Easily assembled cooler

a cooler and easy-to-assemble technology, applied in the direction of indirect heat exchangers, laminated elements, light and heating apparatus, etc., can solve the problems of difficult improvement of productivity, high manufacturing cost, and high manufacturing cost, and achieve the effect of reducing the forming process cost, manufacturing cost, and sufficient contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

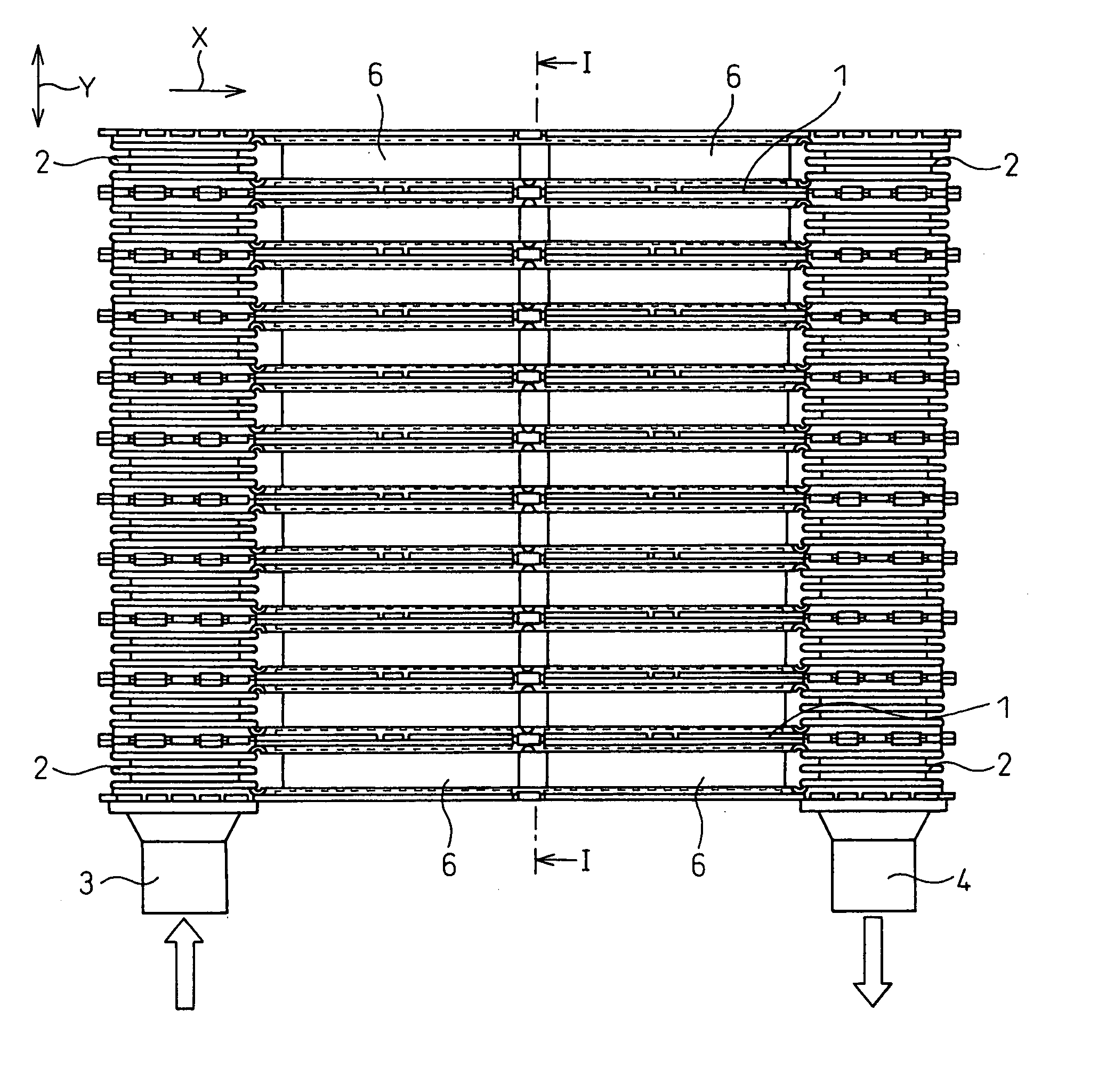

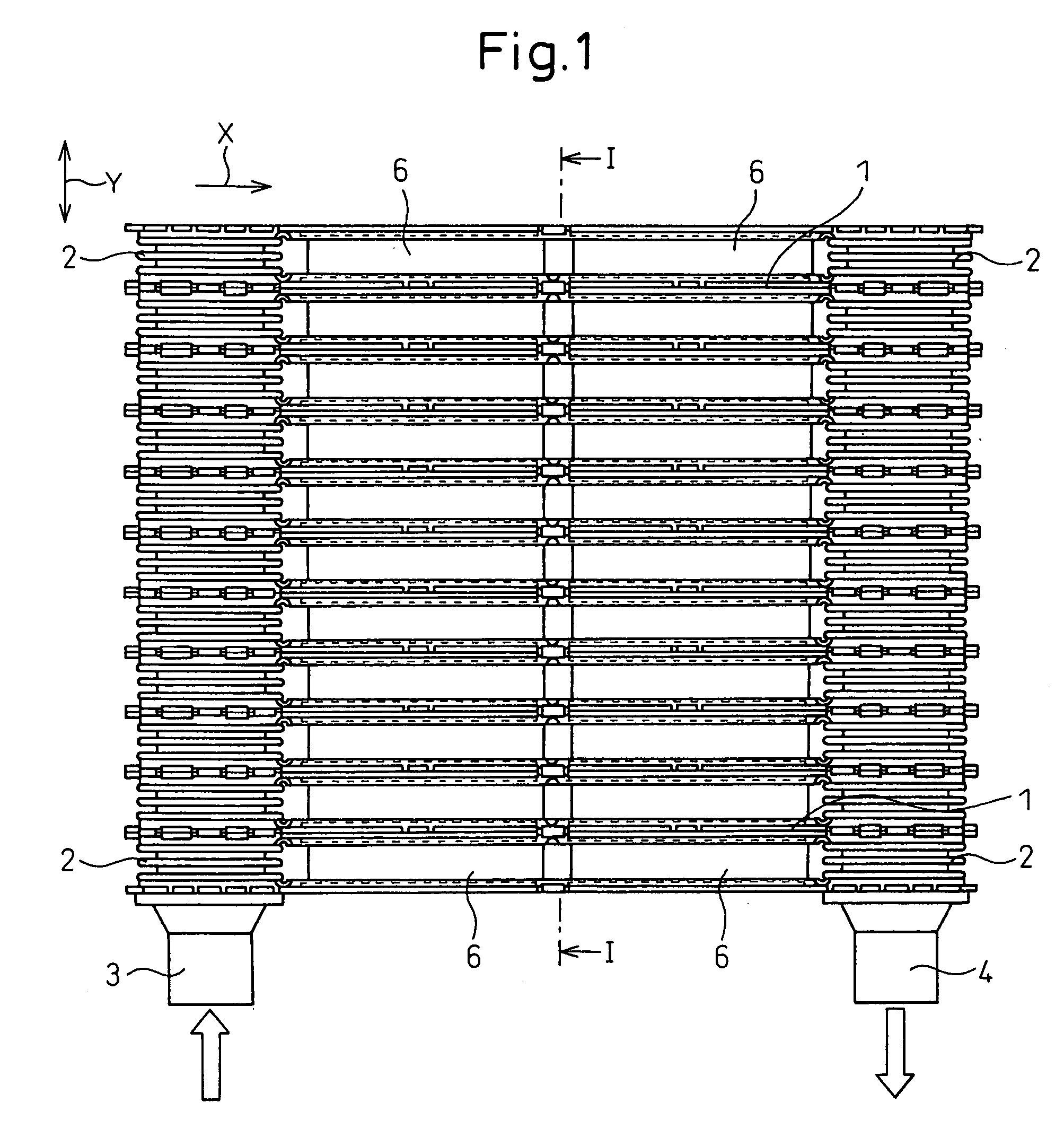

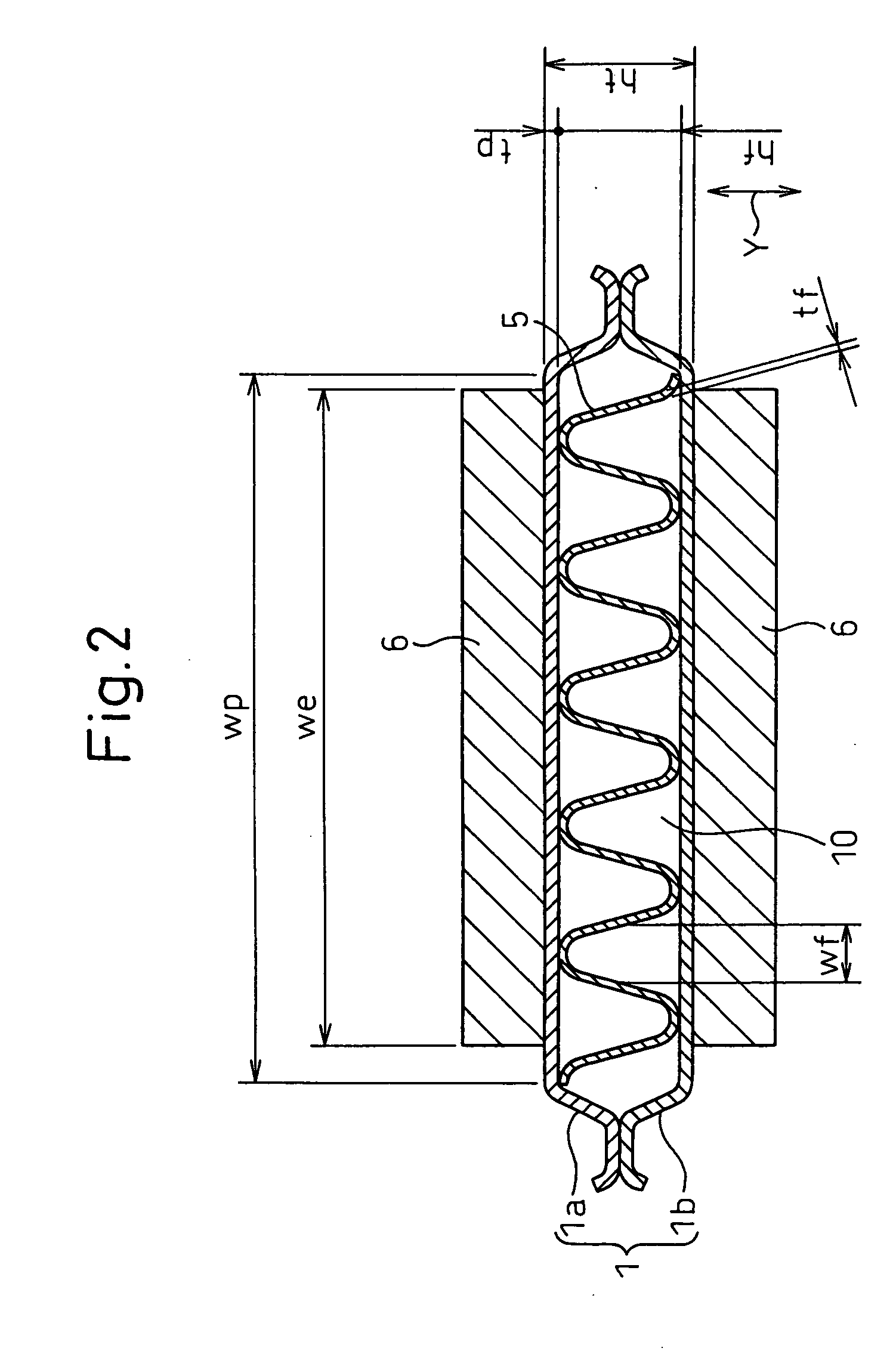

[0147] A cooler according to a first embodiment of the present invention is explained below. FIG. 1 is a front view of the cooler according to the first embodiment, FIG. 2 is a sectional view of an important part along the I-I line in FIG. 1, FIG. 3A is a front view of a tube alone in FIG. 1, FIG. 3B is a plan view of the tube in FIG. 3A, and FIG. 4 is an enlarged view of an important part of a fin in FIG. 2.

[0148] The cooler of the present invention can be used to cool a semiconductor module of a double-sided cooling type in an inverter for a hybrid electric vehicle.

