Patents

Literature

46results about How to "Deterioration of mechanical property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

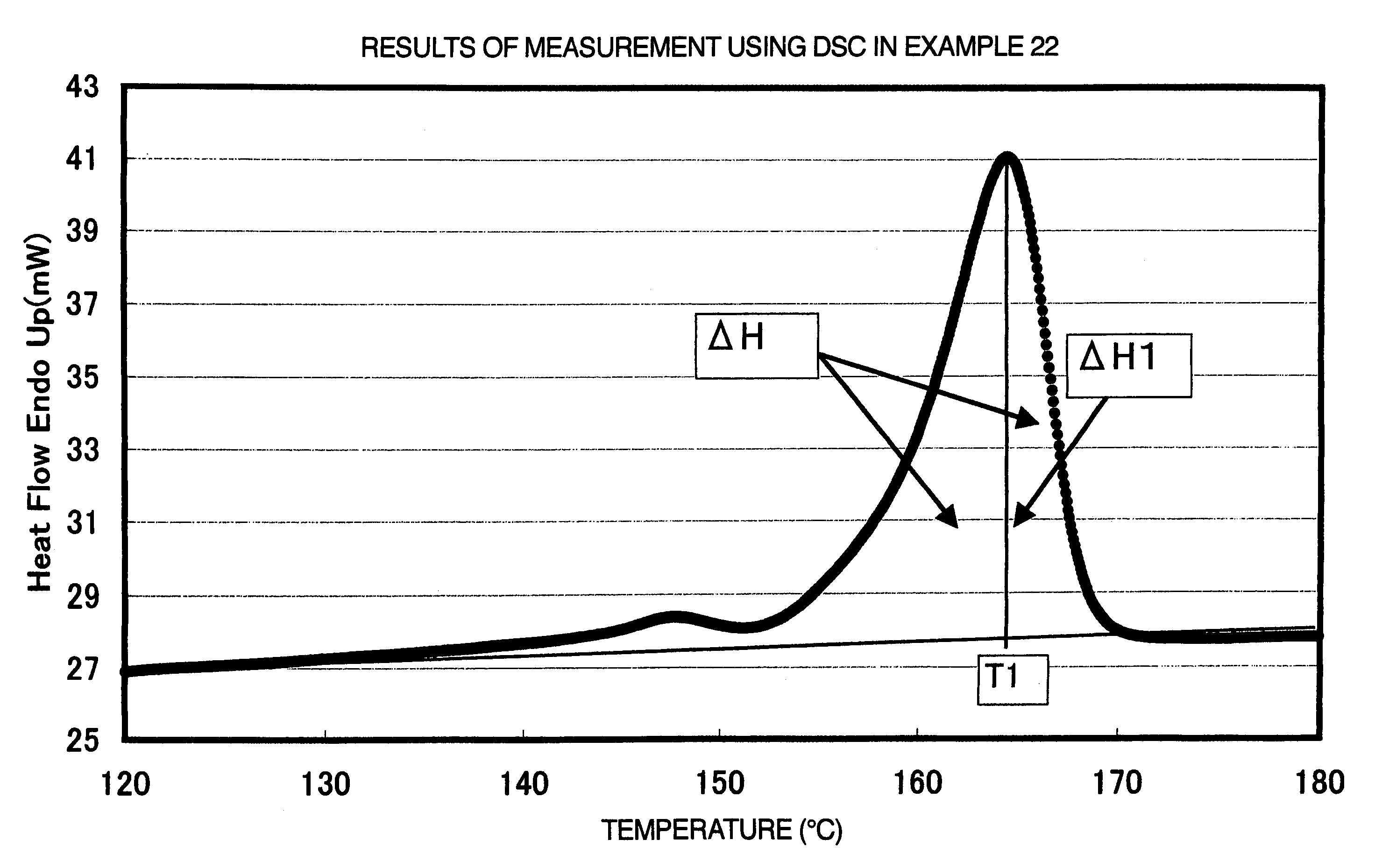

Molded article produced from aliphatic polyester resin composition

ActiveUS20050154148A1DistanceDeterioration of mechanical propertiesPlastic/resin/waxes insulatorsDyeing processShell moldingPolyester resin

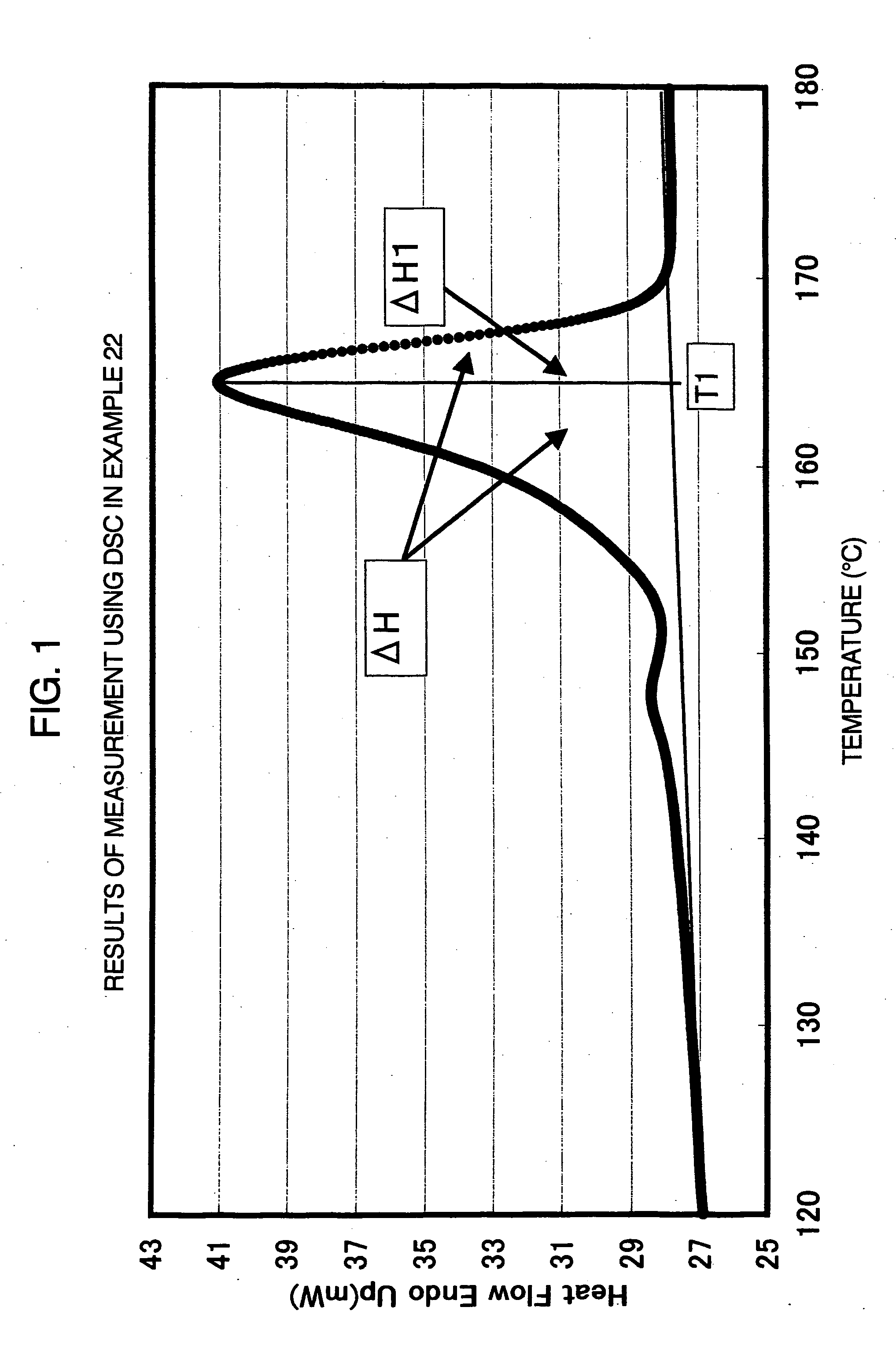

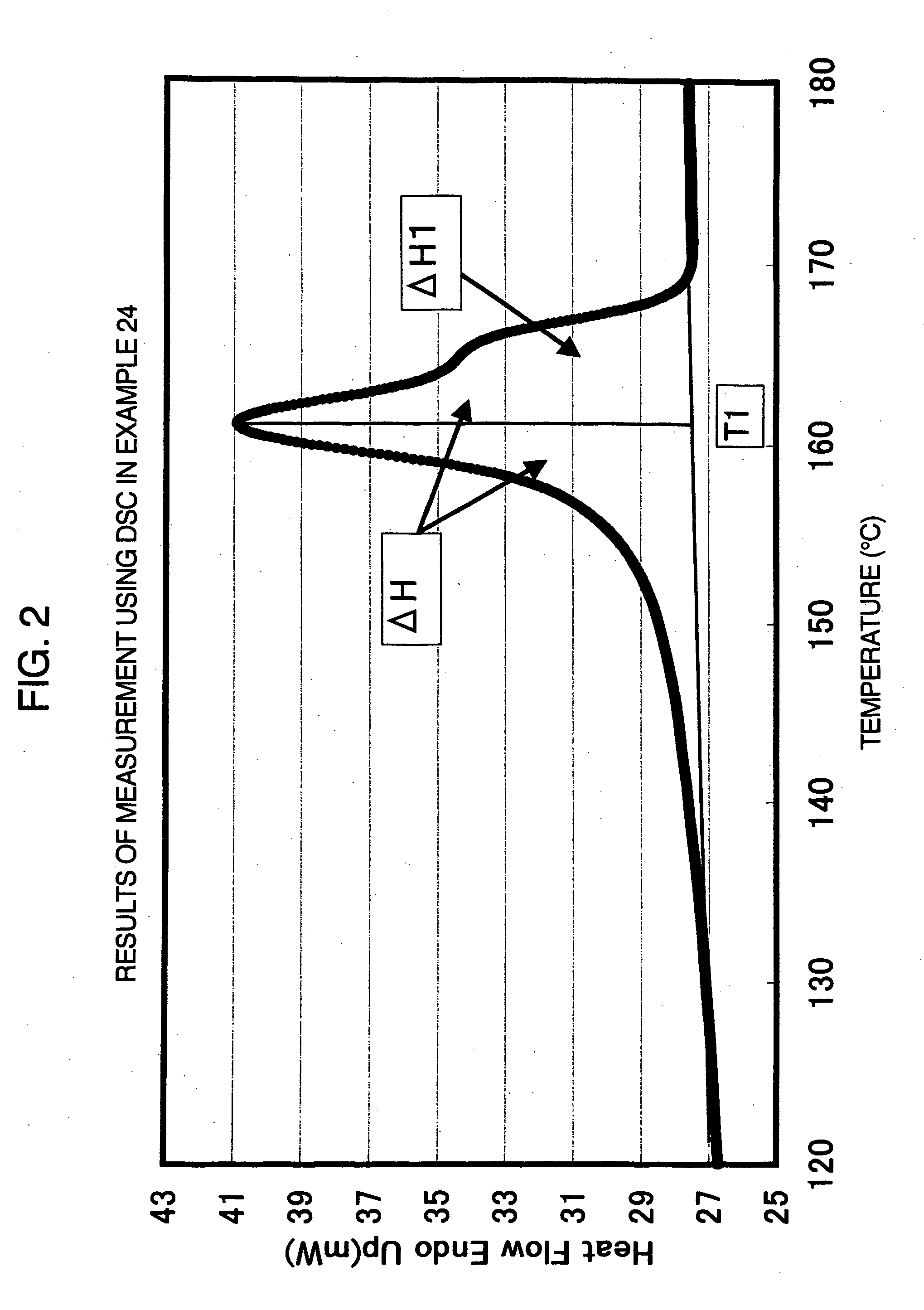

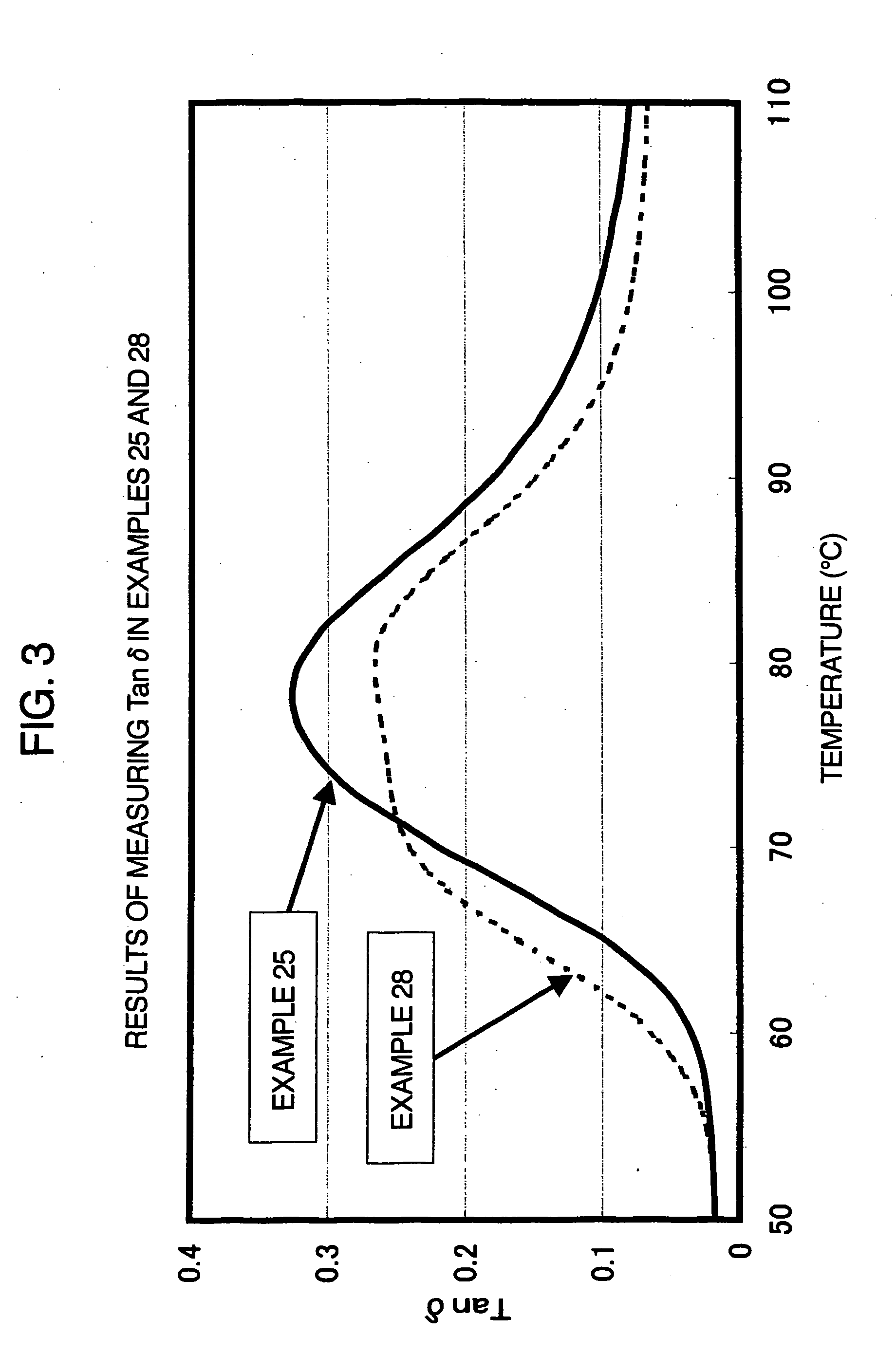

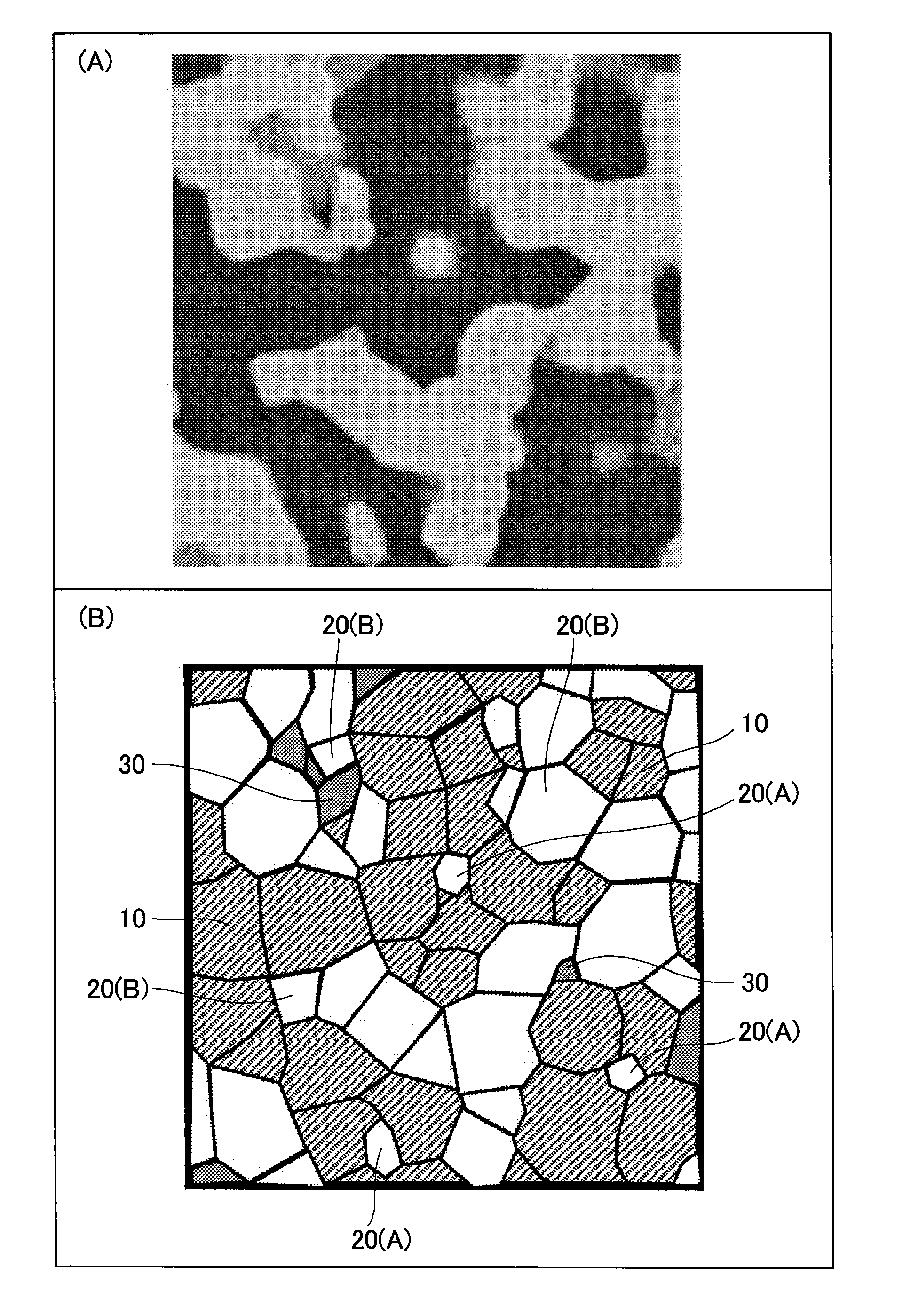

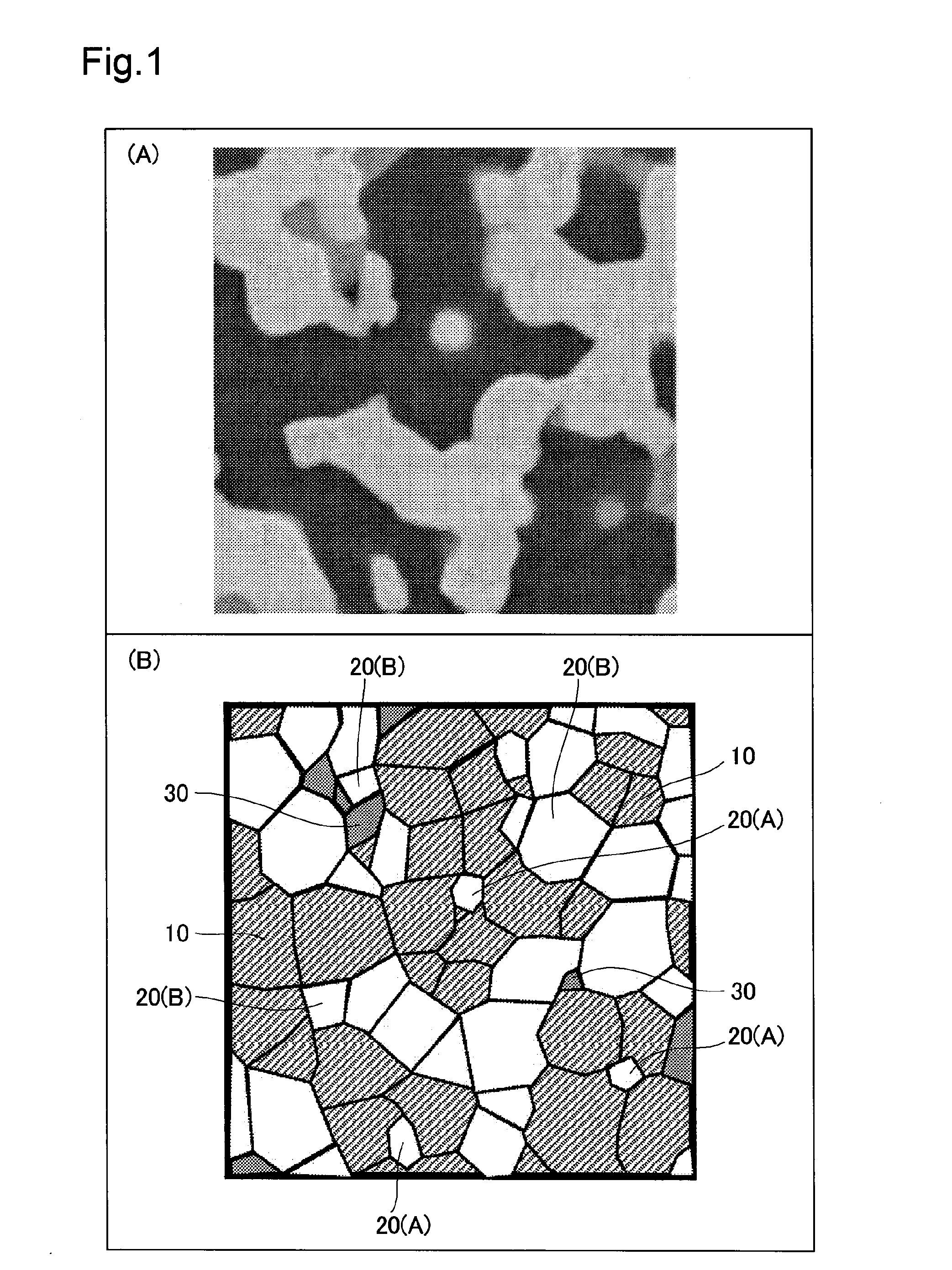

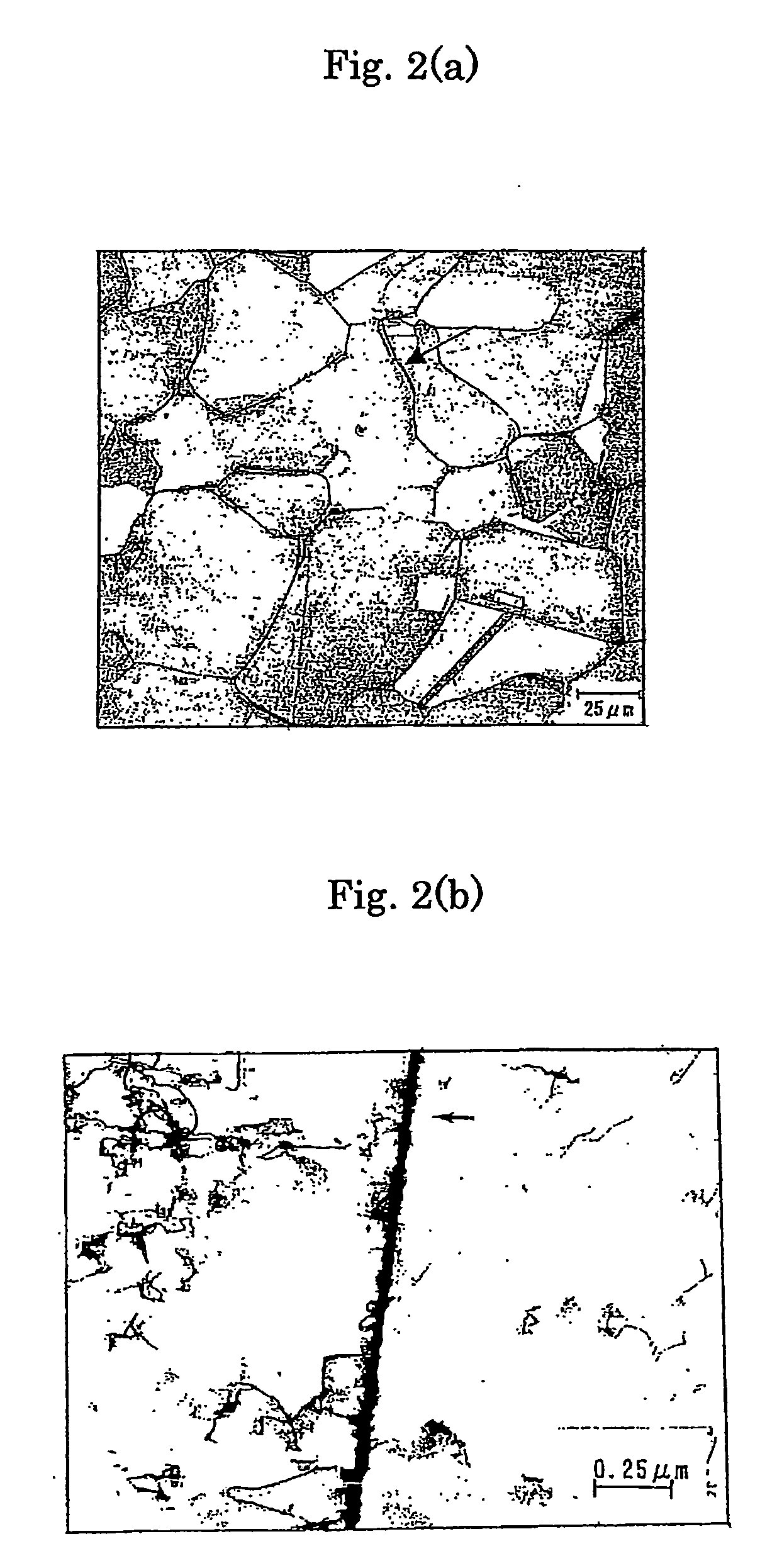

The present invention provides a molded article obtained from an aliphatic polyester resin composition comprising 60 to 99.9 parts by weight of at least one aliphatic polyester (A) and 0.1 to 40 parts by weight of at least one elastic polymer (B), provided that the total amount of the components (A) and (B) is 100 parts by weight, wherein the aliphatic polyester component in the molded article has an enthalpy of crystal fusion ΔH determined using a differential scanning calorimeter of 5 J / g or more, the molded article has a continuous phase composed of the aliphatic polyester (A) and dispersed phases composed of the elastic polymer (B), and the distance T between the walls of the dispersed phases is less than 5.0 μm.

Owner:ASAHI KASEI CHEM CORP

Copper alloy having excellent corrosion cracking resistance and dezincing resistance, and method for producing same

A copper alloy having an excellent corrosion cracking resistance and an excellent dezincing resistance consists of: 58 to 66 wt % of copper (Cu); 0.1 to 0.8 wt % of Sn; 0.01 to 0.5 wt % of Si; at least one of 0.3 to 3.5 wt % of lead (Pb), 0.3 to 3.0 wt % of bismuth (Bi), 0.02 to 0.15 wt % of phosphorus (P), 0.02 to 3.0 wt % of nickel (Ni) and 0.02 to 0.6 wt % of iron (Fe) if necessary; and the balance being zinc (Zn) and unavoidable impurities, wherein the proportion of an alpha phase is 80 vol % or more. The apparent content of zinc (Zn) in the copper alloy is in the range of from 34 to 39 wt %.

