Corrugated plastic pipe sections having flanged ends and structurally tight joints thereof

a corrugated plastic pipe and end fitting technology, which is applied in the direction of flanged joints, fluid pressure sealing joints, sleeves/socket joints, etc., can solve the problems of reducing the stress crack resistance of plastic pipes, twisting and rolling, and slipping of corrugated ends, etc., to achieve cost-effective and simplify the in-plant fabrication of flanged end fittings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example i

[0068] An example of the preferred embodiment is the forming of water tight joints with High Density Polyethylene (HDPE) pipe utilized for drainage and sanitary sewer applications. The circular flange clamp is a "V" retaining coupling fabricated from 301 Stainless Steel and the gasket is extruded and spliced from natural rubber, polyisobutylene or neoprene rubber. In this example, the corrugated HDPE pipe has corrugations that are too flexible to maintain the gasket compression required for water tight sealing. As a result, typically, the corrugations are filled with rigid foam to provide sufficient stiffness. The process of foaming the corrugations is time consuming and relatively expensive. The present invention eliminates stiffening requirements because the rigid clamp provides the stiffness. In this preferred embodiment the wedged shaped gasket may be a cured natural rubber or polyisobutylene having a durometer or hardness on the Shore A scale between 50 and 60. However, a varie...

example ii

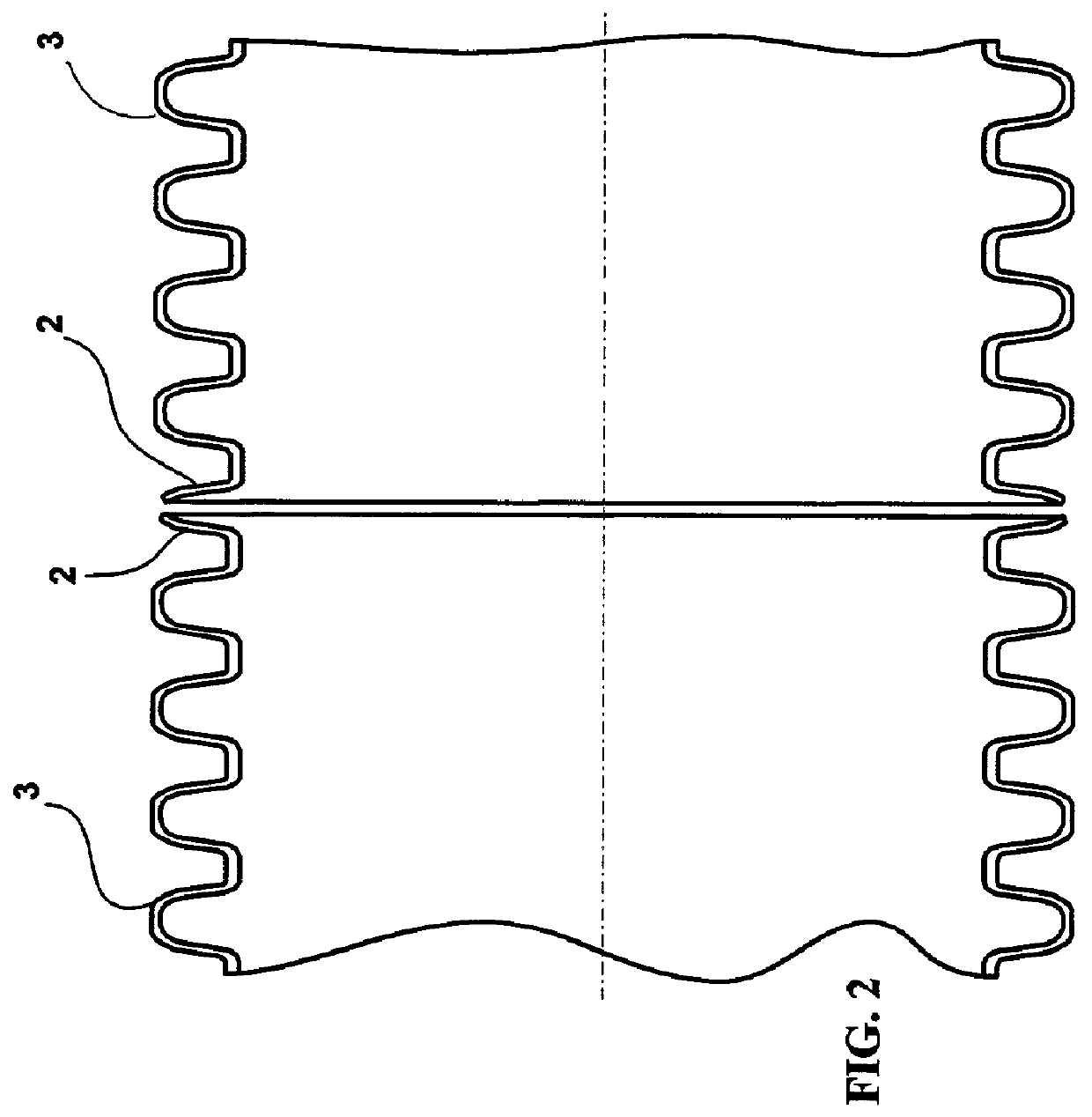

[0070] In this second example, the method and design of soil-tight and water tight joining of single wall corrugated plastic pipe is demonstrated for a second time. FIG. 11A shows two sections of single wall corrugated plastic pipe 3 with a flange 2 formed by a circumferential portion of an end corrugation. FIG. 11B shows the components for fabricating a water tight joint; the single wall plastic pipe 3 with flange 2, the flat gasket 5 and the circular flange clamp 6 in the open position. FIG. 11C shows the assembled joint wherein the circular flange clamp 6 is closed causing the gasket 5 to compress. Flange 2 is in compression avoiding tensile stresses that enhance stress cracking.