[0149] As shown in FIG. 1 and FIG. 2, the cooler comprises: a plurality of tubes 1 in which a fluid passage 10 is formed internally through which a cooling fluid flows and piled at predetermined intervals in the direction Y (hereinafter, referred to as the direction of built-up Y) perpendicular to the direction X (hereinafter, referred to as the direction of flow X) of flow of the cooling fluid in the fluid passage 10...

second embodiment

[0176] A cooler according to a second embodiment of the present invention is explained below. FIG. 9A is a front view of the cooler according to the second embodiment and FIG. 9B is a plan view of the cooler in FIG. 9A. The same numerals or letters are assigned to the parts the same as or similar to those in the first embodiment and no explanation thereof will be given here.

[0177] In FIG. 9B, the broken line denotes the position at which the fin 5 is arranged and the alternate long and short dash line denotes the position at which the semiconductor module 6 is arranged. As shown in FIG. 9B, the two fins 5 are arranged in the single tube 1 and the two fins 5 are arranged apart from each other at an interval 6, along the direction of flow X of the cooling fluid within the fluid passage 10. The semiconductor module 6 is arranged within the area in which the fin 5 is arranged when viewed in the direction of built-up Y of the tubes 1.

[0178] In the present embodiment, as the two fins 5 ...

third embodiment

[0181] A cooler according to a third embodiment of the present invention is explained below. FIG. 10 is a sectional view of a tube in the cooler according to the third embodiment. In the present embodiment, the configuration of the tube 1 differs from that in the first embodiment but the other parts are the same as those in the first embodiment.

[0182] As shown in FIG. 10, the tube 1 in the present embodiment is formed by bending a plate 1c, which is a thin plate formed into a predetermined shape by press molding, and joining by brazing the edges of the plate 1c in a state in which the fin 5 is sandwiched between the bent plate 1c.

[0183] According to the present embodiment, it is possible to reduce the number of parts, the time of the fabricating process and, therefore, the cost compared to the first embodiment in which the tube 1 is formed by the two plates 1a and 1b. It is preferable that the plate 1c uses a brazing sheet material having a sacrifice anode material attached to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com