Vacuum arc evaporation apparatus and method, and magnetic recording medium formed thereby

a vacuum arc and evaporation apparatus technology, applied in vacuum evaporation coatings, magnetic recording layers, coatings, etc., can solve the problems of difficult to provide a cooling mechanism for the magnetic material, difficult to maintain stably the arc discharge, and difficult to discharge the cathode material plasma beam pb toward the desired direction, etc., to achieve high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

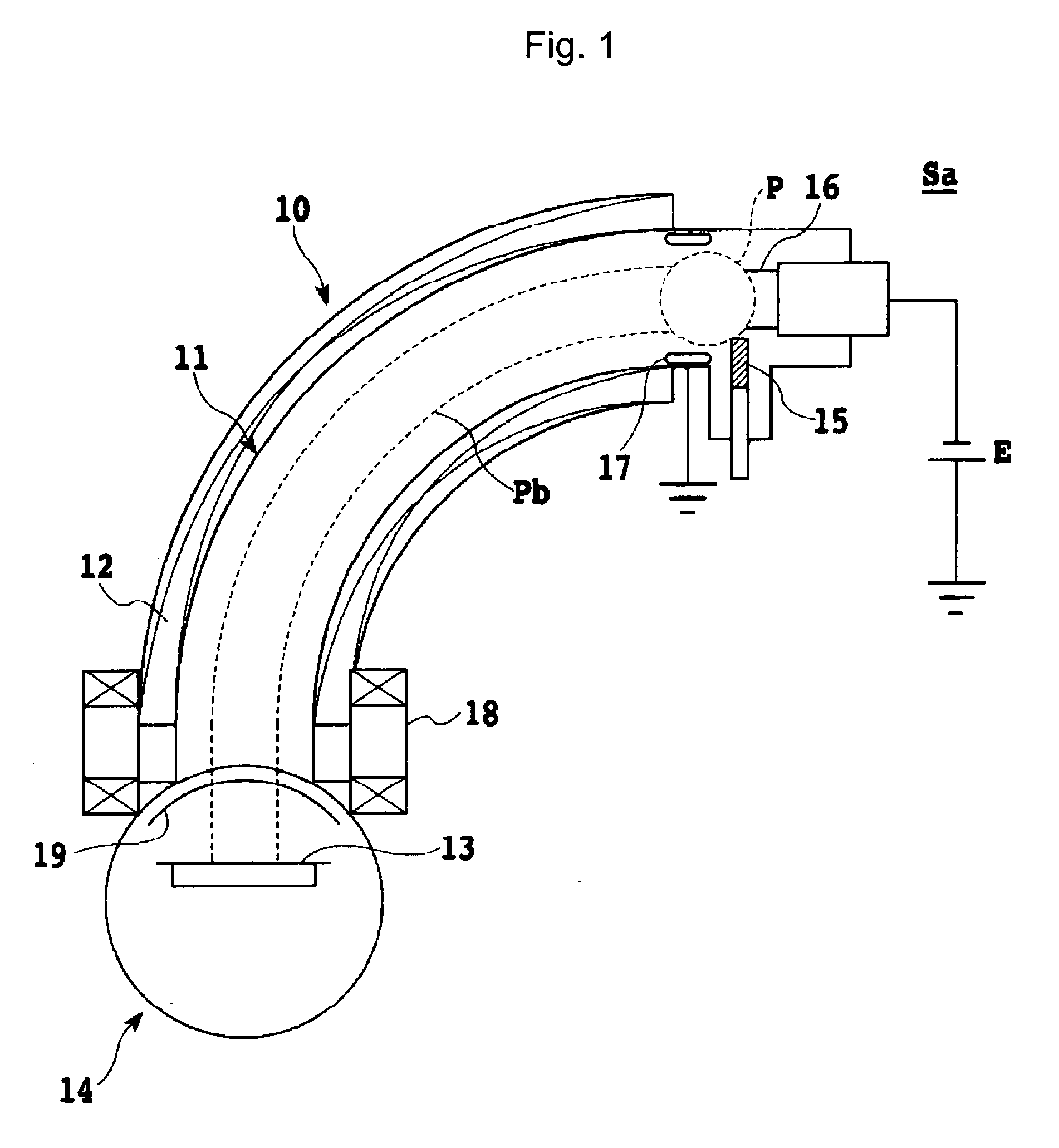

[0017] The present vacuum arc evaporation apparatus can include a deposition vacuum chamber 14, a discharge unit Sa for discharging arc from a cathode target 2, which is made of a deposition material for depositing on a substrate disposed in the deposition vacuum chamber, and a plasma guiding unit 10 disposed between the deposition vacuum chamber and the discharge unit for guiding the cathode material plasma generated by the arc discharge to the deposition vacuum chamber by an induced magnetic field, which can be generated by feeding a current to a coil of the plasma guiding unit, to deposit the cathode target on the substrate.

