Memory device and method of fabrication thereof

a memory device and memory technology, applied in the direction of galvano-magnetic devices, semiconductor devices, magnetic-field-controlled resistors, etc., can solve the problem of increasing power consumption in a write operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

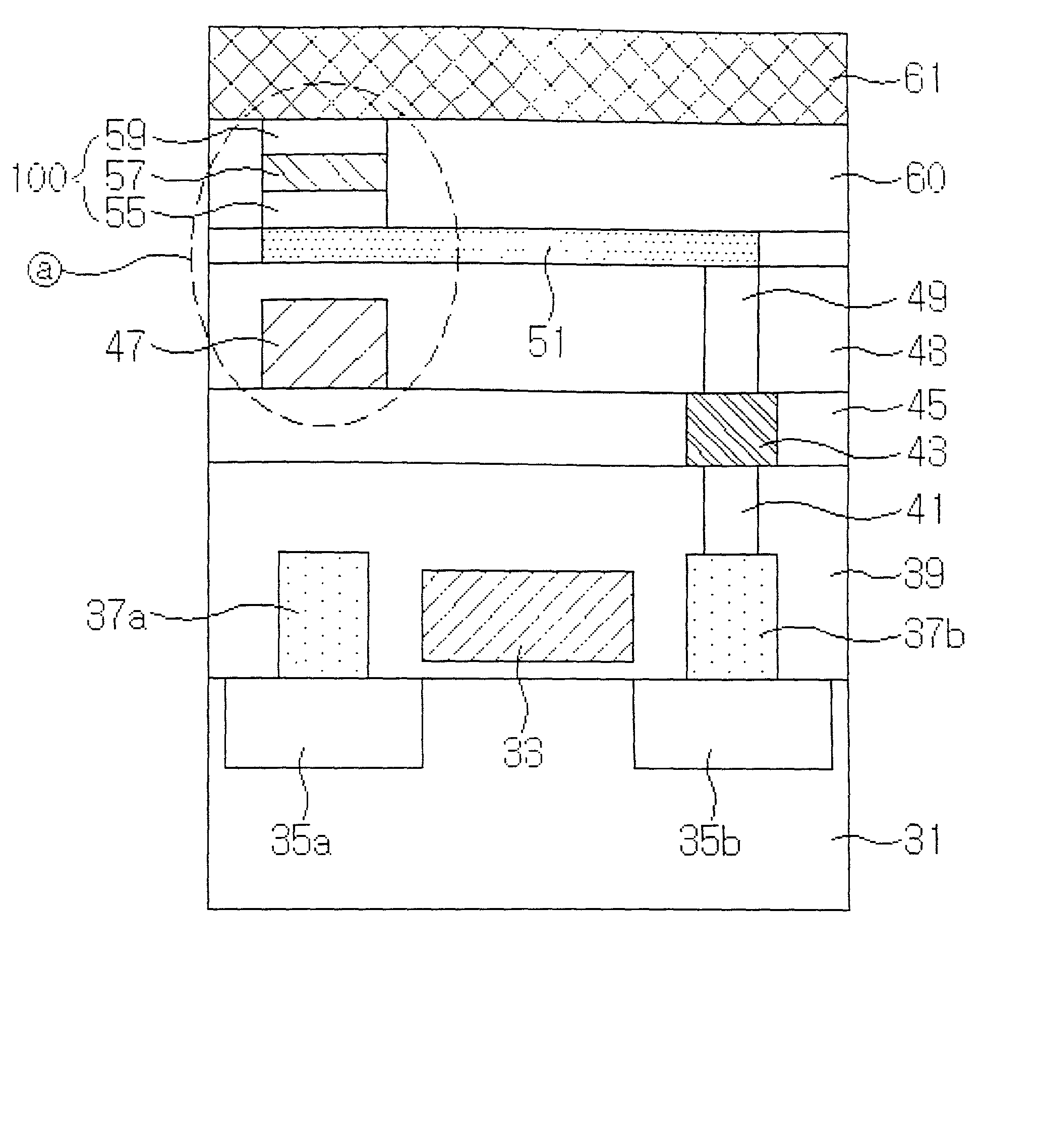

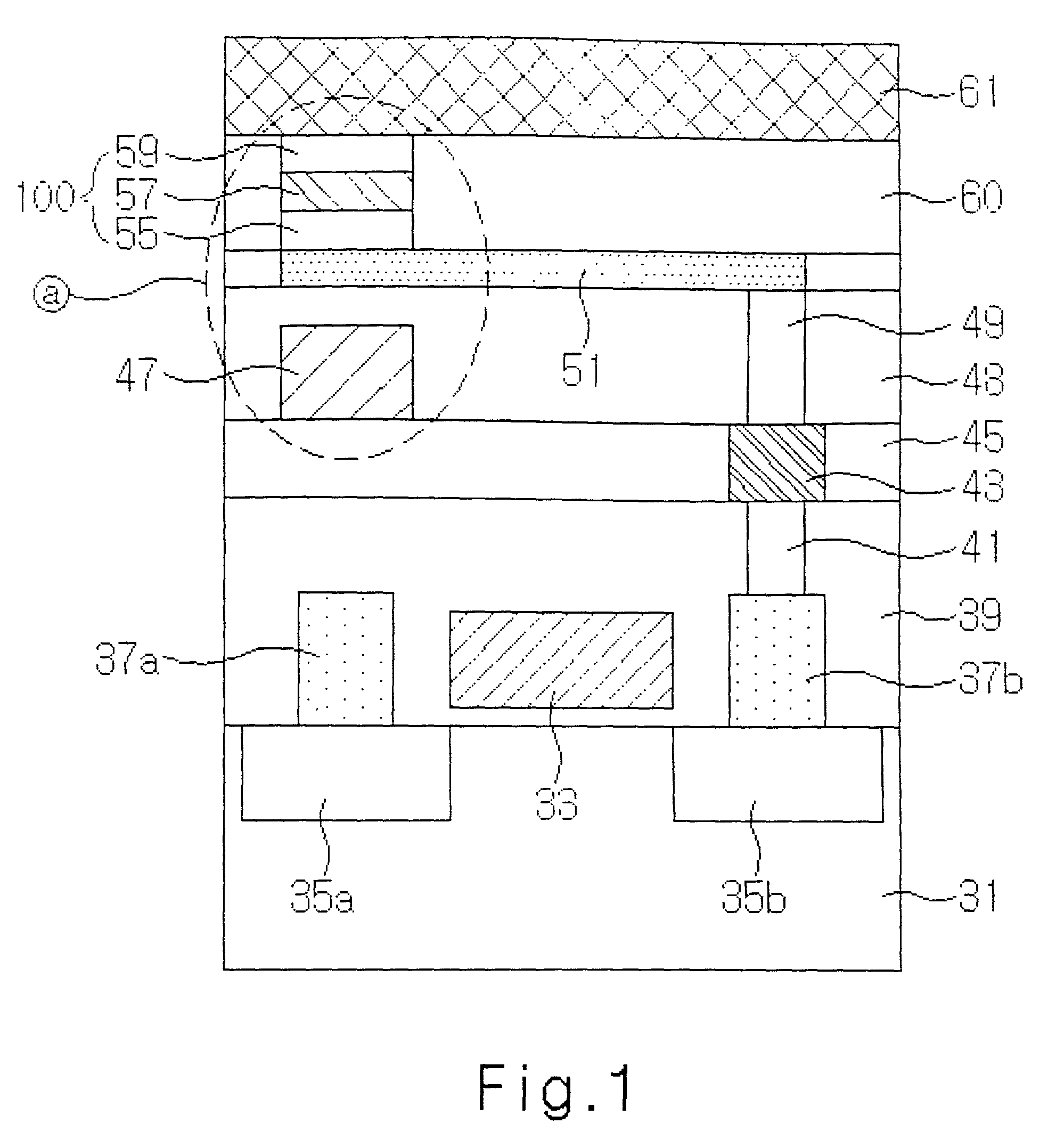

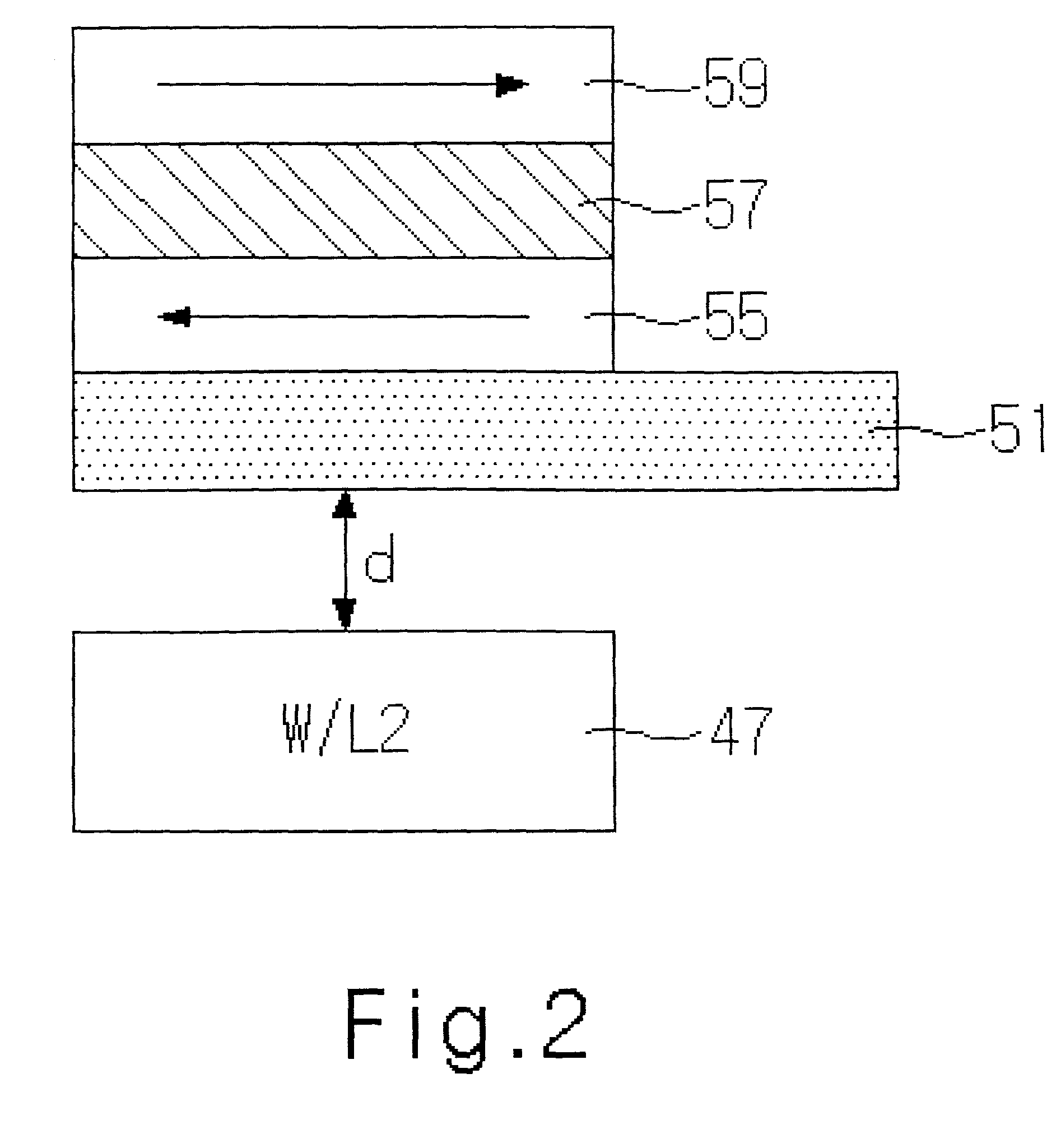

[0030] A memory device and a fabrication method therefor in accordance with a preferred embodiment will now be described in detail with reference to the accompanying drawings.

[0031] FIG. 3 is a cross-sectional diagram illustrating a method for fabricating the memory device in accordance with a preferred embodiment.

[0032] Referring to FIG. 3, a second word line 101 is formed on the second interlayer insulating film 45 of FIG. 1 by patterning. Here, the second word line 101 is formed by using an element selected from the group consisting of tungsten, aluminum, copper and combinations thereof for easy surface oxidation.

[0033] Thereafter, a third interlayer insulating film 102 is formed and planarized to expose the second word line 101. Here, the third interlayer insulating film 102 is formed by using an insulating film having a low dielectric constant. The third interlayer insulating film 102 is formed to cover the second word line 101, and then evenly etched by a chemical mechanical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com