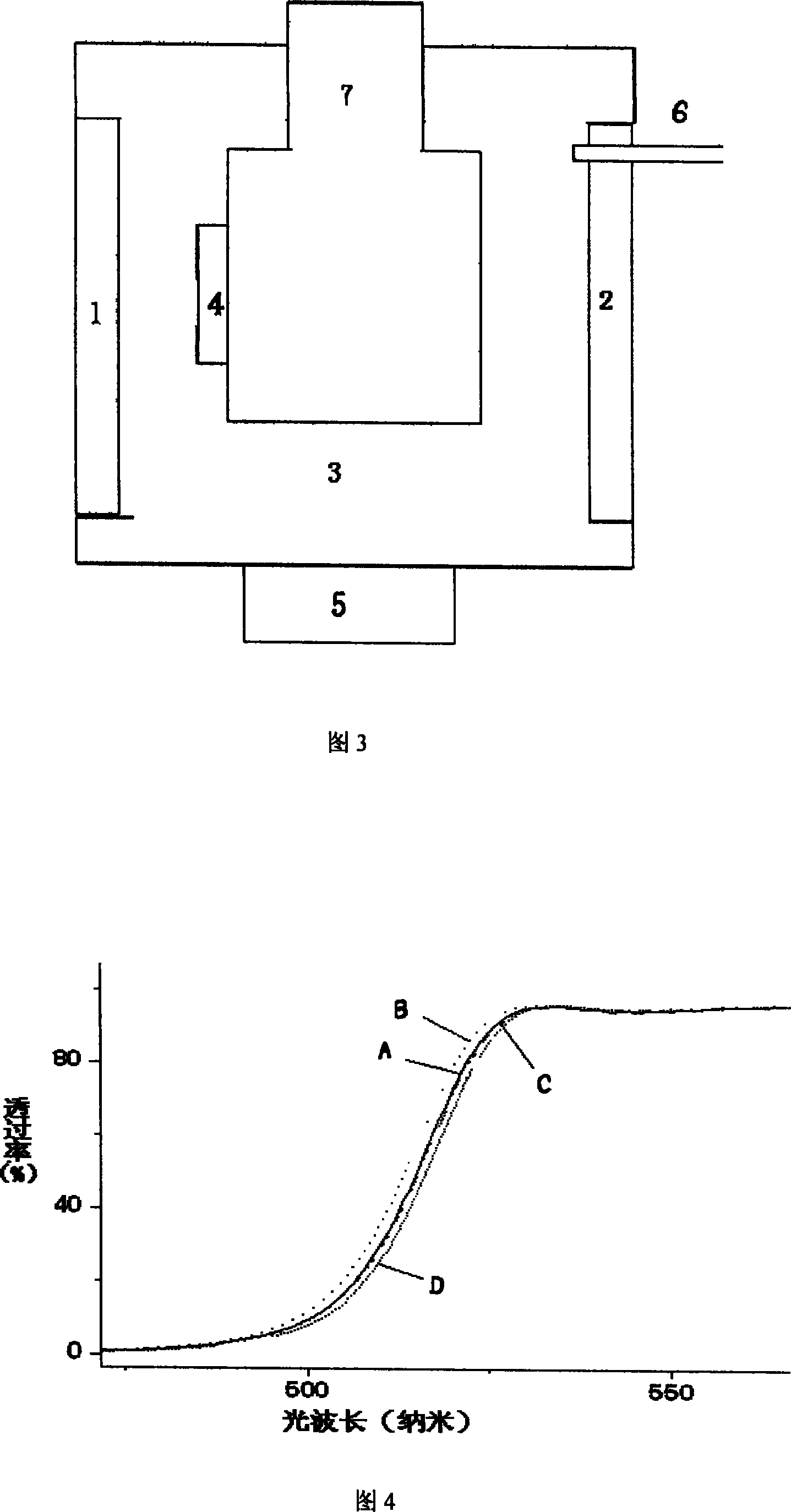

[0018] Example 1: Using magnetron reactive sputtering to prepare a long-wave transmission filter with high temperature resistance

[0019] What is used in this embodiment is the ASC-800 magnetron reactive sputtering apparatus produced by Japan Shincron Company.

[0020] Using the magnetron reactive sputtering apparatus to prepare yttria-stabilized zirconia and silicon dioxide (YSZ / SiO 2 ) The process of the 20-layer long wave passing through the filter is as follows:

[0021] First prepare YSZ and SiO 2 single layer film. The metal target used to prepare the YSZ layer is a mixed metal plate spliced by metal yttrium (Y) and metal zirconium (Zr), as shown in Fig. 1 and Fig. 2 . The mixed target 1 in the schematic diagram of the magnetron sputtering apparatus shown in FIG. 3 needs to be formed by placing two mixed metal plates side by side as shown in FIGS. 1 and 2 . Each mixed metal plate shown in Figures 1 and 2 is arranged with 12 pieces of zirconium metal (squares marke...