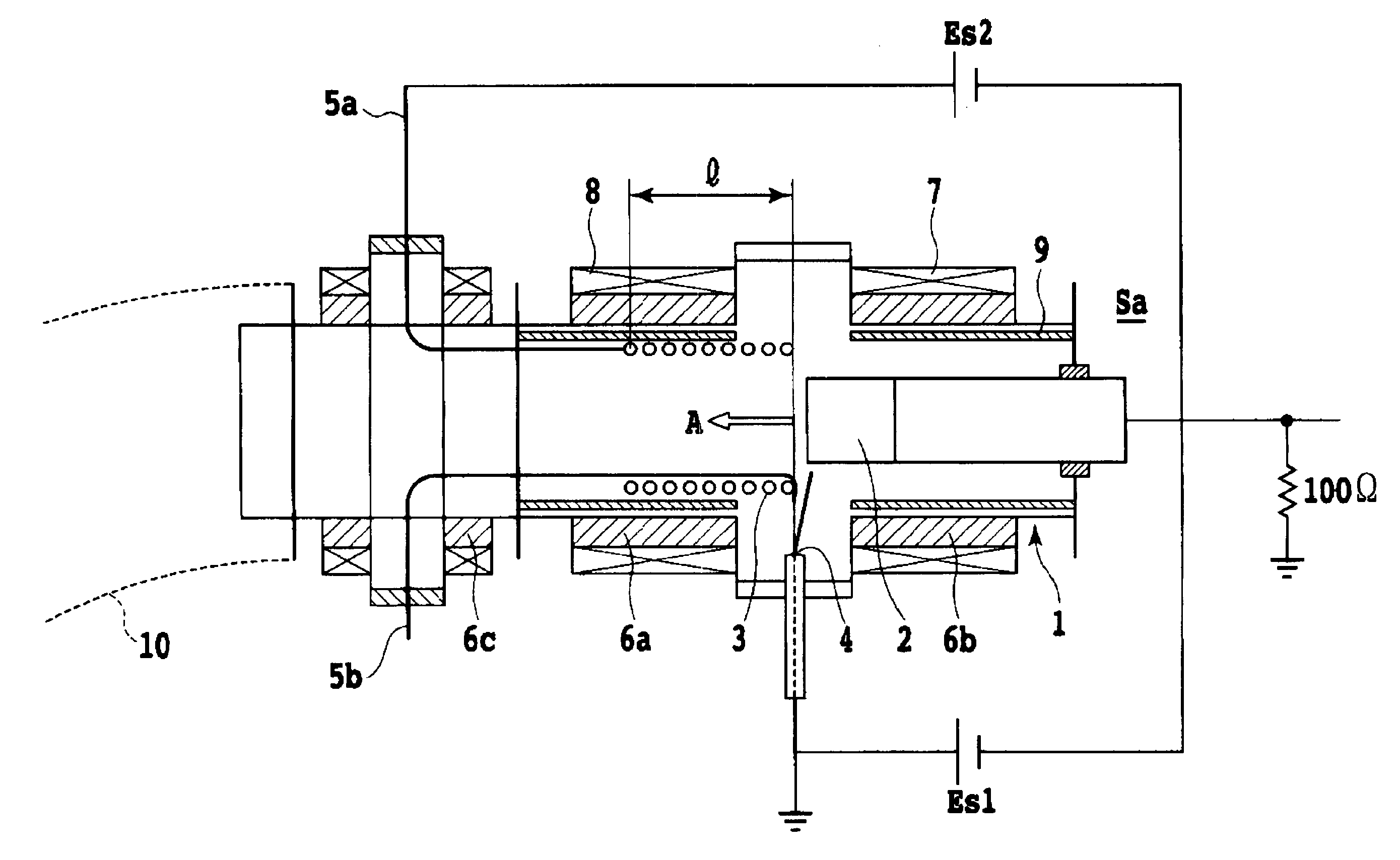

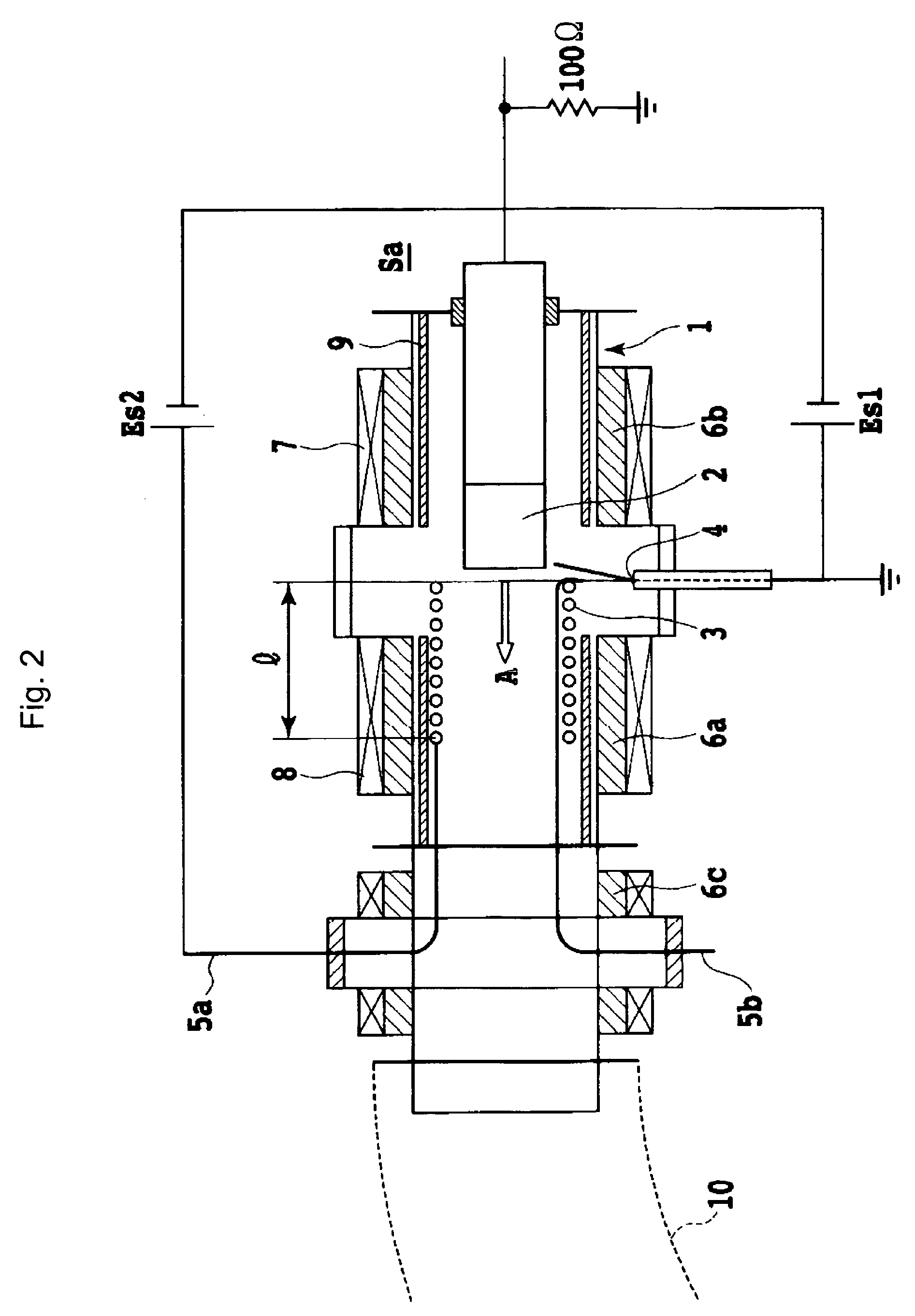

[0018] Referring to FIG. 2, the discharge unit can include an arc source discharge vacuum chamber 1 containing the cathode target 2. The discharge vacuum chamber is electrically grounded while the cathode target 2 is electrically ungrounded and made of the deposition material. An anode 3, which is also electrically ungrounded, can be provided as a first gener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inner diameter | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com