Owner:DOWA METALTECH CO LTD

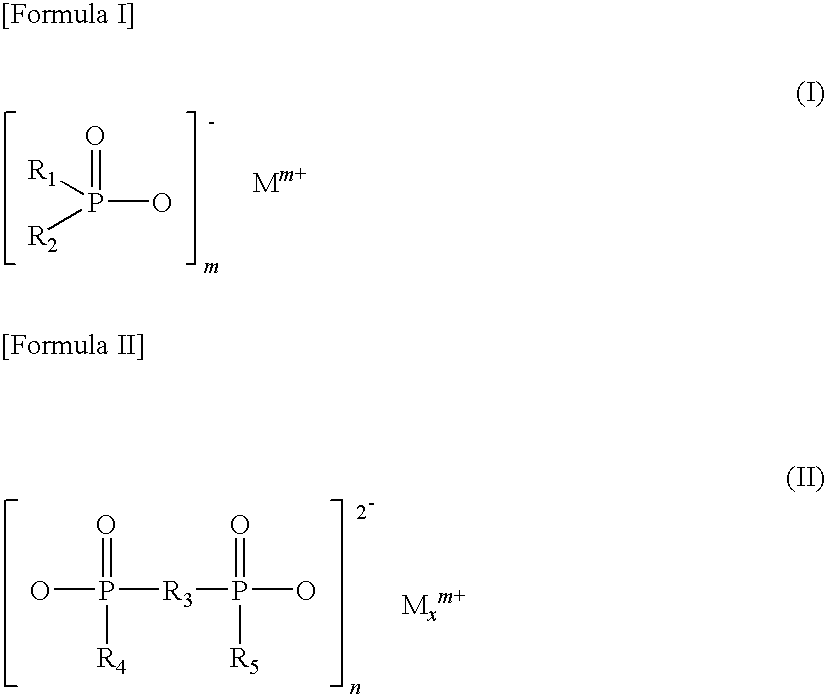

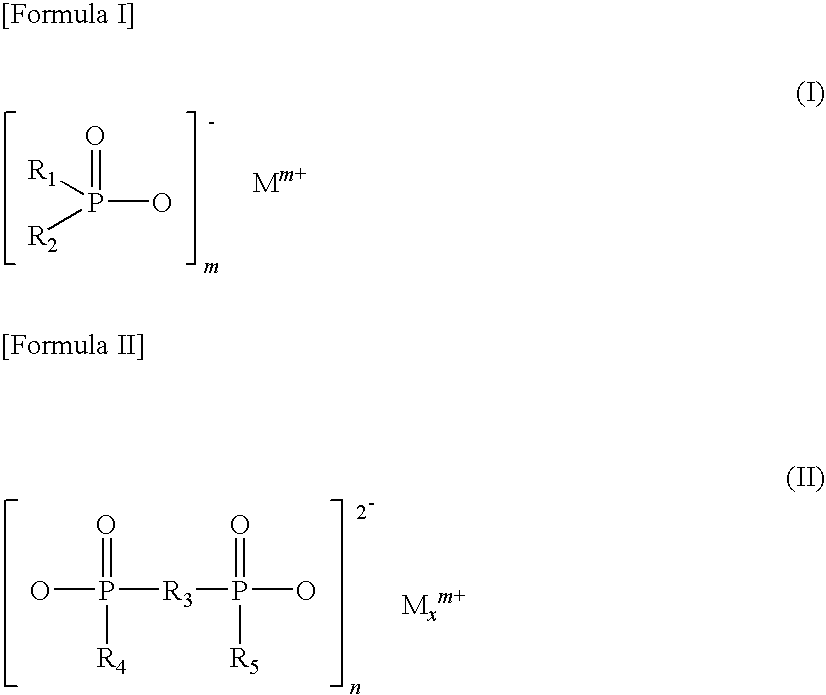

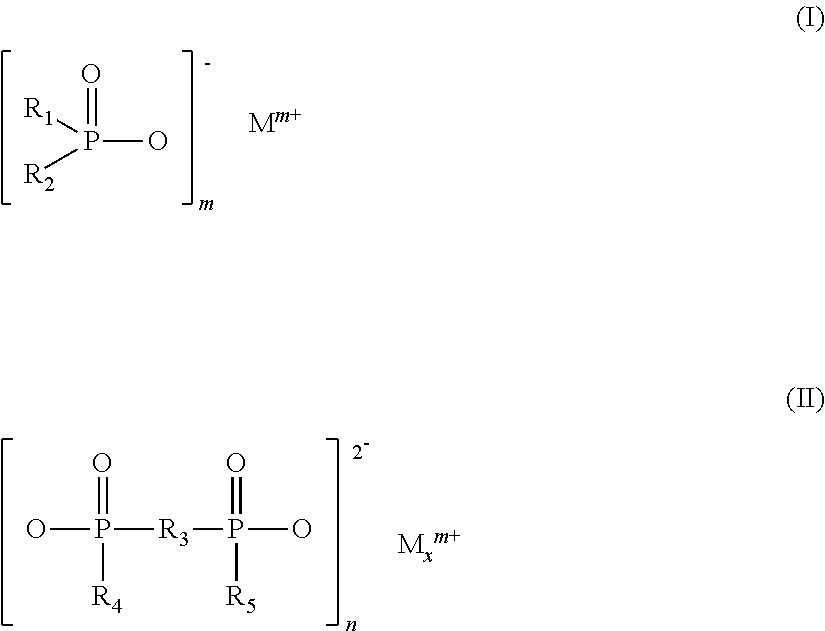

Flame-retardant glass fiber-reinforced polyamide resin composition

InactiveUS20100227957A1Improve rigidityNice appearanceGroup 5/15 element organic compoundsGlass fiberPolymer science

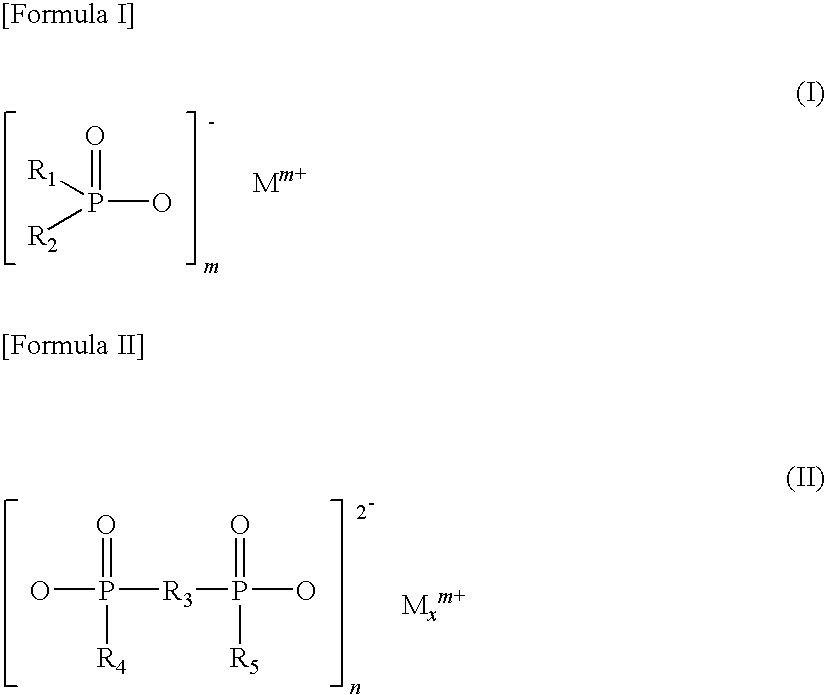

A flame-retardant glass fiber-reinforced polyamide resin composition, containing:100 parts by mass of a flame-retardant resin composition consisting of(A) 60 to 90 percent by mass of a polyamide resin, and(B) 40 to 10 percent by mass of a flame retardant containing no halogen atom,(A)+(B) being 100 percent by mass; and60 to 210 parts by mass of a flattened glass fiber (C) having a flat section of 1.5-10 in a ratio of major axis / minor axis,wherein the polyamide resin (A) contains a crystalline polyamide resin (a1) and an amorphous polyamide resin (a2),the flame retardant containing no halogen atom (B) contains a phosphinate (b1) and / or a diphosphinate (b2), anda blending ratio of the amorphous polyamide resin (a2) in the polyamide resin (A) is 0.1≦(a2) / (A)≦0.5.

Owner:UNITIKA LTD

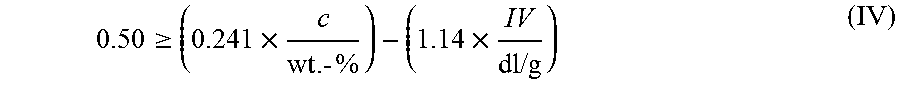

High flow polyolefin composition with high stiffness and toughness

The present invention relates to a polyolefin composition comprising two heterophasic propylene copolymers which differ in the intrinsic viscosity of their xylene soluble fractions.

Owner:BOREALIS AG

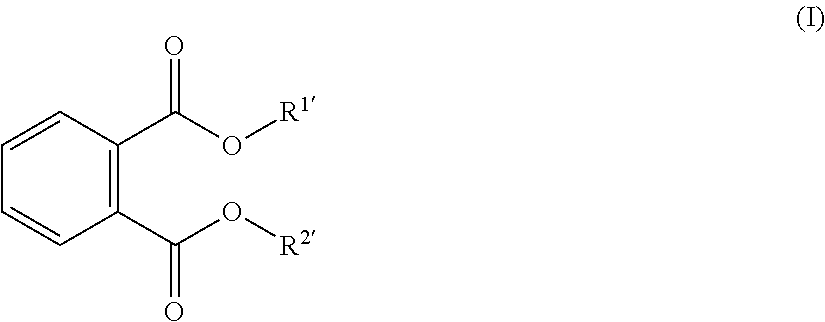

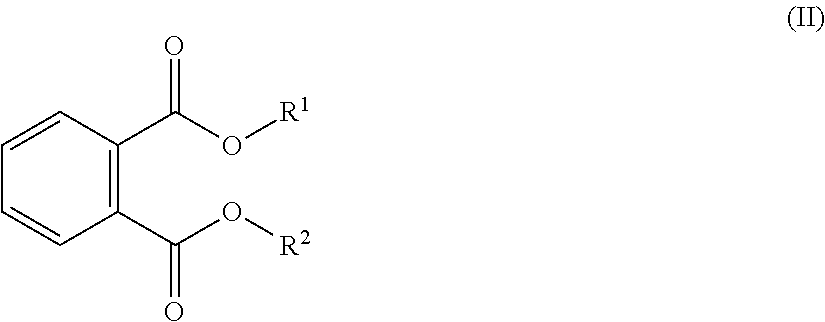

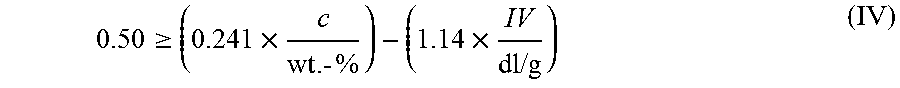

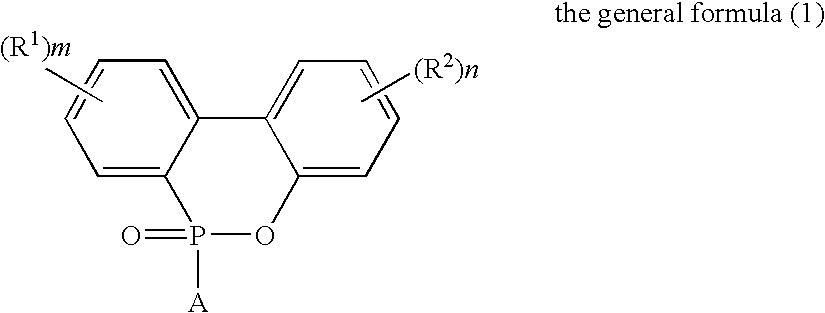

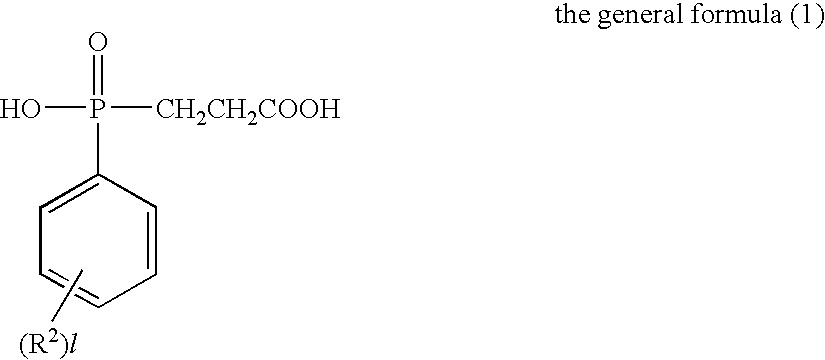

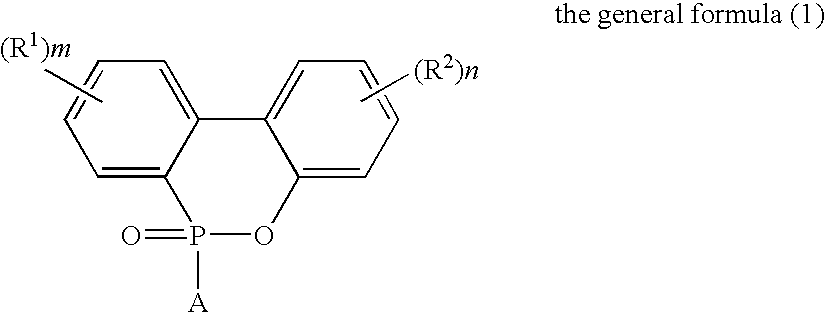

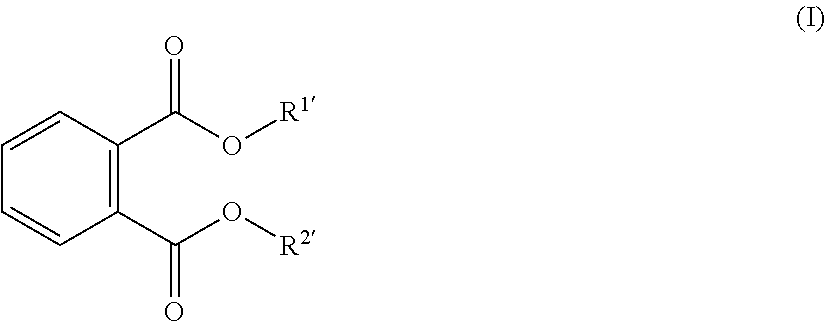

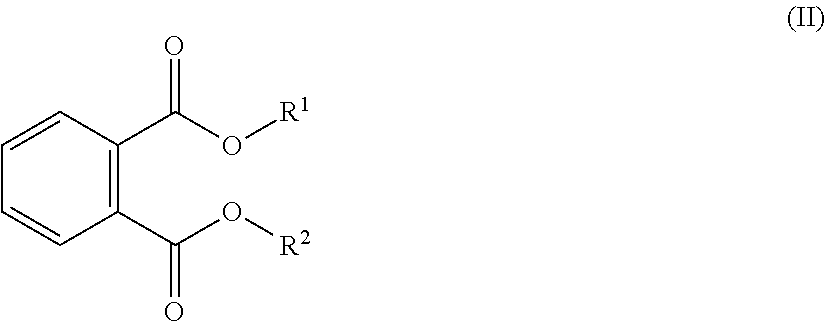

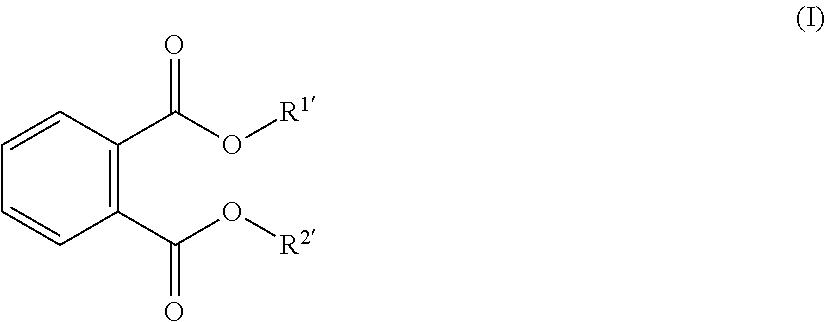

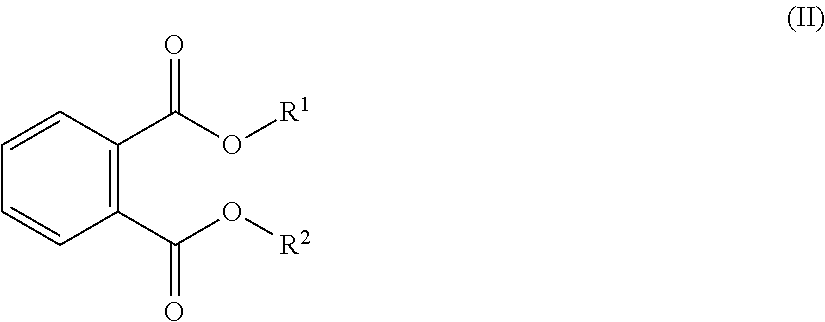

Flame-Retardant Polyester and Process for Producing the Same

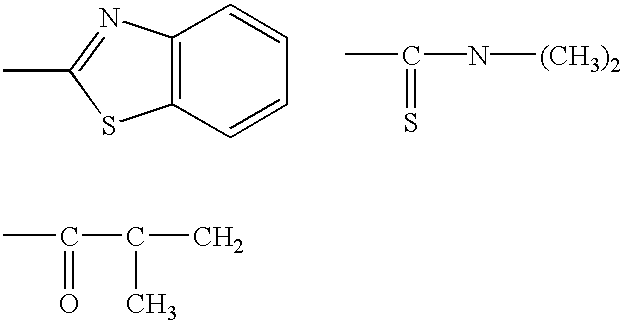

InactiveUS20080300349A1Deterioration of mechanical propertyOperability is deterioratedGroup 5/15 element organic compoundsPolyesterCarboxylic acid

To easily obtain a polyester having excellent mechanical properties, a satisfactory hue, and a high degree of flame retardancy. [MEANS FOR SOLVING PROBLEMS] The flame-retardant polyester is a polyester comprising ethylene terephthalate units as the main structural units and a phosphorus compound copolymerized or incorporated therein or is a resin composition comprising polyesters including that polyester. The flame-retardant polyester is characterized in that a polycarboxylic acid and / or polyol having three or more functional groups capable of forming an ester bond is contained in the polyester in a total amount of 0.05-2.00 mol (per 200 mol of the sum of the dicarboxylic acid ingredient and the diol ingredient), that a specific phosphorus compound having a functional group capable of forming an ester bond is contained in the polyester in an amount of 5,000-50,000 ppm of the polyester in terms of phosphorus amount, and that the polyester pellet obtained has a b value of −5 to 20, an L value of 35 or larger, and a melt viscosity at 280° C. of 1,000-20,000 dPa·s.

Owner:TOYOBO CO LTD

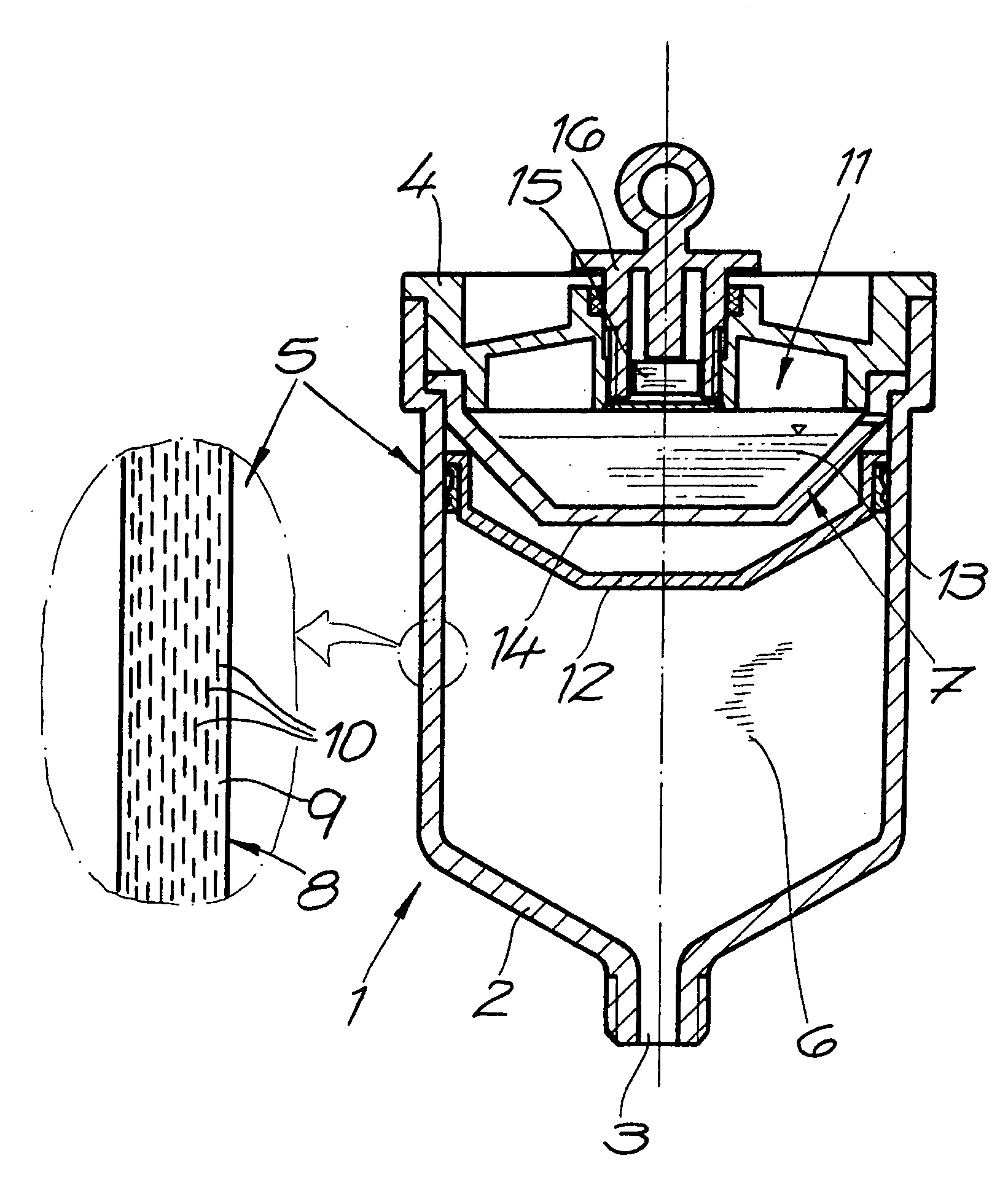

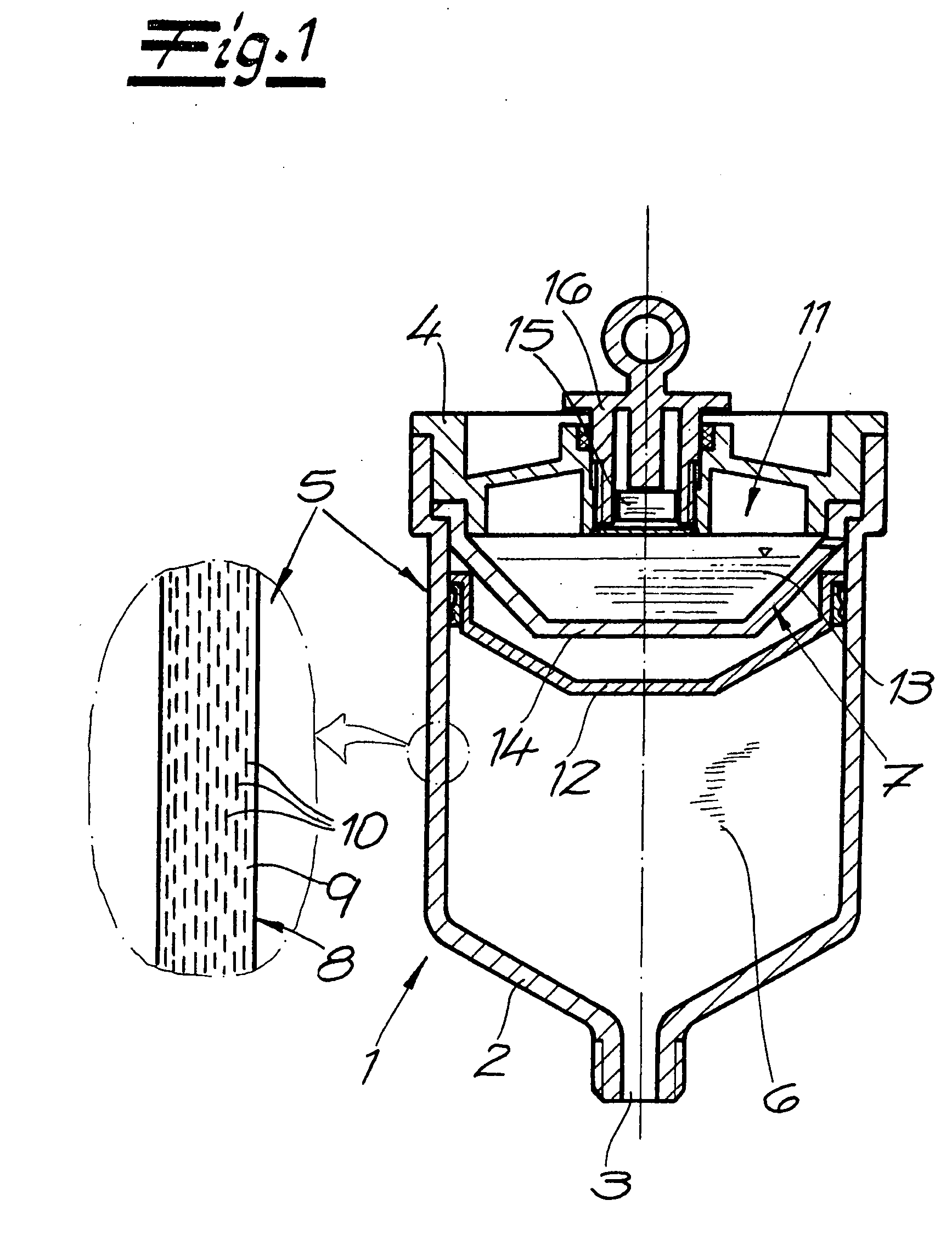

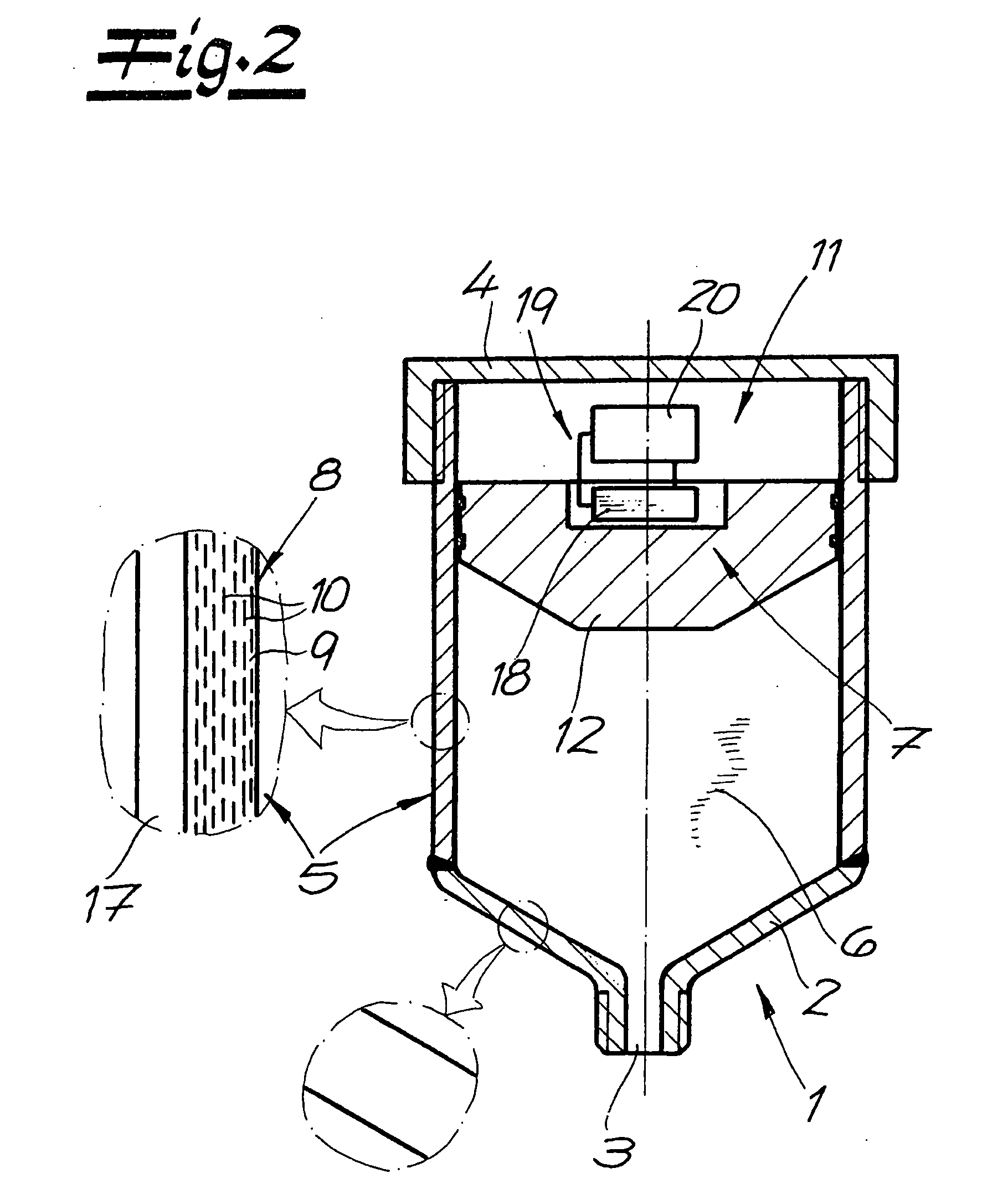

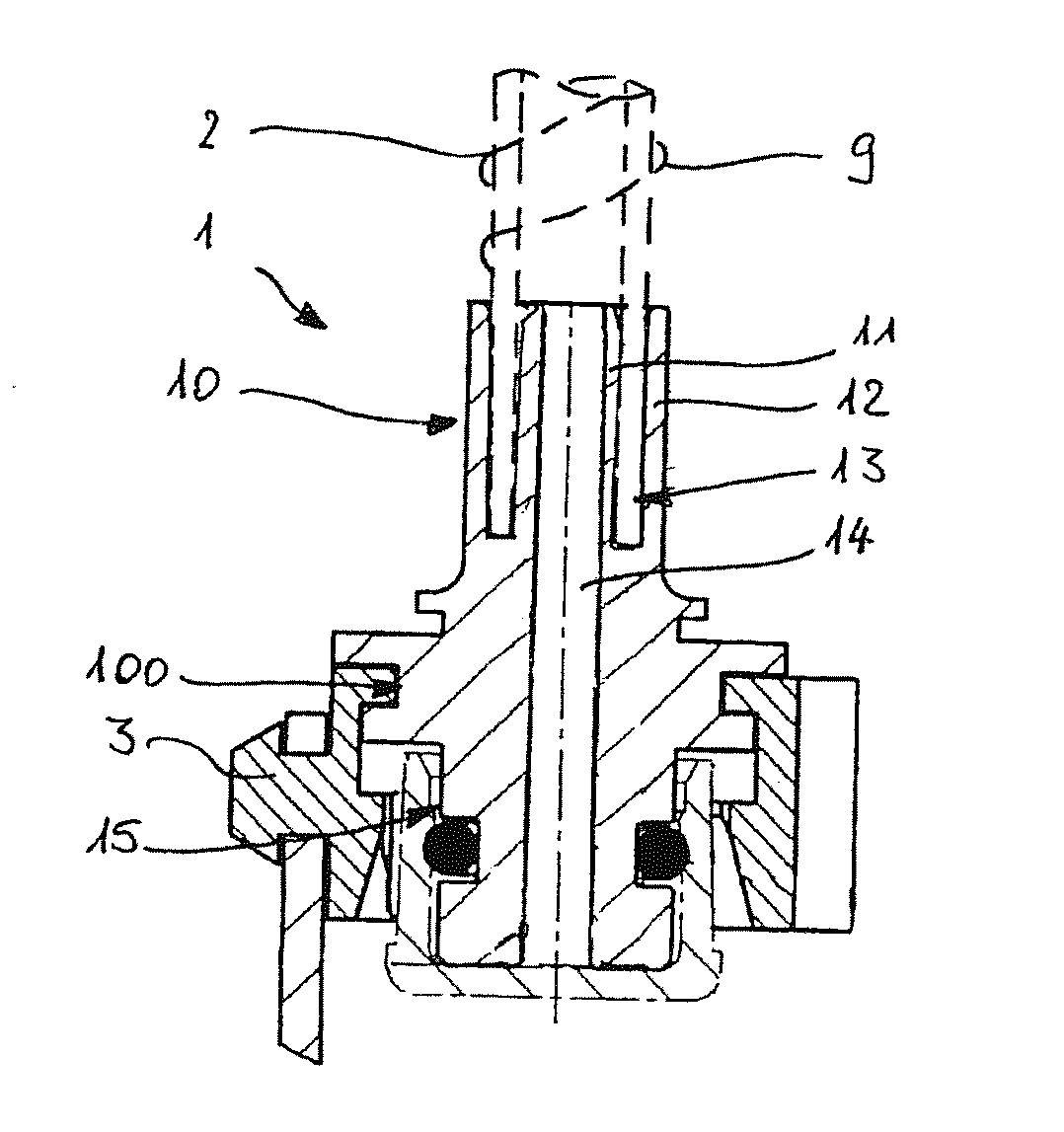

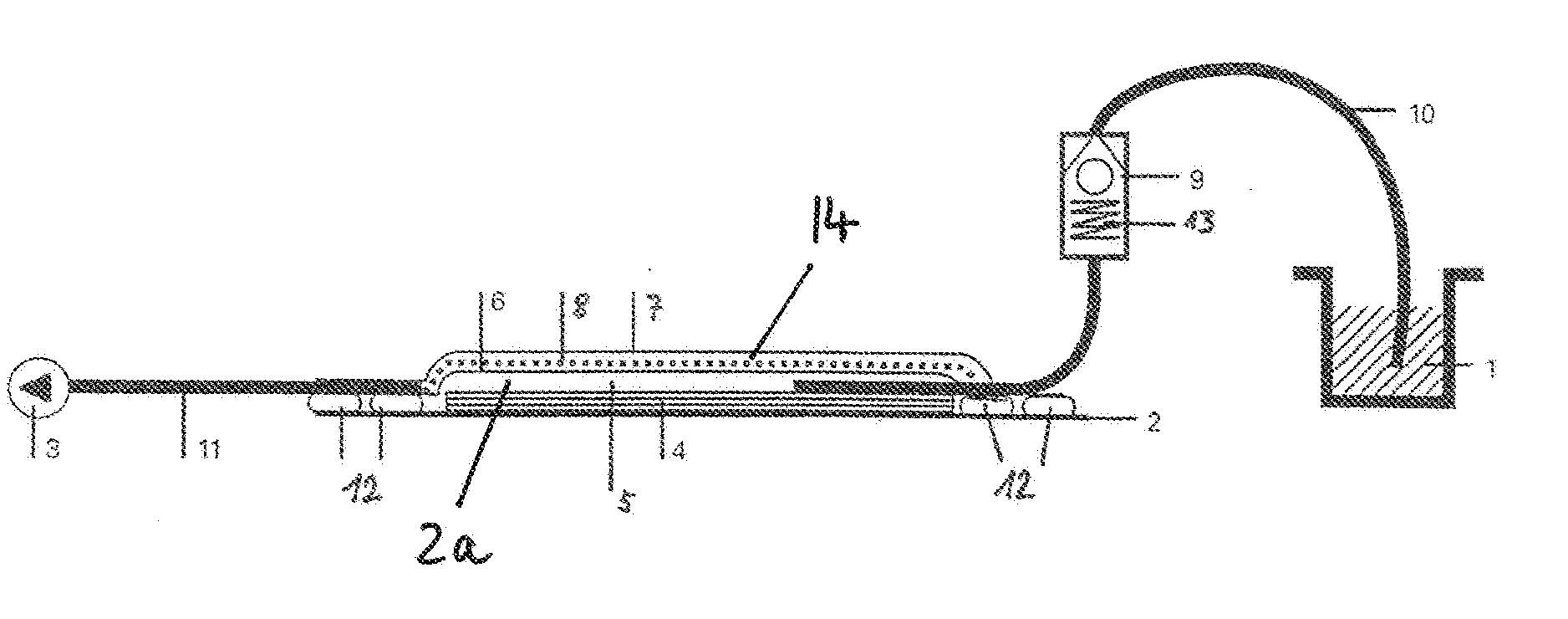

Lubricant Dispenser

InactiveUS20090038888A1Improve barrier propertiesImprove stabilityLubricating pumpsPressure lubricationEngineeringProduct gas

A lubricant dispenser has a housing that has a bottom with a housing opening, a lid, and a housing mantle between them, a lubricant reservoir, and a gas generator disposed in the housing for pressing the lubricant out. The housing mantle is transparent or translucent, at least in some sections, and has at least one barrier layer. The barrier layer has a polymer base substance and an admixture of typically inorganic layer substances to improve the barrier properties.

