Production apparatus of monodisperse particle and production process of monodisperse particle and monodisperse particle produced by the process

a technology of monodisperse particle and production process, which is applied in the direction of metal-working apparatus, granulation using vibration, transportation and packaging, etc., can solve the problems of large particle production, difficult to control particle size, and insufficient to determine the suitability of monodisperse particle for various applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

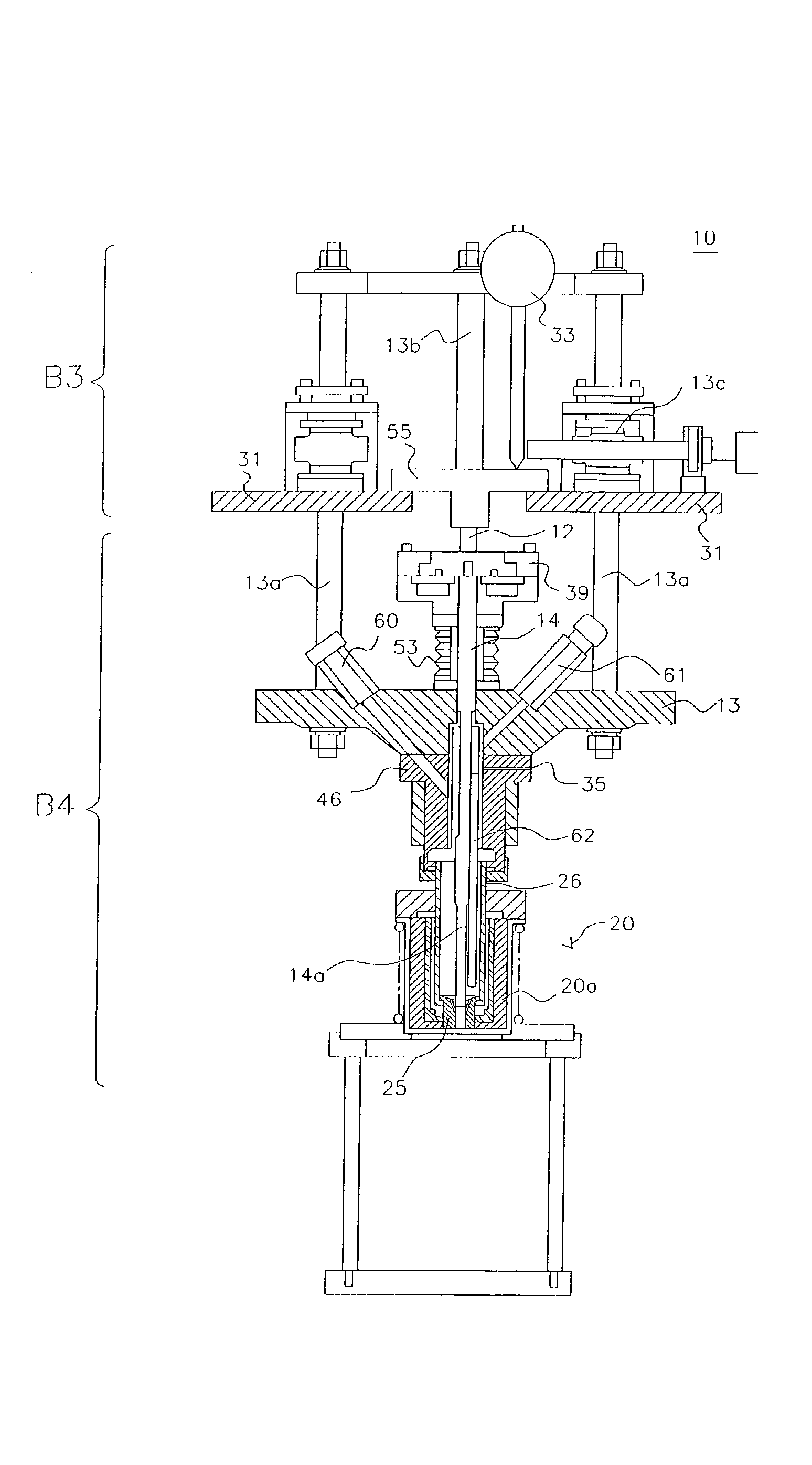

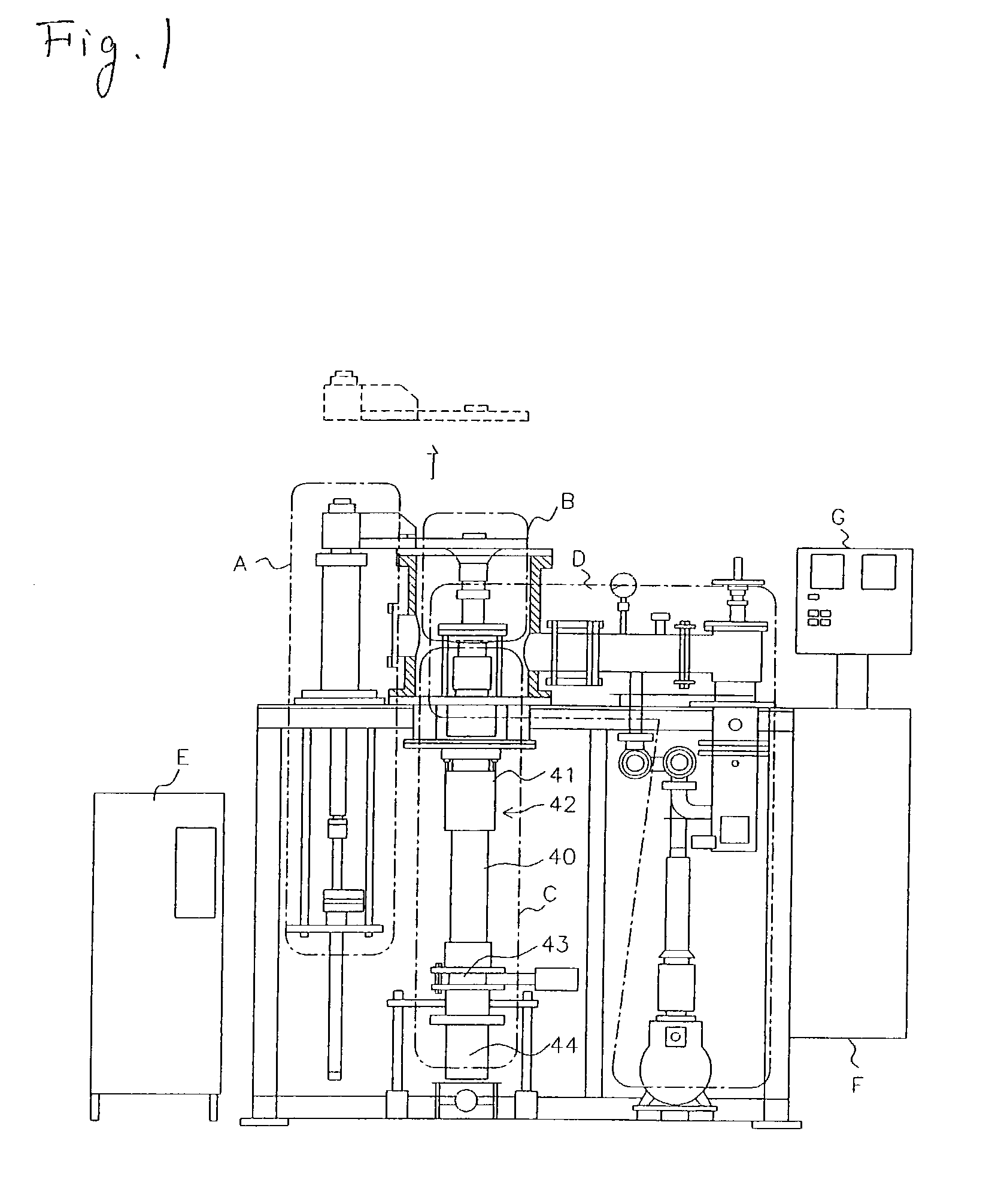

[0188] Thermoelectric semiconductor was produced using the production apparatus of monodisperse particle shown in FIG. 1.

