Filterable composite adsorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0110] Silica Gel / Expanded Perlite Filterable Composite Adsorbent

[0111] A mixture containing 60.6% (w / w) expanded perlite as a functional filtration component (Harborlite.RTM. 2000S, Harborlite Corporation, Lompoc, Calif.), 36.4% (w / w) silica gel as an adsorbent component (Britesorb.RTM. 100, PQ Corporation, Valley Forge, Pa., first dried at 110.degree. C. for 2 hours, with the microparticulates then dispersed with gentle grinding), and 3% (w / w) milled soda ash (Na.sub.2CO.sub.3) as a chemical sintering aid, were placed in a sealed plastic bag and shaken for approximately 5 minutes to thoroughly blend the ingredients. The mixture was then placed in a muffle furnace at 800.degree. C. in air for 20 minutes, then the furnace door was opened and the material raked to disperse the particles for even sintering, and allowed to continue to heat in the muffle furnace at 800.degree. C. in air for an additional 20 minutes.

[0112] The product was then removed and allowed to cool to room temperat...

example 2

[0119] Clay / Expanded Perlite Filterable Composite Adsorbent

[0120] A 10 g sample of activated clay was selected as the adsorbent component (Filtrol.RTM. 105, Engelhard Corporation, Jackson, Miss.), was dispersed in sufficient deionized water to result in a 5% (w / v) slurry, and mixed for 1.5 hours using magnetic stirring to aid in dispersal of the clay microparticles. To the slurry were added 10 g of expanded perlite as the functional filtration component (Harborlite.RTM. 635, Harborlite Corporation, Lompoc, Calif.), 0.5 g of pulverized soda ash (Na.sub.2CO.sub.3) as a chemical sintering aid, and the mixture was further stirred for 15 minutes. The contents were then placed in a conventional microwave oven and dried at high power, which took approximately 20 minutes. The resulting cake was brushed through a mesh screen (i.e., with nominal openings of 600 .mu.m) to disperse the particles of the filterable composite adsorbent.

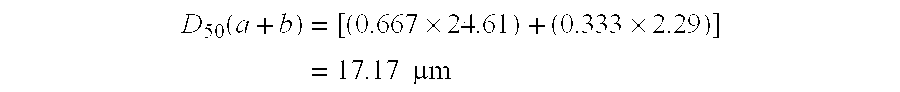

[0121] Permeabilities of the expanded perlite and activated cl...

example 3

[0122] Calcium Silicate Hydrate / Buoyant Polymer Filterable Composite Adsorbent

[0123] A 20 g sample of calcium silicate hydrate product (Micro-Cel.RTM. E, Celite Corporation, Lompoc, Calif.) was selected as an adsorbent component, and spread thinly over a flat plastic surface. Using a 140 mesh (ie., with nominal openings of 106 .mu.m) screen, 10 g of polyvinylchloride-acrylic copolymer (Geon.RTM. Resin 138, Geon, Avon Lake, Ohio) were brushed lightly over the surface of the calcium silicate hydrate layer. The resulting mixture was collected and further mixed in a sealed plastic bag by shaking for 5 minutes, and the mixture was then heated in an oven at 120.degree. C. in air for 1 hour. The resulting material was removed from the oven, cooled, and screened through a 30 mesh (i.e., with nominal openings of 600 .mu.m) screen to disperse the particles, thus resulting in the filterable composite adsorbent.

[0124] In this example, the functional filtration component was formed concurrently ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

| Filterability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com