Polishing body, polishing apparatus, polishing apparatus adjustment method, polished film thickness or polishing endpoint measurement method, and semiconductor device manufacturing method

a polishing body and polishing technology, applied in the direction of grinding machine components, manufacturing tools, lapping machines, etc., can solve the problems of wiring interruptions, drop in electrical capacitance, individual semiconductor manufacturing processes that are more numerous and complicated, etc., to achieve stable detection, reduce the frequency of polishing body replacement, and increase the effect of throughpu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1-1

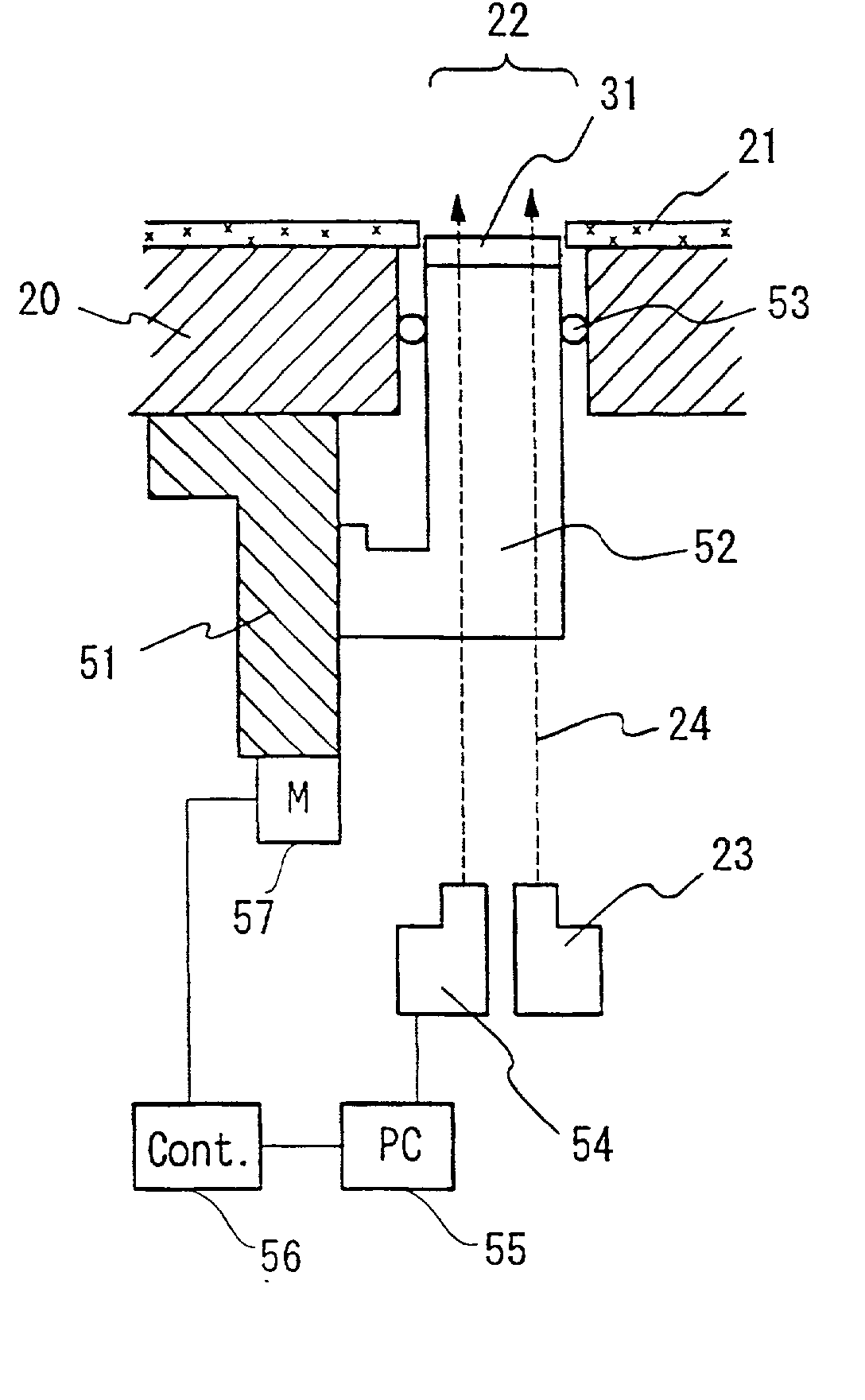

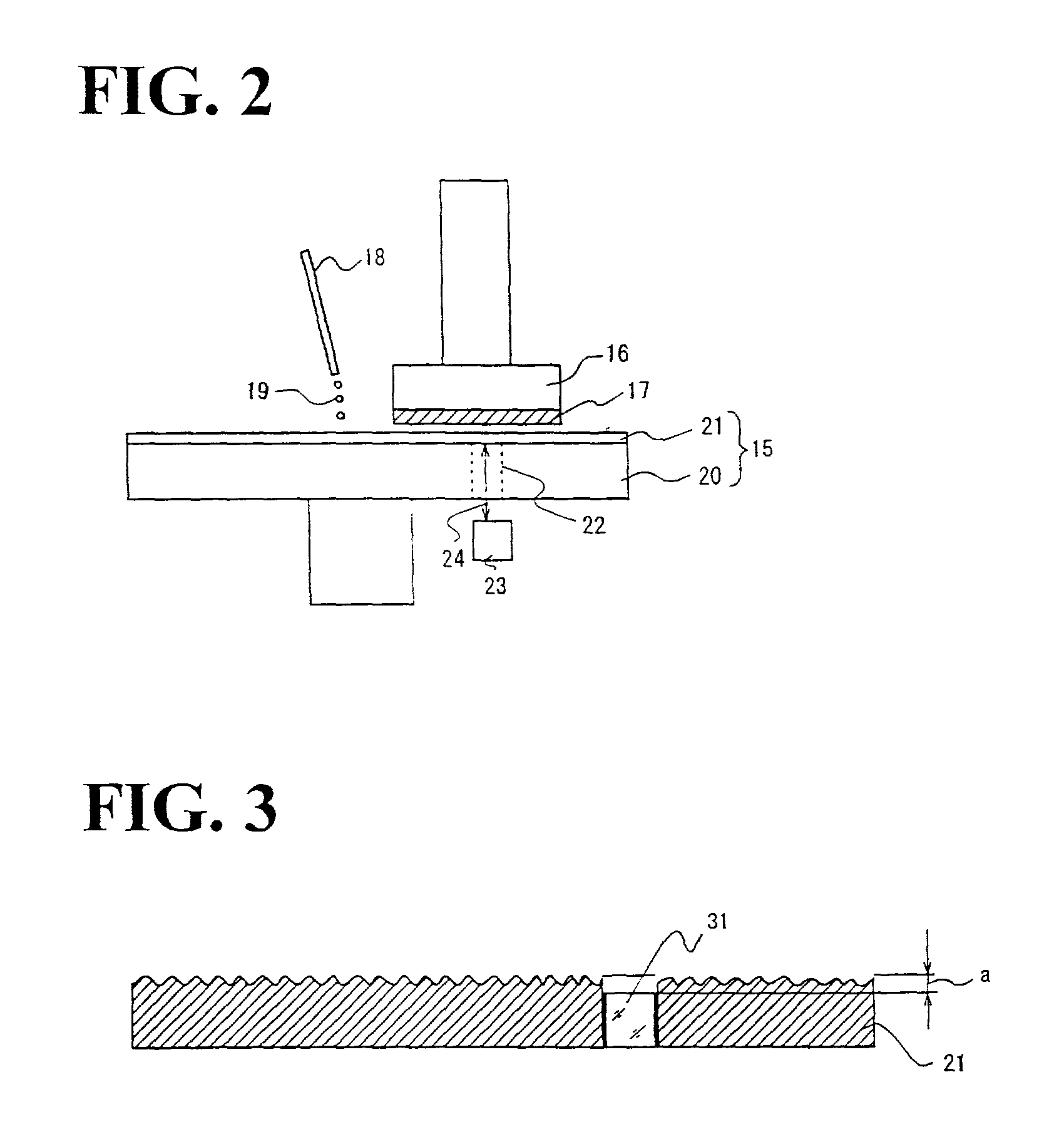

[0104] FIG. 3 is a diagram which is used to illustrate a first example of a polishing pad (polishing body) of the present invention. In the following figures, constituent elements that are the same as constituent elements shown in preceding figures are labeled with the same symbols, and a description of such constituent elements may be omitted. In FIG. 3, 21 indicates a polishing pad, and 31 indicates a transparent window plate.

[0105] The transparent window plate 31 is fit into a hole that is bored in the polishing pad 21. Here, a gap .alpha. is left between the upper surface of the transparent window plate 31 and the outermost surface that constitutes the working surface of the polishing pad 21. During polishing, a polishing head 16 which holds the wafer 17 as shown in FIG. 2 is caused to apply a load to the polishing pad by means of a load-applying mechanism (not shown in the figures), so that the polishing pad 21 and transparent window plate 31 are compressed. In this case, it is...

example 1-2

