Process for making oxide dispersion-strengthened tungsten heavy alloy by mechanical alloying

a technology of tungsten heavy alloy and mechanical alloying, which is applied in the direction of metal-working equipment, weapons, ammunition projectiles, etc., can solve the problems of limited use, processability and abrasion resistance, and no systematic research report on the process of making oxide dispersion-strengthened tungsten heavy metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

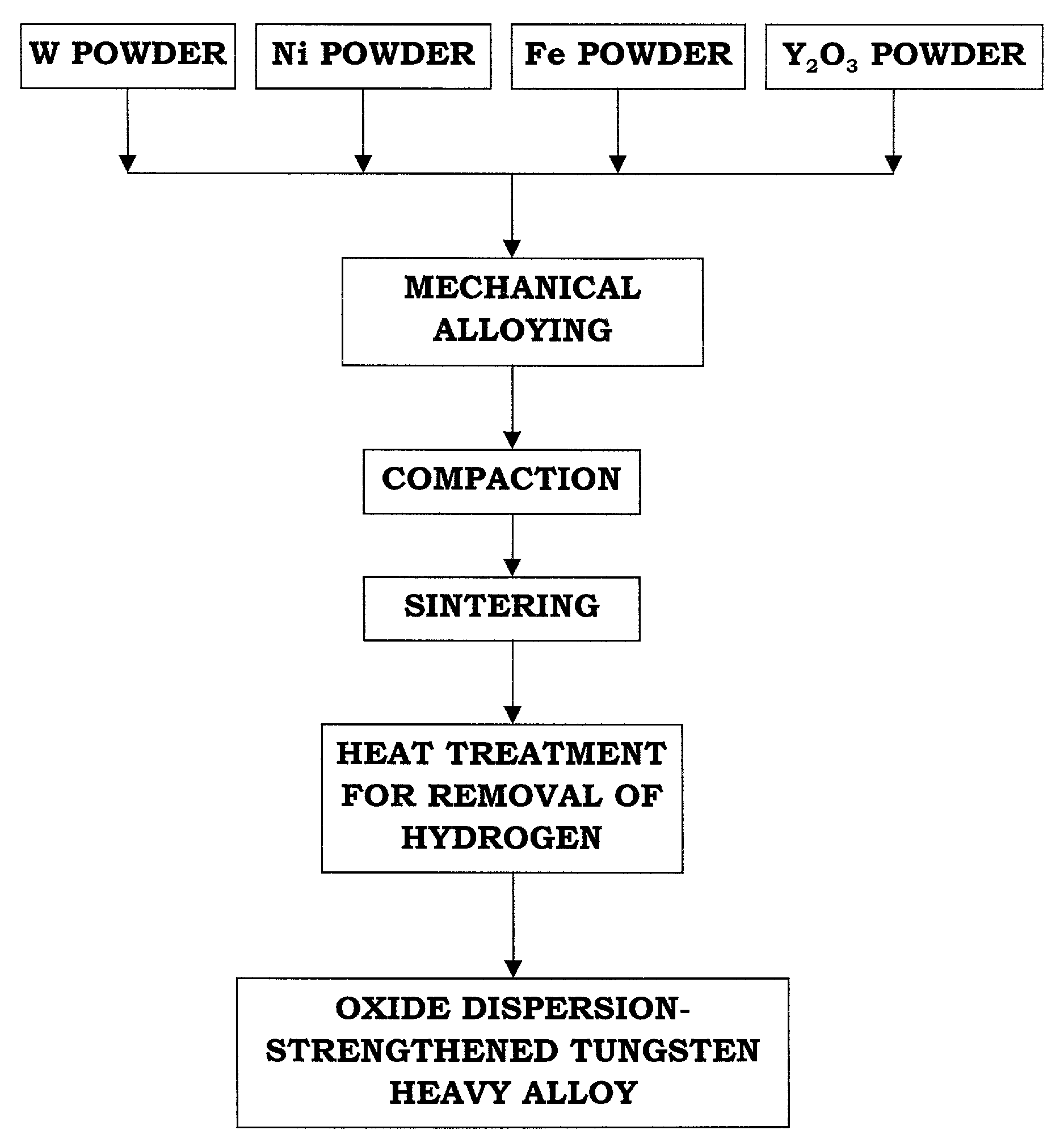

