Method for production of ductile iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

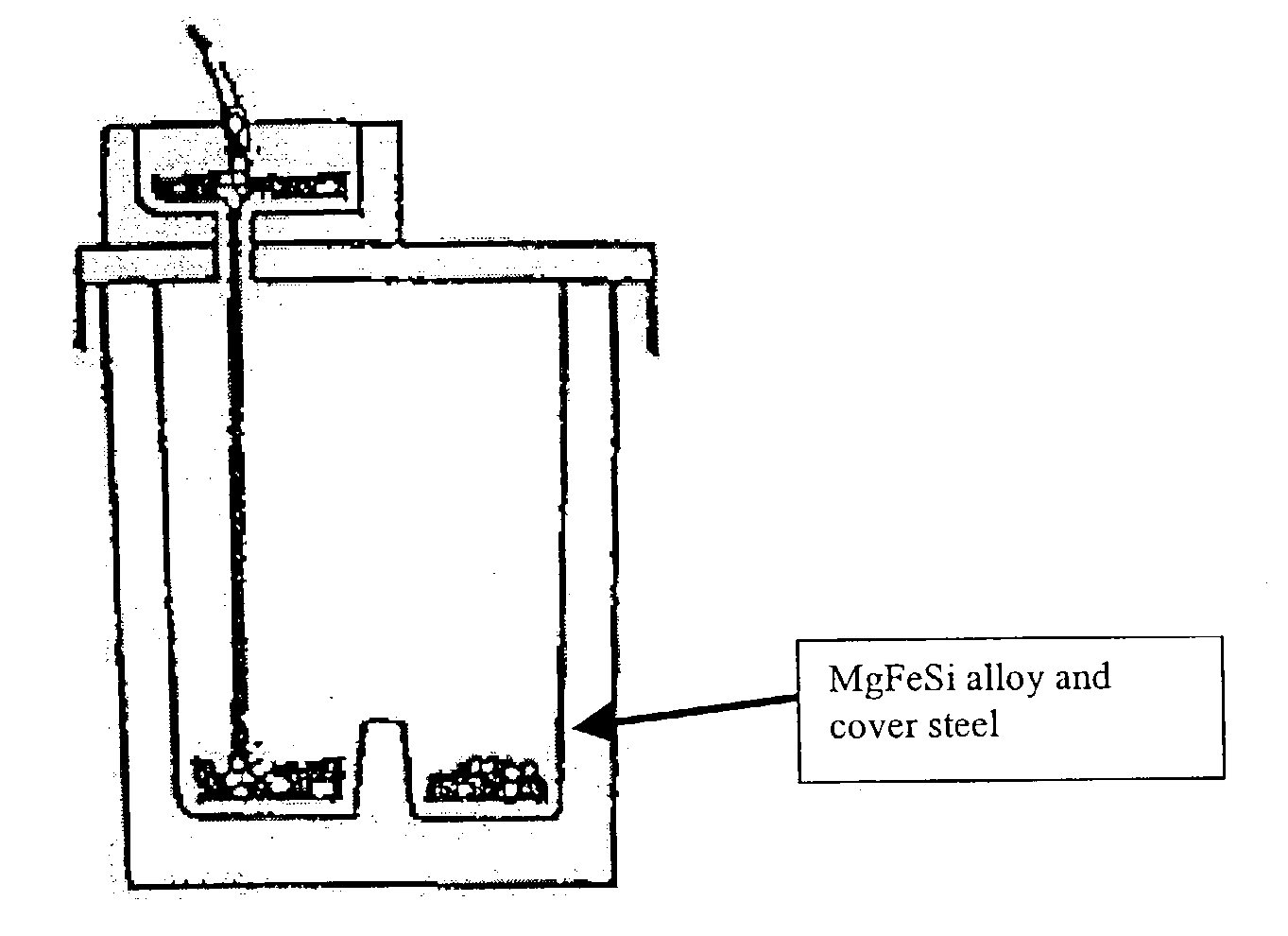

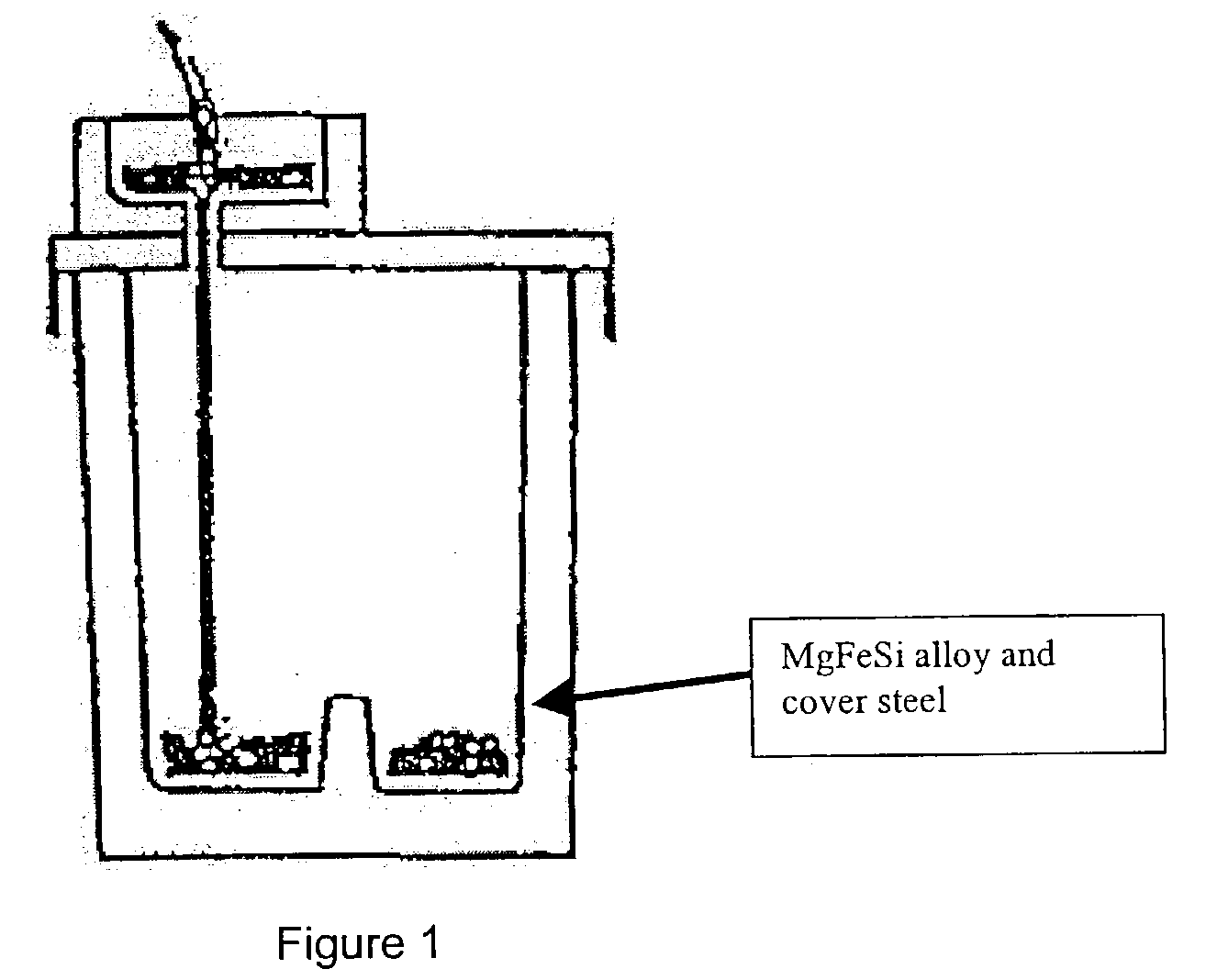

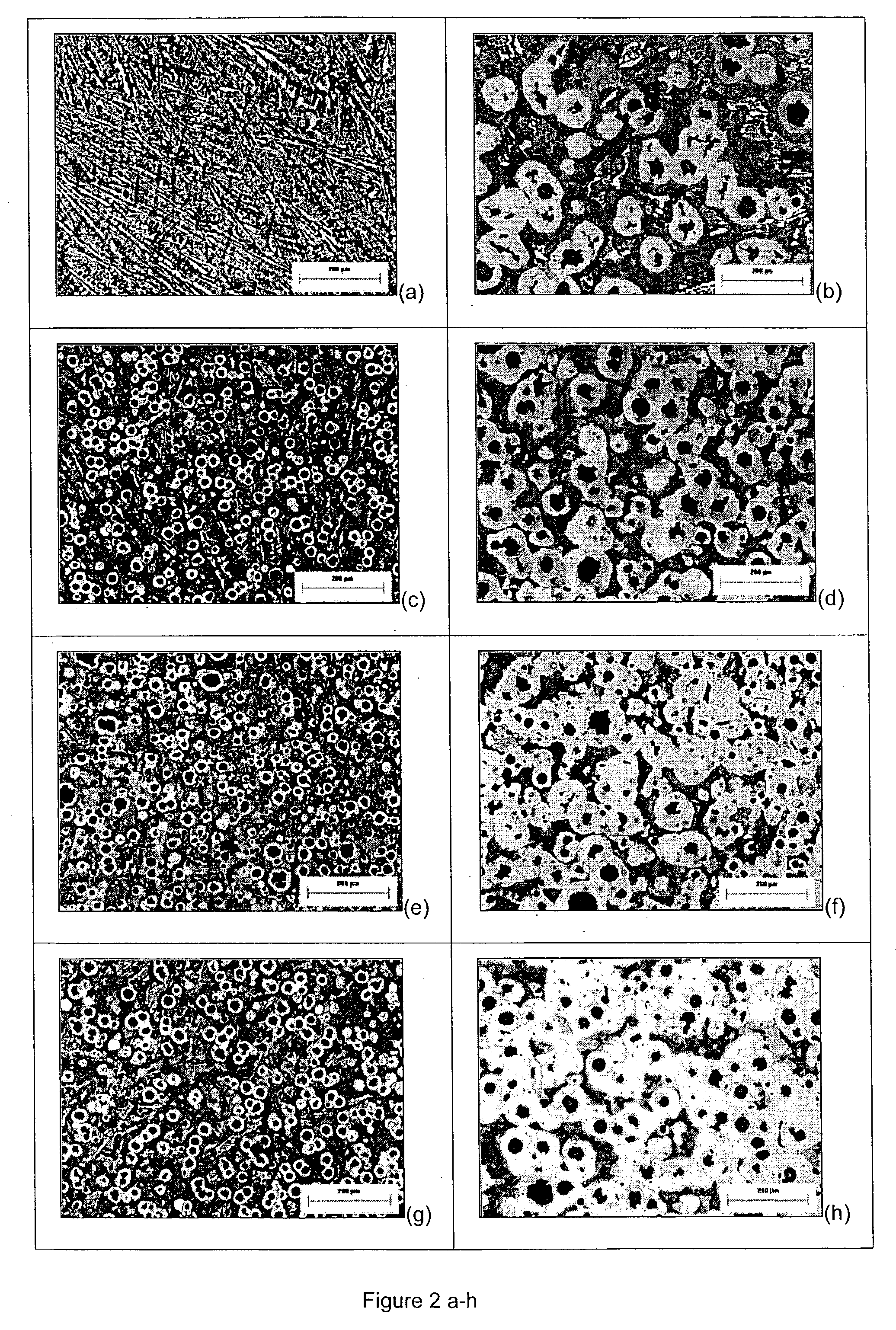

[0022] Ductile irons were produced in an induction furnace using a charge based on 50% by weight of steel, 20% by weight of iron returns and 30% pig iron. The target analysis for the castings was 3.7% by weight of C, 2.4% by weight of Si, 0.4% by weight of Mn, 0.010% by weight of S and 0.040% by weight of Mg. Prior to tapping into a nodularizing treatment ladle, 1.5% by weight of magnesium ferrosilicon alloy (MgFeSi) based on the weight of the cast iron was placed into the ladle and covered by 0.5 kg steel punchings, i.e. nodularizing according to the sandwich treatment method. FIG. 1 shows a schematic representation of the treatment ladle used. Two minutes after the iron was tapped into the ladle, the iron was transferred into pouring ladles. Thus no inoculation was carried out after the nodularizating treatment. Coin shaped samples for chemical composition were extracted from the melt, and the ductile iron heats were then cast into sand moulds to produce a 20 mm thick plate and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com