Owner:PERMA TEC

Process for the production of Al-Fe-V-Si alloys

The present invention relates to an improved process for the production of high strength and high wear resistant Al-Fe-V-Si alloys. The present invention comprises modifying / blocking primary intermetallic phases as well as interdendritic silicide phases by treating the melt with elemental magnesium or magnesium bearing master alloys to get a structure containing uniform distribution of intermetallic phases. The uniform distribution of primary and interdendritic phases are obtained with addition of magnesium or magnesium bearing master alloys because morphology of the interface changes resulting in the creation of more nuclei. It also breaks dendrite of the primary particles leading to structural change and fine particles. The present invention is useful for the industries engaged in production of high strength wear resistant aluminium alloys which are widely used in aerospace, transport and other engineering sectors.

Owner:COUNCIL OF SCI & IND RES

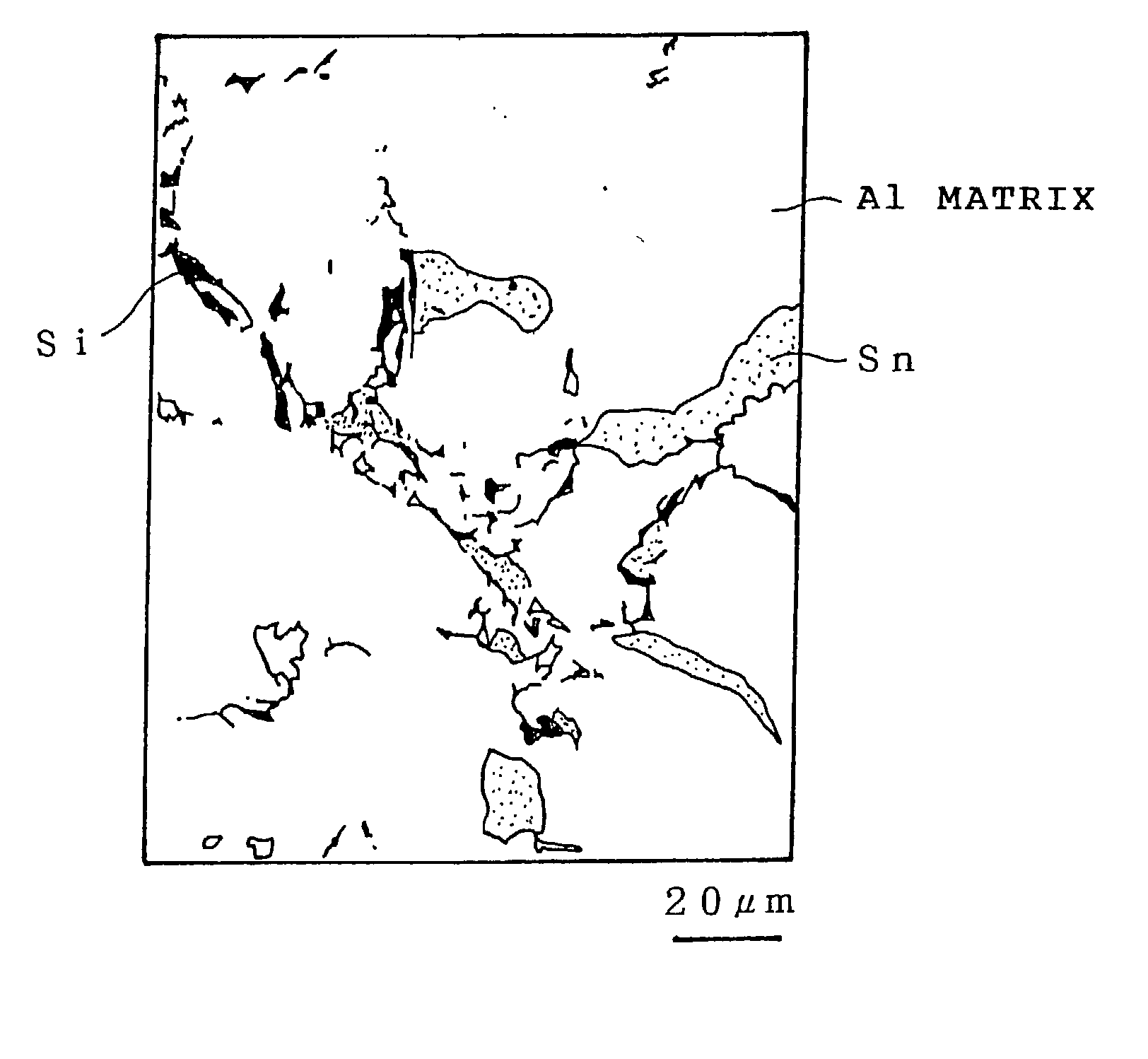

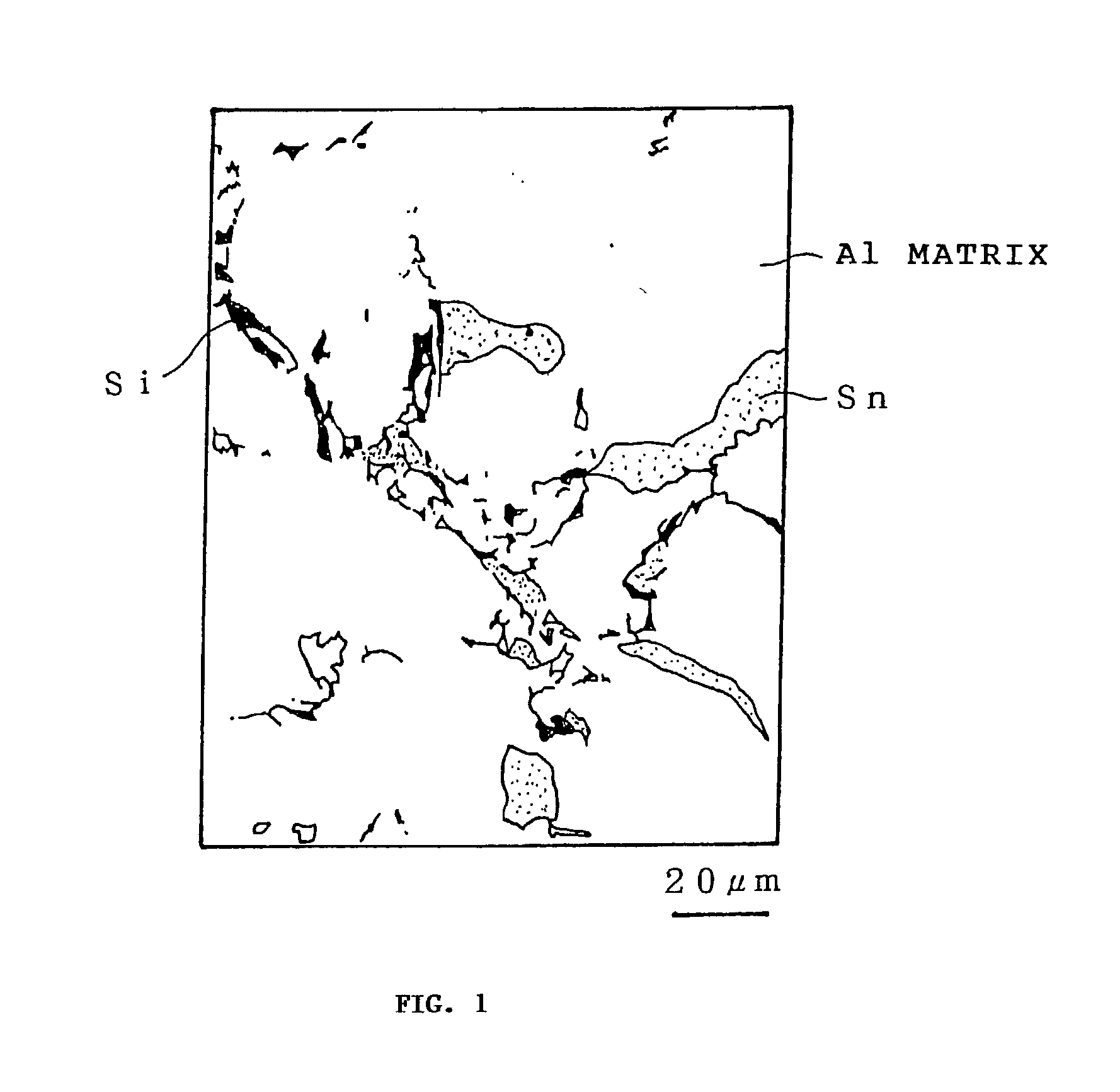

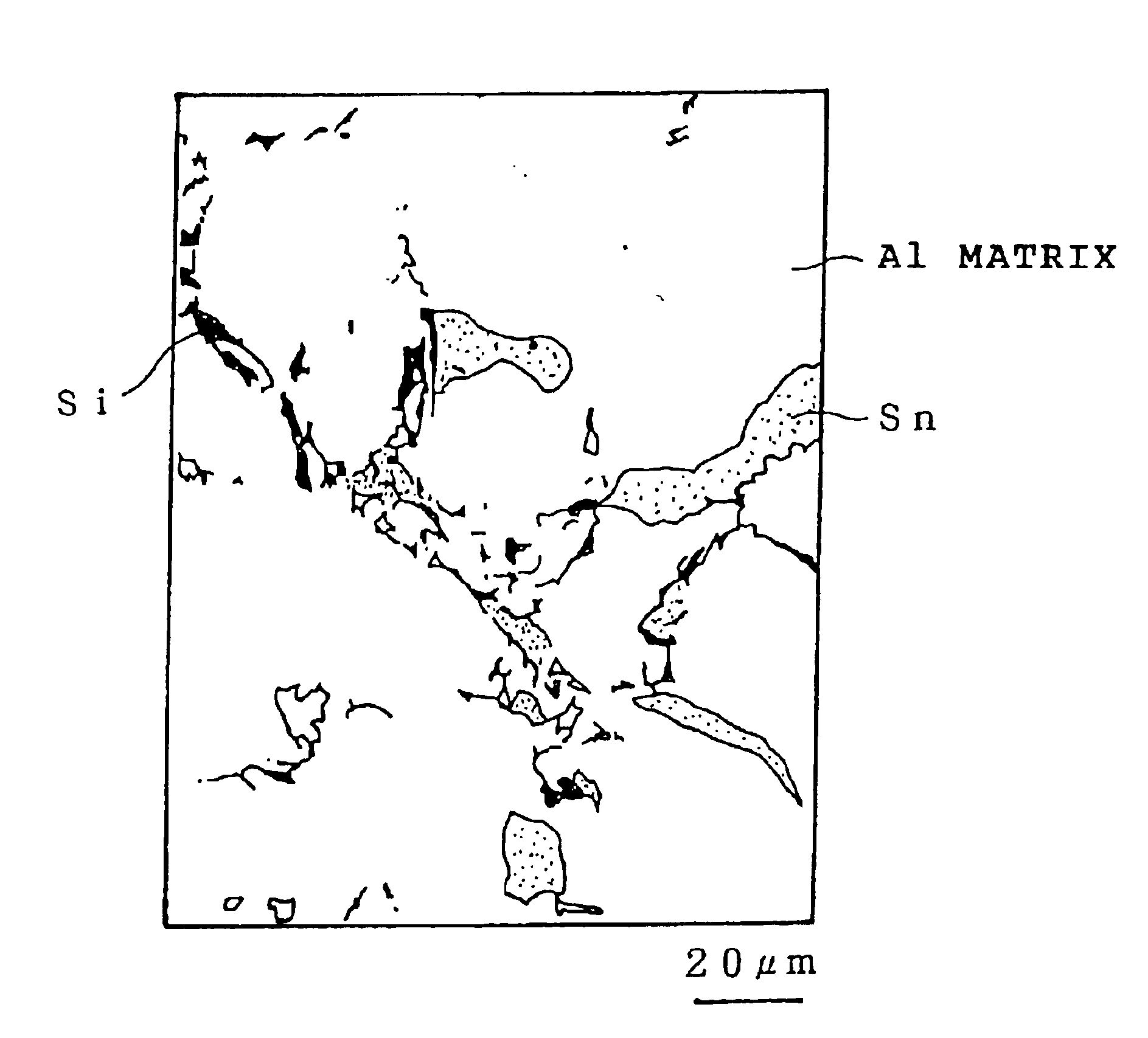

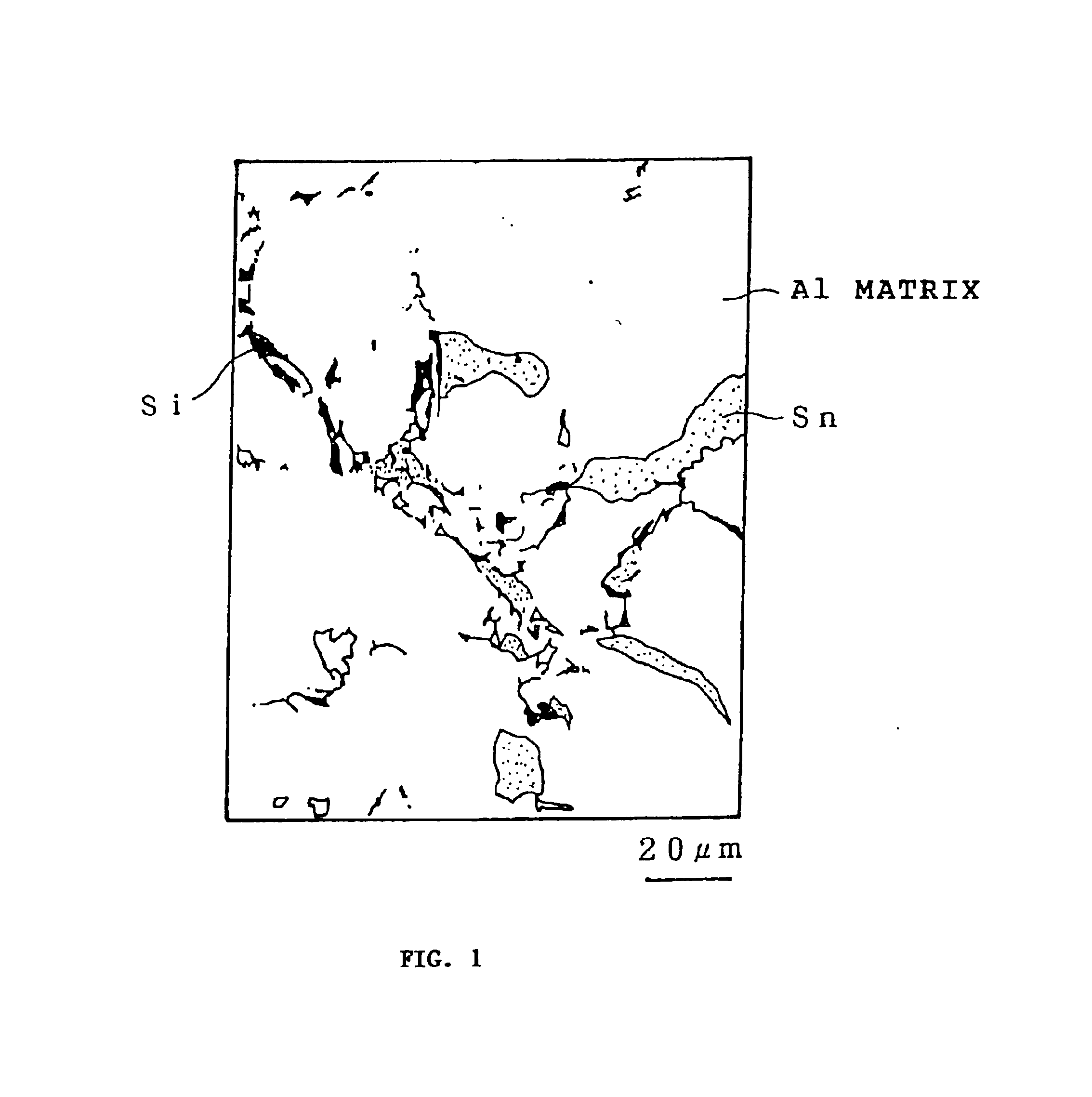

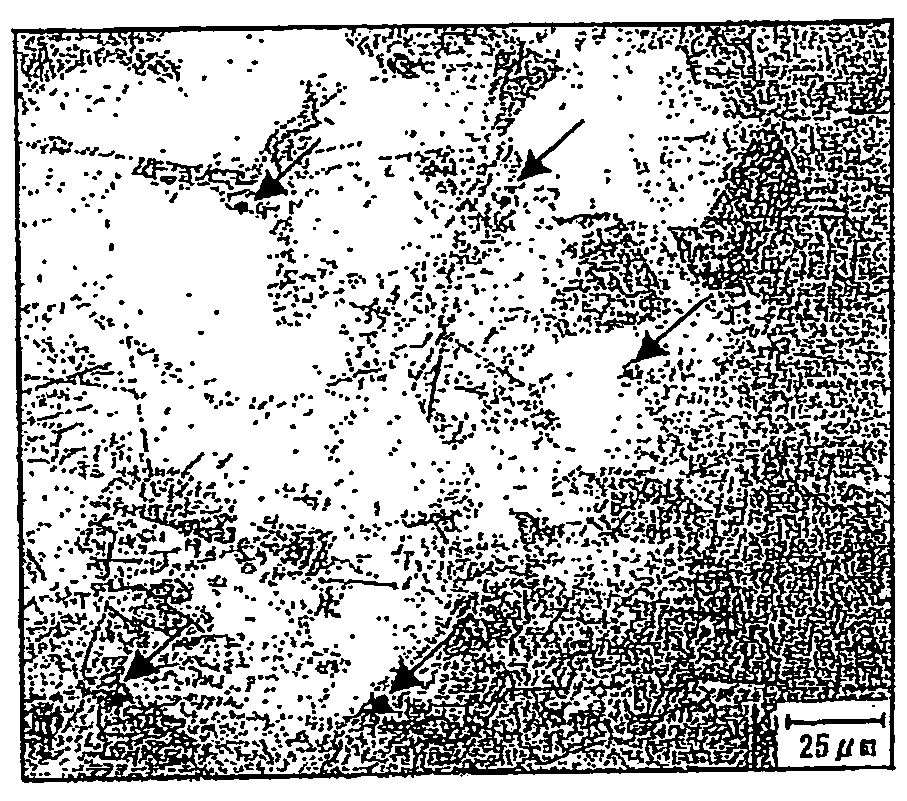

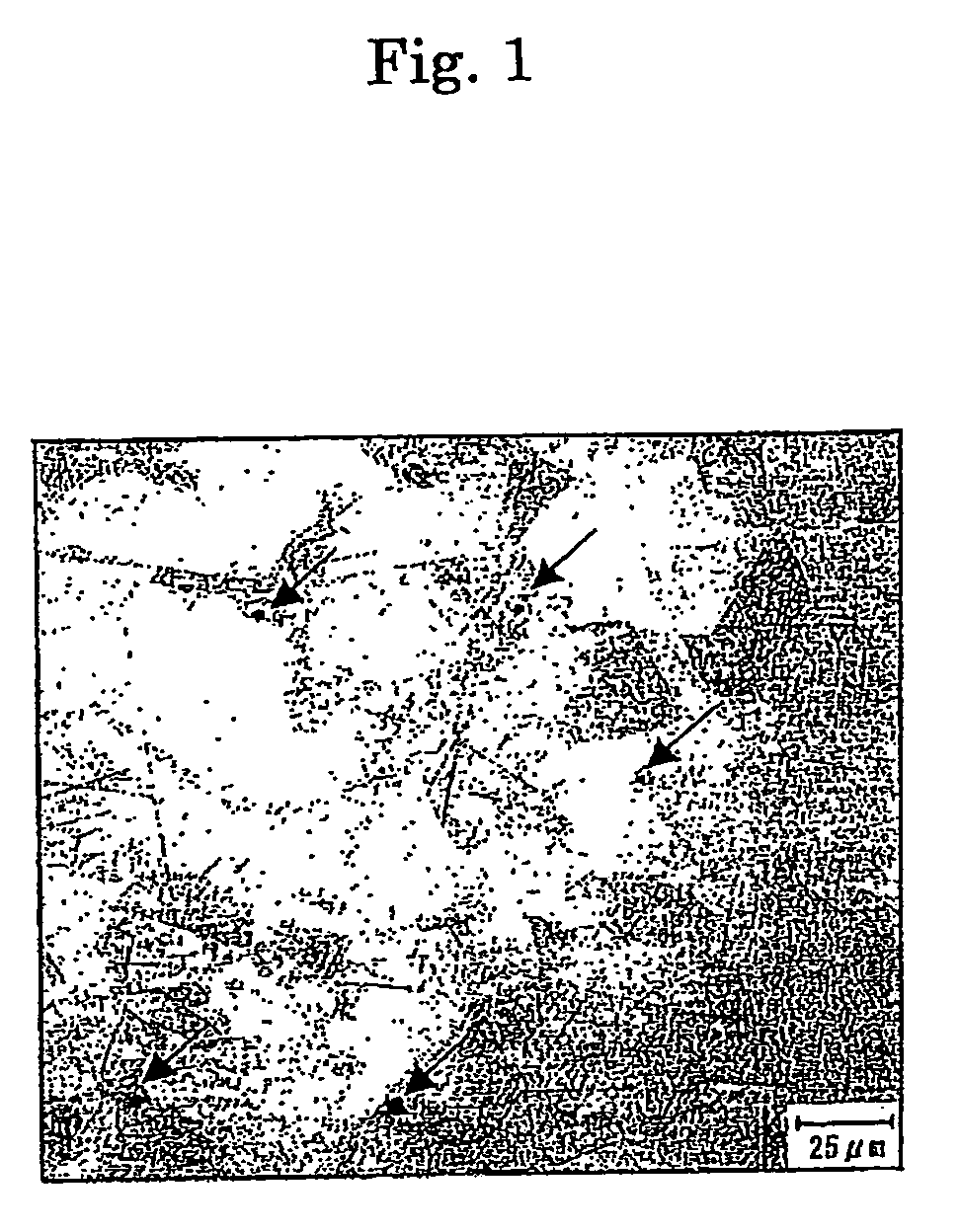

Aluminum bearing-alloy

InactiveUS20030102059A1Excellent in wear and fatigue resistance propertyImprove bearing performanceShaftsBearing componentsMaterials scienceAluminium alloy

An aluminum bearing-alloy containing 1.5 to 8 mass % of Si is provided, in which there can be observed Si grains on the sliding surface of the aluminum bearing-alloy. A fractional area of the observed Si grains having a grain size of less than 4 mum is 20 to 60% of a total area of all the observed Si grains. Another fractional area of the observed Si grains having a grain size of from 4 to 20 mum is not less than 40% of the total area of all the observed Si grains.

