Zeolite in packaging film

a technology of zeolite and packaging film, which is applied in the direction of packaged goods, hydrogen, x-ray tubes, etc., can solve the problems of reducing the transparency of the wall, affecting the quality of the product,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

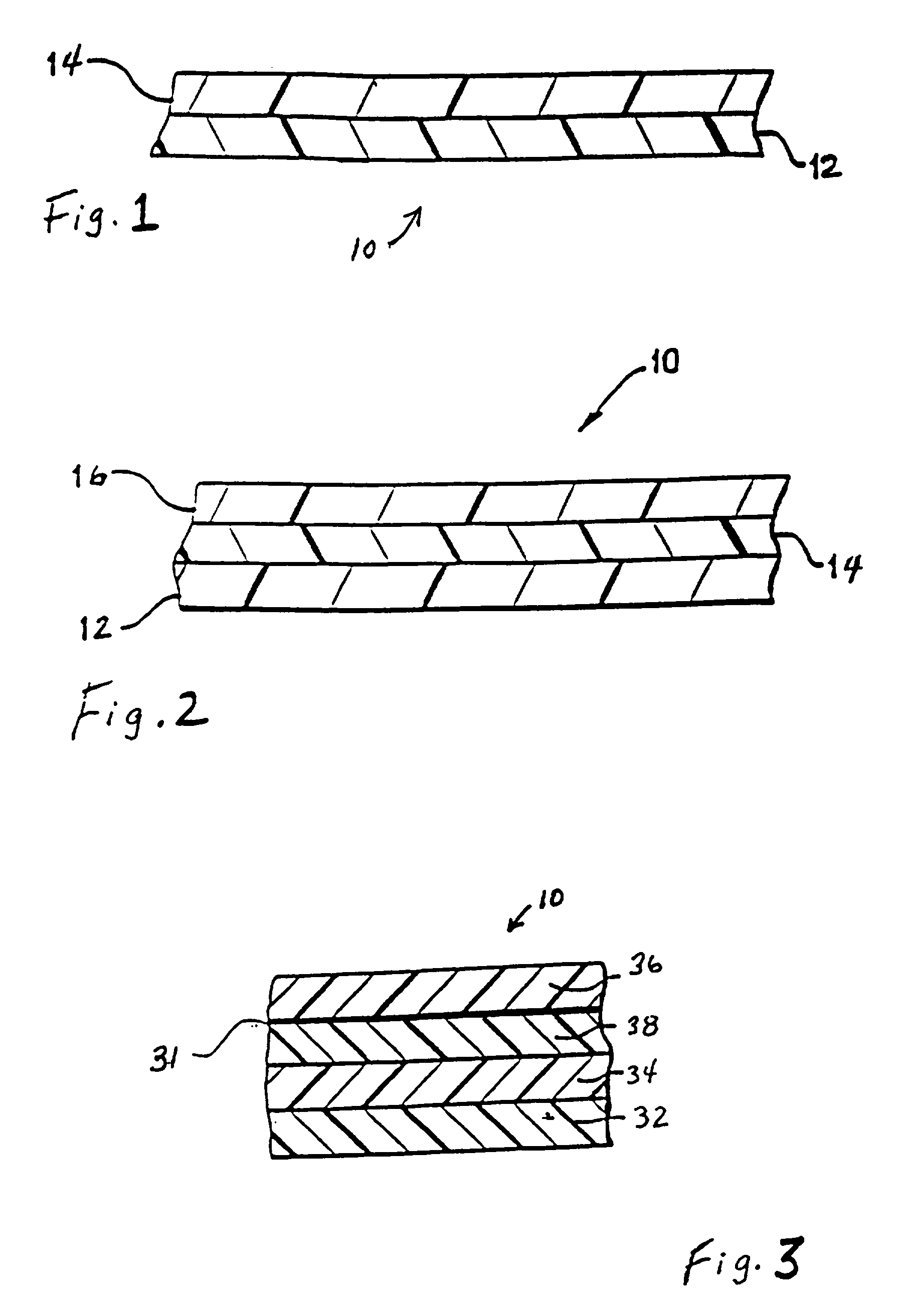

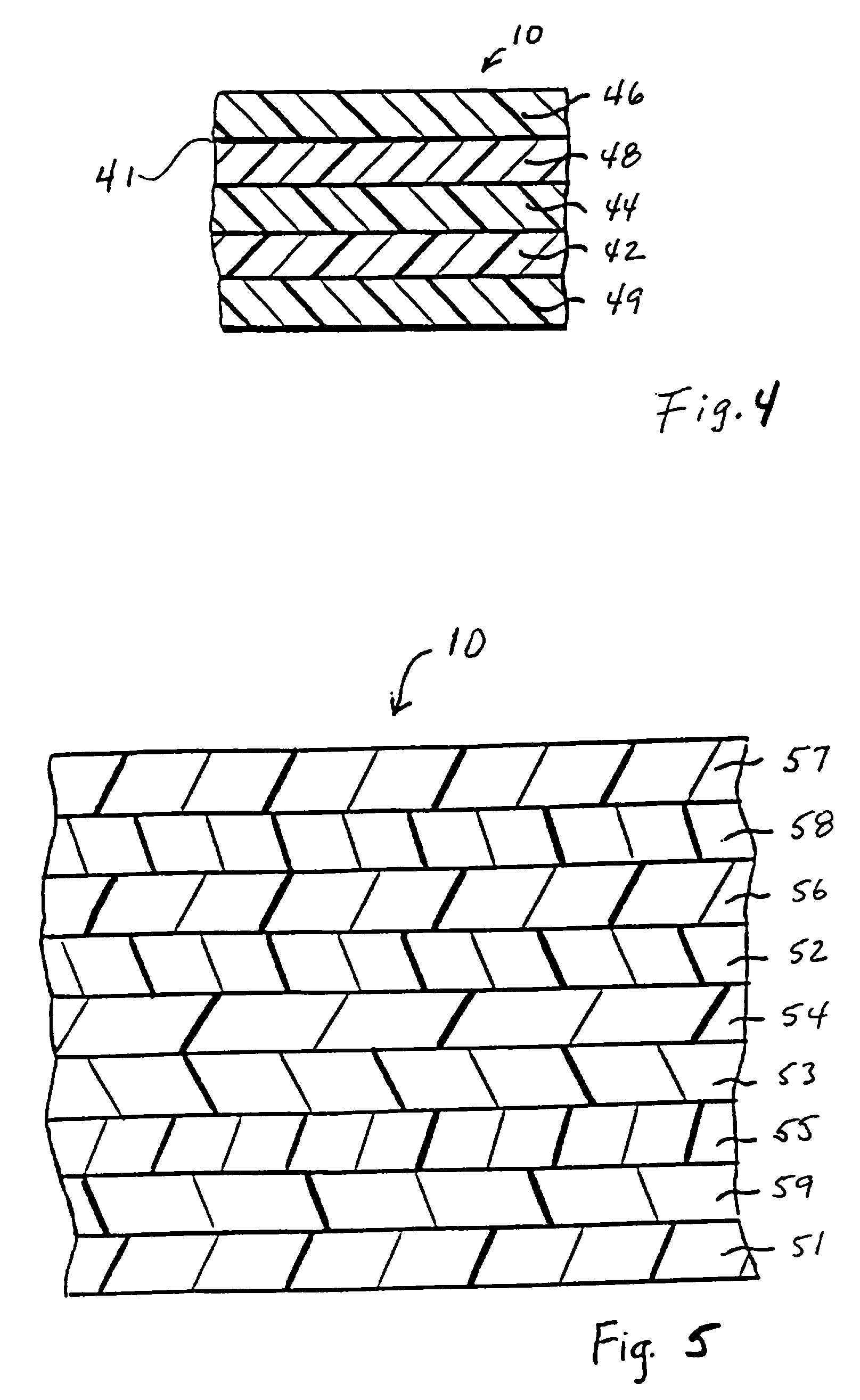

Method used

Image

Examples

Embodiment Construction

2 PE.sub.2 / ZB.sub.2 / OSB.sub.2 / EV.sub.2 / / AD.sub.2 / / F.sub.1 3 PE.sub.2 / ZB.sub.3 / OSB.sub.2 / EV.sub.2 / / AD.sub.2 / / F.sub.1 COMP. 2 PE.sub.2 / OSB.sub.2 / EV.sub.2 / / AD.sub.2 / / F.sub.1

[0069] The target (and approximate actual) gauge (in mils) of each layer of the laminate structures of the invention was:

8 layer 1 layer 2 layer 3 layer 4 adhesive layer 5 0.20 0.20 0.50 1.00 (minimal) 0.50

[0070] The target (and approximate actual) gauge (in mils) of each layer of the comparative laminate structures was:

9 layer 1 layer 2 layer 3 adhesive layer 4 0.40 0.51 1.04 (minimal) 0.50

[0071] The film of Examples 2 and 3 were subjected to food law migration tests to evaluate whether zeolites could remove oxidation by-products. Their efficacy was compared with Comparative 2. The list of extractables can be found in Table 3. The test results from the extraction of the films with Miglyol 812 (available from Huls America), a fatty food simulant, are summarized in Table 7. Zeolites can reduce the concentration of ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com