[0189] A. Apparatus Arrangement

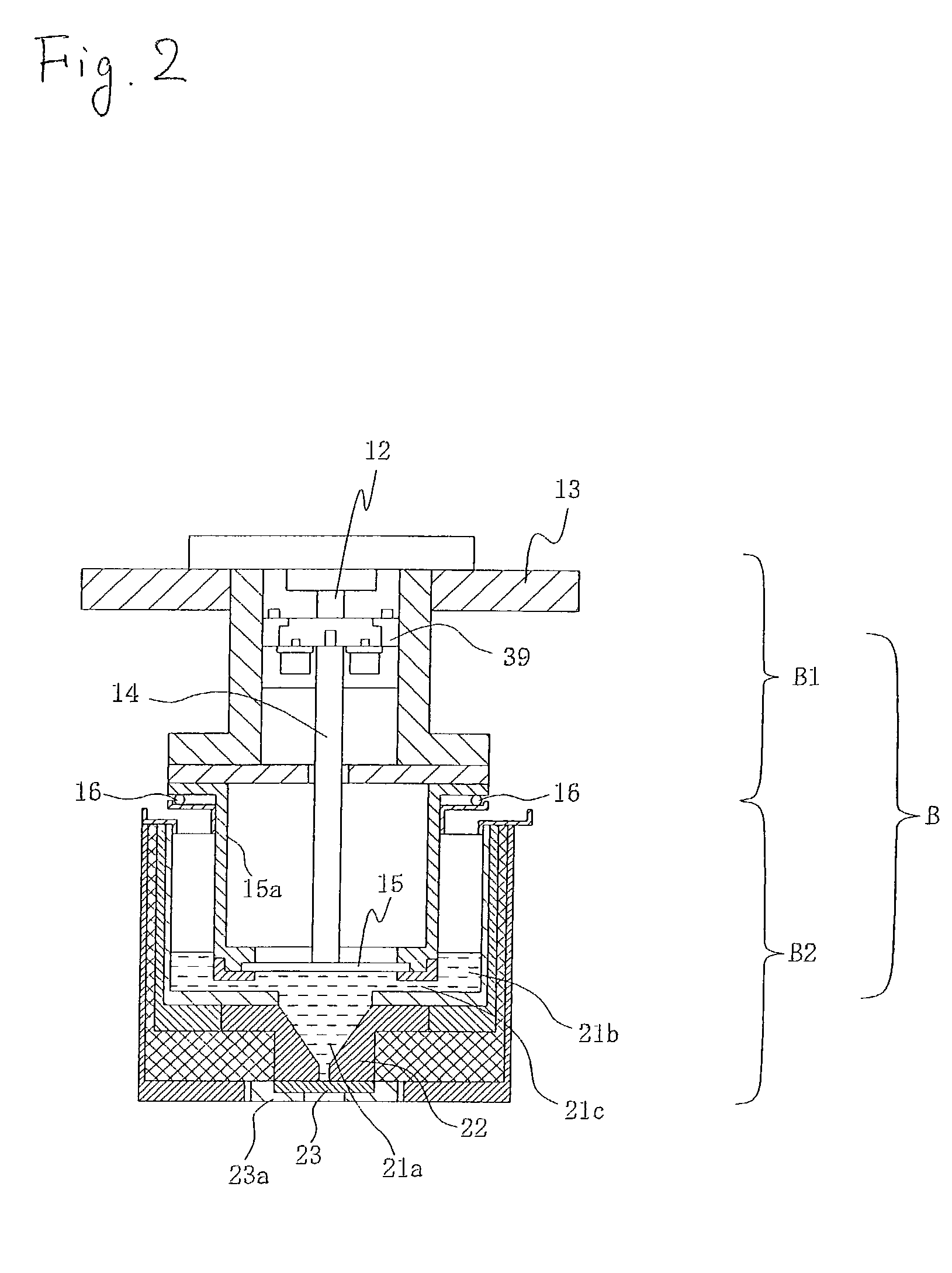

[0190] In the production apparatus of monodisperse particle shown in FIG. 1, for piezoelectric actuator 12, laminar type piezoelectric element (NLA-5.times.5.times.18 made by Tokin Co.) was used. The capability is that the capacity is 1600 nF(.+-.20%), insulating resistance, 2.times.108.OMEGA. (.+-.50%), maximum displacement, 15.2 .mu.m / 100V(.+-.10%), maximum generating force, 85 kgf / 100V. This has slight hysteresis, but generally displace linearly. For diaphram 15, circular plate of stainless with diameter of 3 mm and thickness of 0.2 mm.

[0191] The above maximum displacement (15.2 .mu.m / 100V) is a value when the margin of this piezoelectric actuator is not constrained. However, in here, the piezoelectric actuator is fixed to the actuator press with adhesive, and further this actuator press is fixed to the inside of the holder block ...

example 2

[0203] The production process according to the invention was carried out using Pb-63Sn, and the others were same as the example 1. In this case, the liquid level height in the scrucible 26 was 2.5 cm, the liquid back pressure, that is, the difference in pressure between inside and outside of the scrucible 26 was 0.03 kg / cm.sup.2, and then the monodisperse particle was produced. As a result, the monodisperse particles which were excellent in sphericity were obtained as the example 1 described above.

example 3

[0204] A. Apparatus Arrangement

[0205] In the production apparatus of monodisperse particle, for piezoelectric actuator 12, laminar type piezoelectric element (NLA-5.times.5.times.18 made by Tokin Co.) was used. The capability is that the capacity is 1600 nF(.+-.20%), insulating resistance, 2.times.108.OMEGA. (.+-.50%), maximum displacement, 15.2 .mu.m / 100V(.+-.10%), maximum generating force, 85 kqf / 100V. This has slight hysteresis, but generally displaces linearly. For diaphram 15, circular plate of stainless with diameter of 3 mm and thickness of 0.2 mm was used.

[0206] The above maximum displacement (15.2 .mu.m / 100V) is a value when the margin of this piezoelectric actuator is not constrained. However, in here, the piezoelectric actuator is fixed to the actuator press with adhesive, and further this actuator press is fixed to the inside of the holder block 39. Thus, when the piezoelectric actuator is fixed to the apparatus in this way, the relation between applied voltage and displ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com