Gas sensor and corresponding production method

a technology of gas sensor and production method, which is applied in the direction of superimposed coating process, instruments, coatings, etc., can solve the problem of inability to specify the thickness of the layer in the porous protective coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

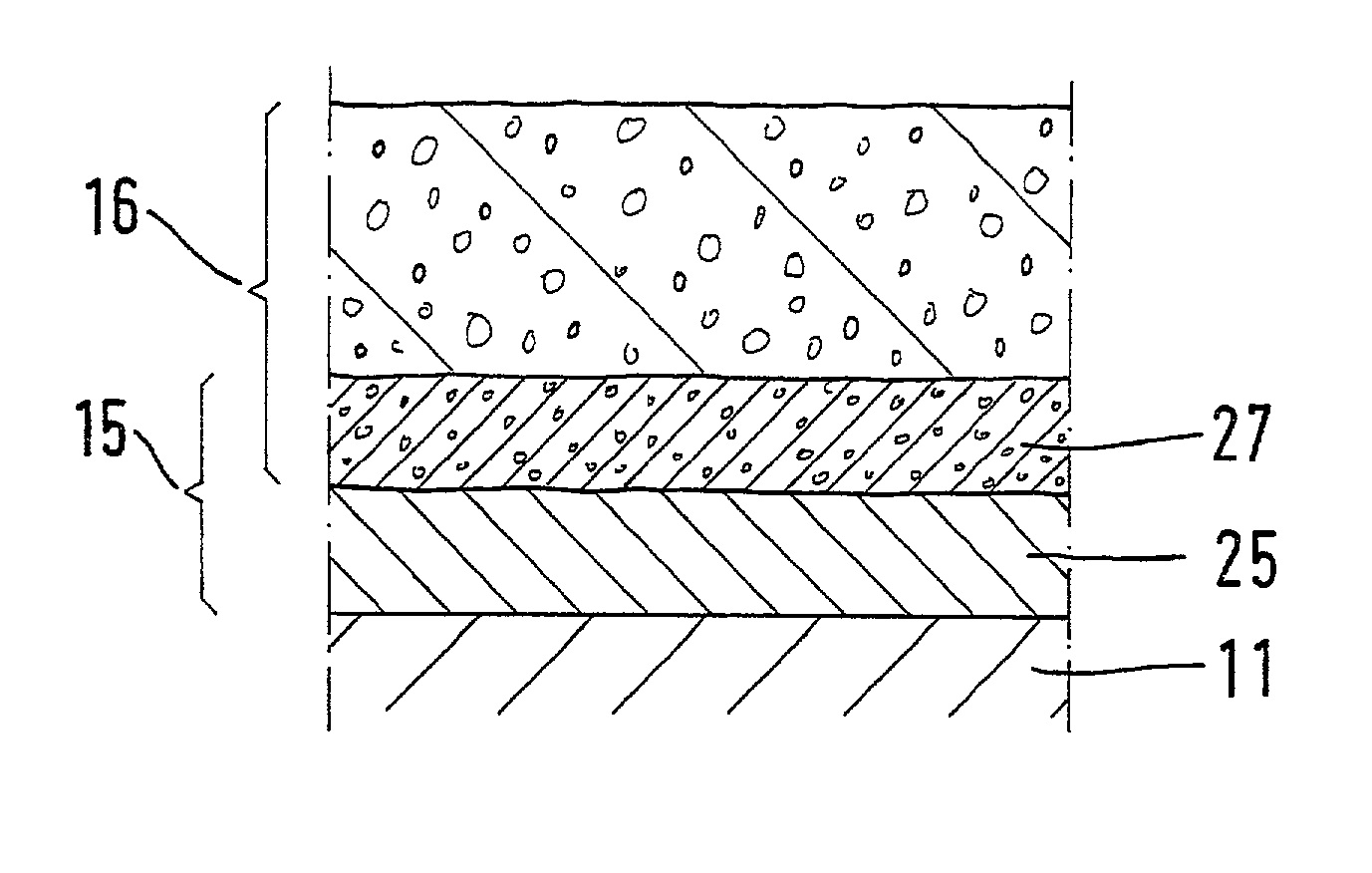

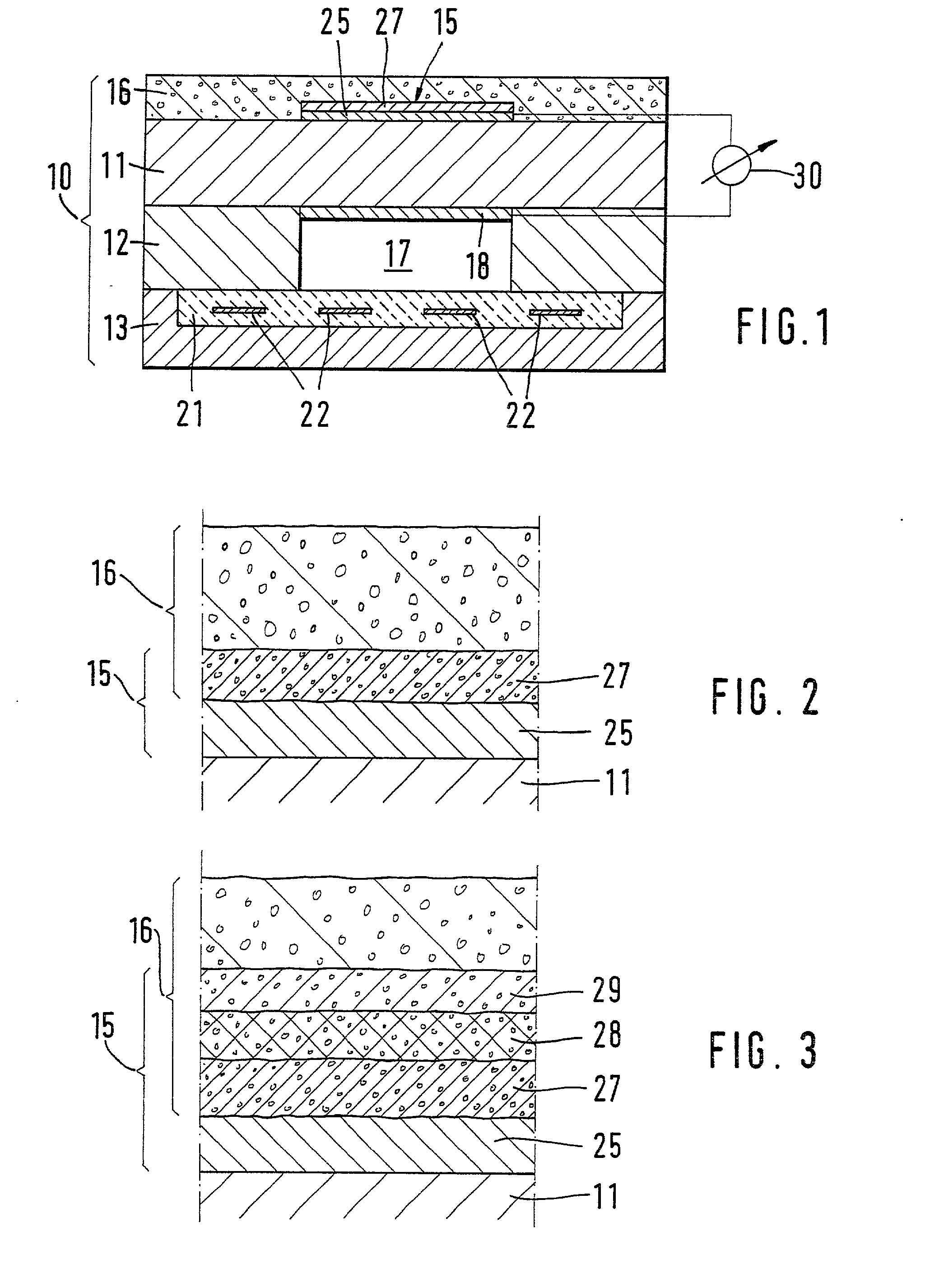

[0011] FIG. 1 shows a gas sensor having a sensor element basic body 10 whose structure corresponds to that of a Nernst-type oxygen sensor (lambda sensor). Basic body 10 includes, for example, a plurality of ceramic solid electrolyte foils 11, 12, 13, which are made of, for example, Y.sub.2O.sub.3-stabilized ZrO.sub.2. An outer measuring electrode 15, which is covered by a porous protective coating 16, is arranged on the outer large surface of first foil 11. Protective coating 16 is made of, for example, porous ZrO.sub.2 or Al.sub.2O.sub.3. A reference channel 17 is provided in second foil 12 and is connected to a reference atmosphere, e.g., air. A reference electrode 18, which is arranged on first foil 11 and faces measuring electrode 15, is arranged in reference channel 17. A heating device 22 is integrated into basic body 10, and on third foil 13 electrical insulating layers 21 are provided, in which heating device 22 is embedded. Heating device 22 is an electrical-resistor-type h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com