Embodiment 2

[0036] Embodiment 2: adjusting the power of the sputtering power supply can obtain the high temperature resistance characteristics of the single-layer YSZ thin films of different proportions

[0037] For mixed metal targets, the Y in the final film can be adjusted by changing the ratio of Y and Zr in the target, or adjusting the power of its sputtering power supply. 2 o 3 with ZrO 2 The molar ratio is 7--25:100, so that the film has high temperature resistance. This is because the sputtering rate ratio of metal Y and metal Zr is different under different powers, so the ratio of the film prepared by using the mixed metal target changes with the power; and for the alloy target of Y and Zr, The sputtering rate ratio of Y and Zr strictly follows the ratio of Y and Zr in the alloy, and does not change with the change of power. Therefore, for alloy targets, the ratio of Y and Zr in the target can only be adjusted to adjust the sputtering rate in the final film. the Y 2 o 3 with...

Embodiment 3

[0042] Embodiment 3: Changing the power supply to prepare another kind of single-layer YSZ film and its high temperature resistance characteristics

[0043] In this embodiment, the metal target used for preparing YSZ transparent single-layer film by magnetron reactive sputtering device is the mixed target designed and used in embodiment 1 by splicing metal Y and Zr; the sputtering process pressure is 0.17Pa, Adjust the power supply to 4kW, and the flow rates of oxygen and argon are both 100 milliliters per second under standard conditions.

[0044] Analyze the YSZ thin film prepared in the present embodiment with X-ray photoelectron spectroscopy, draw its Y 2 o 3 with ZrO 2 The molar ratio is 7:100.

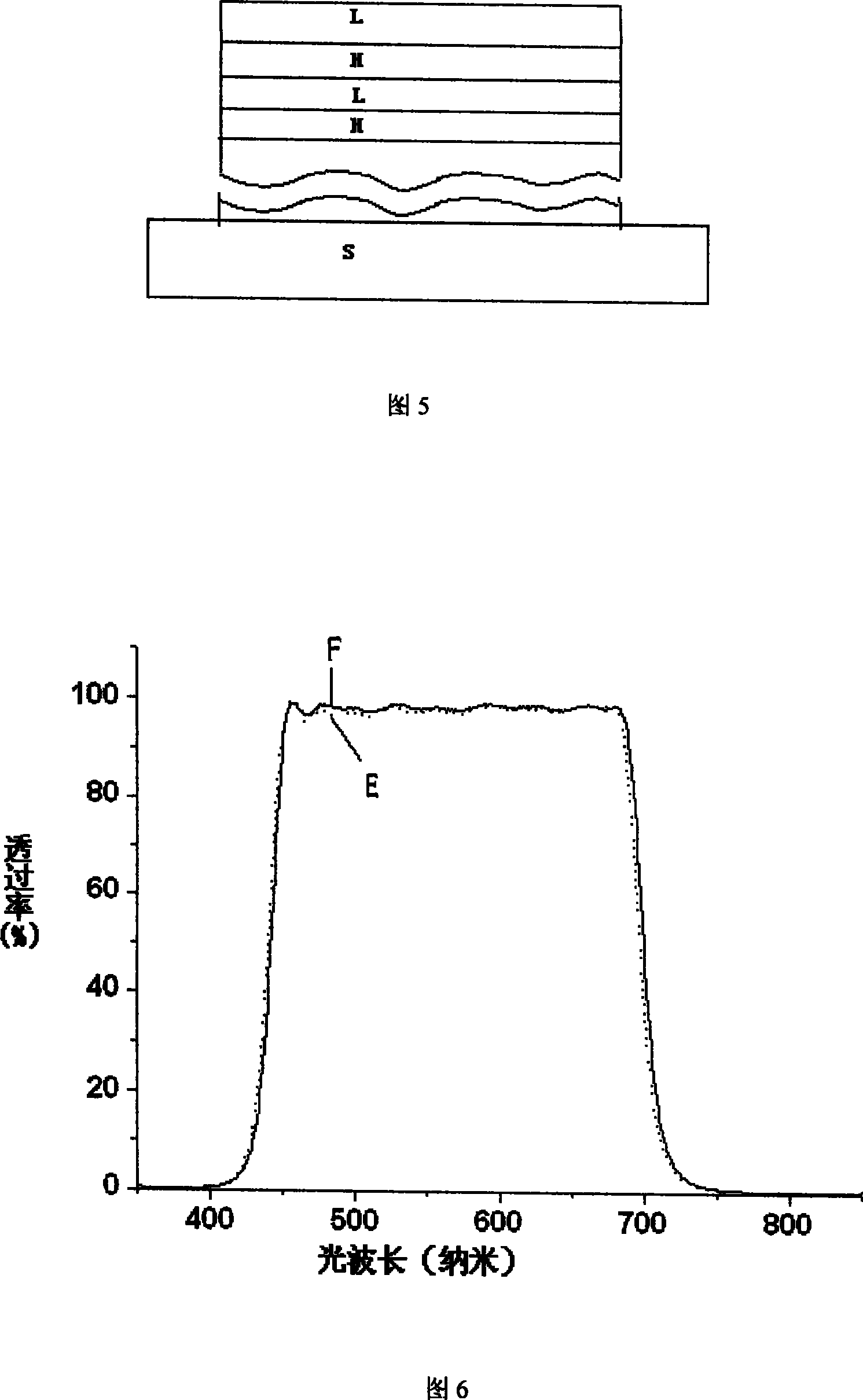

[0045] By selecting several temperatures within the temperature range of 400°C to 1000°C for the test of the transmittance spectrum of the YSZ film prepared in this example, the curve of the obtained transmittance curve corresponding to the wavelength basically does not change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com