example iii

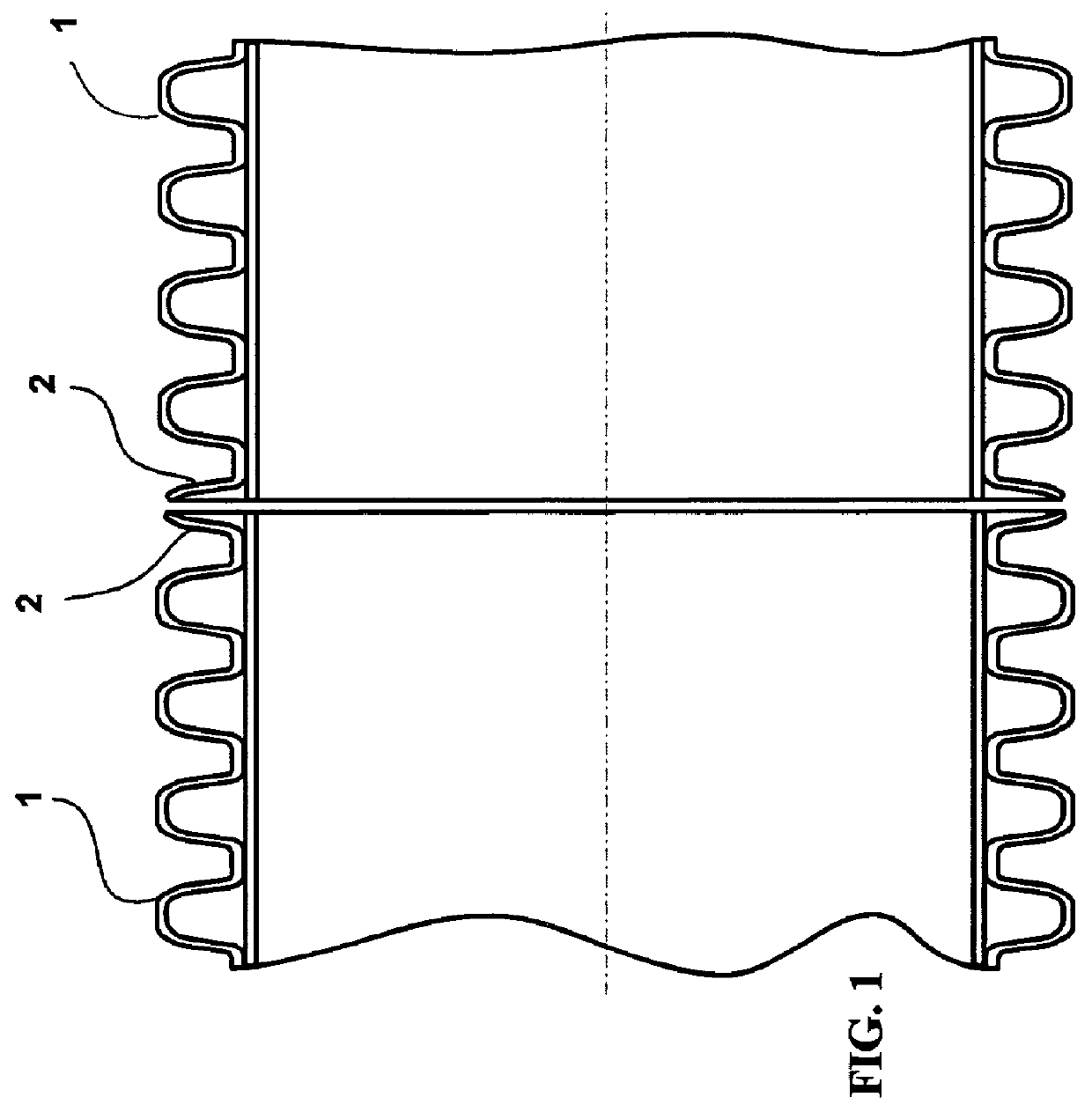

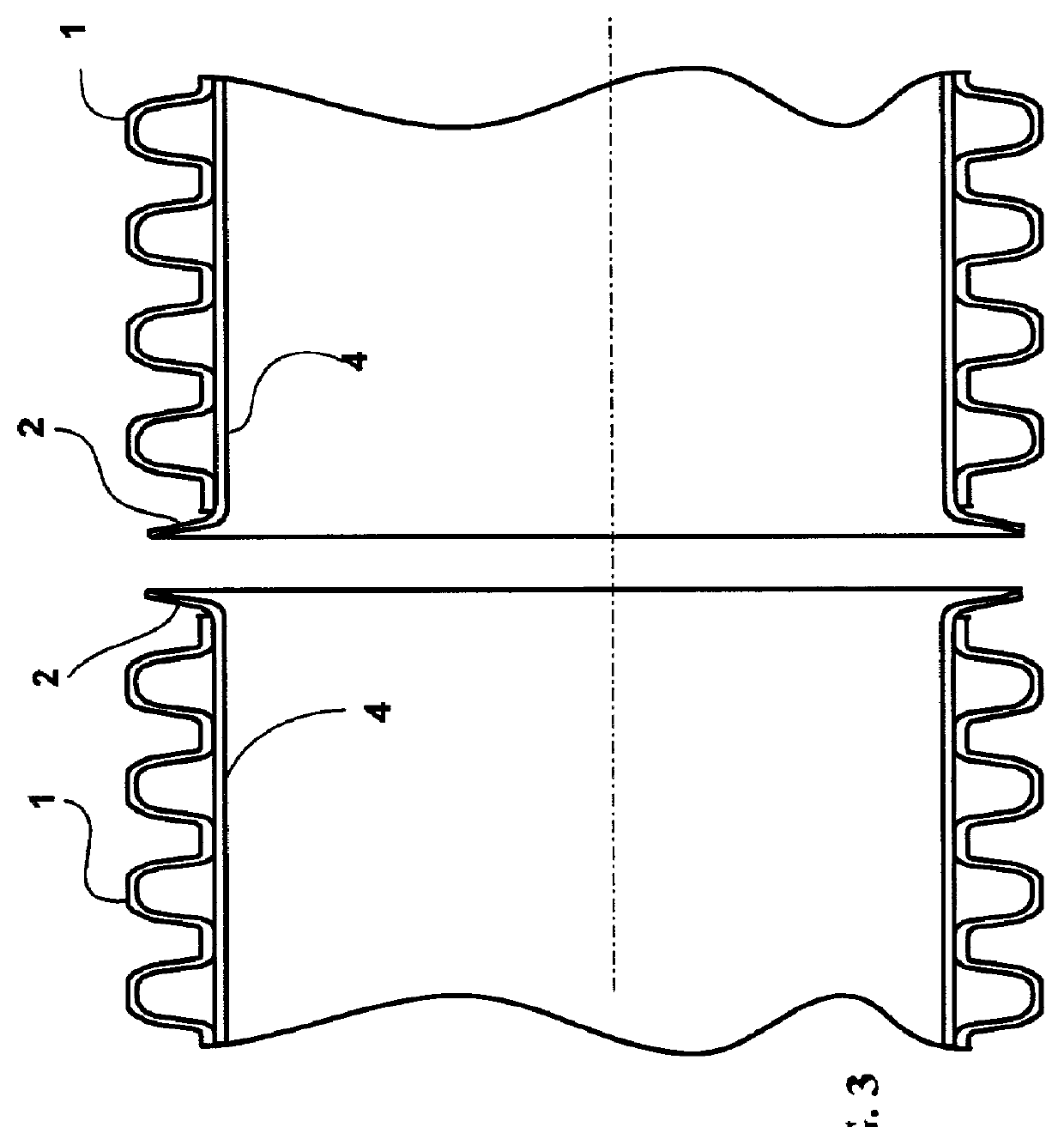

[0071] This example shows an alternate means of applying the disclosed invention to the water tight joining of dual wall corrugated plastic pipe. FIG. 2A shows two sections of dual wall plastic pipe 1 having transverse corrugations and flanges 2 at the pipe end formed from the liner. FIG. 12B shows the components for fabricating a water tight joint; the dual wall plastic pipe 1 with flange 2 formed from the liner 4, the flat gasket 5 and the circular flange clamp 6 in the open position. FIG. 12C shows the assembled joint wherein the circular flange clamp 9 is closed causing the gasket 5 to compress.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com