High back EMF, high pressure subwoofer having small volume cabinet, low frequency cutoff and pressure resistant surround

a subwoofer and high-back emf technology, applied in the direction of transducer casings/cabinets/supports, stereophonic arrangments, electrical transducers, etc., can solve the problems of low frequency, difficult design of cones of that size, and difficulty in many full-range loudspeakers to reprodu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

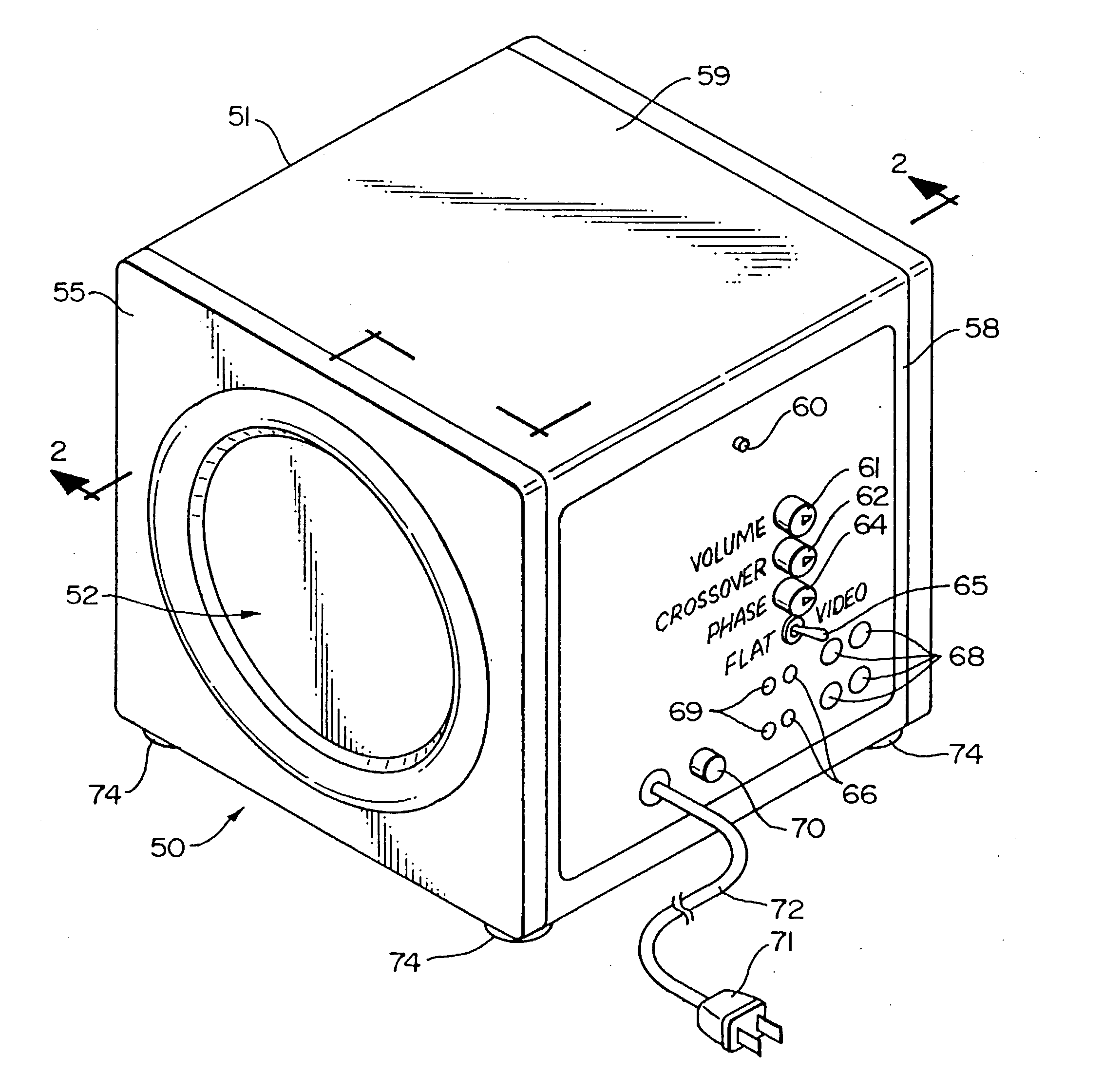

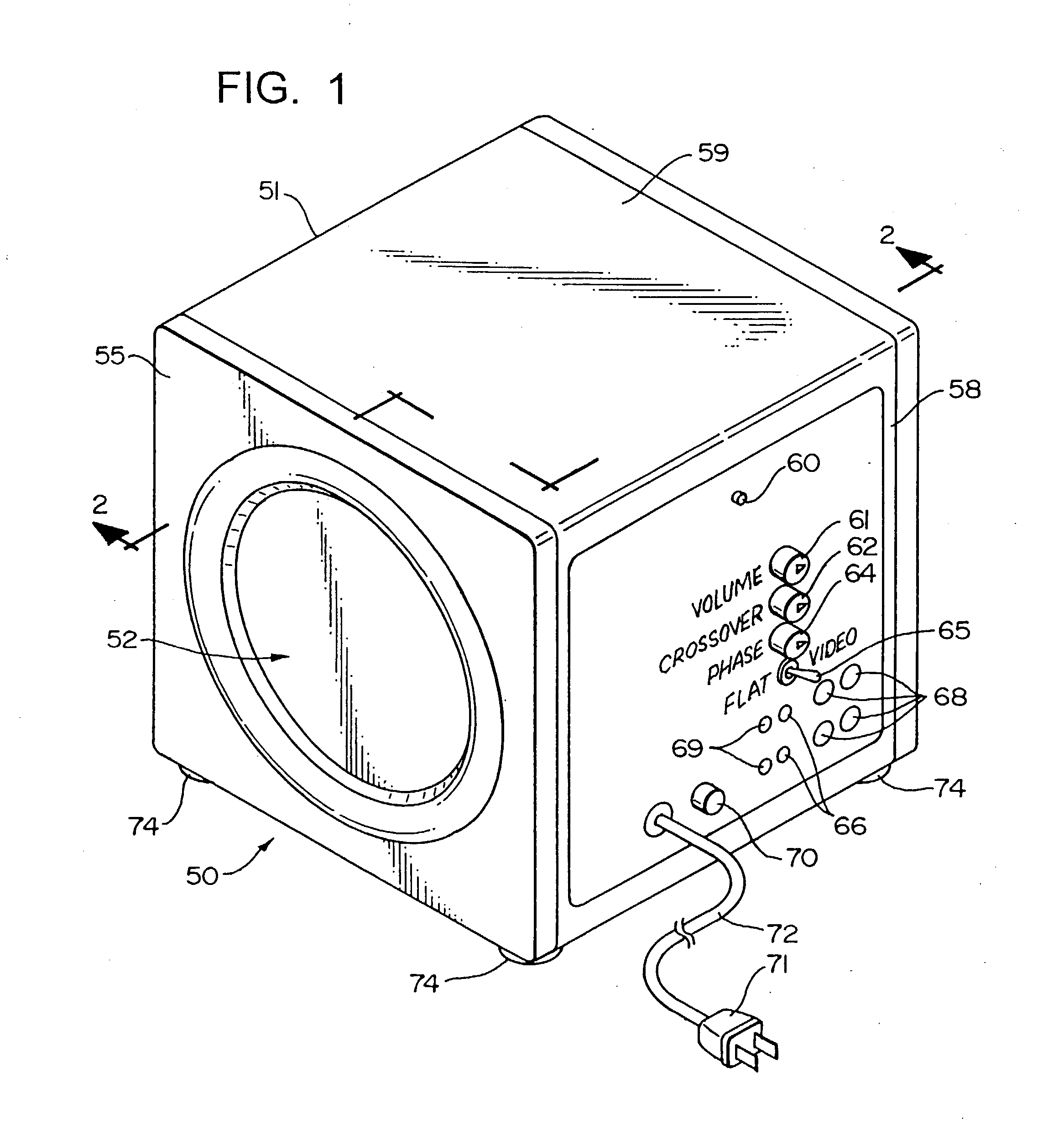