Owner:DAIDO METAL CO LTD

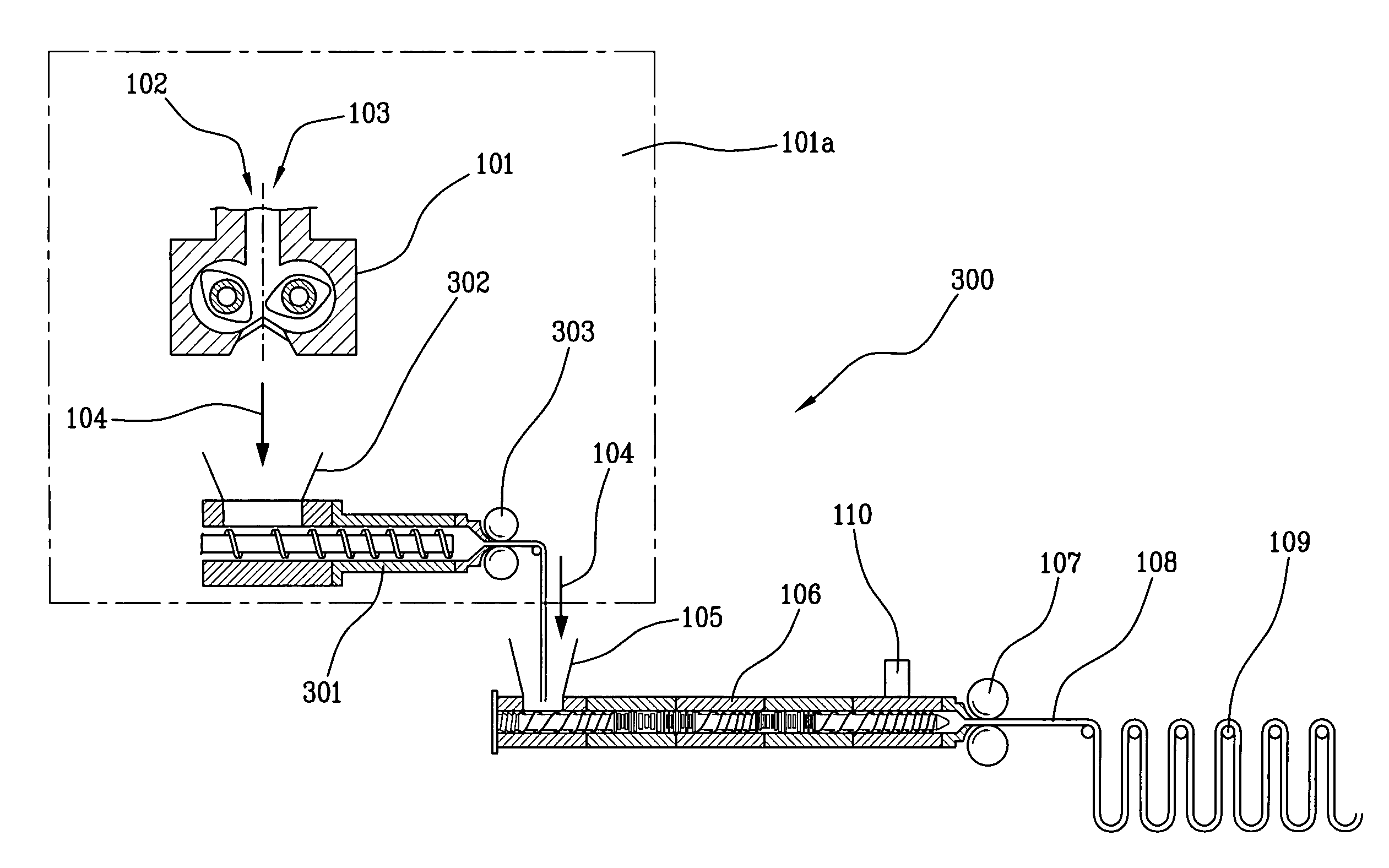

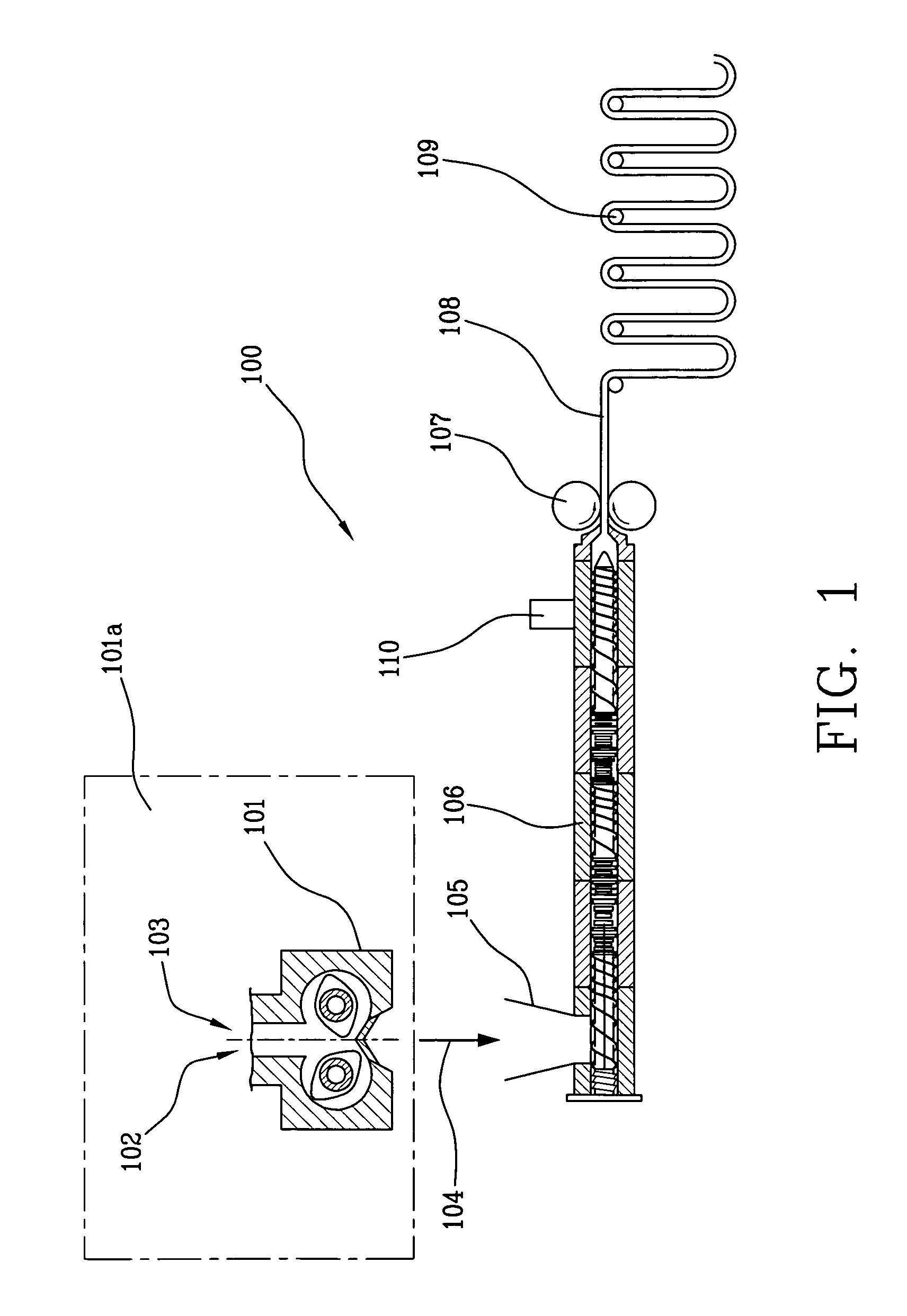

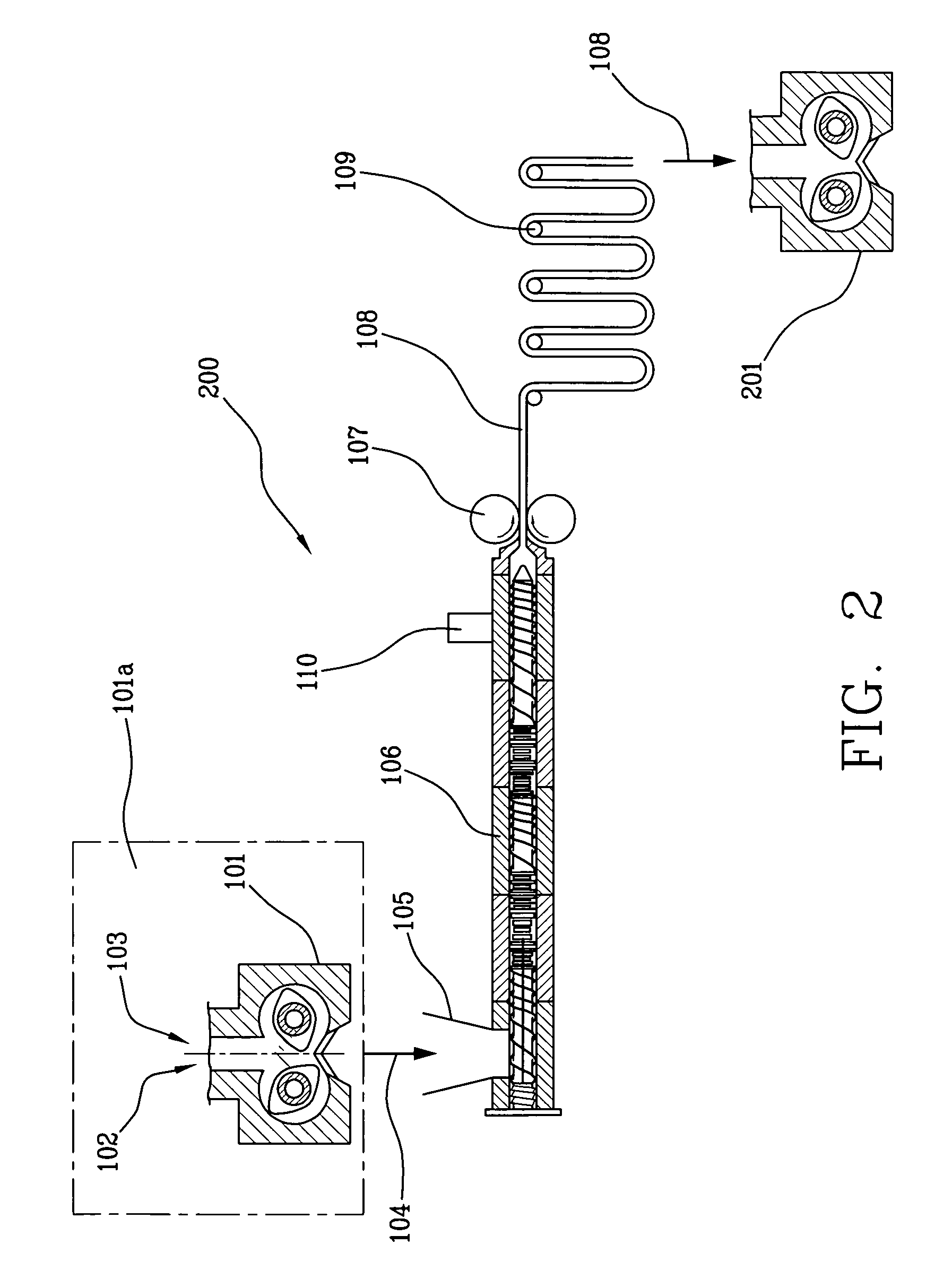

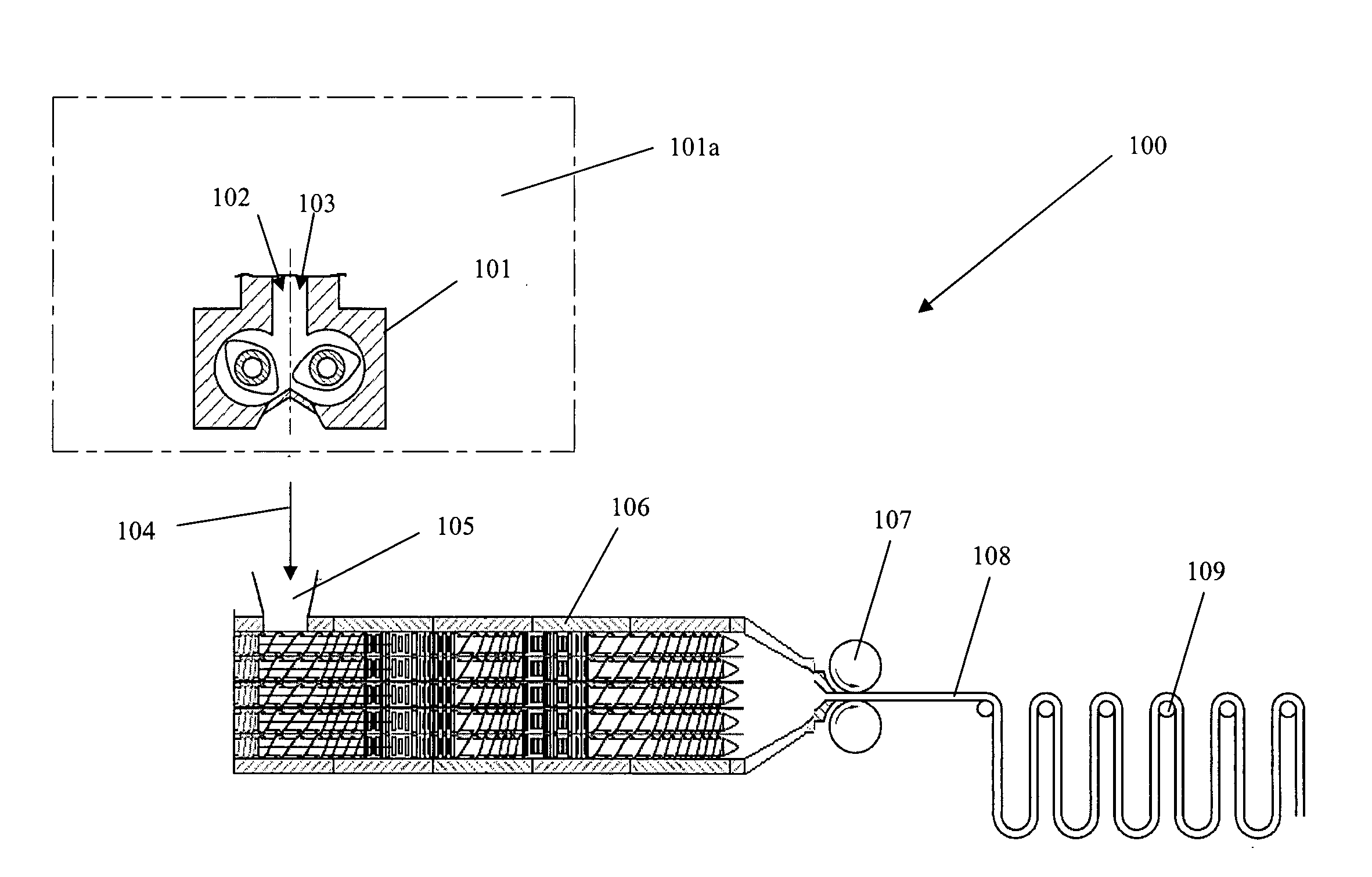

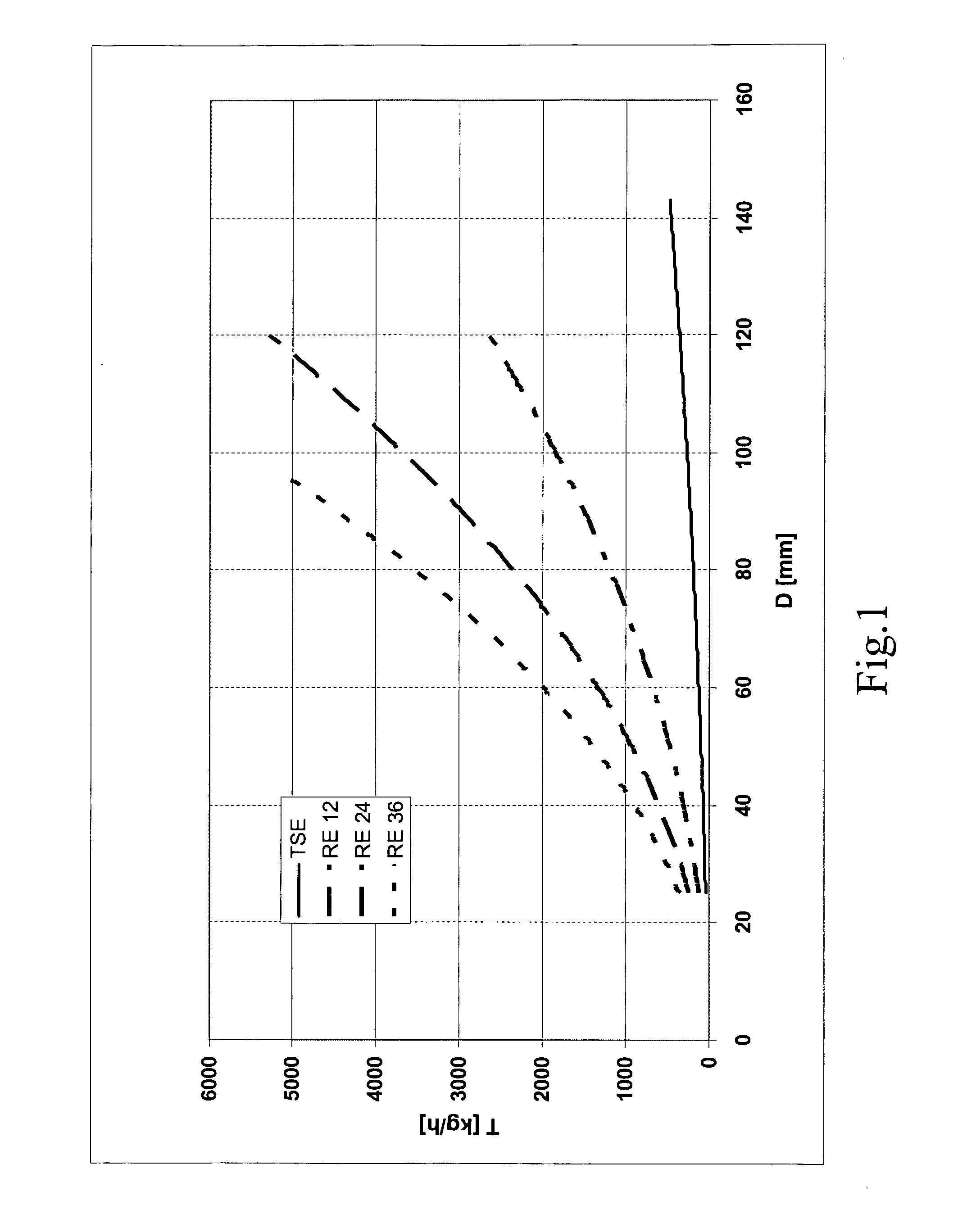

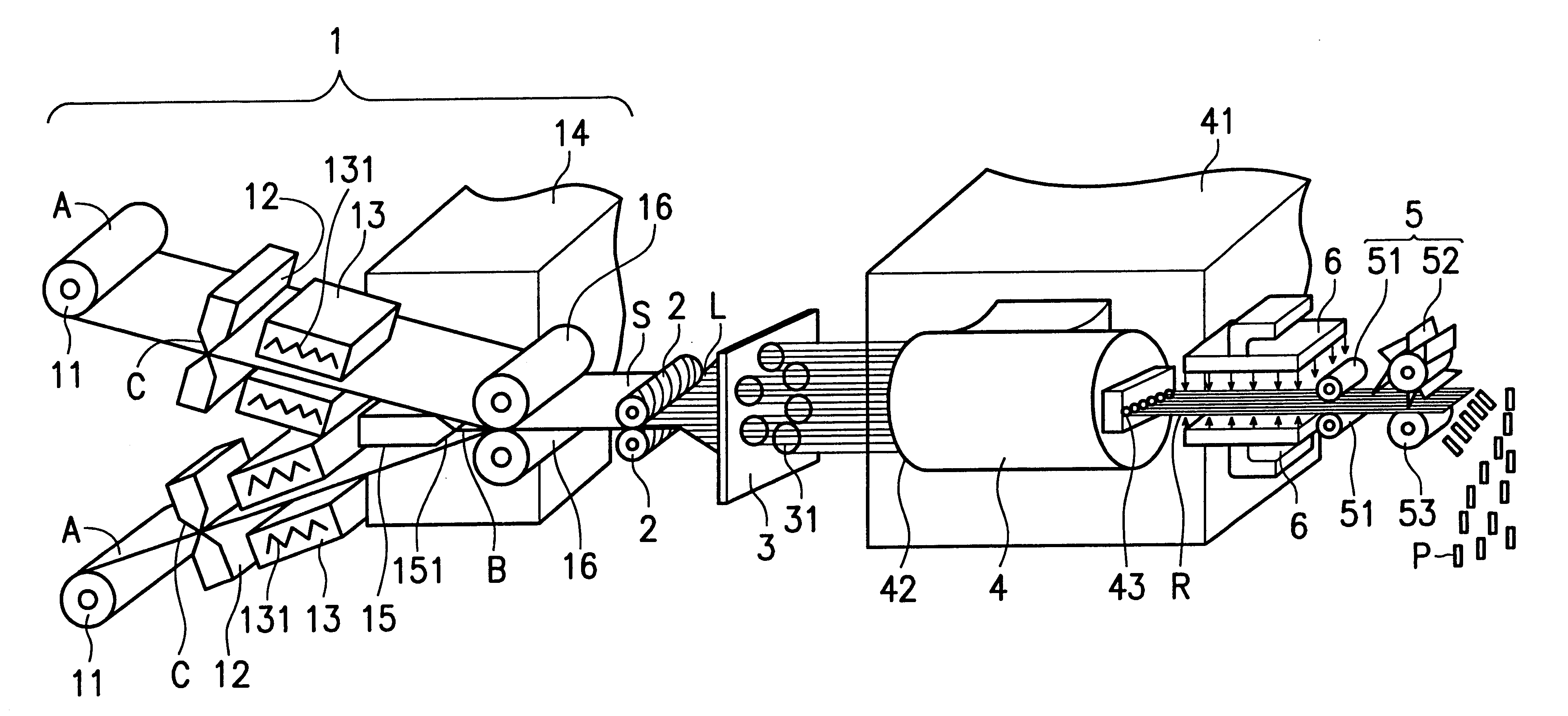

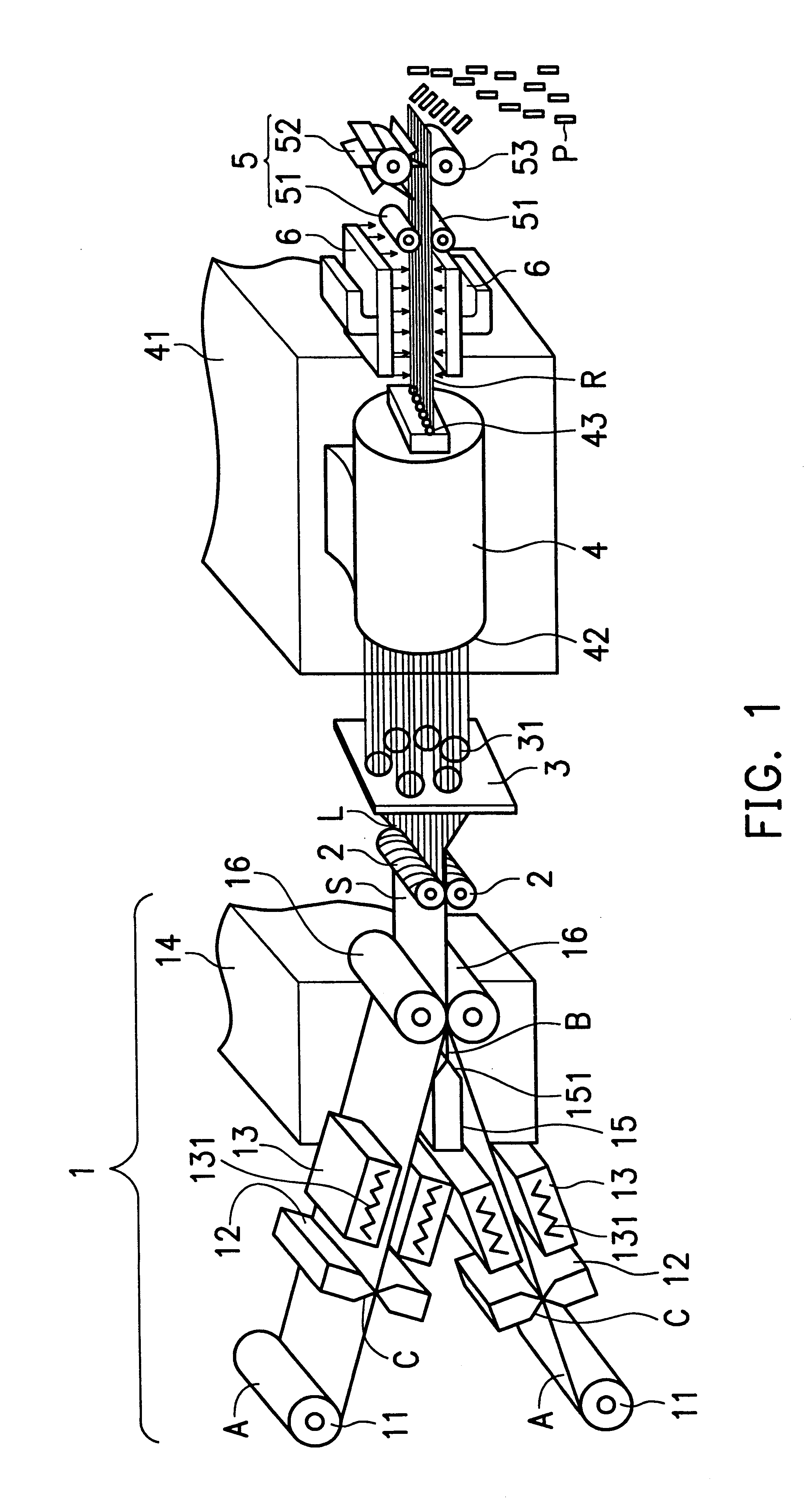

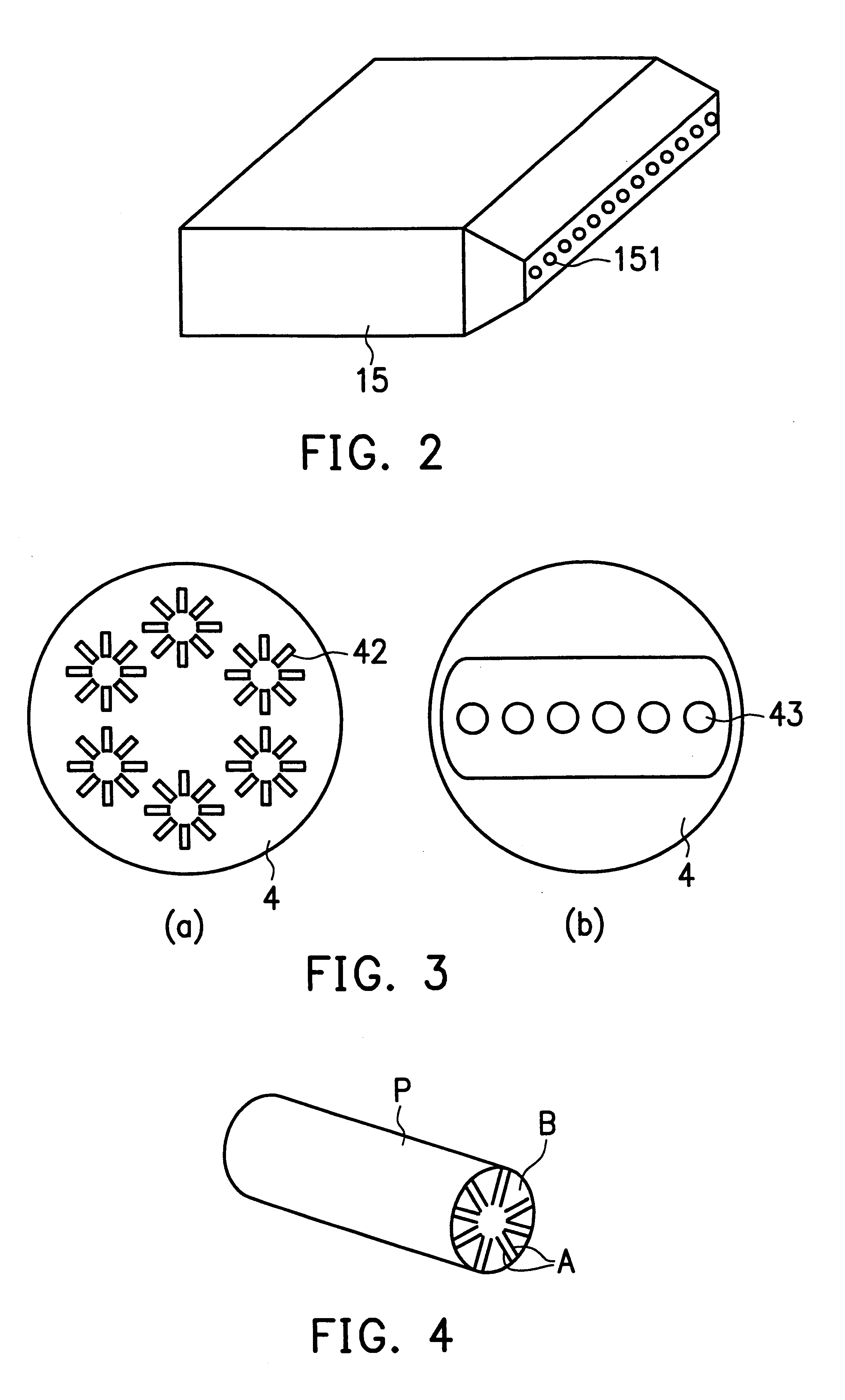

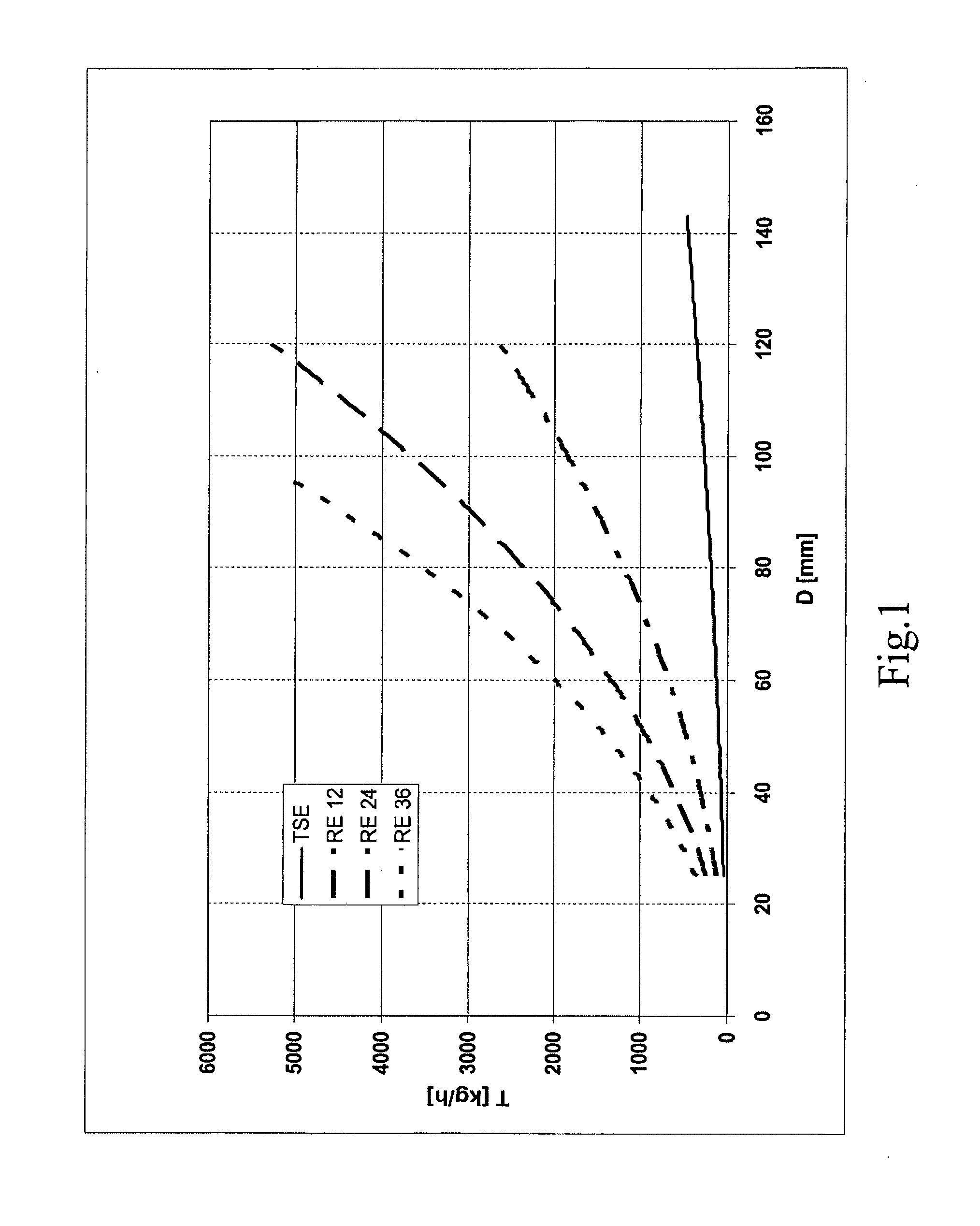

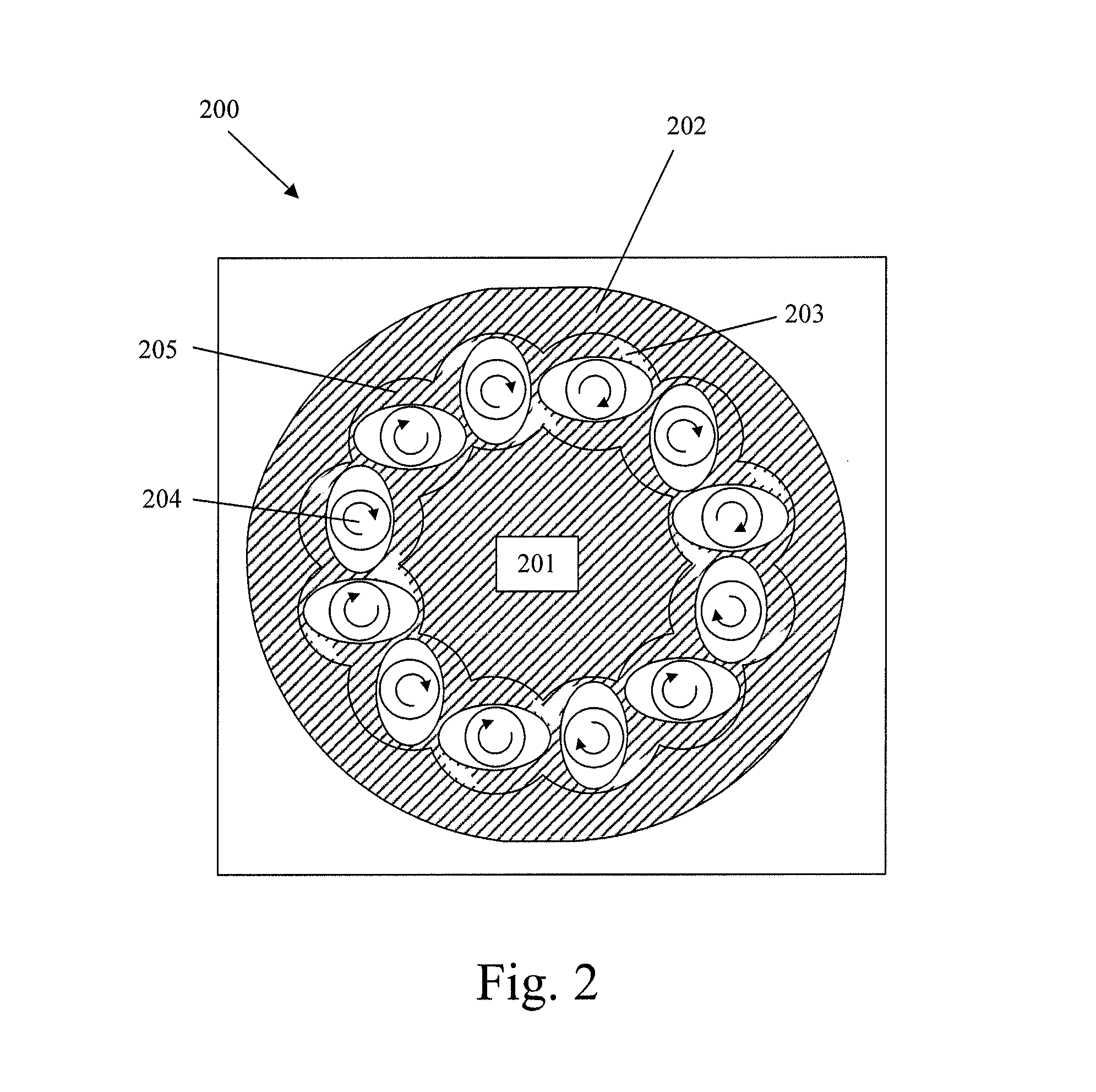

Process and plant for producing an elastomeric compound

A process for producing an elastomeric compound, includes: feeding at least one elastomeric polymer and at least one reinforcing filler to a mixing apparatus including at least one batch mixing device; mixing and dispersing, in the at least one mixing apparatus, the at least one reinforcing filler into the at least one elastomeric polymer, so as to obtain a first elastomeric compound; discharging the first elastomeric compound from the at least one mixing apparatus; feeding the first elastomeric compound to at least one continuous mixing device, said continuous mixing device including at least two rotating screws; mixing the first elastomeric compound in the at least one continuous mixing device, so as to obtain a second elastomeric compound; and discharging said second elastomeric compound from said at least one continuous mixing device.

