Liquid processing method making use of pipette device and apparatus for same

a pipette and liquid processing technology, which is applied in the field of liquid processing methods using pipette devices and apparatus for same, can solve the problems of difficult to smoothly execute analysis, work for isolating dna from tissue or cell, and complex work, and achieves high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

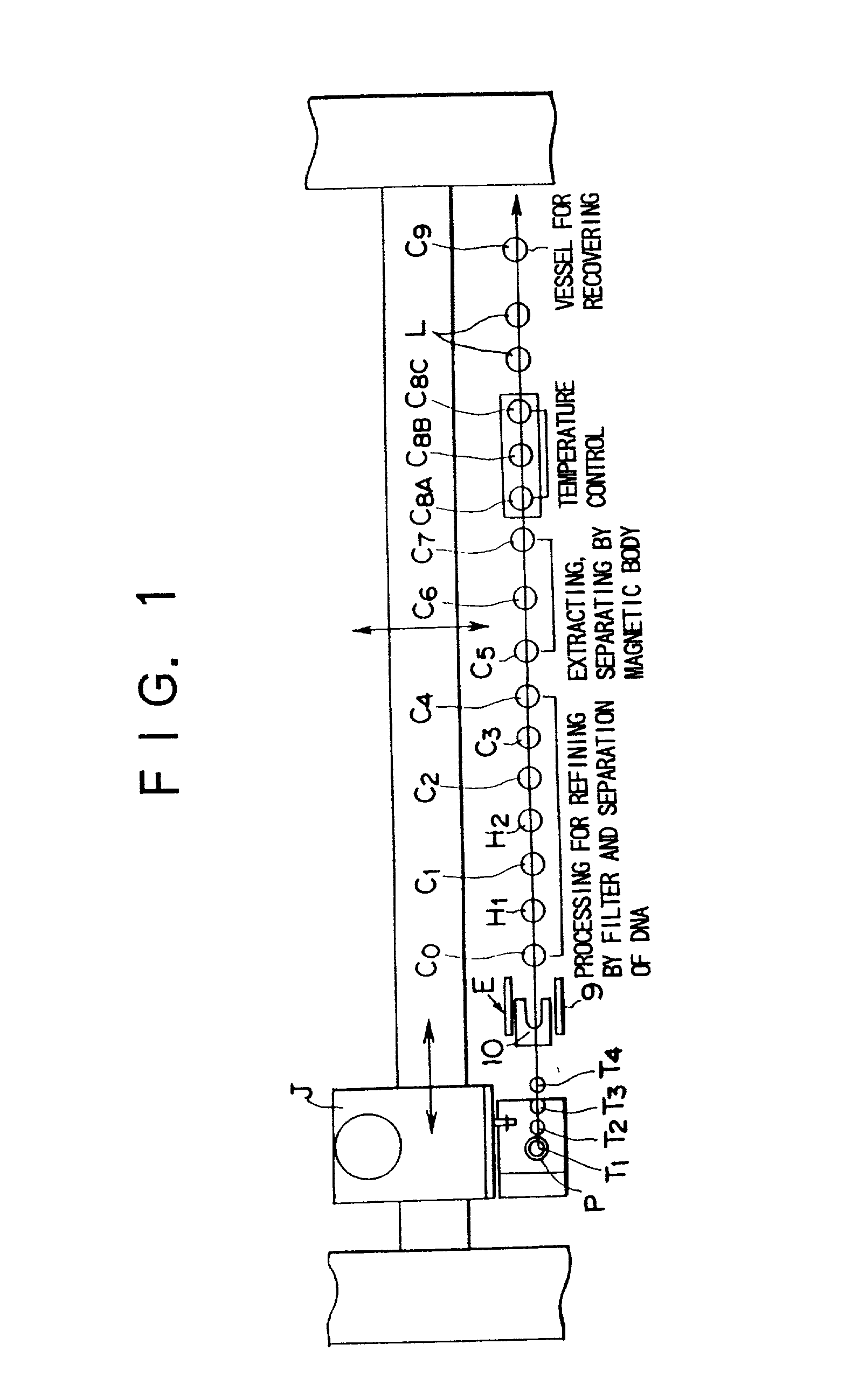

[0161] The above description of the present invention assumes a case where the filter holders H.sub.1, H.sub.2, sample cell C.sub.0, and cells C.sub.1 to cell C.sub.9 are arrayed in the order of reaction steps, but the present invention is not limited to this configuration, and as shown in FIG. 20, excluding the sample cell C.sub.0 and DNA recovery cell C.sub.9 each of a group of cells C.sub.1 to C.sub.4 used for refining with a filter, a group of filter holders H.sub.1, H.sub.2, a group of cells C to C.sub.7 processed with the magnetic particles G, and a group of thermostatic cells C.sub.8A to C.sub.8C may be set in a cassette with the pipette nozzle P driven and controlled according to the processing sequence described above. It is needless to say that the covering body L may be provided in parallel to a cassette of the thermostatic cells C.sub.8A to C.sub.8C.

second embodiment

[0162] FIG. 21 shows the present invention, and this embodiment shows a case where a plurality of reaction lines, for instance, 4 arrays of reaction lines each having the same configuration as that of the single reaction line are provided and the lines are separated from each other with a partition wall X. It is needless to sat that, in this case, a required number of pipette nozzles are provided in series for each reaction line so that a plurality of samples can simultaneously be processed.

[0163] Also it should be noted that the reagent vessels Ra, Rb, Rc, Rd, Re, Rf arrayed along each of the reaction lines above and chips T.sub.5A, T.sub.5B, T.sub.5C, T.sub.5E, T.sub.5F each for pipetting each reagent are provided in parallel along the trajectories of the pipette nozzles P.sub.1, P.sub.2, P.sub.3, P.sub.4 moving along each of the reaction lines.

[0164] The partition wall X comprises a rectangular plate body having a size in a range including a tip section of each of the pipette noz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com