Wax and candle compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

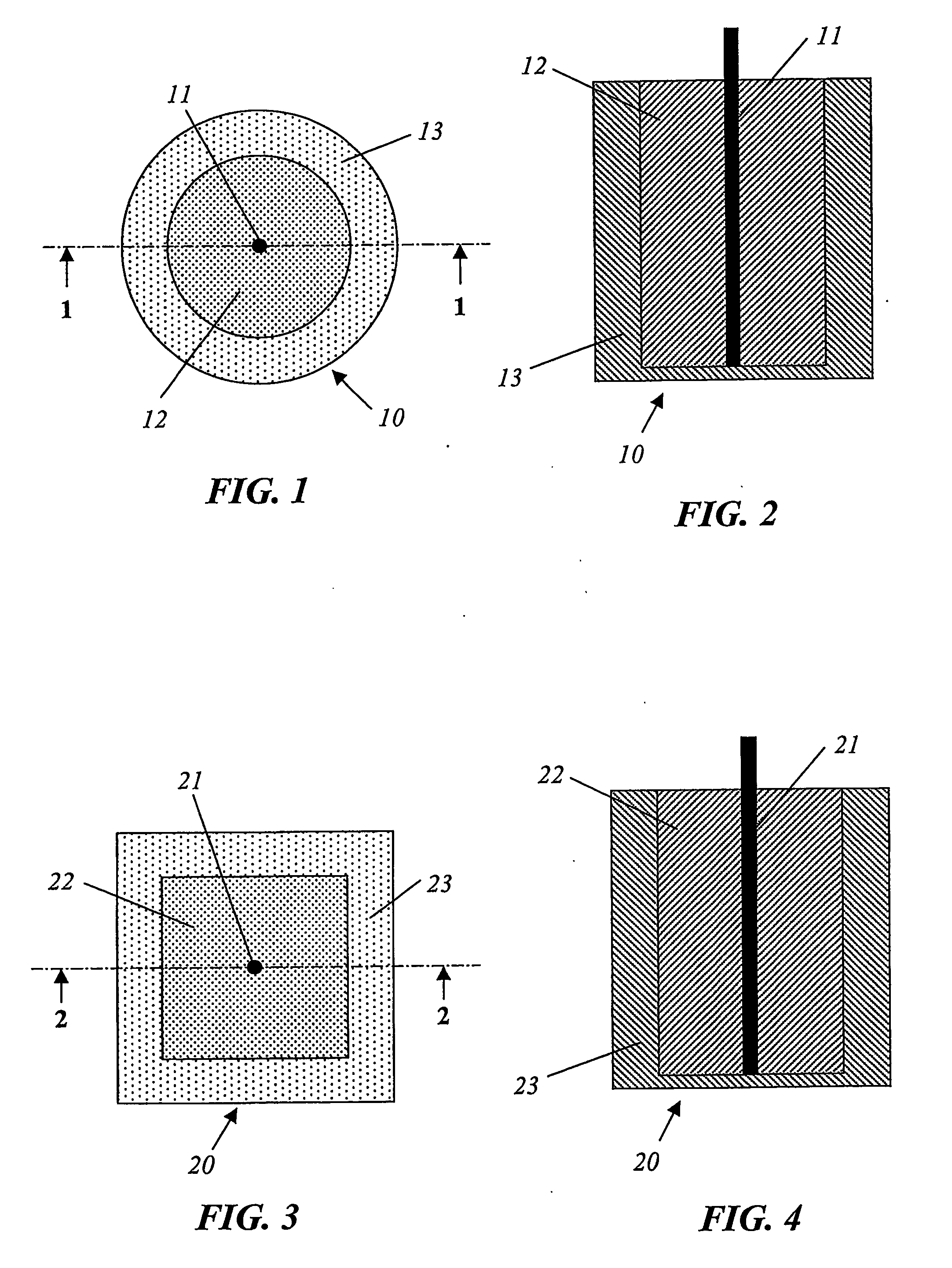

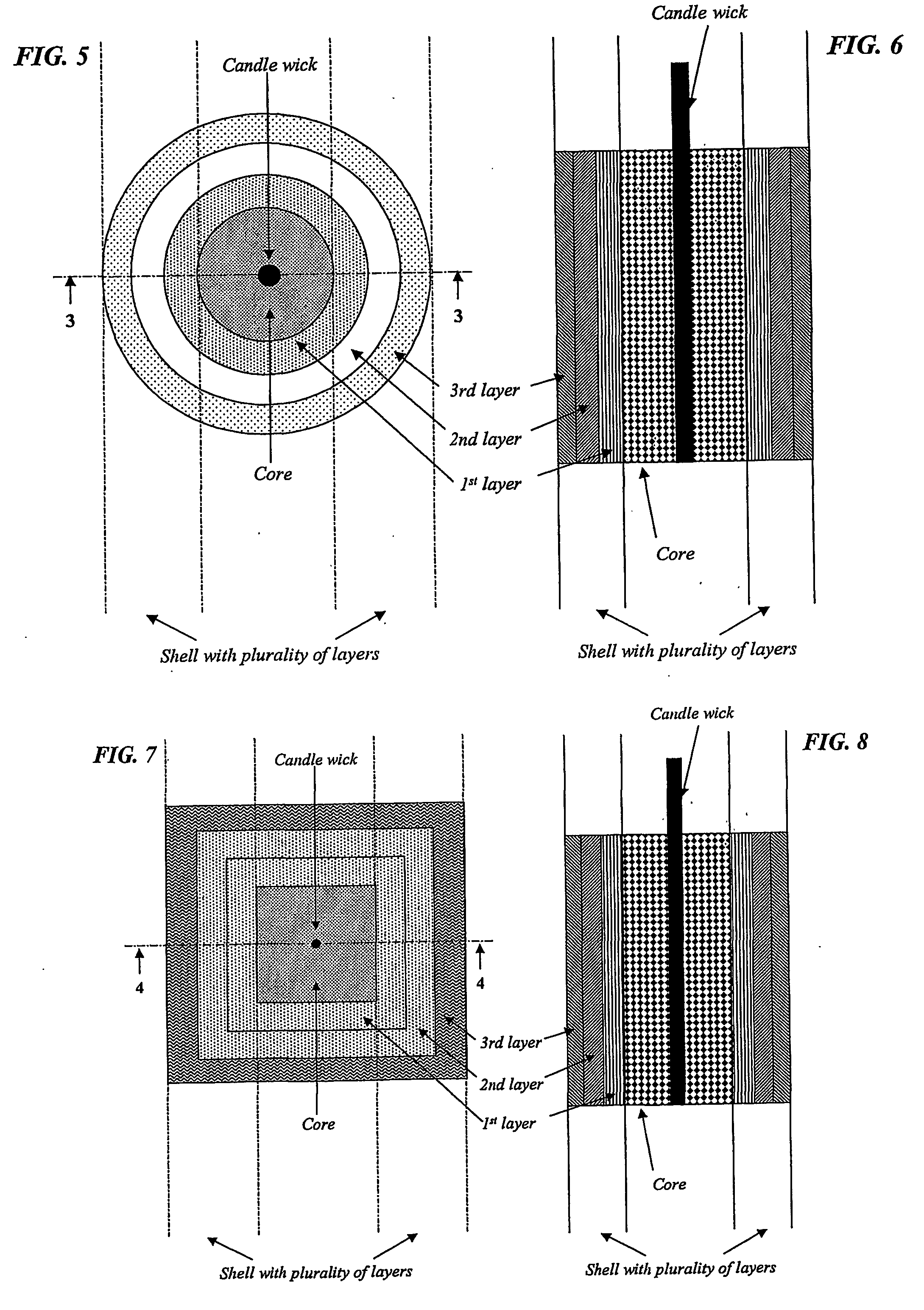

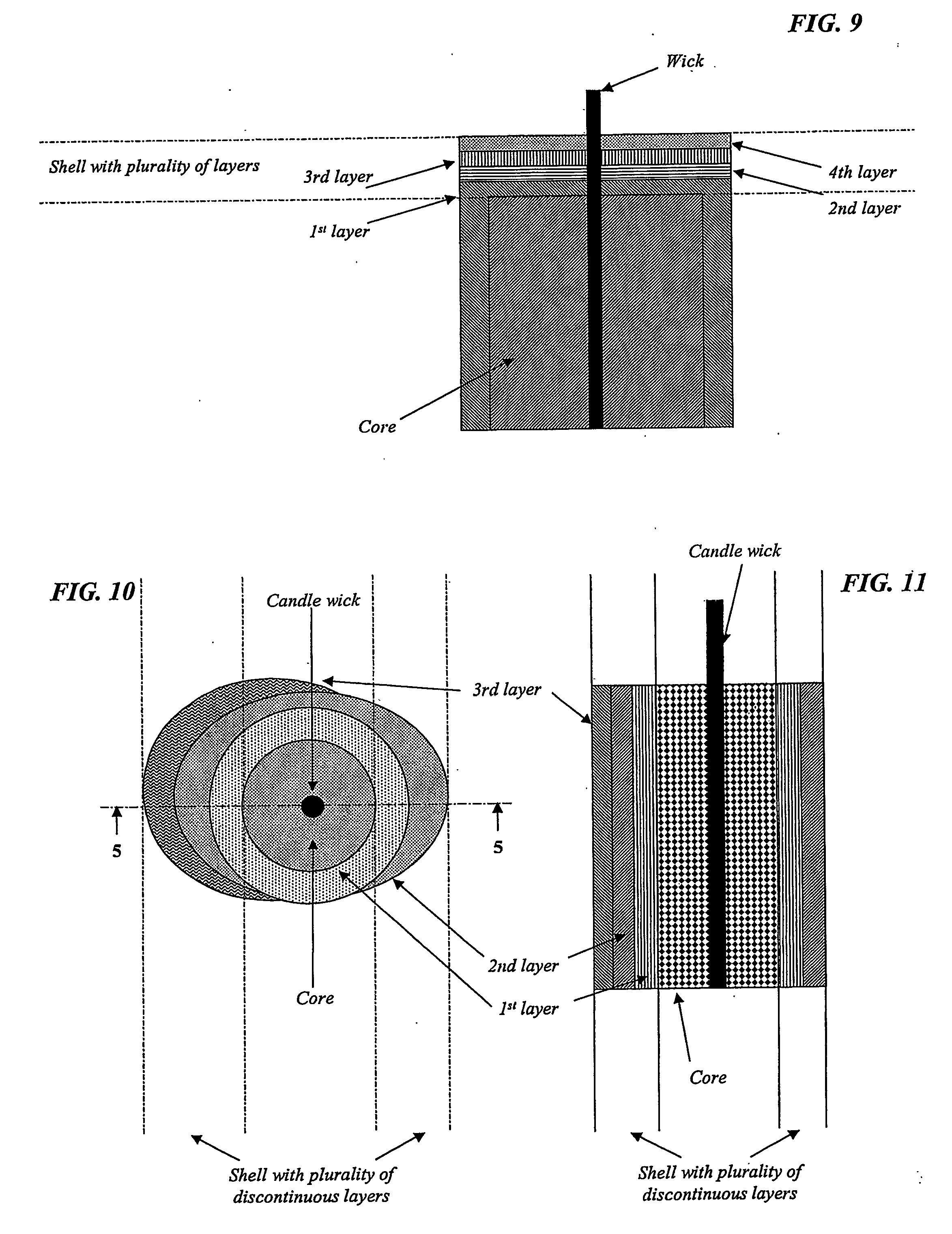

[0076] A core was formed using a commercially available unfragranced cylindrical pillar candle with a single wick extending along the candle axis. The core had a diameter of approximately 50 mm, a height of approximately 105 mm and a total mass of 172.3 g.

[0077] A shell composition was prepared by heating 150.0 g of a perfume base (lavender scent) and 100.0 g of LAO C30+ (available from Aiglon S.A.) in a sealed 500 ml glass powder jar to 90° C. in a water bath, whereupon the linear alpha olefin dissolved in the perfume base. The mixture was agitated until completely homogeneous and then cooled to 75° C.

[0078] The core was dipped into the molten shell composition, removed and allowed to cool. This dipping and cooling process was repeated until the total mass of the candle had increased to 189.0 g. The shell thus had a total mass of about 16.7 g, a thickness of about 1 mm and contained approximately 10.0 g of the perfume base.

[0079] The free standing pillar candle thus produced was...

example 2

[0081] 4.0 g of a perfume base (lavender scent) was mixed with 196.0 g of a molten commercially available paraffin wax blend, and 150.0 g of the resulting mixture poured into a cylindrical candle mould and allowed to cool to ambient temperature. A fragranced core, with an axially embedded wick, was thus produced. The core had a diameter of approximately 43 mm and a height of approximately 115 mm.

[0082] A shell composition was prepared by heating 125.0 g of a perfume base (lavender scent) and 125.0 g of LAO C30+ (available from Aiglon S.A.) in a sealed 500 ml glass powder jar to 90° C. in a water bath, whereupon the linear alpha olefin dissolved in the perfume base. The mixture was agitated until completely homogeneous and then cooled to 75° C.

[0083] The core was dipped into the molten shell composition, removed and allowed to cool. This dipping and cooling process was repeated until the total mass of the candle had increased by 14.0 g. The shell had a thickness of about 1 mm and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com