Owner:PIRELLI TYRE SPA

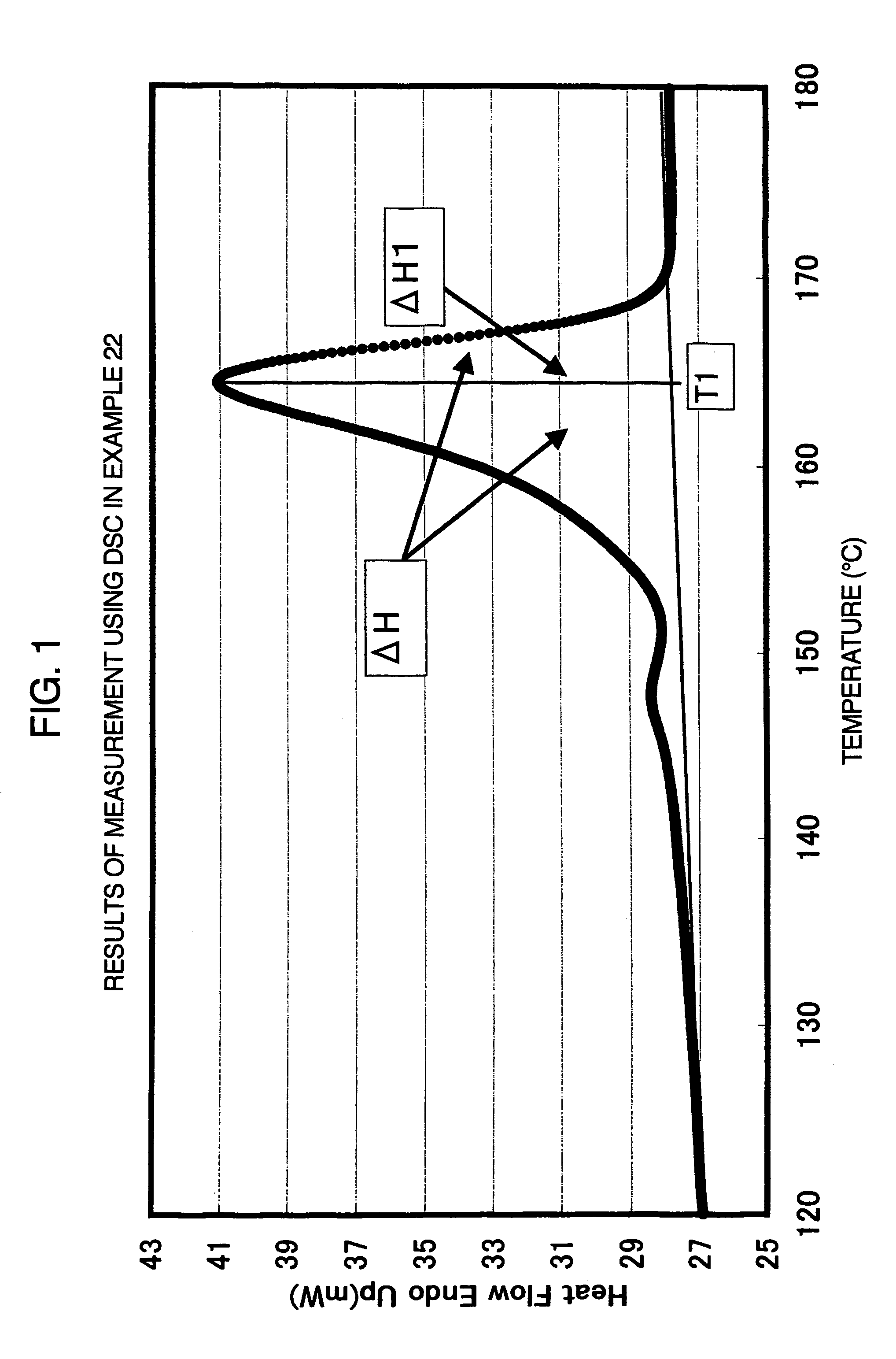

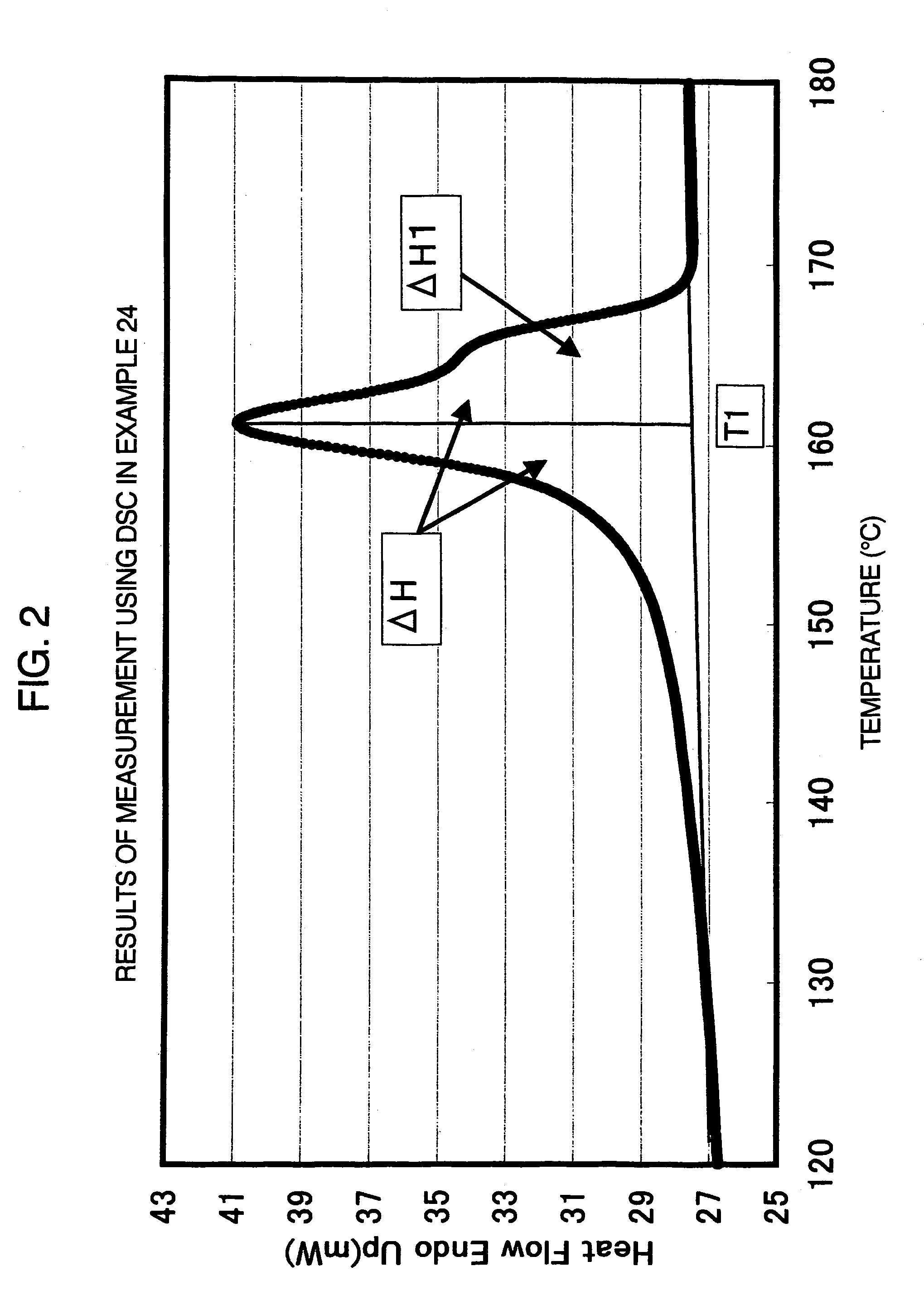

Molded article produced from aliphatic polyester resin composition

ActiveUS7514503B2DistanceImprove impact resistancePlastic/resin/waxes insulatorsDyeing processPolymer sciencePolyester resin

The present invention provides a molded article obtained from an aliphatic polyester resin composition comprising 60 to 99.9 parts by weight of at least one aliphatic polyester (A) and 0.1 to 40 parts by weight of at least one elastic polymer (B), provided that the total amount of the components (A) and (B) is 100 parts by weight, wherein the aliphatic polyester component in the molded article has an enthalpy of crystal fusion ΔH determined using a differential scanning calorimeter of 5 J / g or more, the molded article has a continuous phase composed of the aliphatic polyester (A) and dispersed phases composed of the elastic polymer (B), and the distance T between the walls of the dispersed phases is less than 5.0 μm.

Owner:ASAHI KASEI CHEM CORP

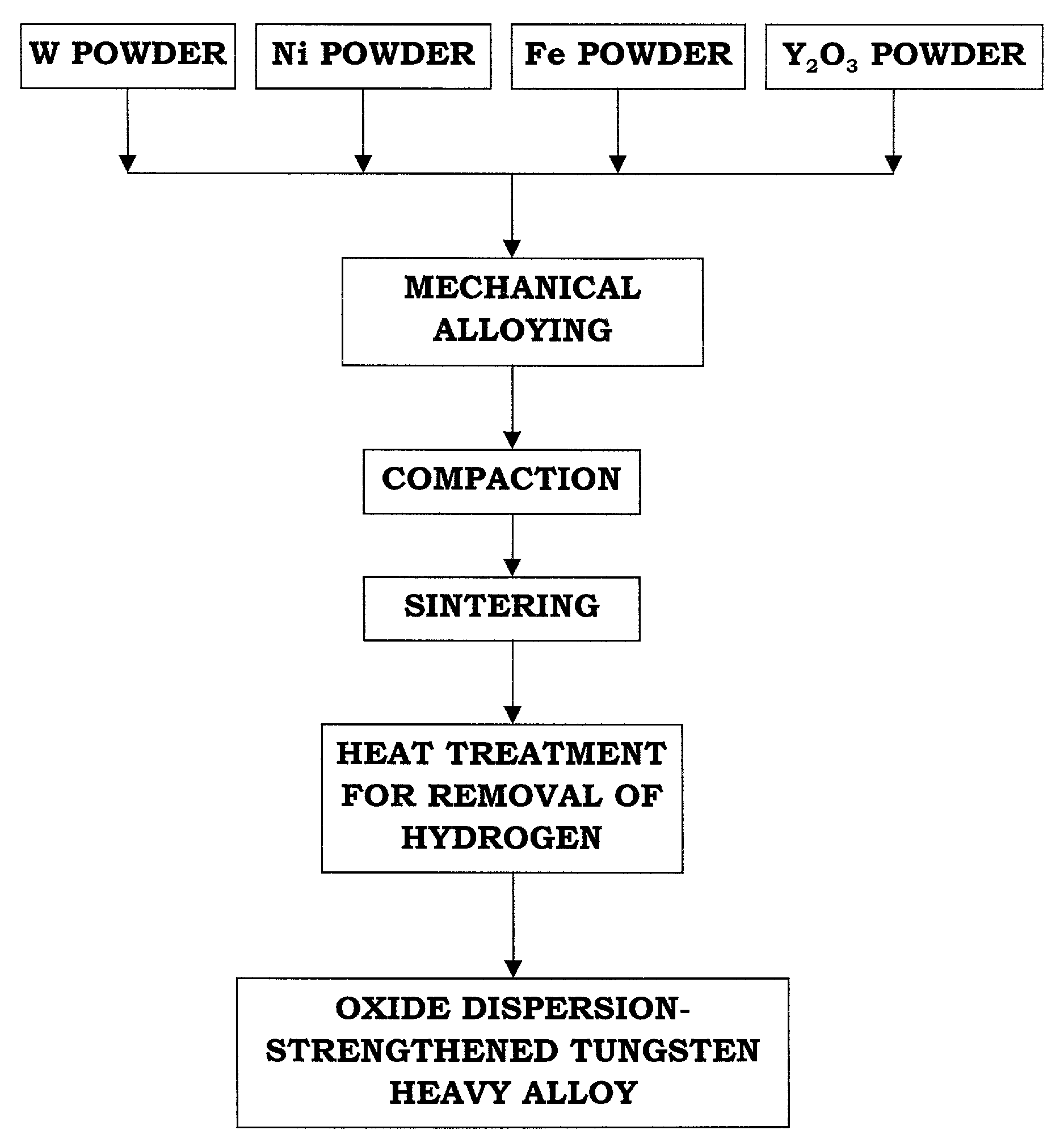

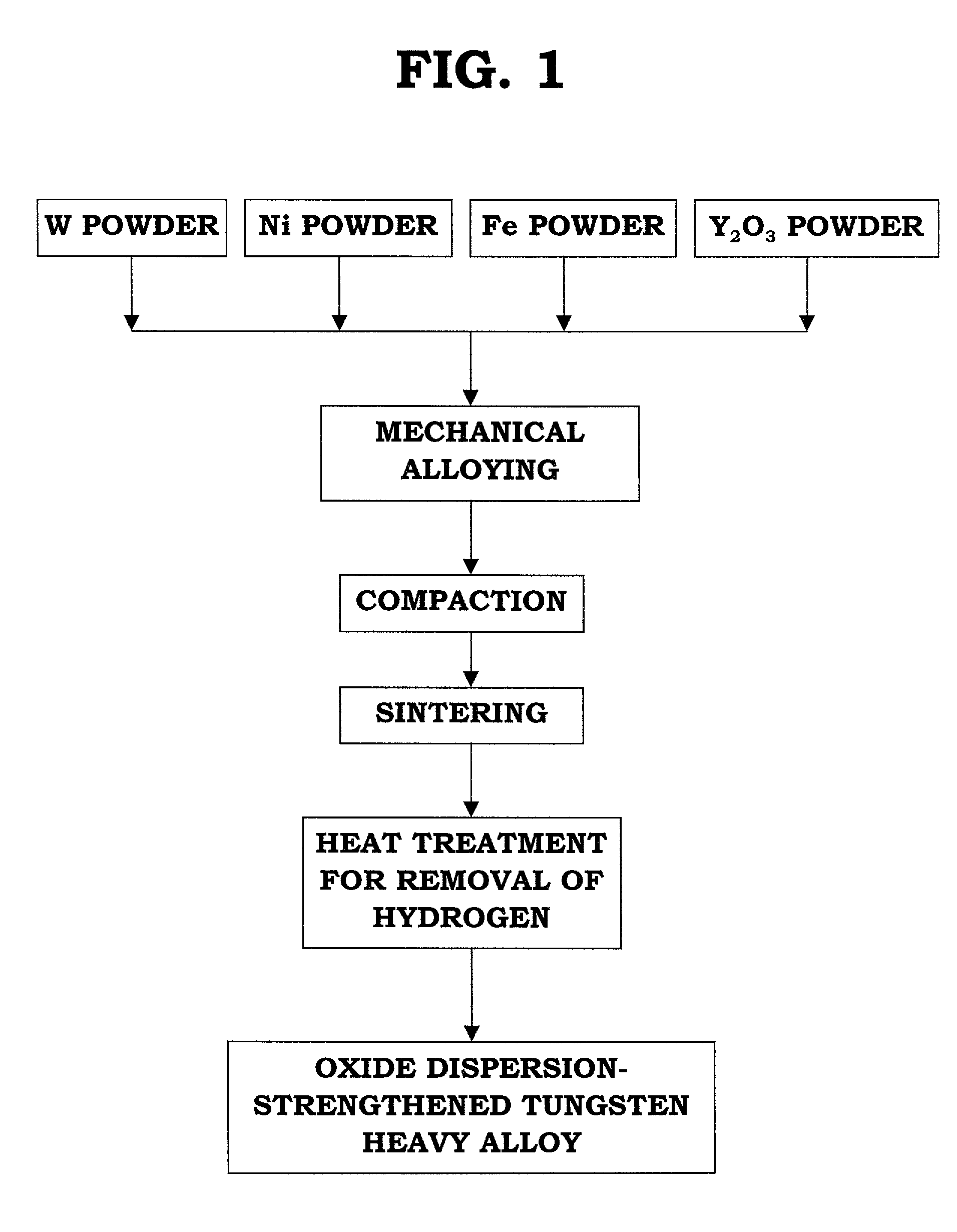

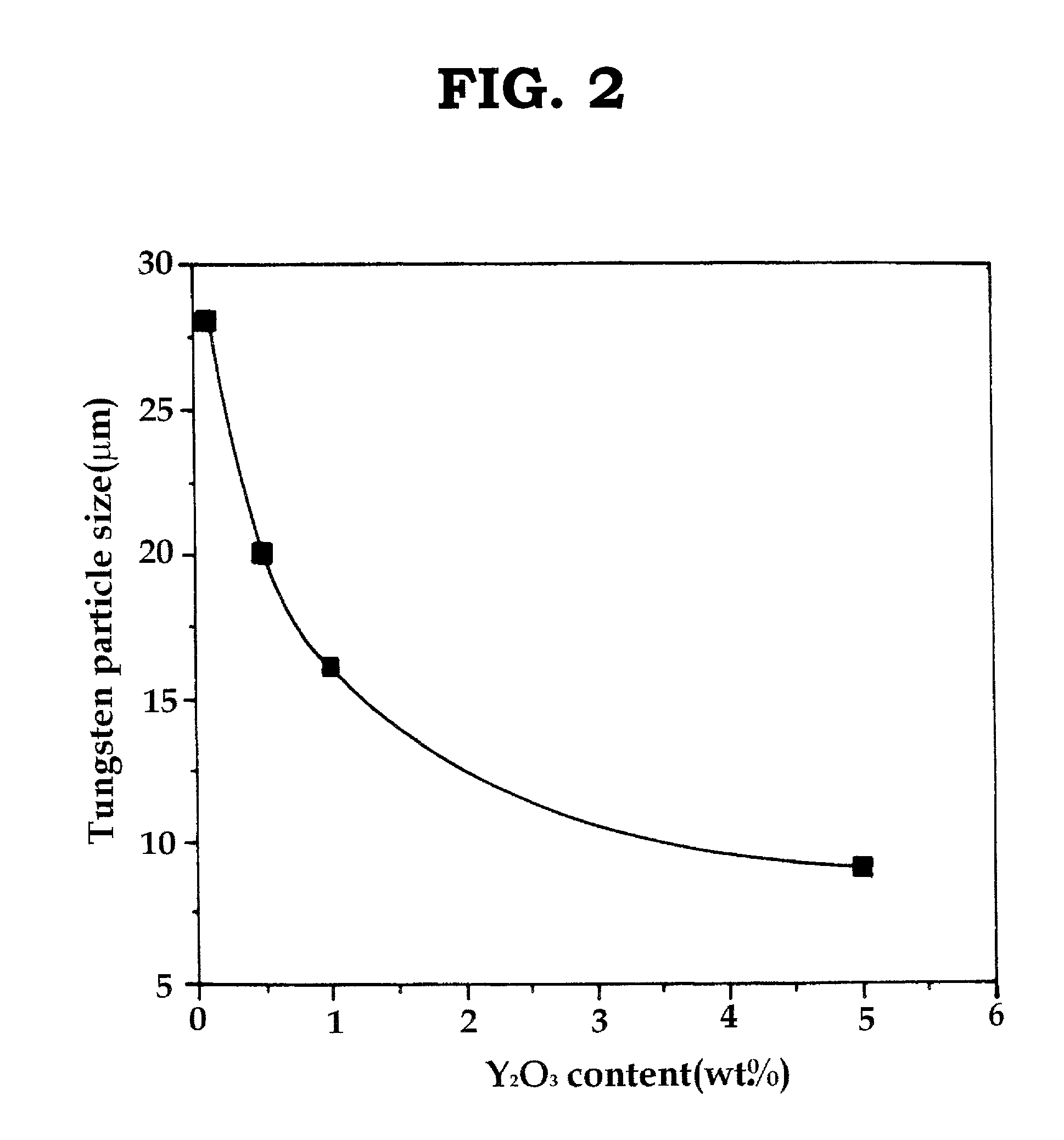

Process for making oxide dispersion-strengthened tungsten heavy alloy by mechanical alloying

InactiveUS20020002879A1Reduce shear strainHigh temperature strengthAmmunition projectilesTransportation and packagingIron powderAlloy

Disclosed is a process for making an oxide dispersion-strengthened tungsten heavy alloy by mechanical alloying that includes the steps of: adding 0.1 to 5 wt. % of Y2O3 powder to a mixed powder comprising more than 90 wt. % of tungsten powder, and nickel and iron powders for the rest; and subjecting the resulting mixture to a mechanical alloying to prepare an oxide dispersion-strengthened tungsten heavy alloy powder. The oxide dispersion-strengthened tungsten heavy alloy prepared by the mechanical alloying is characterized in that fine Y2O3 particles are uniformly dispersed in the matrix which are stable at high temperatures results in enhanced high-temperature strength and a reduction of the shearing strain of the fracture during high-speed shear deformation.

Owner:KOREA ADVANCED INST OF SCI & TECH

High flow polyolefin composition with high stiffness and toughness

The present invention relates to a polyolefin composition comprising two heterophasic propylene copolymers which differ in the intrinsic viscosity of their xylene soluble fractions.

Owner:BOREALIS AG

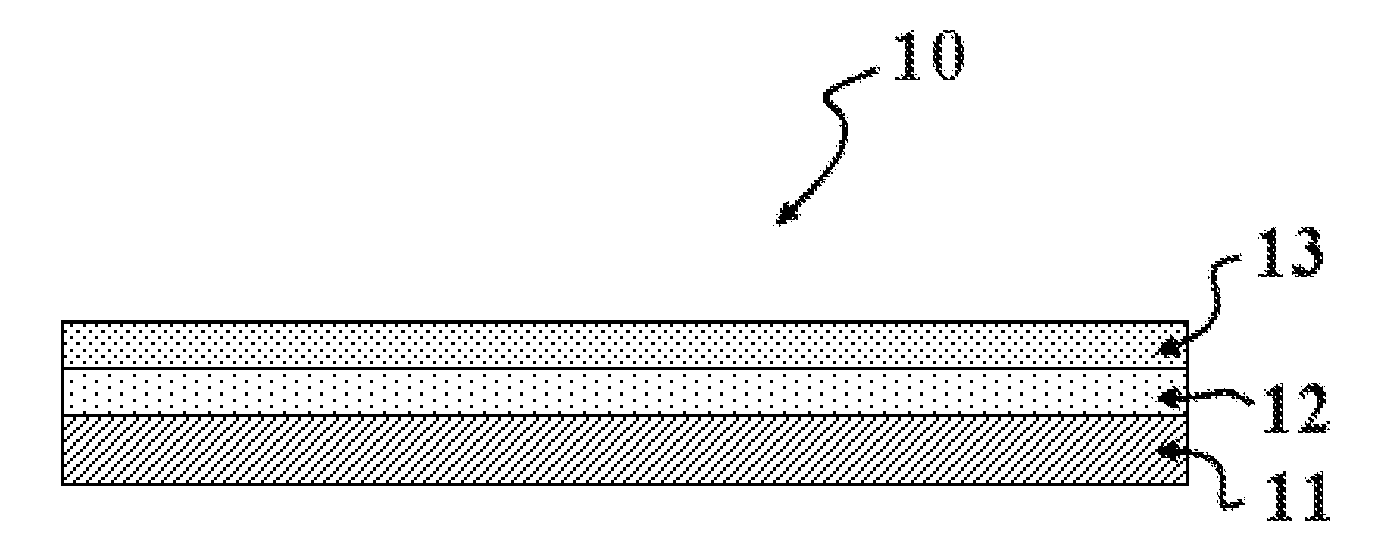

Multilayer structured transparent electrically-conductive film and method of manufacturing the same

ActiveUS20110281092A1Feel goodImprove mechanical propertiesSynthetic resin layered productsElectrical equipmentTransmittanceRefractive index

The present invention relates to a transparent electrically-conductive film comprising a substrate having a refractive index of n1, a first coating layer having a refractive index of n2, a second coating layer having a refractive index of n3, and an electrically-conductive oxide layer having a refractive index of n4 in a sequentially laminated form, wherein said refractive index of each layer complies with n1≦n3<n2<n4, and a method of preparing the same.The transparent electrically-conductive film according to the present invention has especially excellent color feeling and mechanical property as well as excellent transmittance.

Owner:LG CHEM LTD

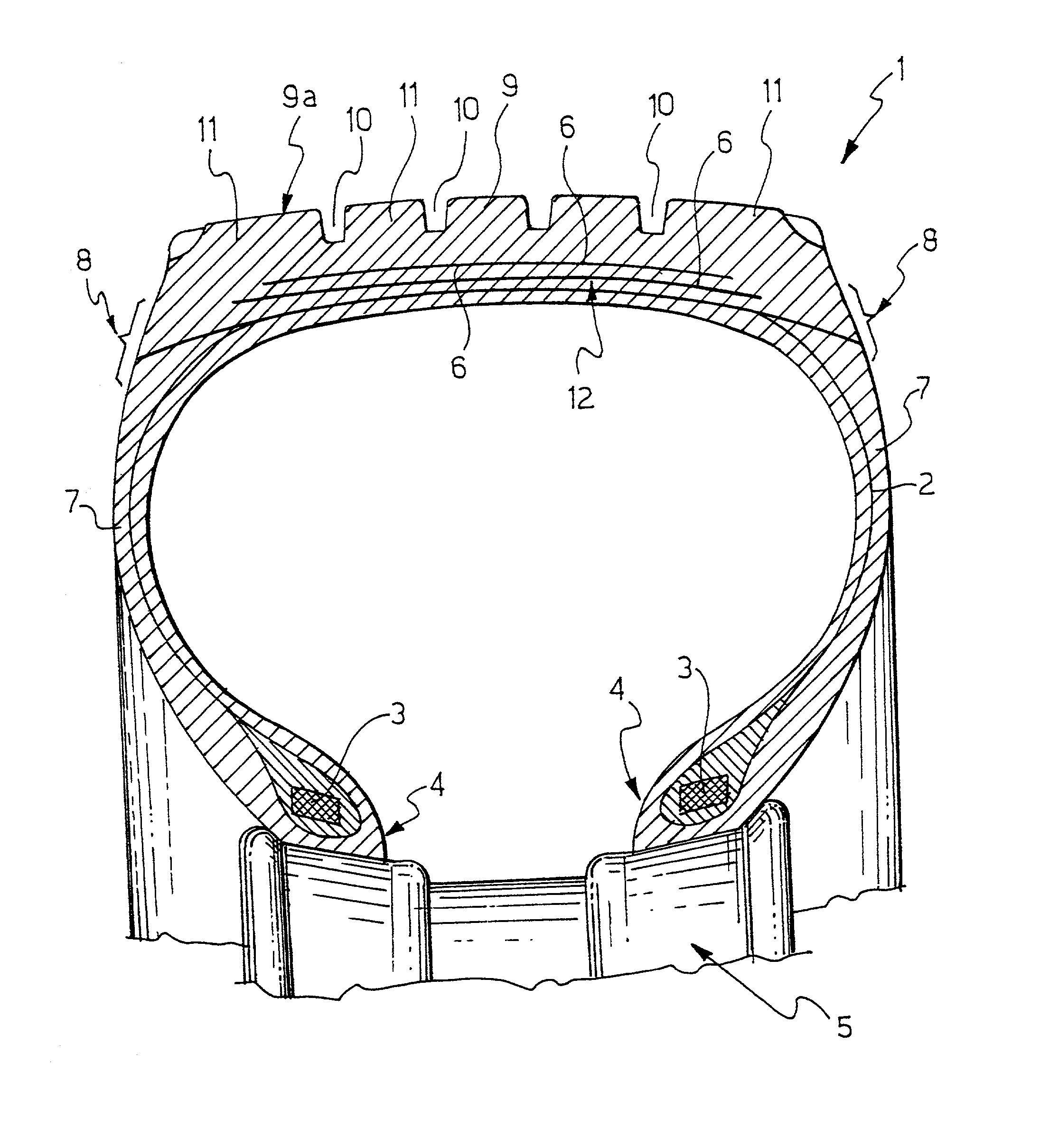

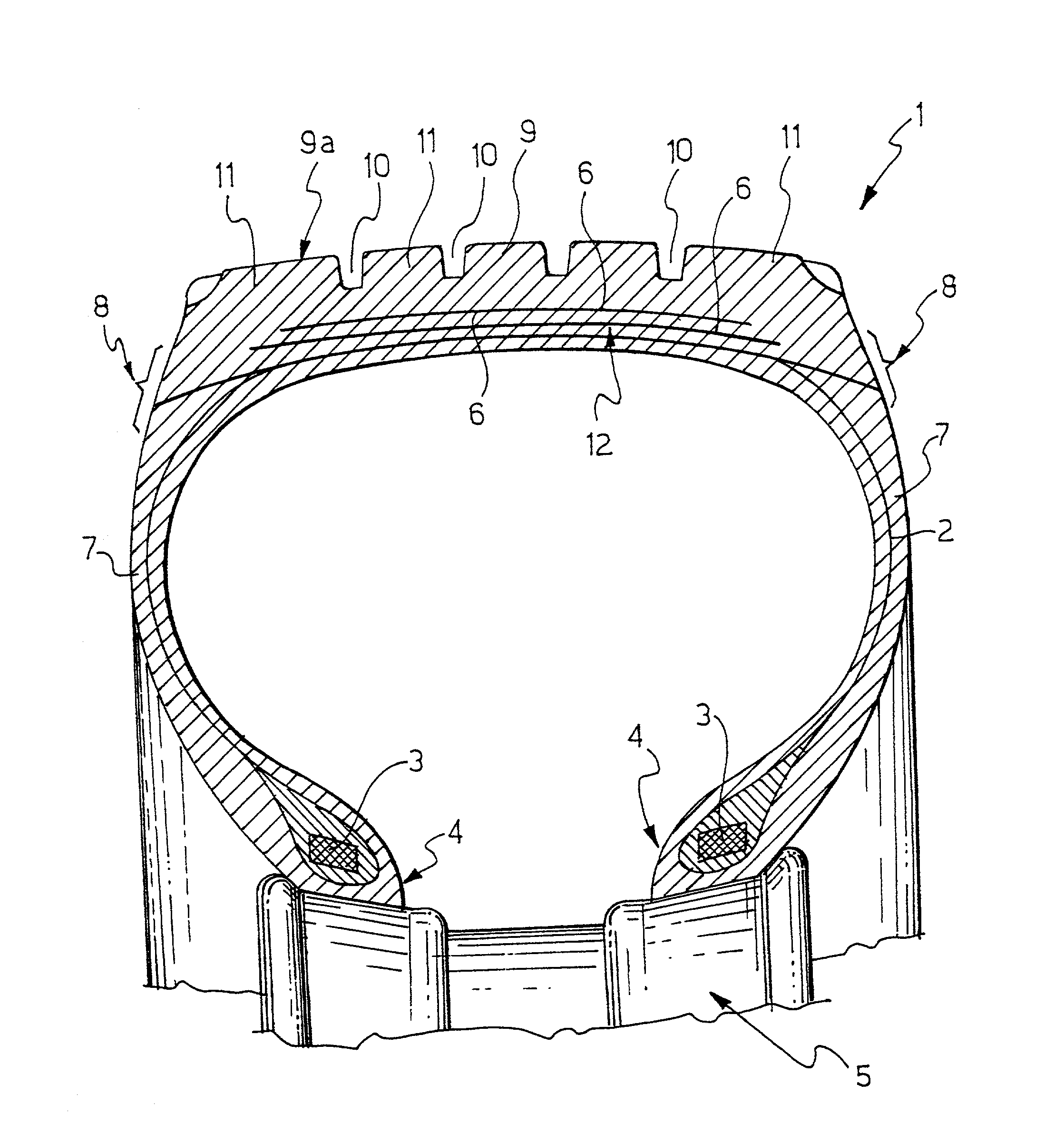

Low rolling resistance tire for vehicles

InactiveUS20020143096A1Reduce mixing actionLarge specific surface areaOther chemical processesSpecial tyresRolling resistanceProject area

A low rolling resistance tire (1) for vehicles is described which comprises a belt structure (12) coaxially extending around a carcass structure (2) and a tread (9), coaxially extending around the belt structure (12) and being externally provided with a rolling surface (9a) designed to get in touch with the ground, the tread (9) comprising a vulcanized polymer base including at least a first silica-based reinforcing filler, the tire being characterized in that the first silica-based reinforcing filler has: an average projected area of the aggregates as measured before incorporation into the polymer base lower than 20,000 nm2; a dispersion index in the vulcanized polymer base of the tread (9) not lower than 97%; and a projected area of the aggregates after incorporation into the polymer base comprised between 8500 and 18000 nm2. Advantageously, said tire has mechanical properties improved or at least comparable with respect to those of the known tires for the same type of use.