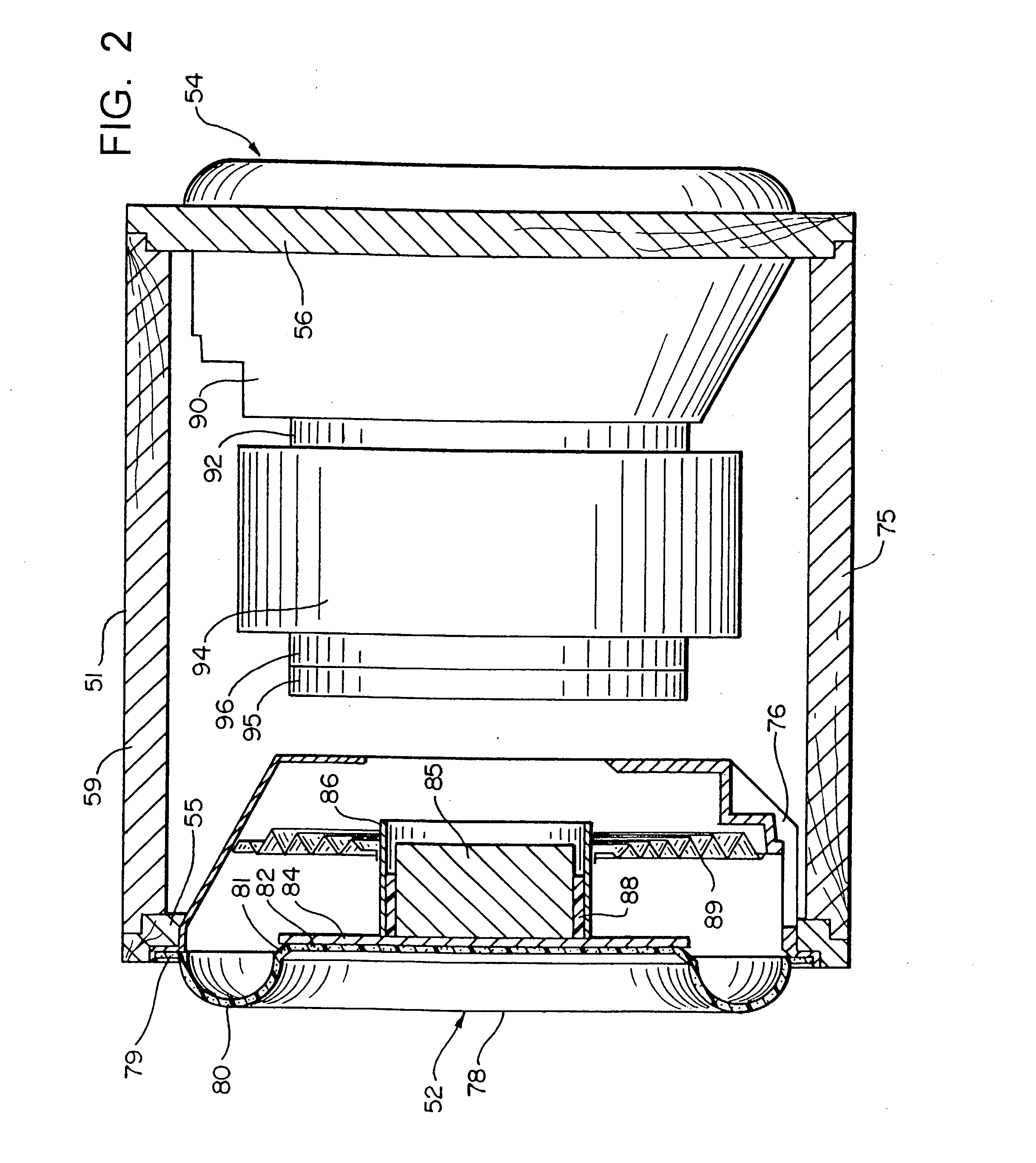

Turning now to the drawings, exemplary embodiments of the present invention will now be described. Thus, referring first to FIG. 1, an exemplary subwoofer, generally indicated at 50, embodying features of the present invention has been depicted. As here shown, the subwoofer 50 includes a cabinet 51 which encloses two drivers, generally indicated at 52 and 54 (only driver 52 is visible in FIG. 1; and, the details of the two exemplary drivers 52, 54 are more specifically shown in FIGS. 2, 3 and 5), which are each oriented in a PUSH / PULL configuration on opposite sides of the cabinet 51. That is, the visible driver 52 depicted in FIG. 1 comprises a mass driven driver shown in greater detail in FIG. 2 and is mounted in one wall of the cabinet (here the left sidewall 55 of the cabinet 51 as viewed in FIG. 1) and fires in PUSH / PULL directions; while the second driver 54 (not visible in FIG. 1, but shown in elevation in FIG. 2 and in section in FIG. 3) is mounted in the opposite or right ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com