Exhaust gas purifying method and exhaust gas purifying system

a technology of exhaust gas purification and purification method, which is applied in the direction of exhaust treatment electric control, electrical control, separation process, etc., can solve the problems of reducing sulfur purge efficiency, reducing the efficiency of sulfur purge, and difficult to keep the stoichiometric air-fuel ratio state, so as to minimize the deterioration of fuel efficiency, reduce the temperature of the nox occlusion type catalyst, and efficiently perform sulfur purge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

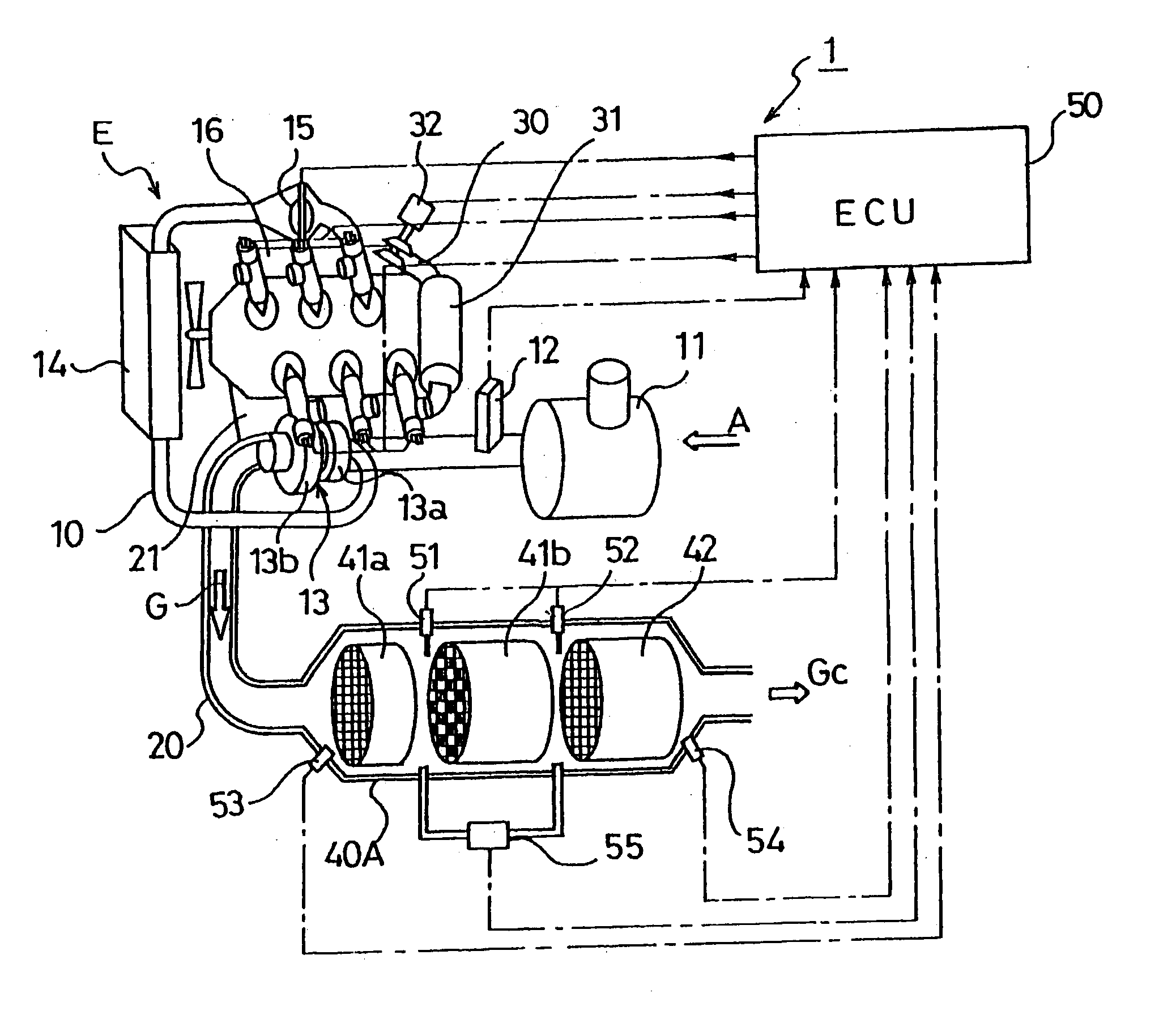

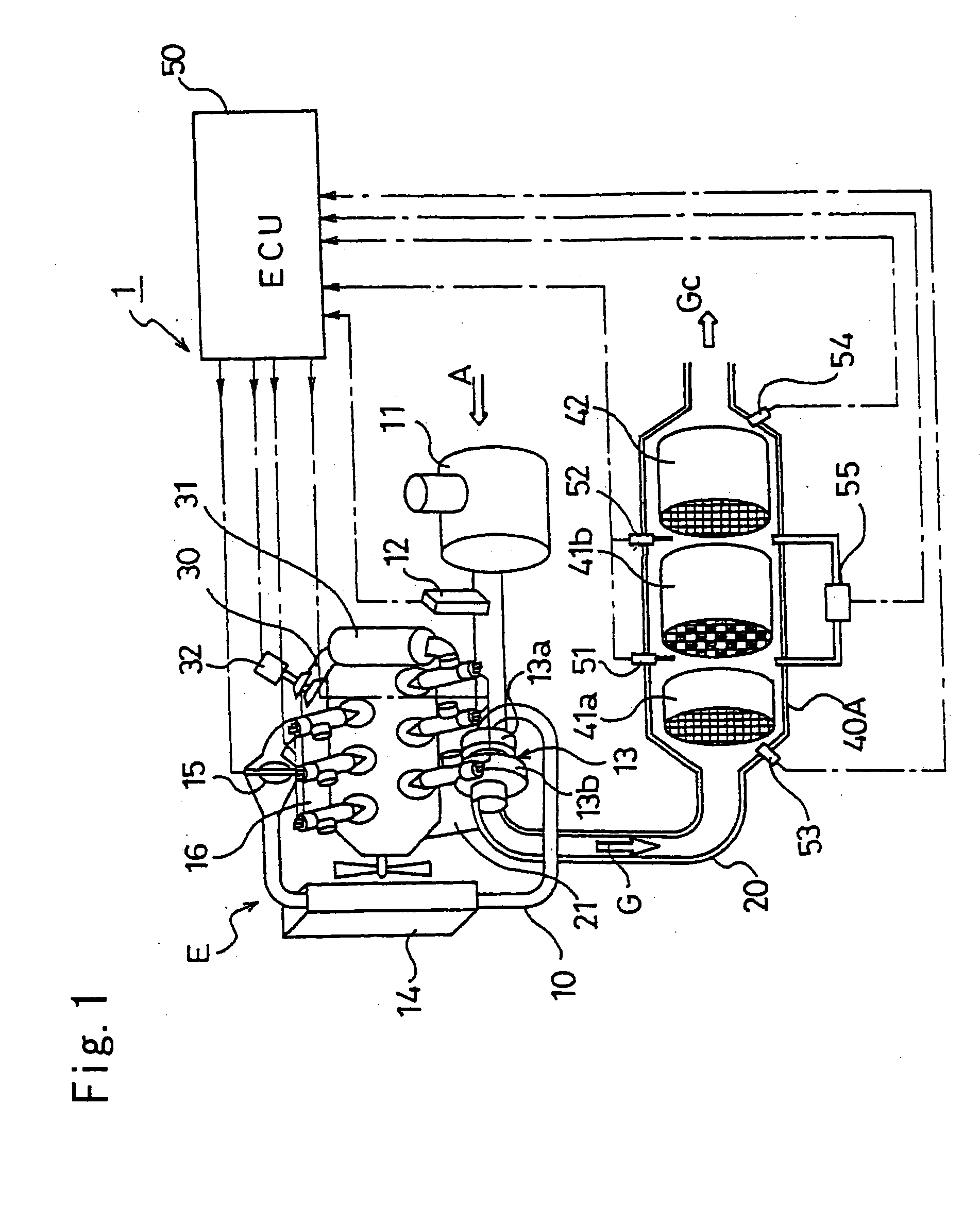

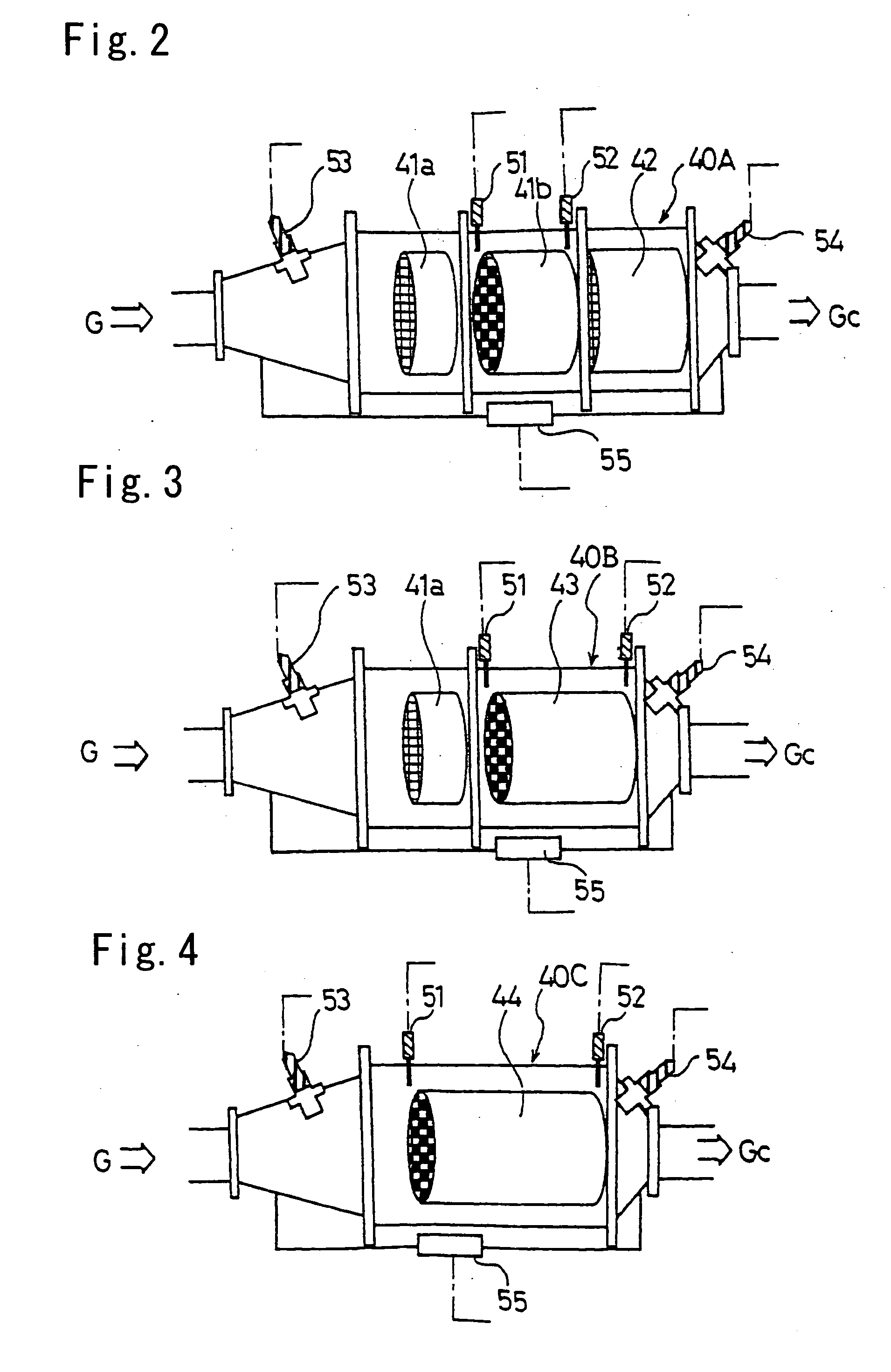

Method used

Image

Examples

embodiments

[0081]FIG. 7 shows the excessive air rate λ, pressure difference ΔP between front and rear of a DPF, catalyst temperature (bed temperature of NOx occlusion reduction type catalyst converter) Tn, and concentrations of NOx and SO2 at the downstream side of an exhaust gas purifying system when performing sulfur purge in accordance with the control flow shown in FIG. 6 by using the exhaust gas purifying system shown in FIG. 2.

[0082] According to FIG. 6, by intermittently repeating the sulfur purge control for decreasing the excessive air rate λ immediately before a NOx occlusion reduction type catalyst converter to 1.01 to 1.02 while performing the regeneration control of a DPF, it is found that the catalyst temperature Tn rises at the time of the sulfur purge control and SO2 is discharged. Moreover, the quantity of the SO2 to be discharged at one time is decreased because the sulfur purge control is kept for a short time.

[0083] Furthermore, because the pressure difference ΔP between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com