Owner:PIRELLI TYRE SPA

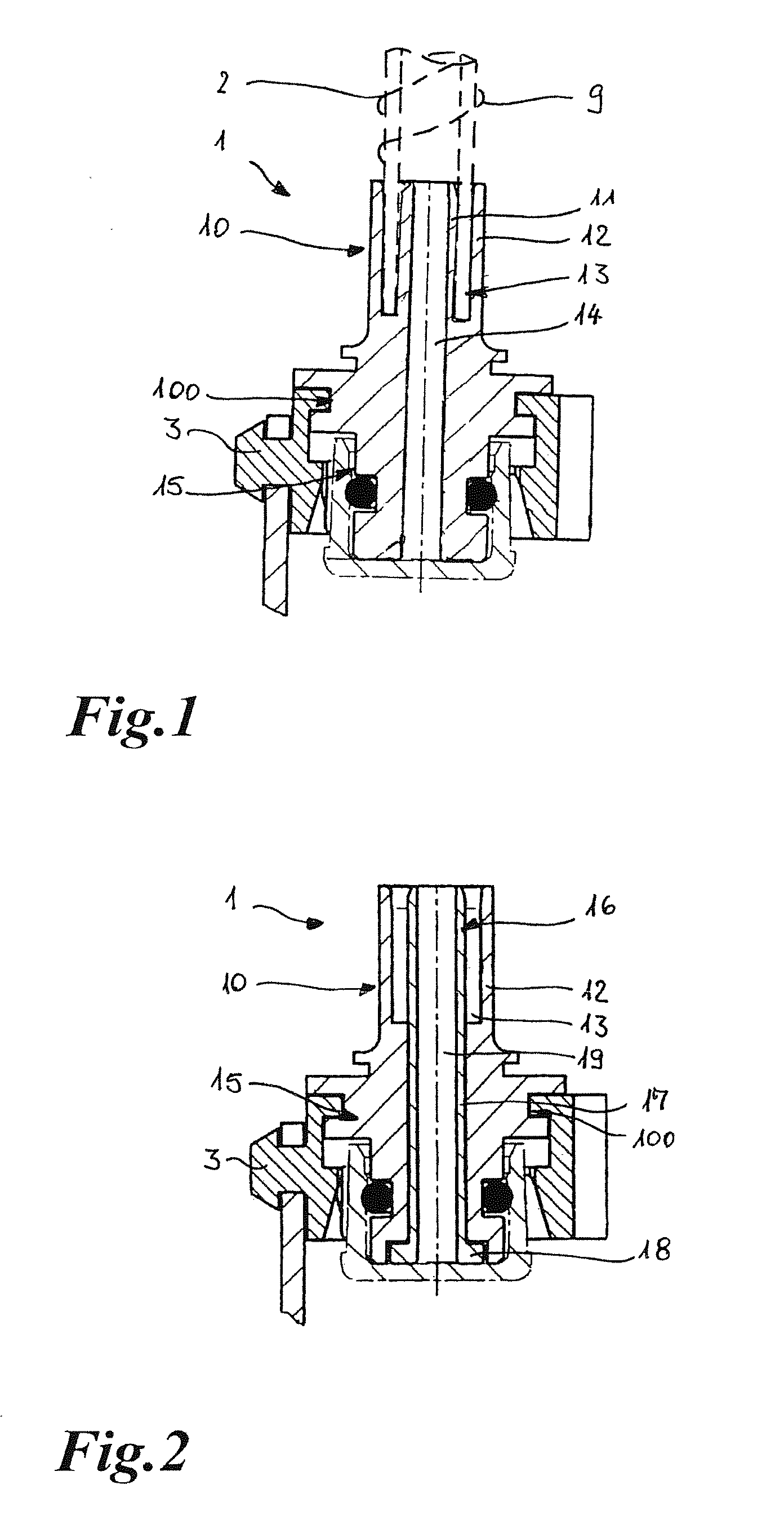

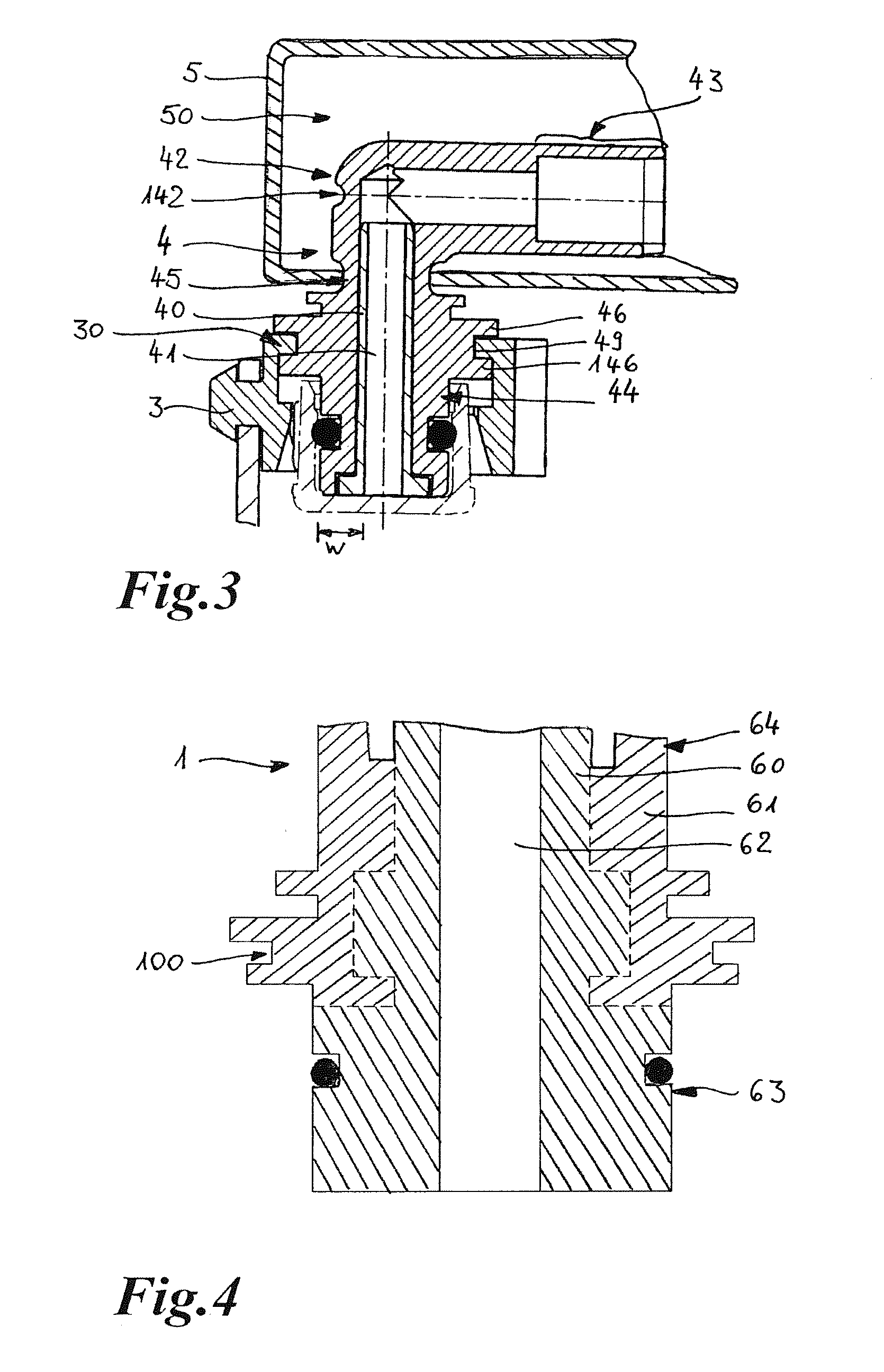

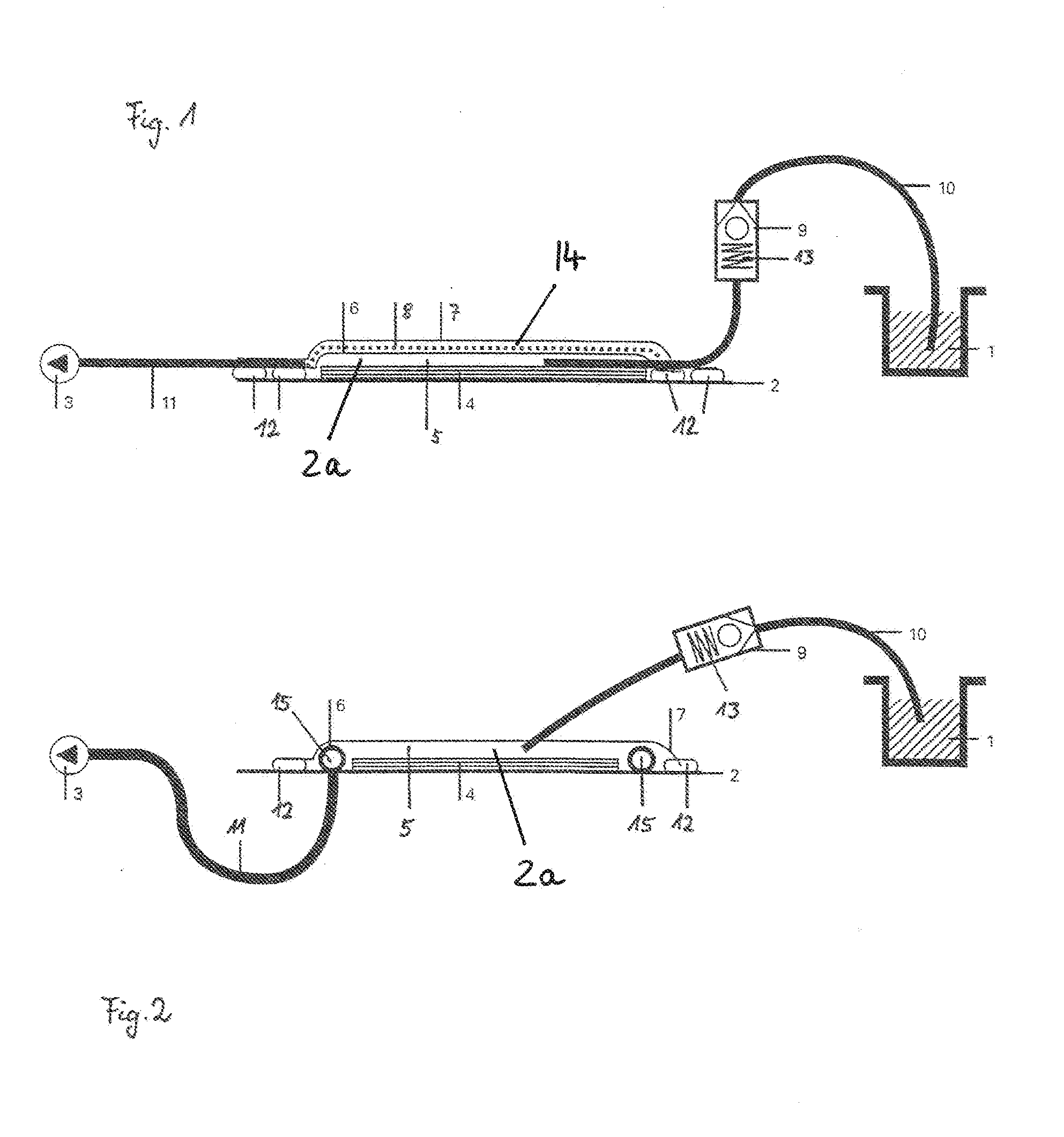

At least partially heatable line-connector for a heatable media line, and an assembled media line comprising such a line-connector

InactiveUS20140230941A1More cost-effectivelySolve the real problemPipe heating/coolingMachines/enginesEngineeringHeating system

An at least partially heatable line-connector for a media line which can be heated, the line-connector at least partially including a thermally-conductive or thermally-conducting material, with a heating system and / or heating elements being associated outside the body of the line-connector. An assembled media line with at least one heatable media line is provided with at least one such at least partially heatable line-connector.

Owner:VOSS AUTOMOTIVE

High flow polyolefin composition with high stiffness and toughness

The present invention relates to a polyolefin composition comprising two heterophasic propylene copolymers which differ in the melt flow rate.

Owner:BOREALIS AG

Ceramic composition and cutting tool

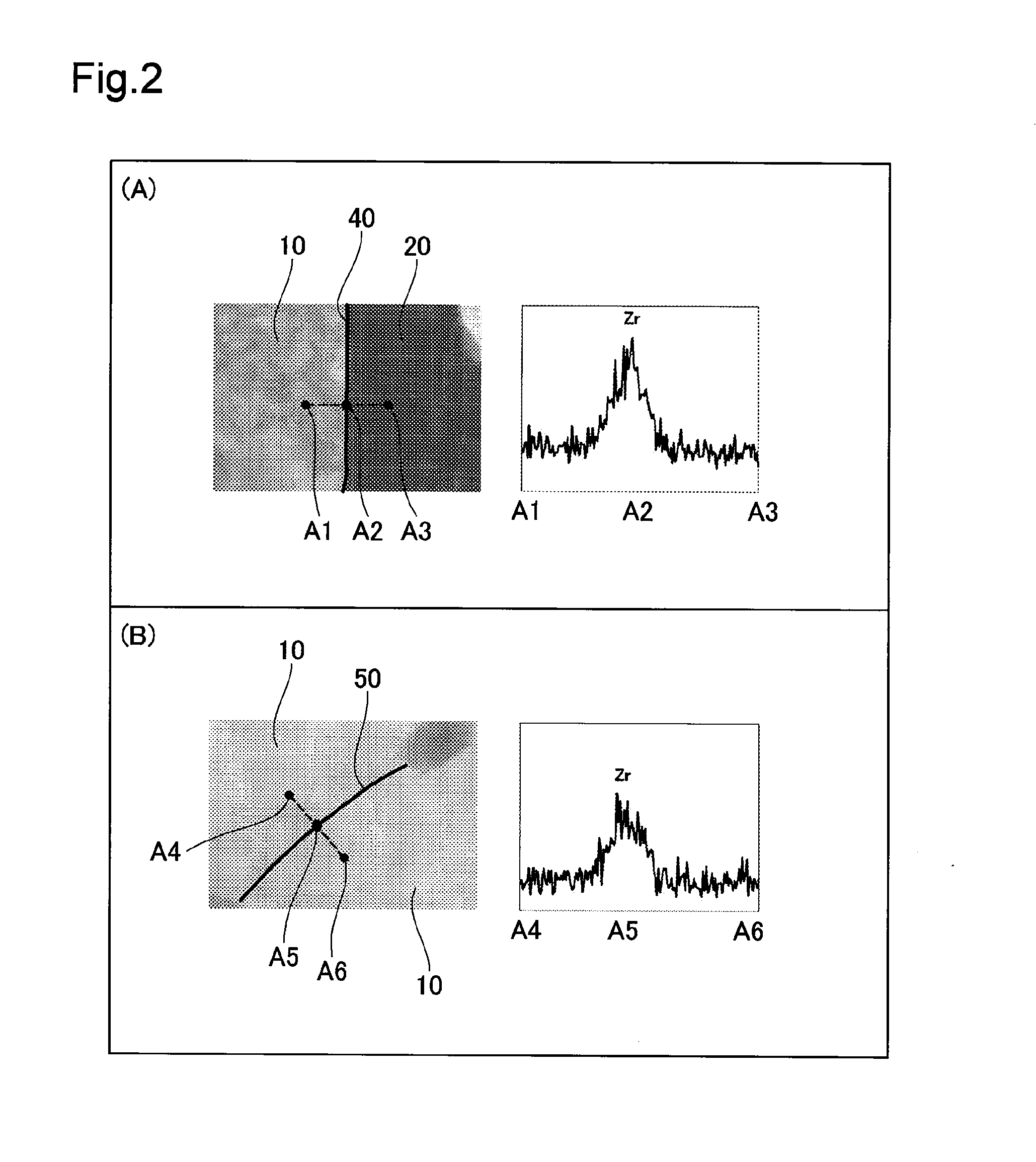

ActiveUS20160023952A1Deterioration of mechanical propertiesReduced durabilityGrain boundaryZirconium

Owner:NGK SPARK PLUG CO LTD

Multi-layered sheet and method of preparing same

ActiveUS20130171447A1Increase production costIncrease temperatureLiquid surface applicatorsFilm/foil adhesivesWeather resistanceThermal deformation

Provided are a multi-layered sheet, a backsheet for a photovolatic cell, a method of preparing the same and a photovoltaic module. The multi-layered sheet in which a resin layer including a fluorine-based resin has excellent durability and weather resistance, and also exhibits strong interfacial adhesion to a substrate or polymer coating layer is provided. When a drying process is performed at a low temperature in preparation of the multi-layered sheet, production cost can be reduced, producibility can be increased, and degradation in the quality of a product caused by thermal deformation or thermal shock can be prevented. Such a multi-layered sheet may be effectively used as a backsheet for various photovoltaic cells.

Owner:LG CHEM LTD

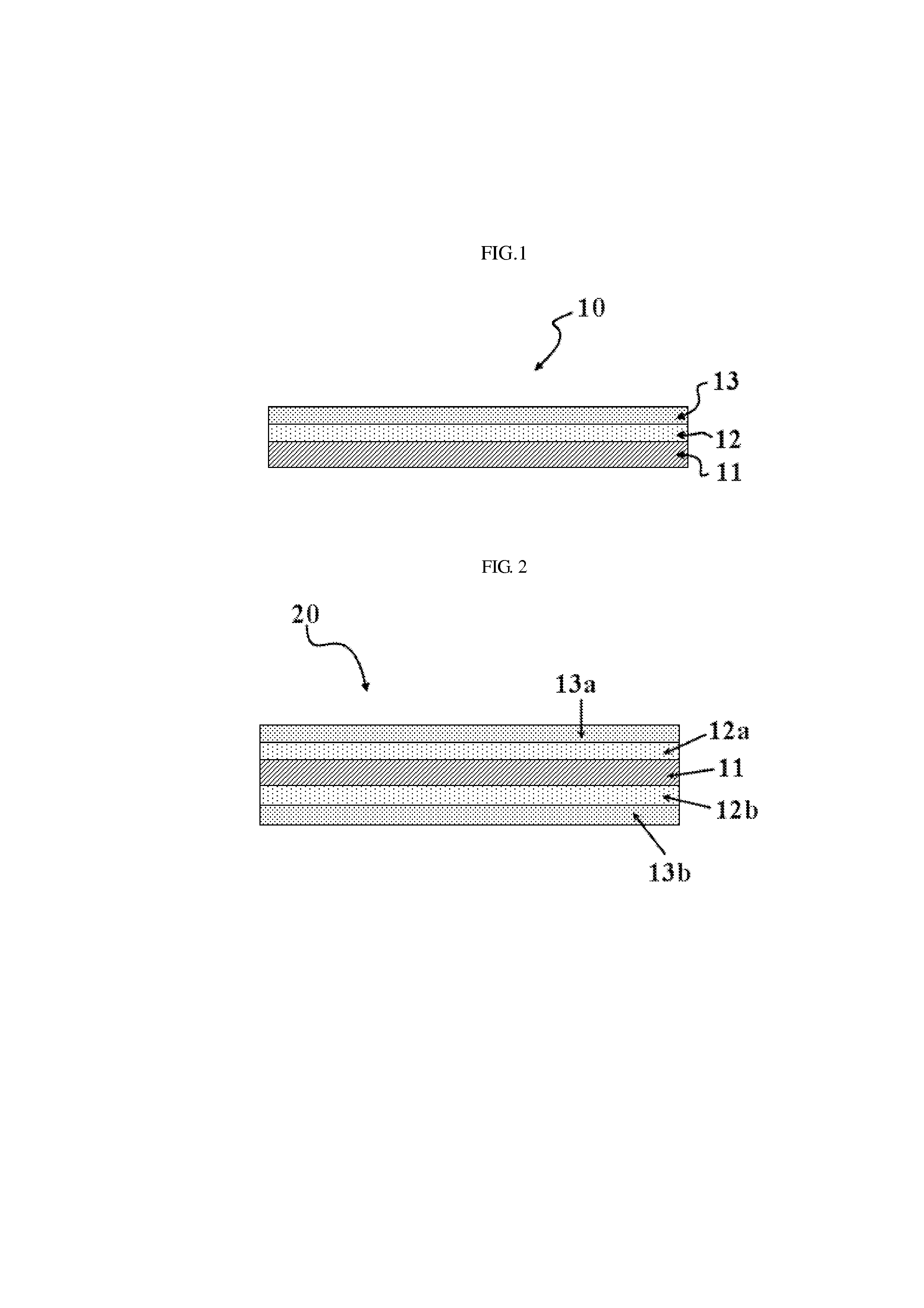

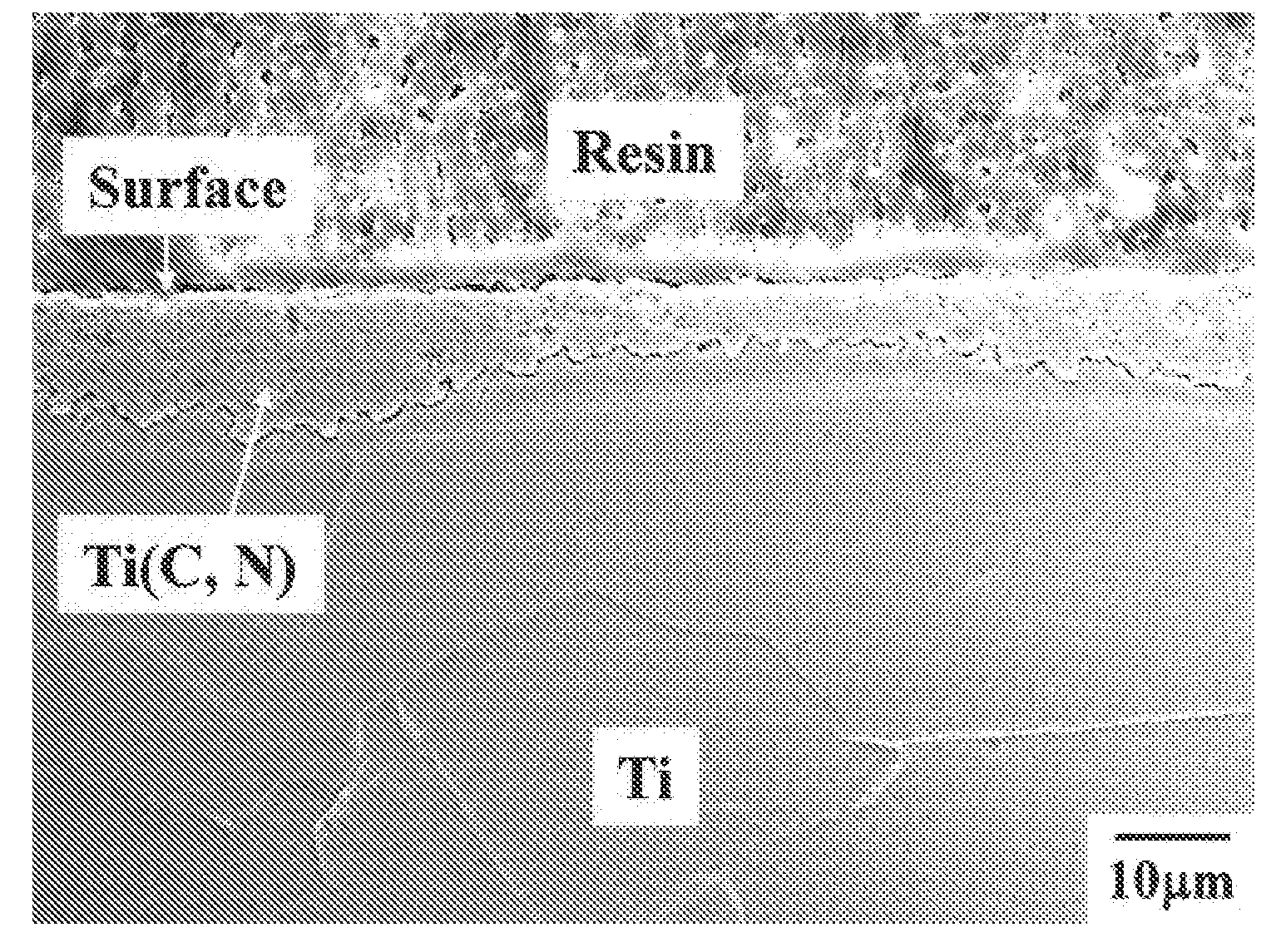

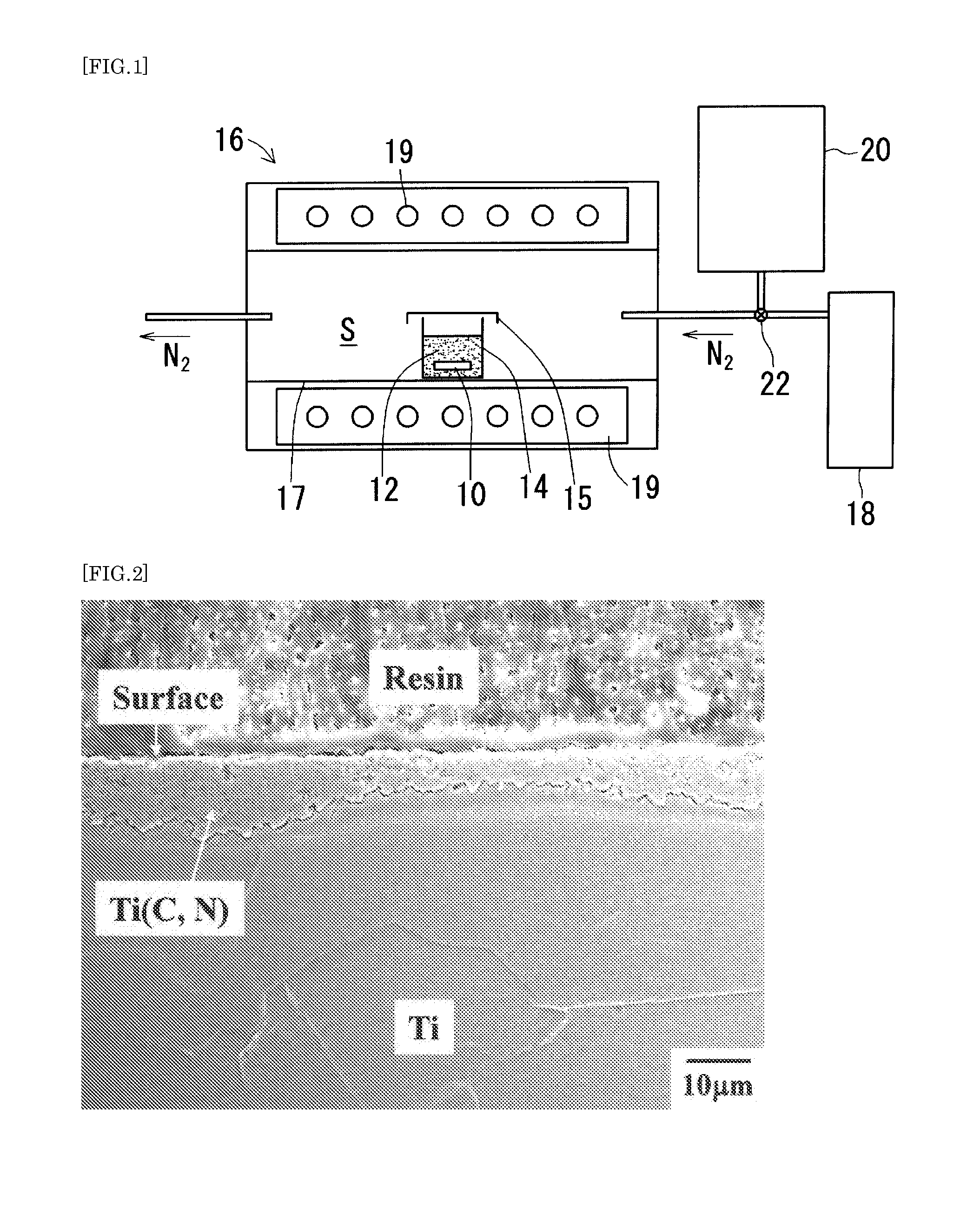

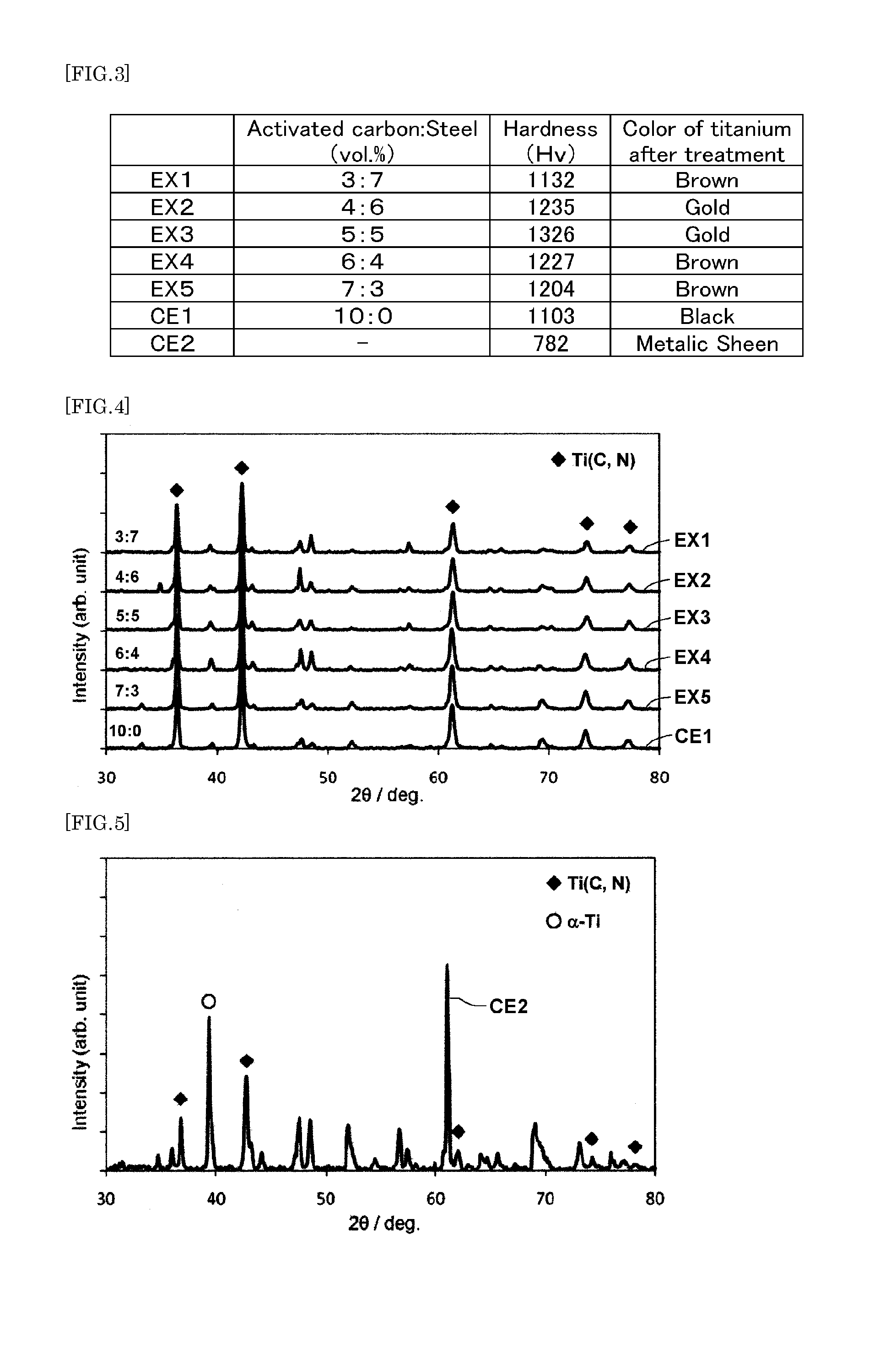

Method for treatment of metal surface, and surface-modified metal product

InactiveUS20120325373A1Improve surface propertiesLow costSolid state diffusion coatingMetal layered productsCarbon sourceNitrogen gas

Provided is a method of treating a metal surface, which can improve surface properties of a target metal, such as surface hardness and wear resistance in a simple manner and at low cost using very simple equipment alone, and which can prevent the deterioration of the metal to create high added value. The present invention is comprised of a method of treating a metal surface, characterized in that: heat-treating a target metal (10) to be surface-modified in nitrogen gas atmosphere (S), in such a state where the target metal (10) is buried in a carbon source powder (12) comprising a carbon powder and a powder of iron or an iron alloy mainly comprising iron and containing carbon, whereby the surface of the target metal (10) is at least nitrided or nitrogen-absorbed to modify the surface.

