Magnesium injection agent for ferrous metal

a technology of ferrous metal and injection agent, which is applied in the direction of furnace details, crucible furnaces, furnaces, etc., can solve the problems of certain grades of alloys that are not wanted, and achieve the effects of improving metal recovery, reducing magnesium loss, and improving alloying of magnesium metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

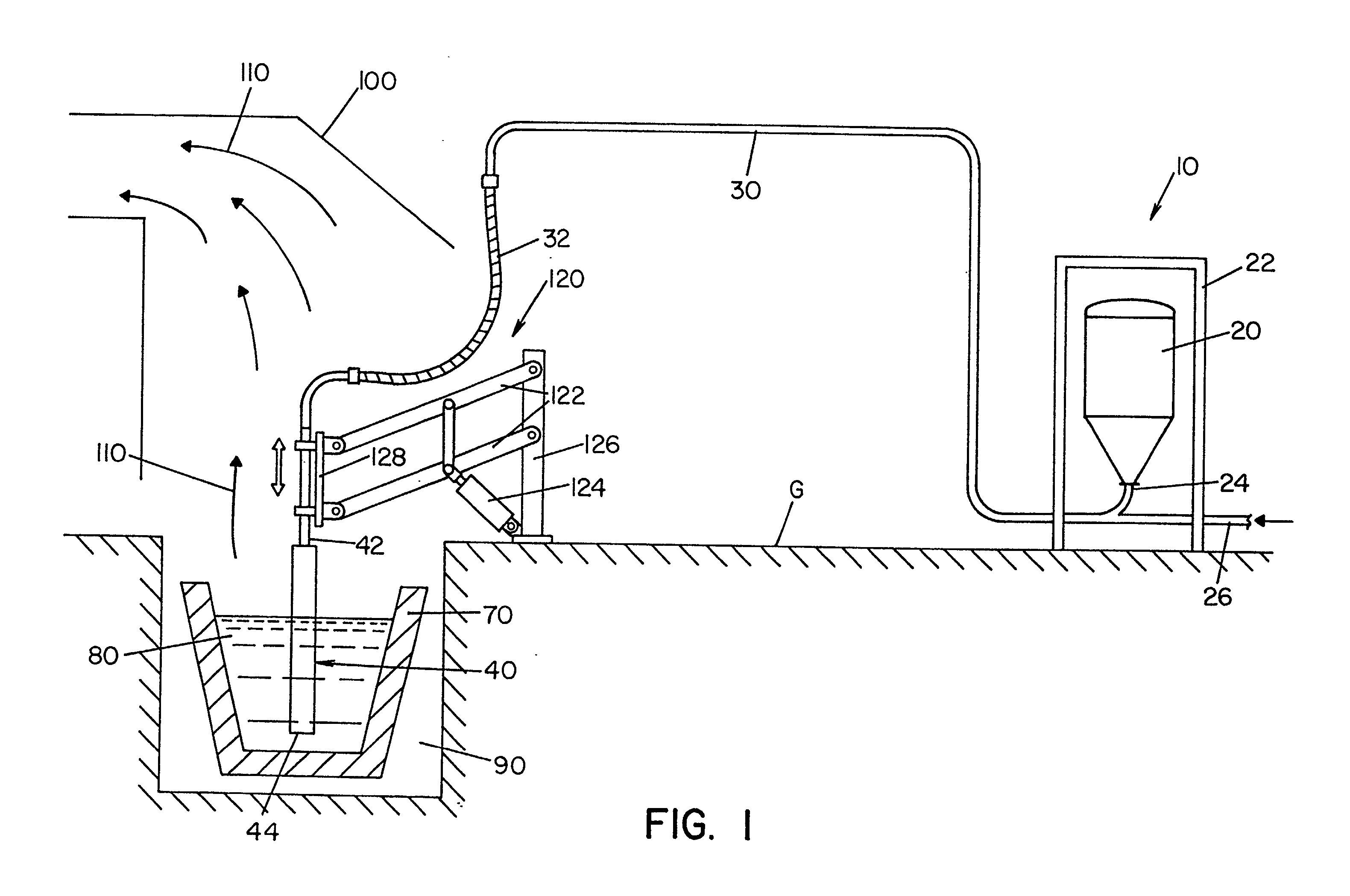

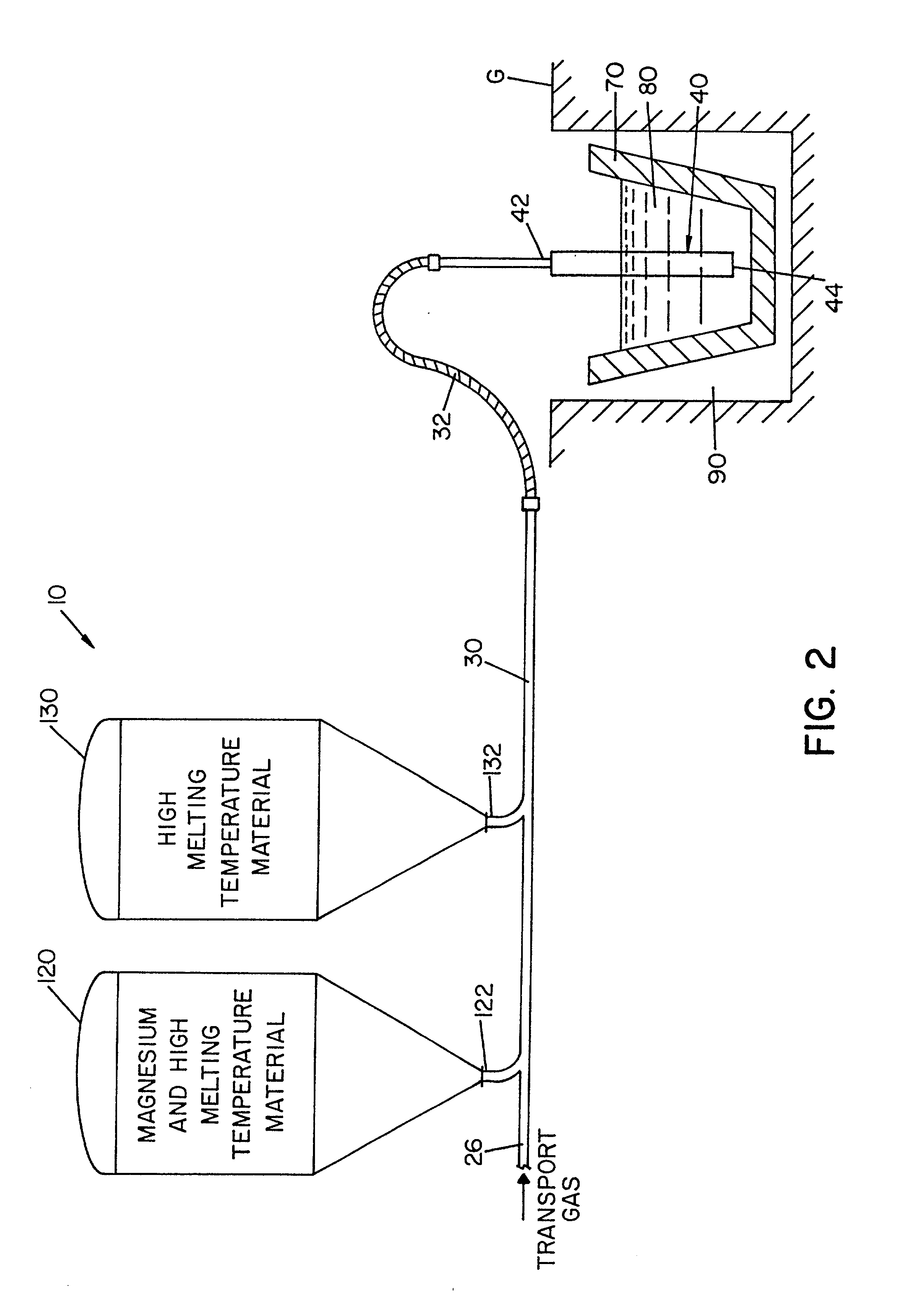

[0027] Referring now to the drawings where the showings are for the purpose of illustrating a preferred embodiment only and not for the purposes of limiting the same, FIG. 1 illustrates one preferred arrangement for injecting magnesium into a molten bath of ferro-silicon. As shown in FIG. 1 injection assembly 10 includes an injector 20 which is supported by an injector frame 22 and includes an injector port 24 for dispensing particles within injector 20 into an injection pipe 30. The particles in injector 20 are a mixture of magnesium particles and particles of a high melting temperature alloy such as ferro-silicon or magnesium-ferro-silicon. The particle size of the magnesium particles and the particles of high melting temperature alloy are substantially the same with an average particle size of less than about 1.5 mm, and preferably between about 0.18 and 1.5 mm. The ratio of magnesium particles to the high melting temperature particles in injector 20 ranges from about 5:95 to abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com