[0117] FIG. 4 is a diagram which is used to illustrate a second example of a polishing pad (polishing body) of the present invention. FIG. 4(a) is a plan view, FIG. 4(b) is a sectional view of the portion indicated by line A-O in FIG. 4(a), FIG. 4(c) is a sectional view of the portion indicated by line B-O in FIG. 4(a), and FIG. 4(d) is a sectional view of the portion indicated by line C-O in FIG. 4(a). In FIG. 4, 31a through 31c indicate window plates, and 32a through 32c indicate opening parts.

[0118] In the present example, the polishing body 21 has three opening parts 32a, 32b and 32c. Furthermore, a window plate 31a is disposed in the opening part 32a, a window plate 31b is disposed in the opening part 32b, and a window part 31c is disposed in the opening part 32c. In FIGS. 4(b), (c) and (d), the surface on the upper side of the polishing body 21 is the top surface of the polishing body 21, and the surfaces on the upper sides of the window plates 31a through 31c are the surfaces...

example 1-3

[0131] FIG. 5 is a diagram which is used to illustrate a third example of a polishing pad (polishing body) of the present invention. FIG. 5(a) is a plan view, and FIG. 5(b) is a sectional view of the portion indicated by line D-E in FIG. 5(a). In FIG. 5, 32 indicates an opening part, and 33a through 33c indicate respective parts of a window plate 31.

[0132] The polishing body 21 of the present example has a single opening part 32. The window plate 31 disposed in this opening part 32 has a step-form cross section, so that the amount of recess of the surface of the window plate 31 on the side of the object of polishing with respect to the surface of the polishing body 21 differs in the three parts 33a, 33b and 33c. The amount of recess of the surface of the window plate 31 on the side of the object of polishing with respect to the surface of the polishing body 21 is smallest in the part 33a, and largest in the part 33c. In the part 33b, this amount of recess is more or less intermediat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thicknesses t1 | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com