Owner:NAT UNIV CORP KUMAMOTO UNIV

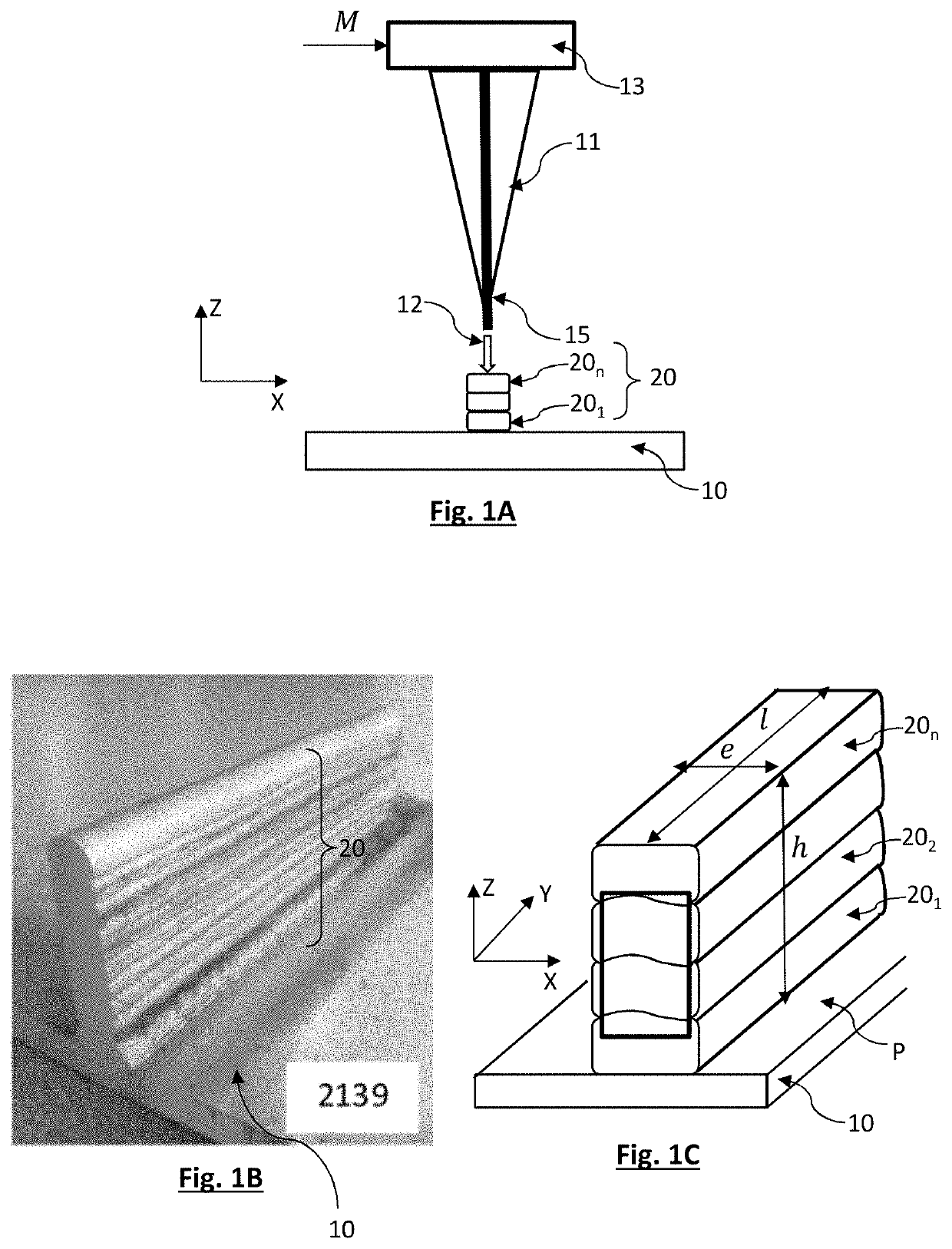

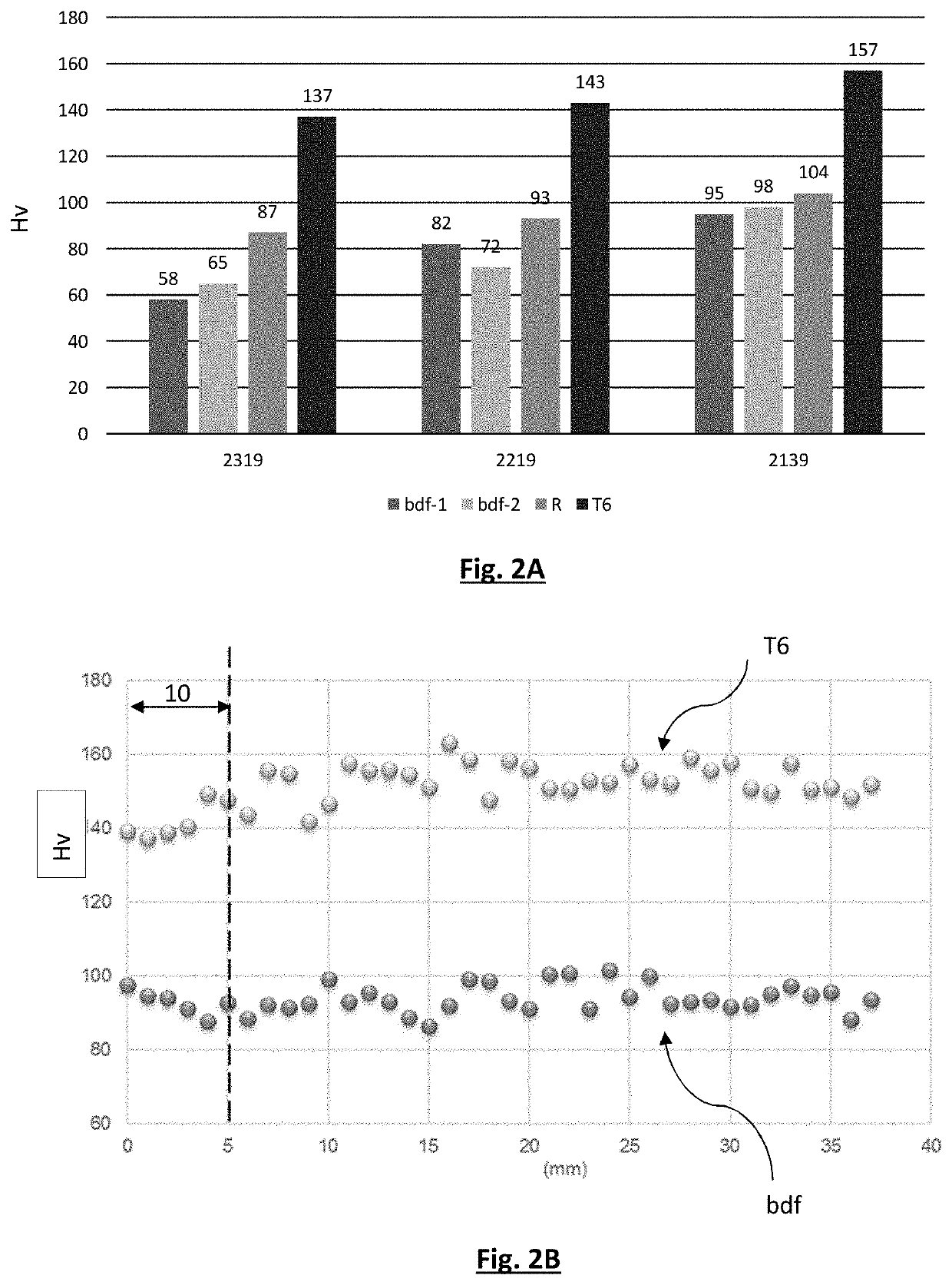

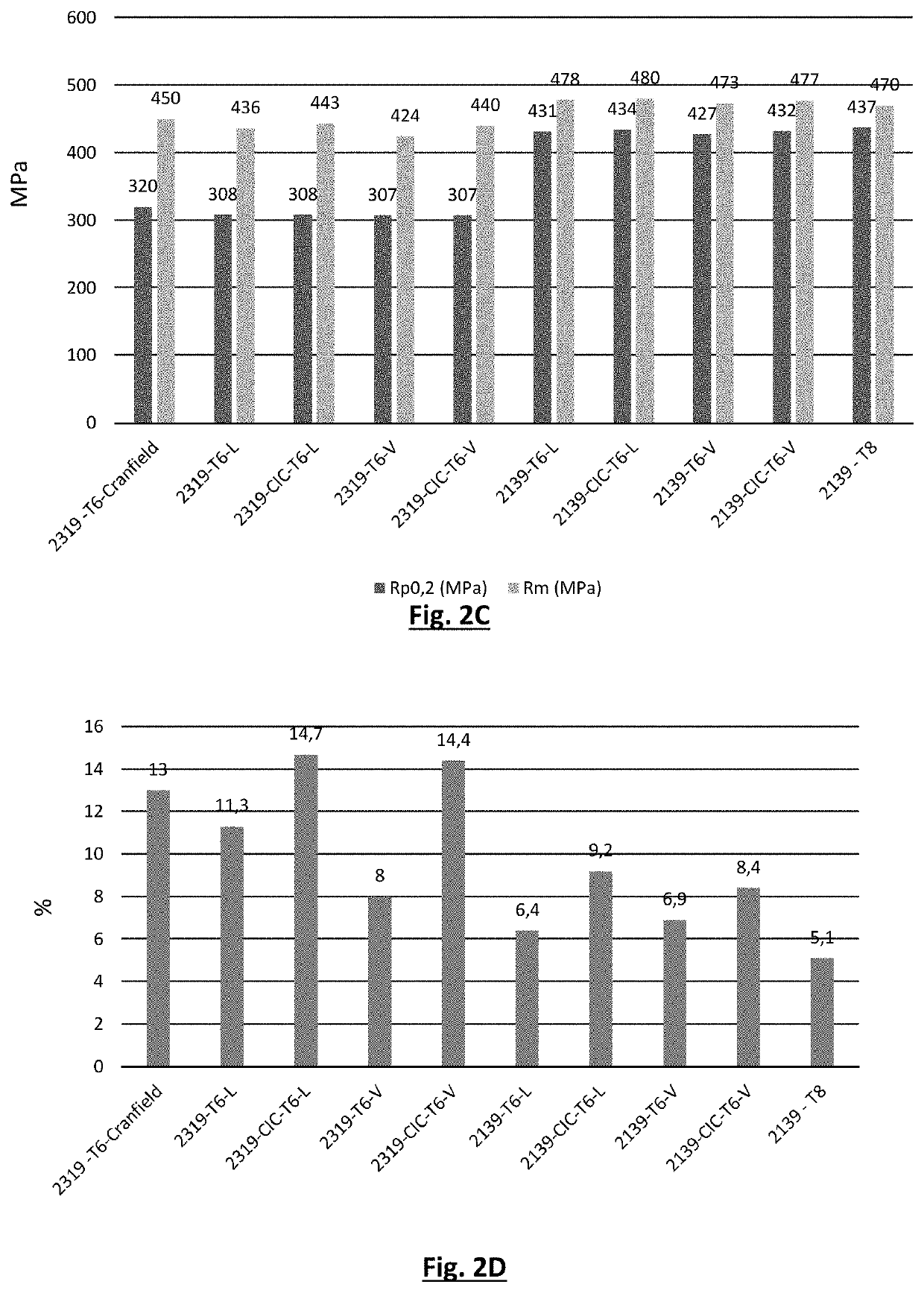

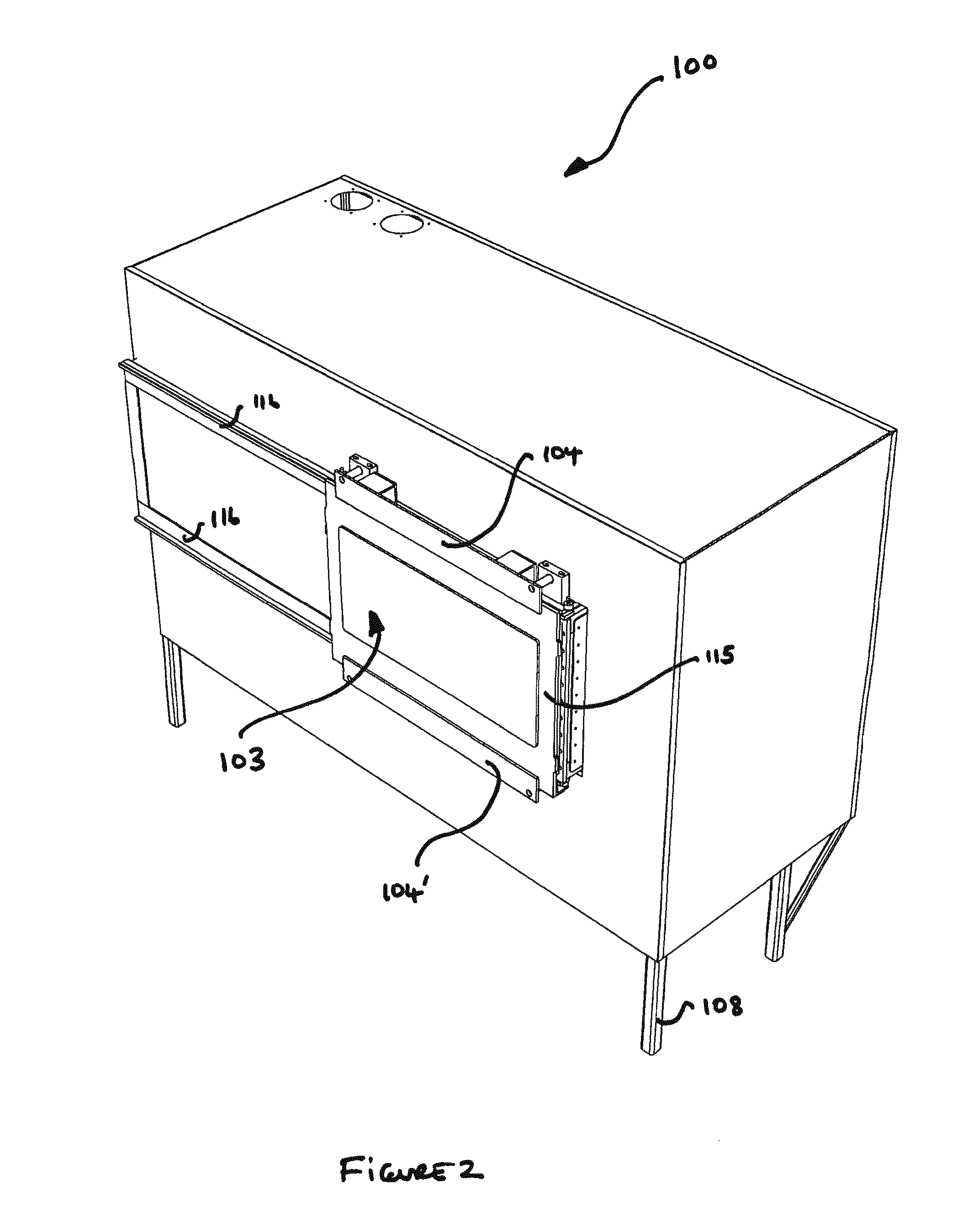

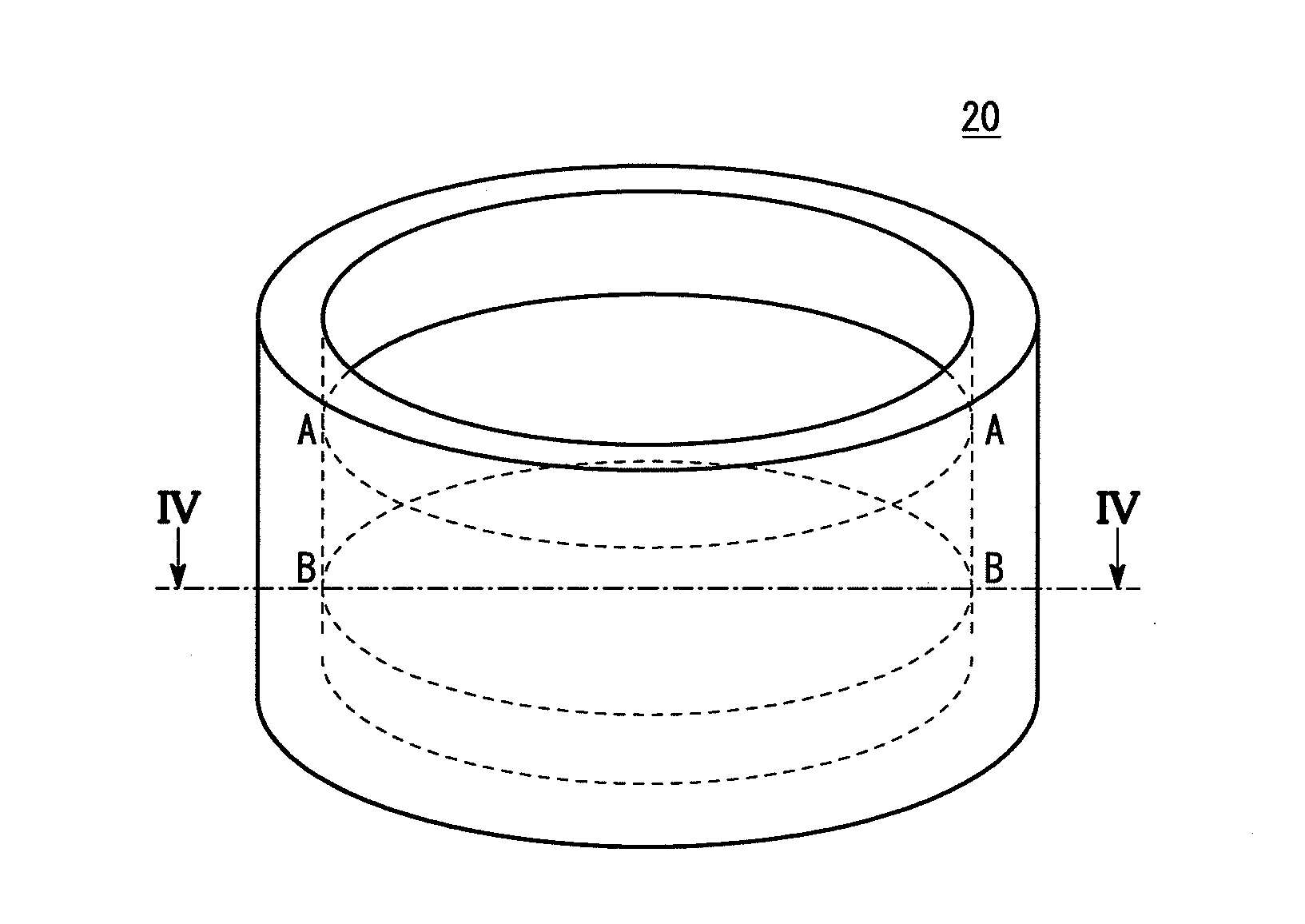

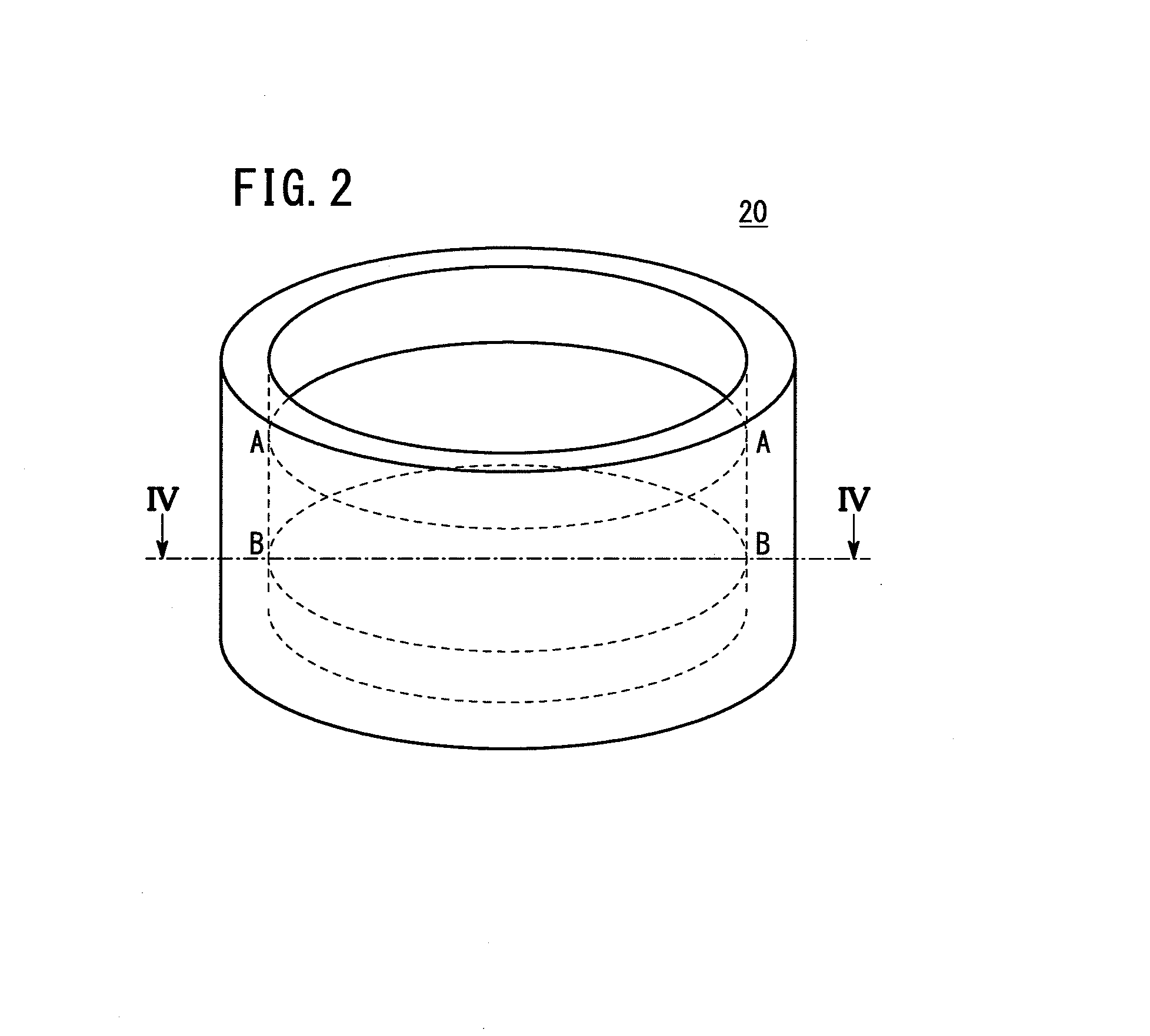

Process for manufacturing an aluminum alloy part

PendingUS20200156154A1High material hardnessHigh hardnessAdditive manufacturing apparatusIncreasing energy efficiencyAlloy elementFiller metal

The present invention relates to a process for manufacturing a part (20) comprising a formation of successive metal layers (201 . . . 20n), superimposed on one another, each layer describing a pattern defined from a numerical model, each layer being formed by the deposition of a metal (15, 25), referred to as a filling metal, the filling metal being subjected, at a pressure greater than 0.5 times the atmospheric pressure, to an input of energy so as to melt and constitute said layer, the process being characterized in that the filling metal is an aluminium alloy of the 2xxx series, comprising the following alloying elements:Cu, in a weight fraction of between 3% and 7%;Mg, in a weight fraction of between 0.1% and 0.8%;at least one element, or at least two elements or even at least three elements chosen from:Mn, in a weight fraction of between 0.1% and 2%, preferably of at most 1% and in a preferred manner of at most 0.8%;Ti, in a weight fraction of between 0.01% and 2%, preferably of at most 1% and in a preferred manner of at most 0.3%;V, in a weight fraction of between 0.05% and 2%, preferably of at most 1% and in the preferred manner of at most 0.3%;Zr, in a weight fraction of between 0.05% and 2%, preferably of at most 1% and in a preferred manner of at most 0.3%;Cr, in a weight fraction of between 0.05% and 2%, preferably of at most 1% and in the preferred manner of at most 0.3%; andoptionally at least one element, or at least two elements or even at least three elements chosen from:Ag, in a weight fraction of between 0.1% and 0.8%;Li, in a weight fraction of between 0.1% and 2%, preferably 0.5% and 1.5%;Zn, in a weight fraction of between 0.1% and 0.8%.

Owner:C TEC CONSTELLIUM TECH CENT

Aluminum bearing-alloy

InactiveUS6875290B2Excellent in wear and fatigue resistance propertyImprove bearing performanceShaftsBearing componentsAluminium alloyCrystallite

An aluminum bearing-alloy containing 1.5 to 8 mass % of Si is provided, in which there can be observed Si grains on the sliding surface of the aluminum bearing-alloy. A fractional area of the observed Si grains having a grain size of less than 4 μm is 20 to 60% of a total area of all the observed Si grains. Another fractional area of the observed Si grains having a grain size of from 4 to 20 μm is not less than 40% of the total area of all the observed Si grains.

Owner:DAIDO METAL CO LTD

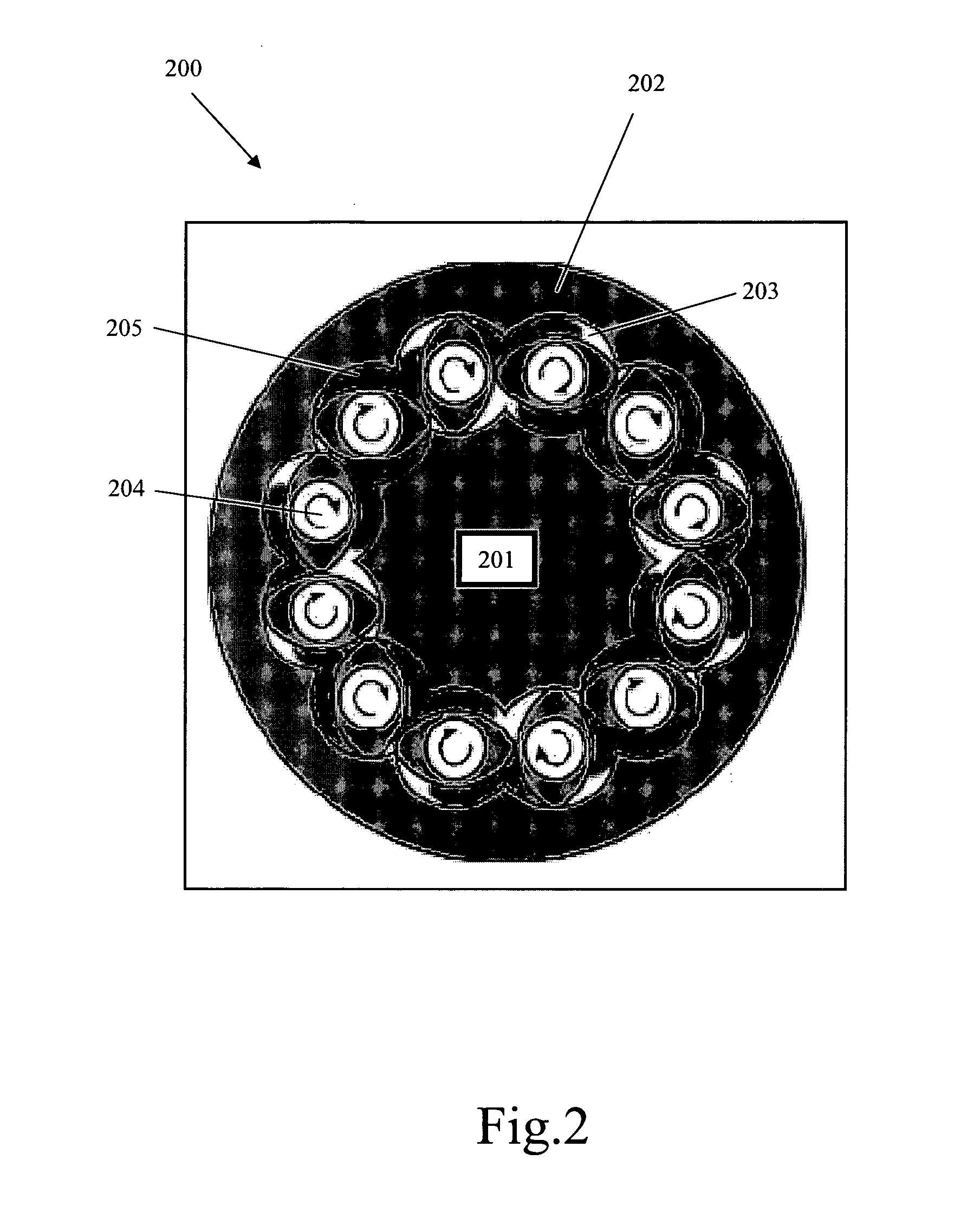

Process and plant for producing tyres

A compound plant for processing elastomeric compounds for tyres with both a high quality and a high throughput includes at least one batch mixing device in combination with at least one multi-shaft continuous mixing device having a high number of shafts. For example, the multi-shaft continuous mixing device could be a ring extruder having a plurality of co-rotating screws disposed to form a ring. In operation, a first elastomeric compound is discharged from the at least one batch mixing device and processed with the at least one multi-shaft continuous mixing device to obtain a second elastomeric compound