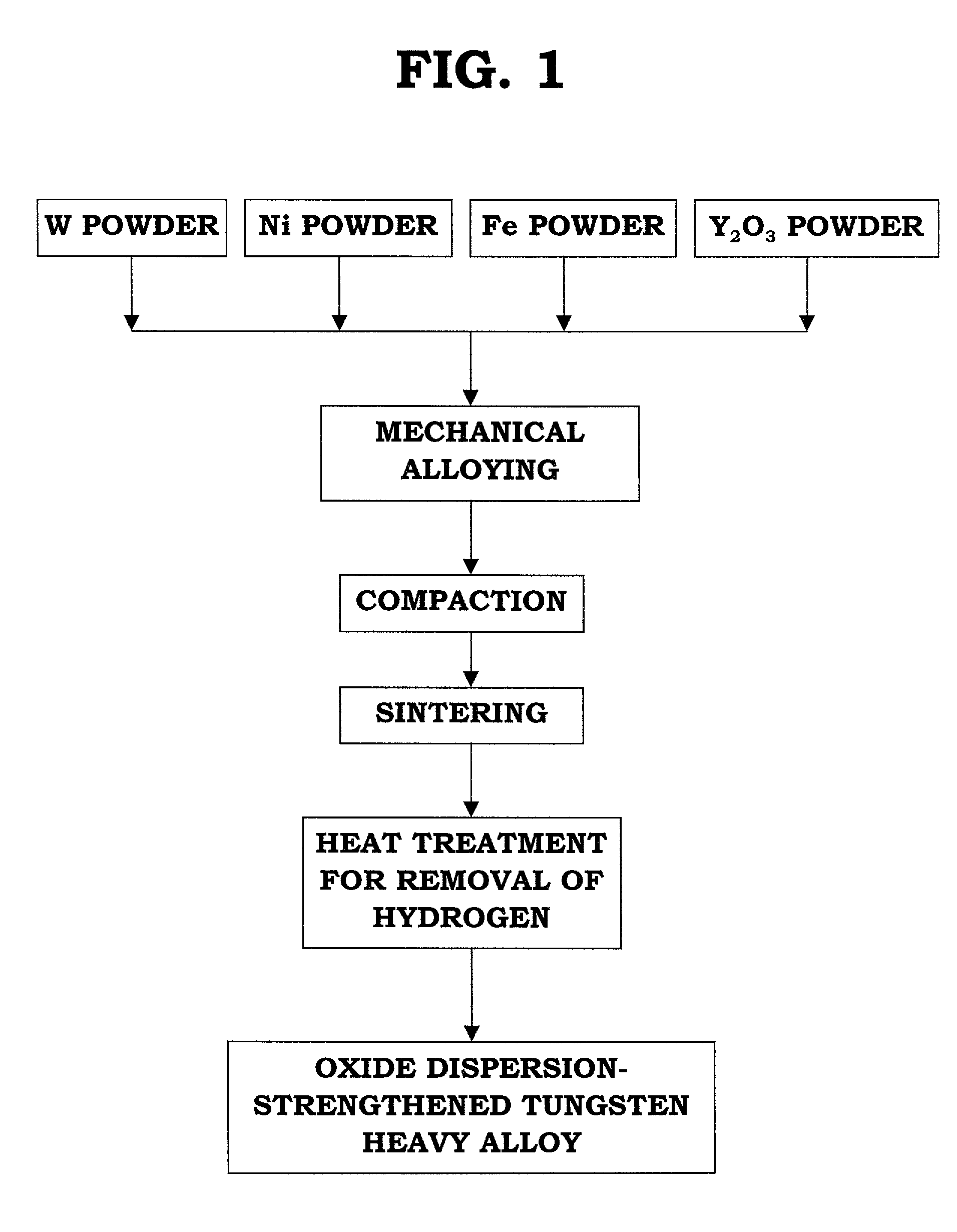

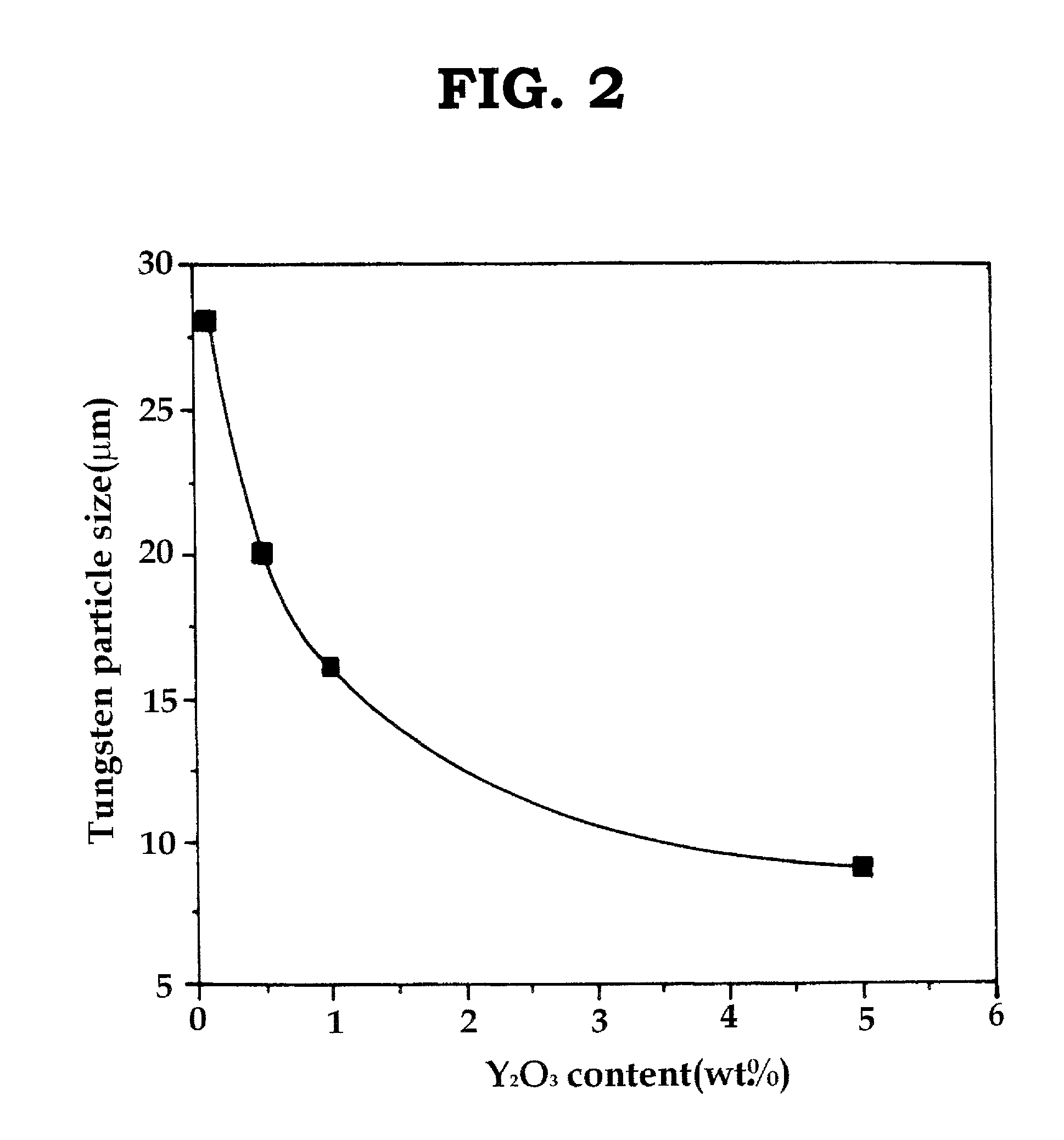

[0024] 0.1 to 5 wt. % of Y.sub.2O.sub.3 powder was added to a tungsten heavy alloy comprising 93 wt. % of W, 5.6 wt % of Ni and 1.4 wt. % of Fe and the mixture was uniformly mixed by a mechanical alloying method. The W powder had a purity of 99.9% and a particle size of 2.5 .mu.m, the Ni powder having a purity of 99.7% and a particle size of 2.5 .mu.m, the Fe powder having a purity of 99.6% and a particle size of 3.5 .mu.m, the Y.sub.2O.sub.3 powder having a purity of 99.9% and a particle size of 2 .mu.m. The mechanical alloying method using ball milling was carried out under the conditions that the milling speed was 75 rpm, the ball-to-powder ratio 20:1, the ball packing percentage 15% and the milling time 72 hours.

[0025] The oxide dispersion-strengthened tungsten heavy alloy thus obtained by the mechanical alloying was compacted into a compressed powder under the pressure of 100 MPa using a press. The compacted compressed powder was then sintered under the hydrogen atmosphere at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com