Devices and methods for percutaneously treating aortic valve stenosis

a technology for aortic valves and stenosis, which is applied in the field of devices and methods for percutaneous treatment of aortic valve stenosis, can solve the problems of reducing cardiac output, affecting the treatment effect, so as to increase the flow of aortic valves and improve the treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

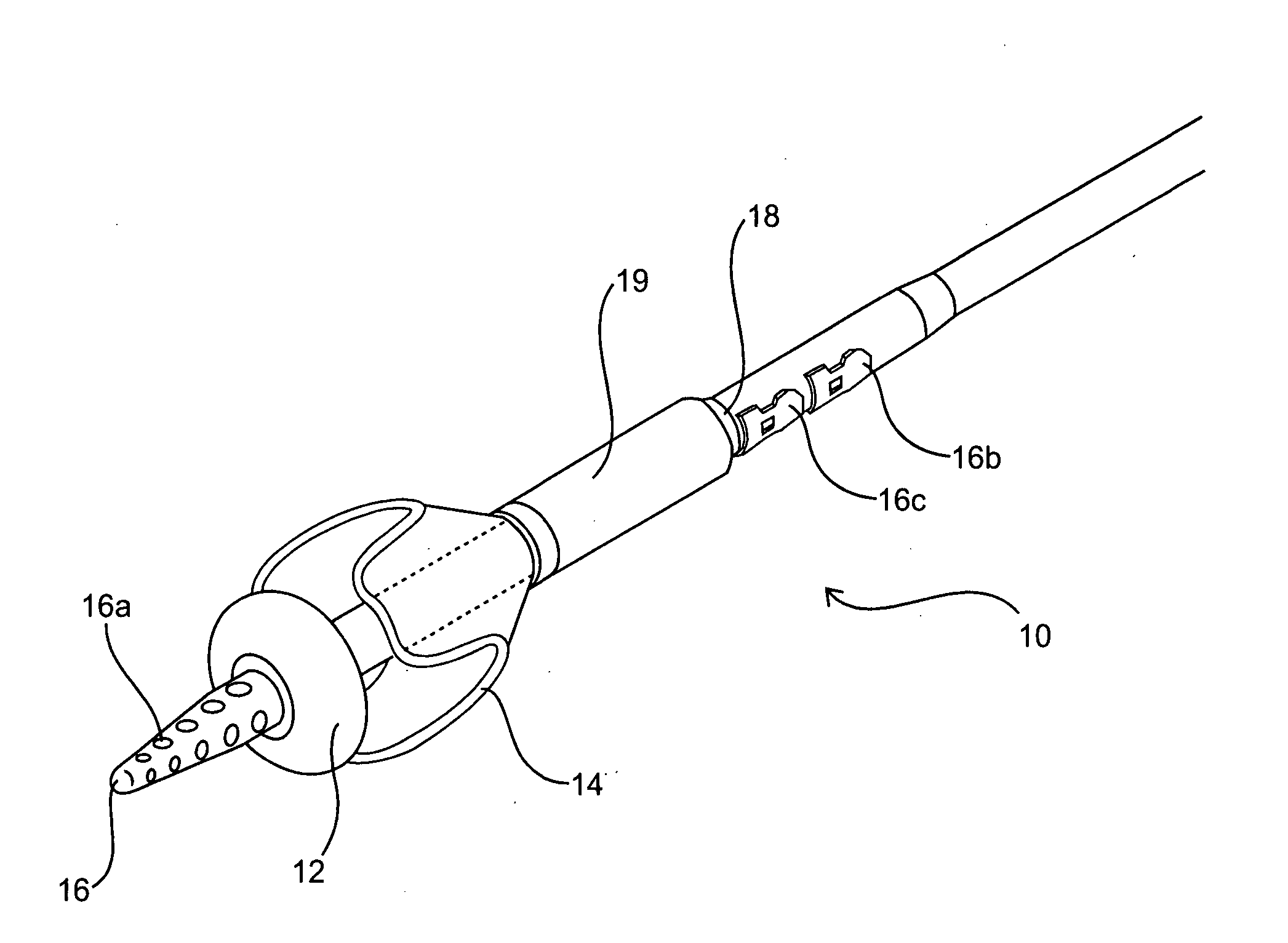

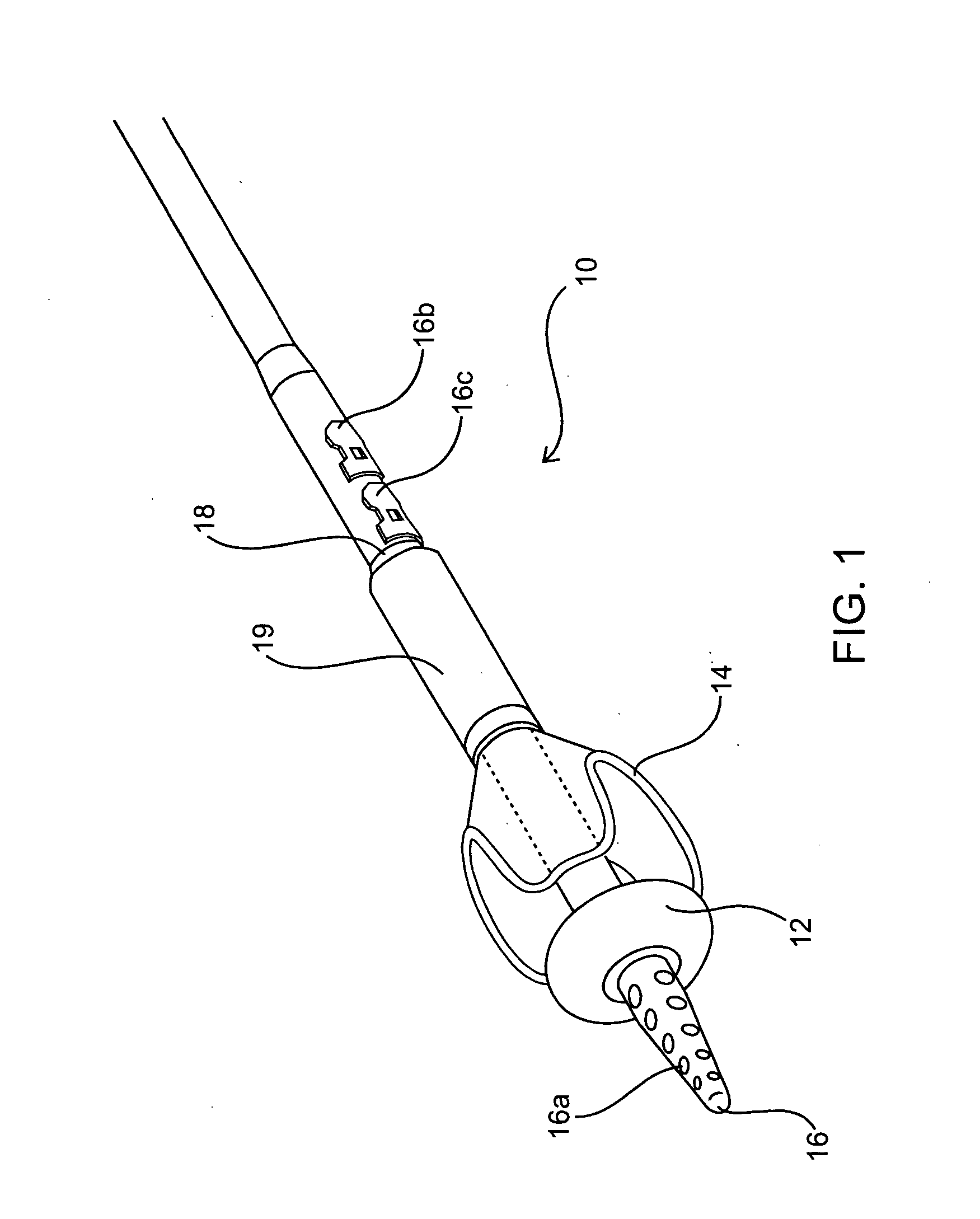

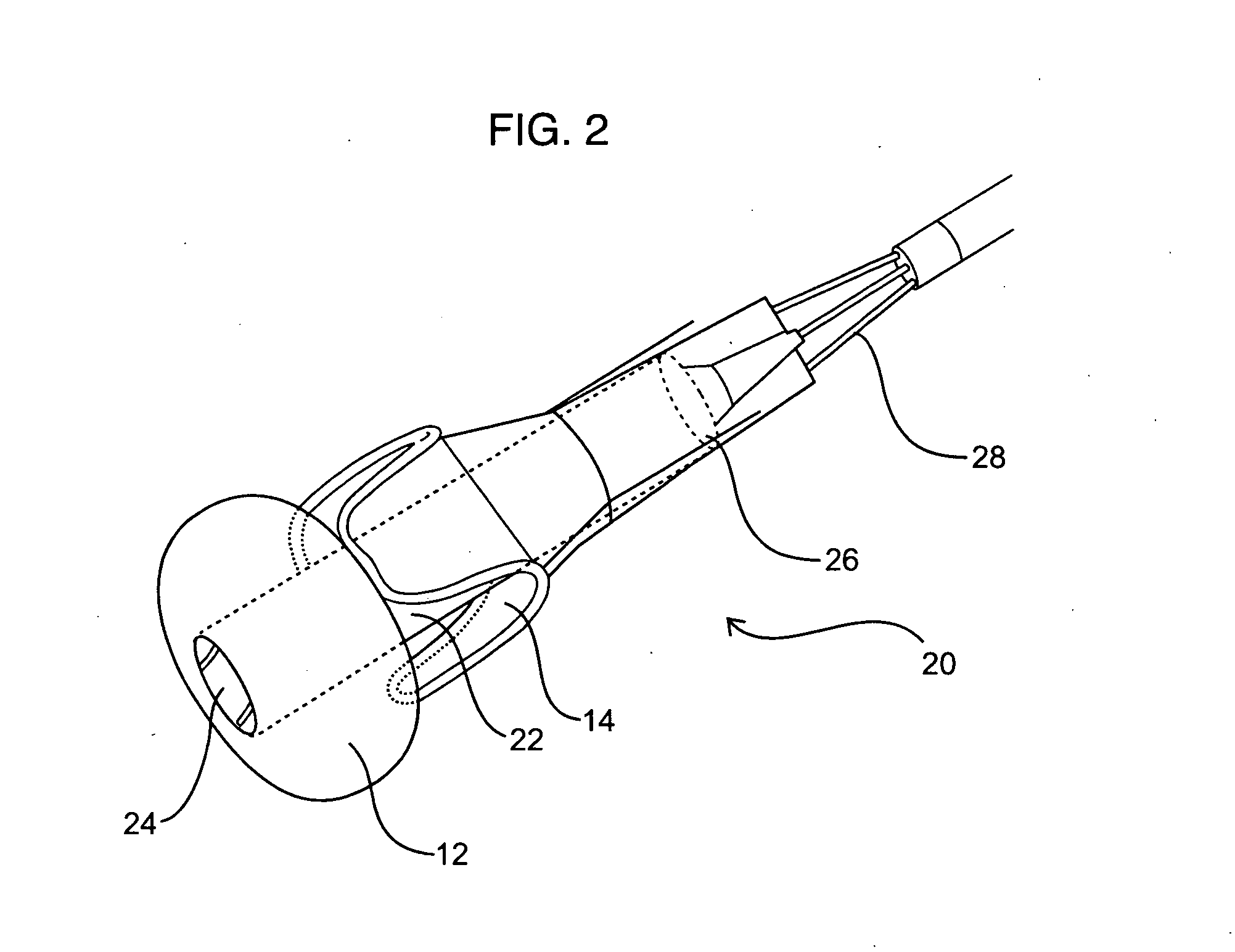

[0016] Devices and methods for their use in percutaneously increasing the aortic valve flow of a stenotic aortic valve are provided. The subject devices include an aortic valve isolation element, a shunt element and an aortic valve flushing element. The aortic valve isolation element is made up of a ventricular side aortic valve occlusion element and a proximal side aortic valve isolation element. The shunt element is made up of a shunt lumen that includes one or more ventricular side blood inflow ports and one or more proximal side valves that provide for one-way exit of blood from the shunt lumen into the aorta. The aortic valve flushing element is made up of a fluid introducing element and a fluid removal element. In practicing the subject methods, a stenotic aortic valve is first isolated. Next, the isolated valve is flushed with a dissolution fluid, e.g., an acidic dissolution fluid, for a period of time sufficient for the aortic valve flow of the treated valve to be increased....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com