Owner:PIRELLI TYRE SPA

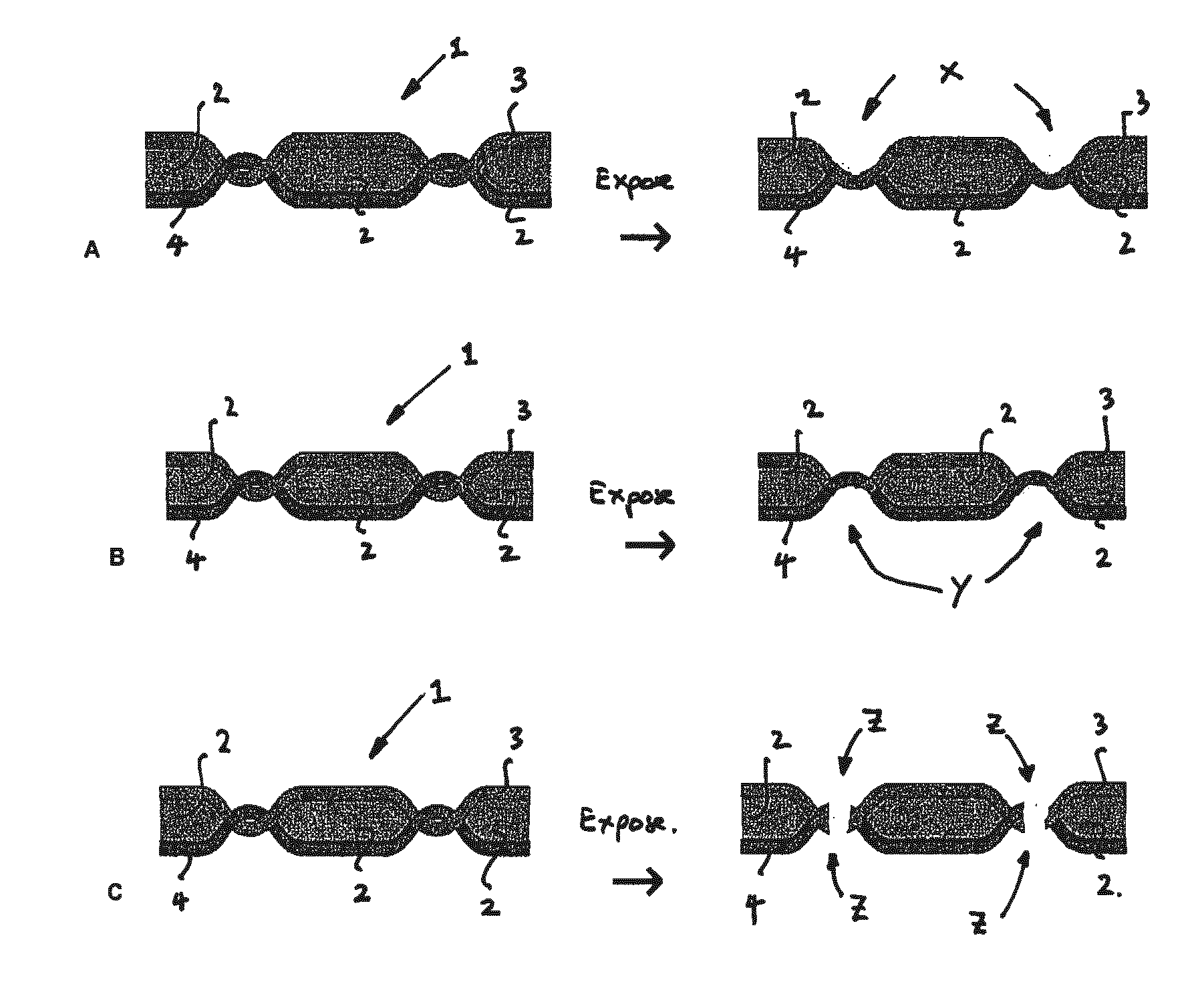

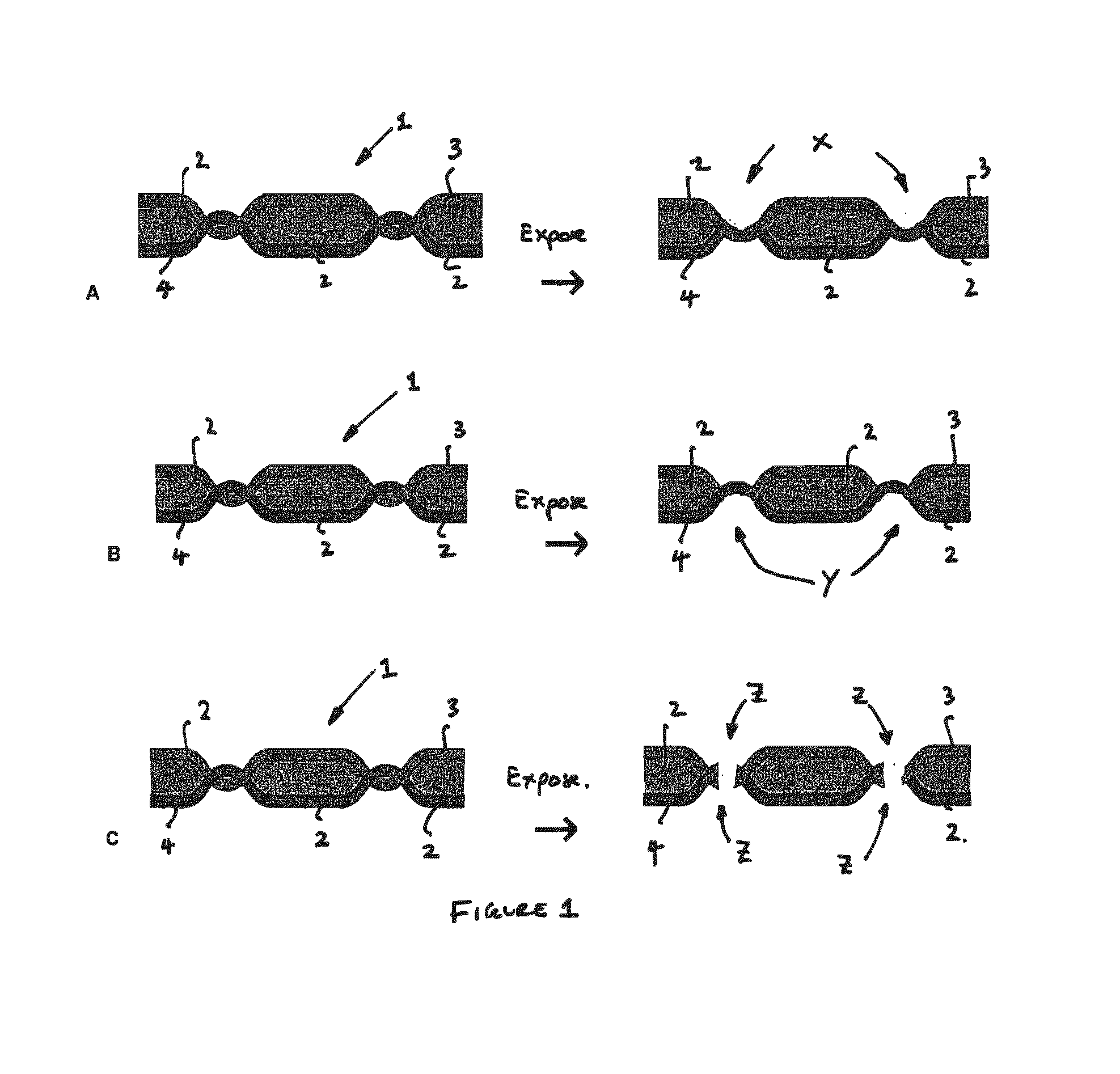

Article assembly disassembly system

ActiveUS20150167230A1Easy to produceModifying colour and appearanceGarmentsPlastic recyclingYarnMicrowave

There is described a system, article, method, connectors and apparatus for article reuse or recycling, which system including the assembling of an article from at least two components at least one of which has a textile material brought into communication with each other through one or more connectors and the subsequent disassembling of the article and use of one or more of the components in the assembling stage. The assembled article is susceptible to automatic or semi-automatic disassembly through one or more of its connectors being susceptible to a reduction in one or more mechanical properties under exposure of the article to electromagnetic energy especially microwave. The article may be a garment that has joins stitched with a microwave susceptible yarn. The yarn is ideally manufactured from pseudo-conductive materials and is metal free.

Owner:WEAR2GO BV

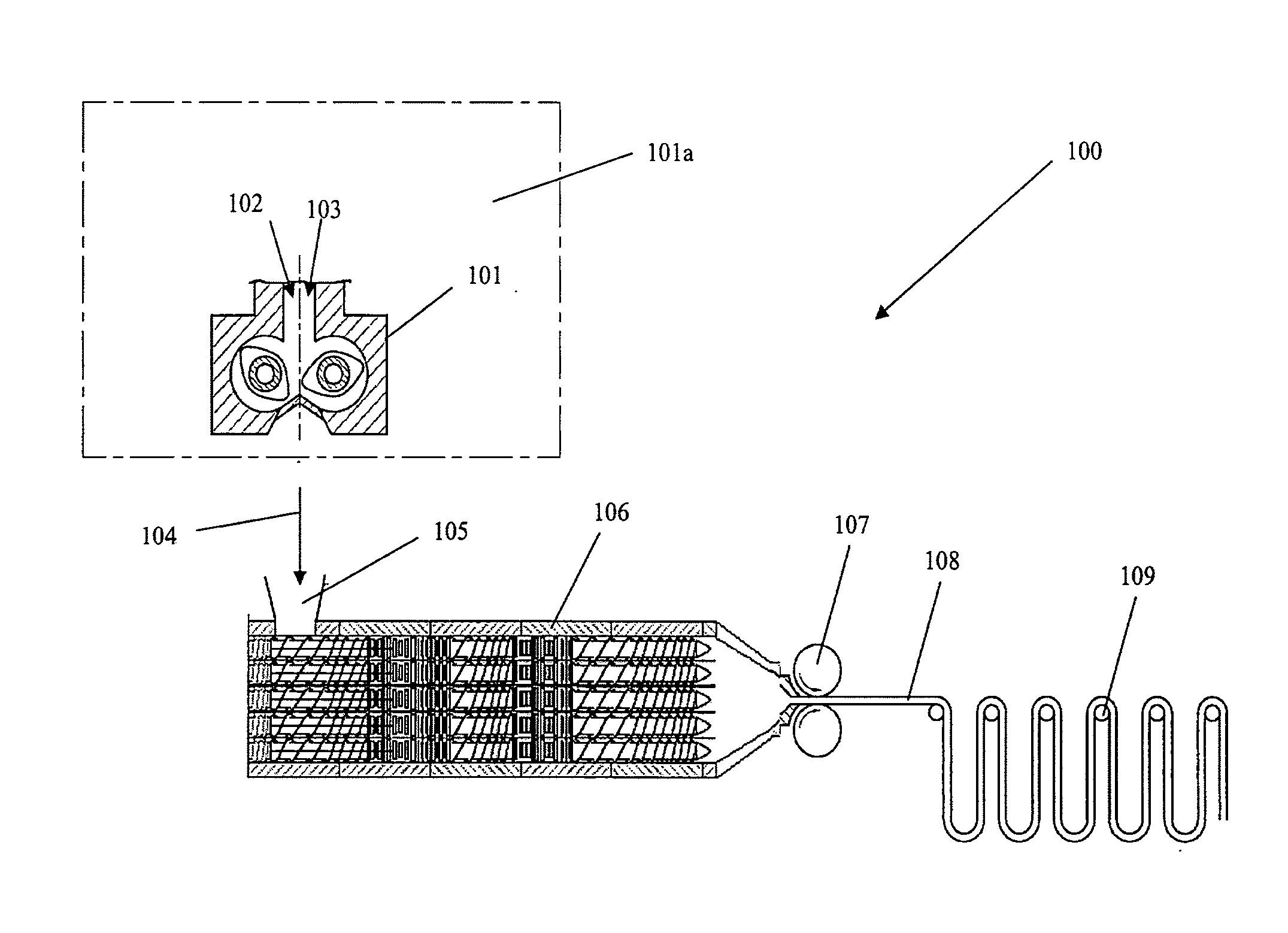

Process and apparatus for making radially arranged aluminum foil-filled plastic pellets to shield against electromagnetic interference

InactiveUS6210521B1High aspect ratioLight weightLamination ancillary operationsMagnetic/electric field screeningElectromagnetic interferenceEngineering

Owner:NAT SCI COUNCIL

Process and plant for producing tyres

A compound plant for processing elastomeric compounds for tyres with both a high quality and a high throughput includes at least one batch mixing device in combination with at least one multi-shaft continuous mixing device having a high number of shafts. For example, the multi-shaft continuous mixing device could be a ring extruder having a plurality of co-rotating screws disposed to form a ring. In operation, a first elastomeric compound is discharged from the at least one batch mixing device and processed with the at least one multi-shaft continuous mixing device to obtain a second elastomeric compound.

Owner:PIRELLI TYRE SPA

Nickel material for chemical plant

A nickel material, which comprises by mass percent, C: 0.003 to 0.20% and one or more elements selected from Ti, Nb, V and Ta: a total content less than 1.0%, the contents of these elements satisfying the relationship specified by the formula of “( 12 / 48)Ti+( 12 / 93)Nb+( 12 / 51)V+( 12 / 181)Ta—C≧0”, with the balance being Ni and impurities, does not deteriorate in the mechanical properties and corrosion resistance even when it is used at a high temperature for a long time and / or it is affected by the heat affect on the occasion of welding. Therefore, it can be suitably used as a member for use in various chemical plants including facilities for producing caustic soda, vinyl chloride and so on. Each element symbol in the above formula represents the content by mass percent of the element concerned.

Owner:NIPPON STEEL CORP

Flame-retardant glass fiber-reinforced polyamide resin composition

InactiveUS8193263B2Reduce the mixing ratioImprove suppression propertiesGroup 5/15 element organic compoundsGlass fiberHalogen

A flame-retardant glass fiber-reinforced polyamide resin composition, containing:100 parts by mass of a flame-retardant resin composition consisting of(A) 60 to 90 percent by mass of a polyamide resin, and(B) 40 to 10 percent by mass of a flame retardant containing no halogen atom,(A)+(B) being 100 percent by mass; and60 to 210 parts by mass of a flattened glass fiber (C) having a flat section of 1.5-10 in a ratio of major axis / minor axis,wherein the polyamide resin (A) contains a crystalline polyamide resin (a1) and an amorphous polyamide resin (a2),the flame retardant containing no halogen atom (B) contains a phosphinate (b1) and / or a diphosphinate (b2), anda blending ratio of the amorphous polyamide resin (a2) in the polyamide resin (A) is 0.1≦(a2) / (A)≦0.5.

Owner:UNITIKA LTD

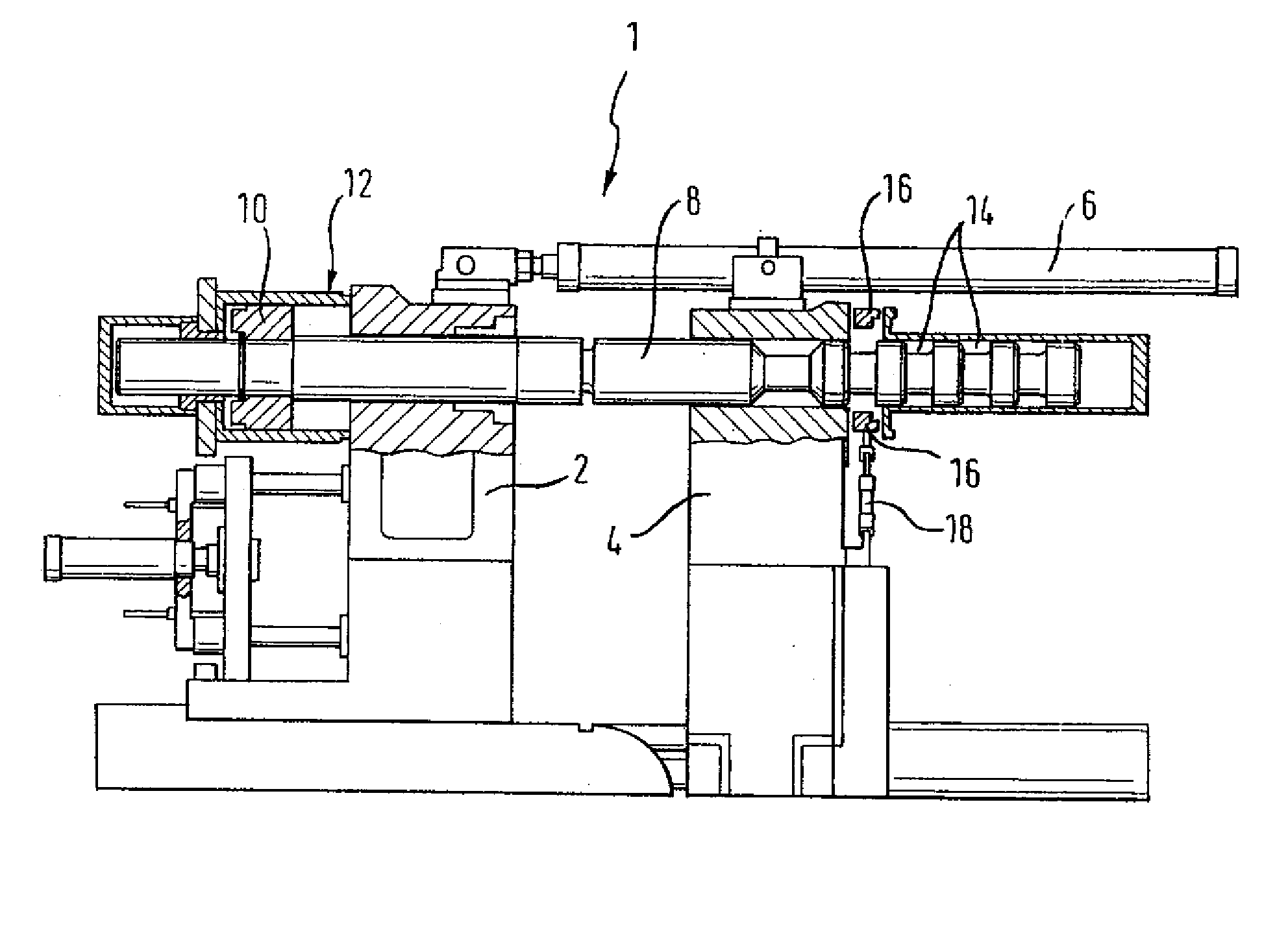

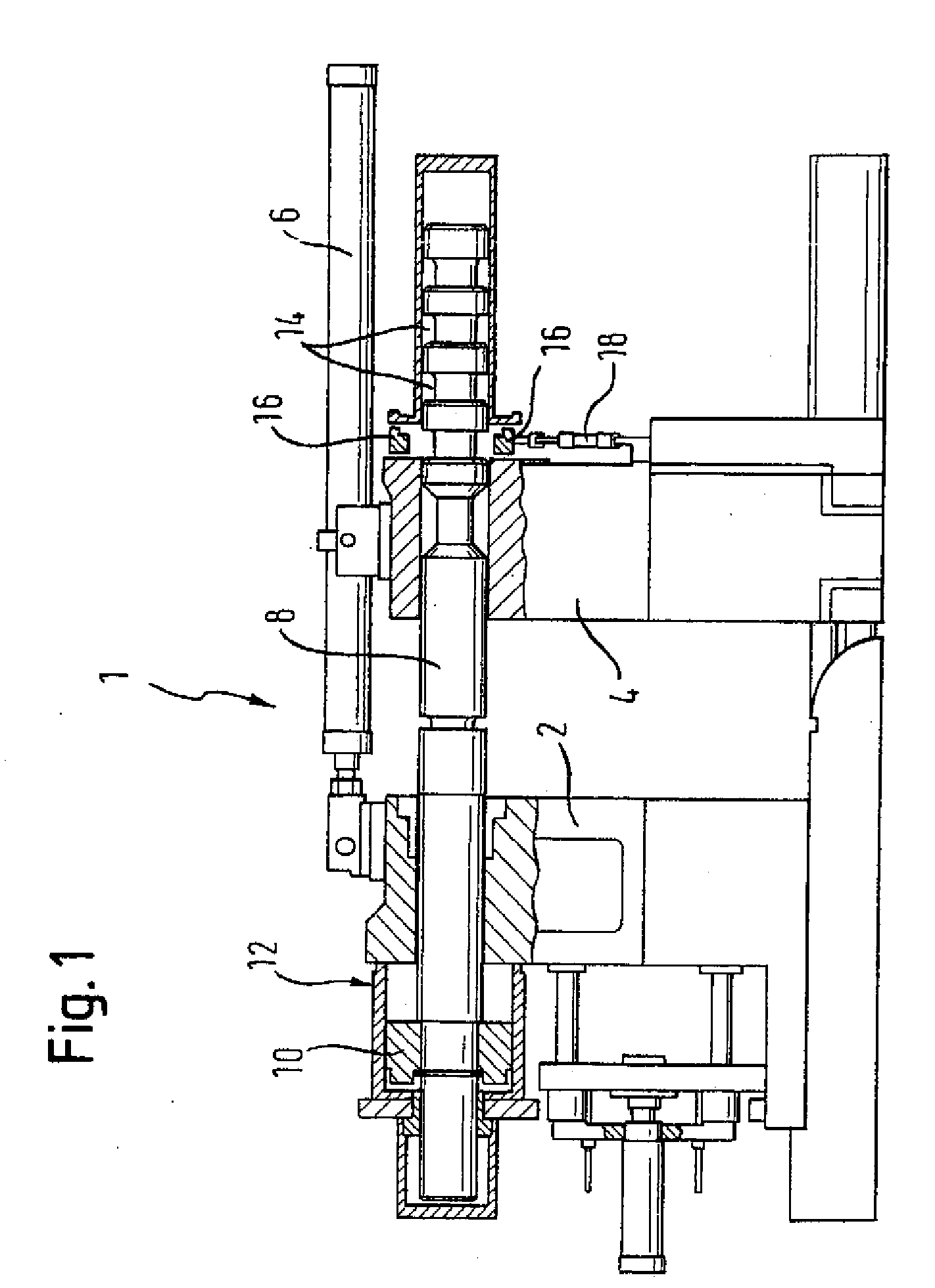

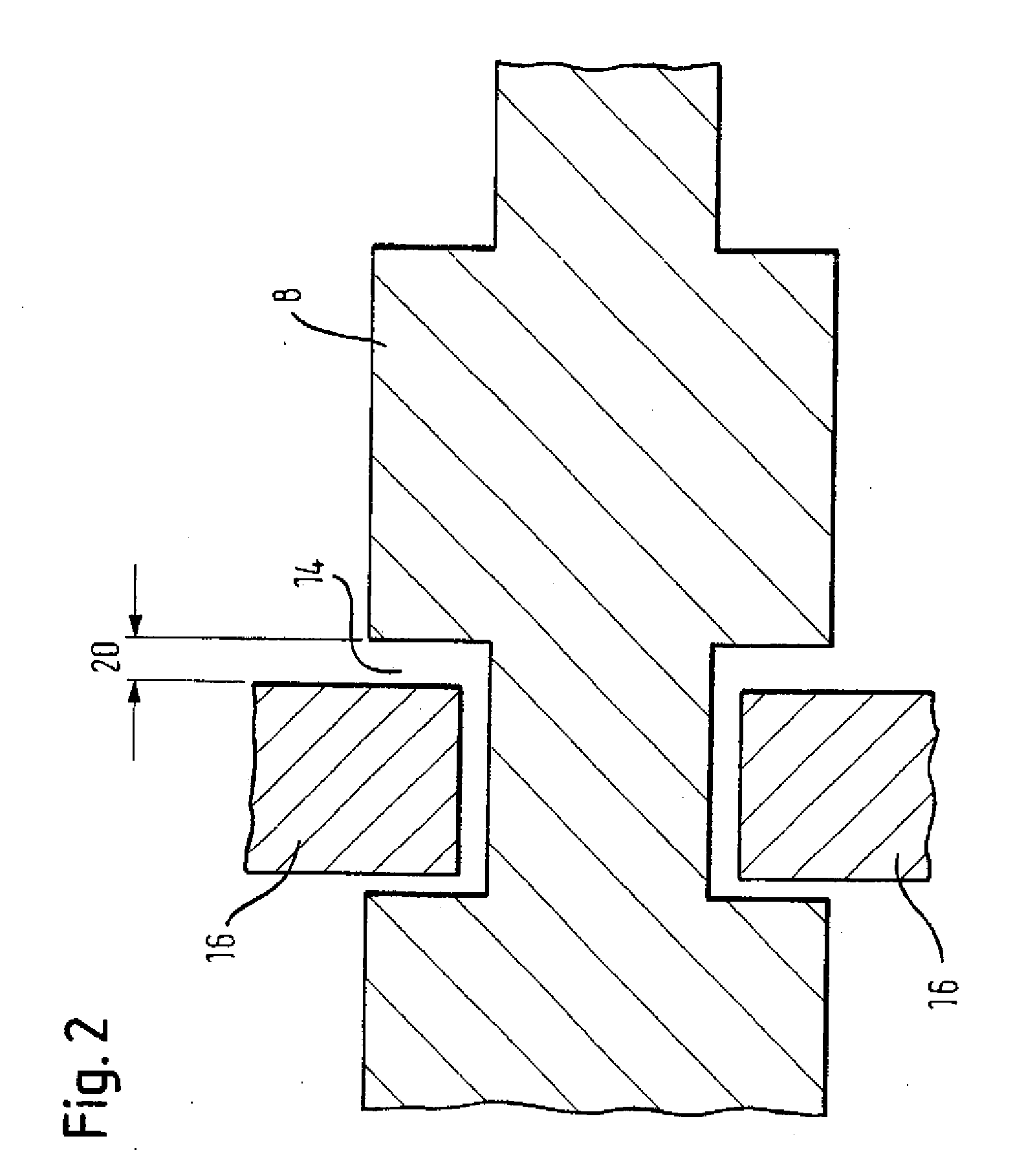

Device for manufacturing components from fiber-reinforced composites

InactiveUS20140234458A1Accurate limitDeterioration of mechanical propertyAuxillary shaping apparatusFiber-reinforced compositeActuator

A device for producing fiber-reinforced composites has a mold with an airtightly closed mold chamber for forming a composite of fiber material and matrix material. A membrane in the mold separates fiber and matrix material from a gas suction passage. A suction connector is connected to the mold and sucks gas out of the mold chamber via the gas suction passage. The matrix material flows from the resin container into the mold chamber through an inflow connector. A sensor provided on the inflow connector or the resin connector and connected to the actuator measures actual pressure existing in the inflow connector or the resin connector. An actuator is connected to the closure element and moves the closure element, when activated by a trigger signal emitted by the sensor, from an open into a closed position so that the closure element closes off the inflow connector or the resin container.

Owner:FASERVERBUND INNOVATIONS UG HAFTUNGSBESCHRANKT

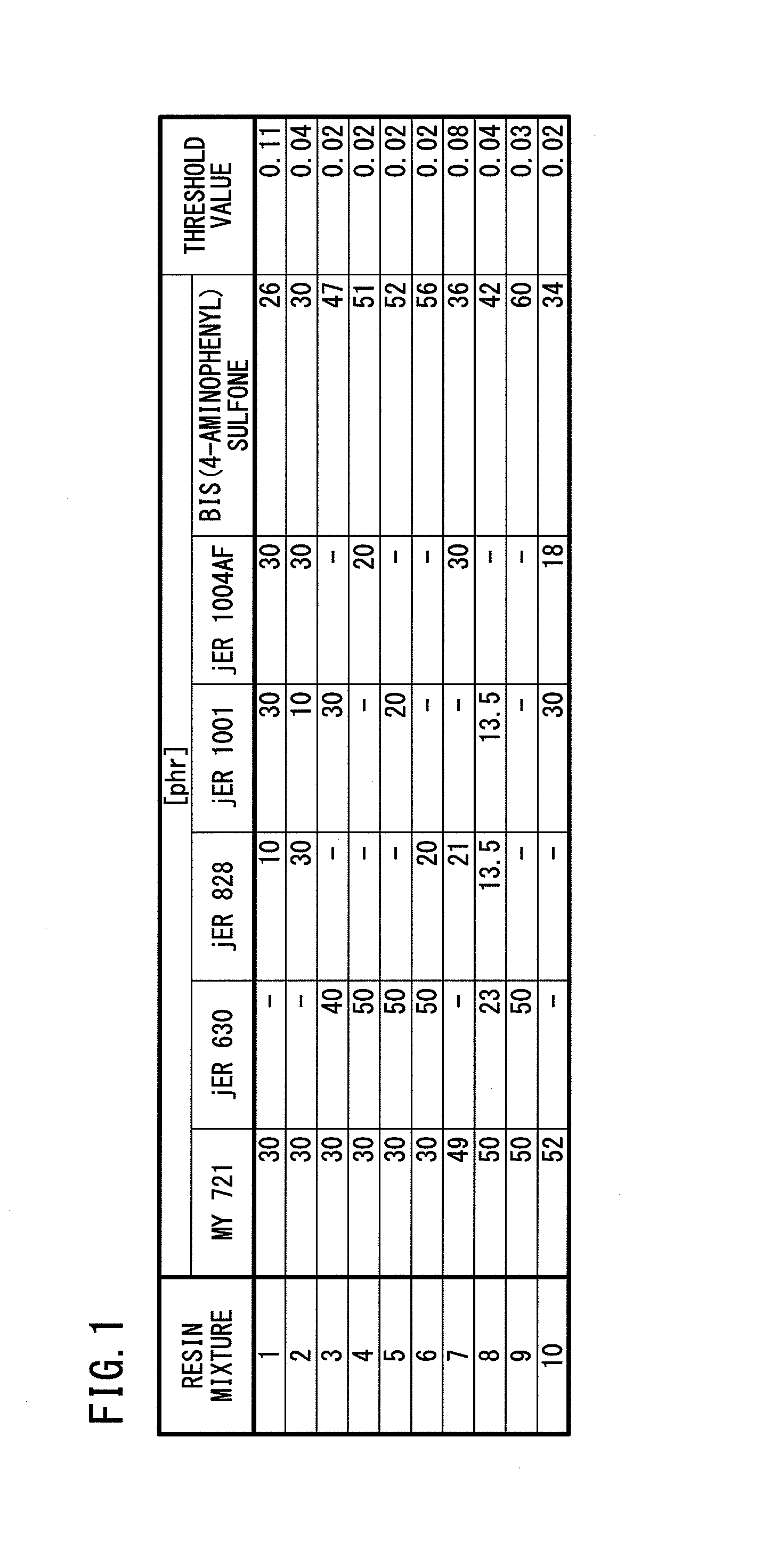

Method of evaluating dispersion degrees of mixed epoxy resins

ActiveUS20140152984A1Efficiently obtainedSufficient dispersion degreeRadiation pyrometryAbsorption/flicker/reflection spectroscopyEpoxyPhysical chemistry

A method of evaluating dispersion degrees of mixed epoxy resins includes, first, obtaining a resin mixture by mixing a plurality of aromatic epoxy resins, and taking a plurality of measurement samples from a plurality of sites of the resin mixture. The measurement samples are spectroscopically analyzed to obtain the spectra, and a plurality of common functional group peaks in the spectra are selected. The absorbances of the selected peaks are standardized to obtain absorbance ratios, based on the absorbance of a standard peak, in each of the spectra. Then, the standard deviations of the absorbance ratios of the selected peaks are calculated between the measurement samples. The maximum value of the obtained standard deviations is compared with a predetermined threshold value to evaluate the dispersion degrees of the aromatic epoxy resins.

Owner:HONDA MOTOR CO LTD

Method of compression molding thermoplastic material

InactiveUS20070187872A1Shorten cycle timeLess shear stressFood shapingCompression moldingThermoplastic materials

In a method of compression molding thermoplastic material, a compression gap is set between half-molds of a mold having fixed and movable platens for respective attachment of the half-molds. After setting the compression gap, the mold is closed and the platens are locked by moving locking elements into respective receiving elements. Injection of plasticized material then commences into a cavity formed between the half-molds when the mold is closed. The mold then opens as a result of pressure generated by the injected plasticized material until a distance between the half-molds corresponds to the compression gap. Subsequently, the mold undergoes a closing movement through application of a clamping force, thereby compressing the plasticized material.

Owner:SUMITOMO SHI DEMAG PLASTICS MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com