Synthetic fuel with reduced particulate matter emissions and a method of operating a compression ignition engine using said fuel in conjunction with oxidation catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

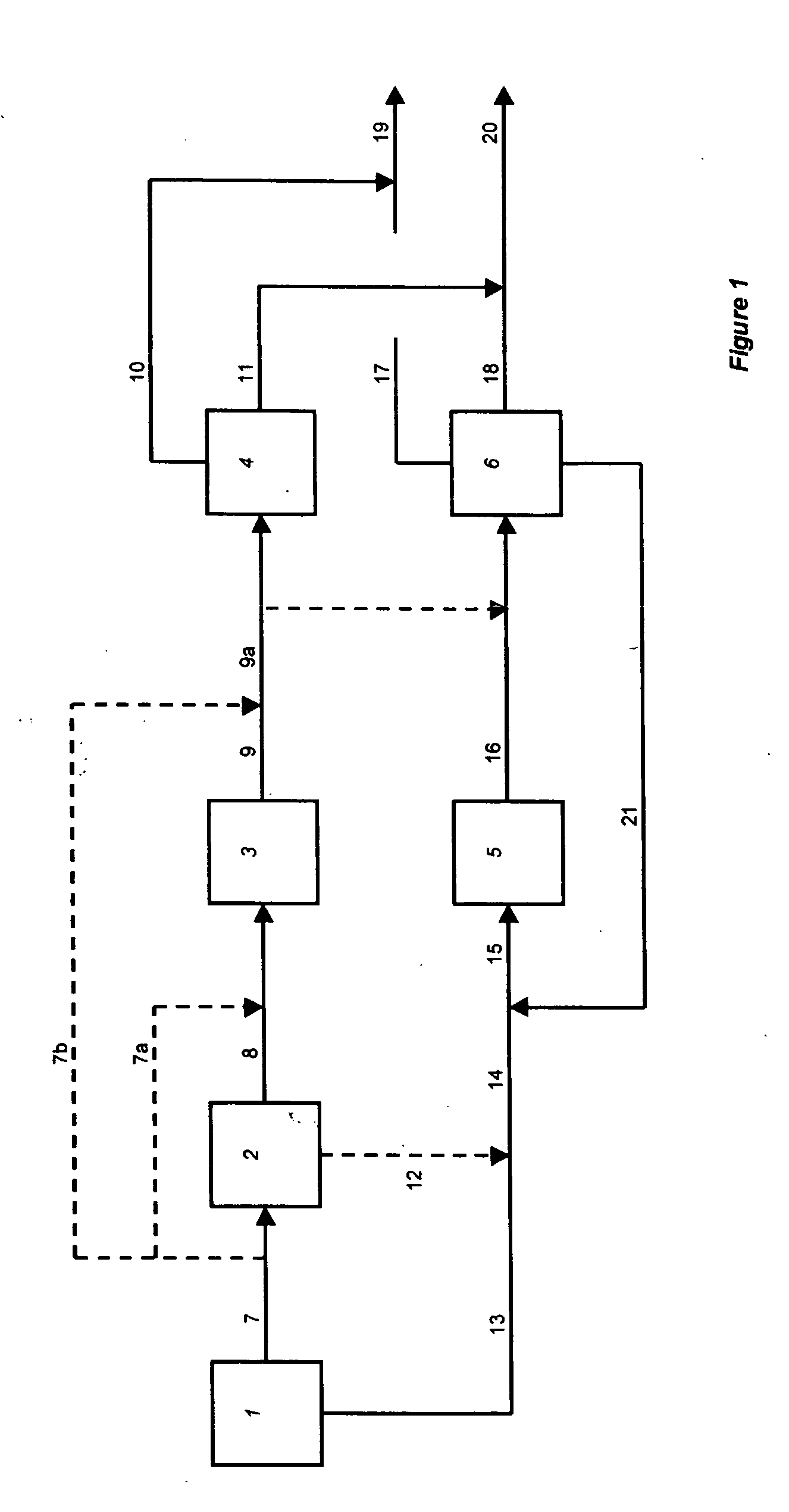

Image

Examples

example 1

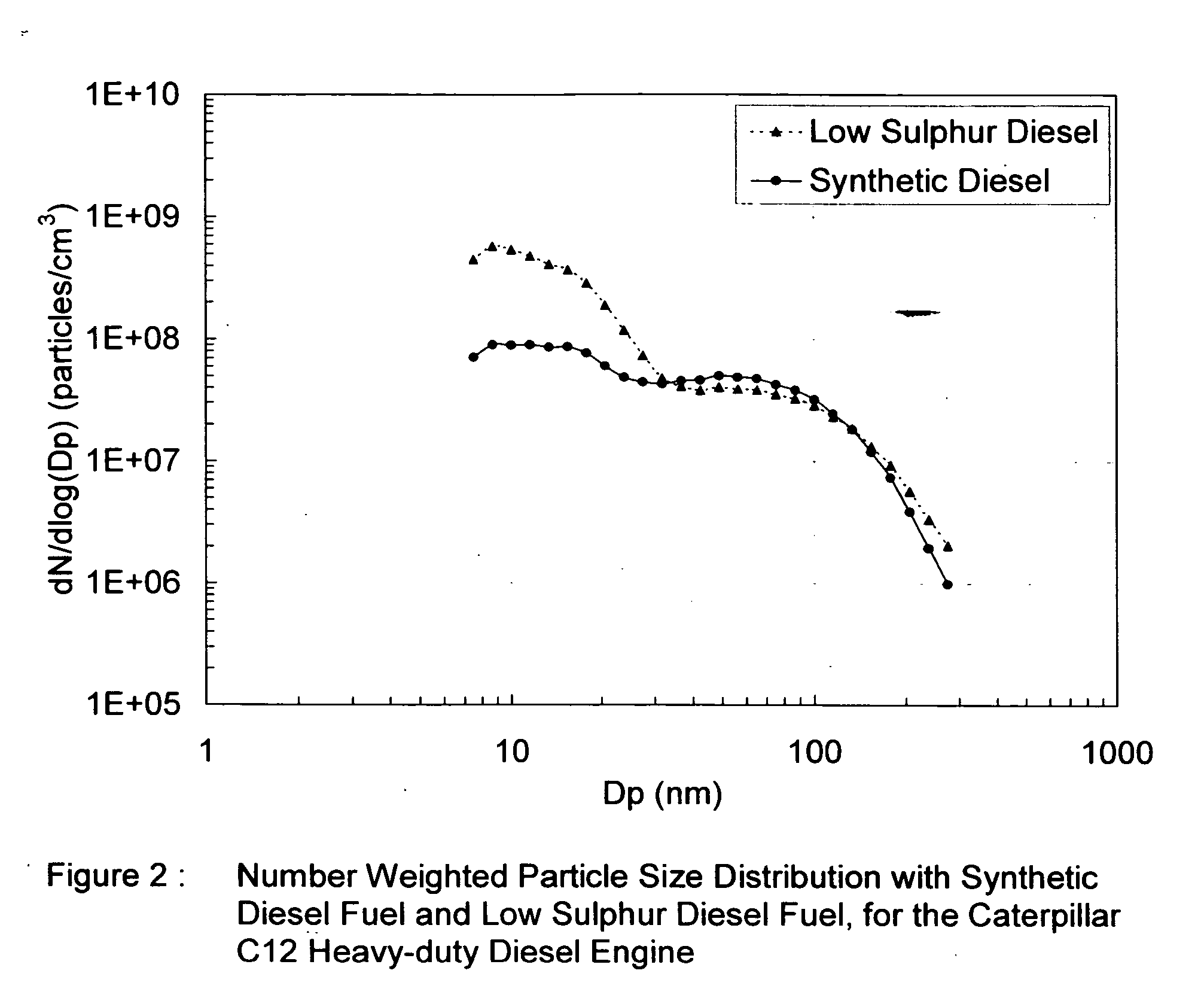

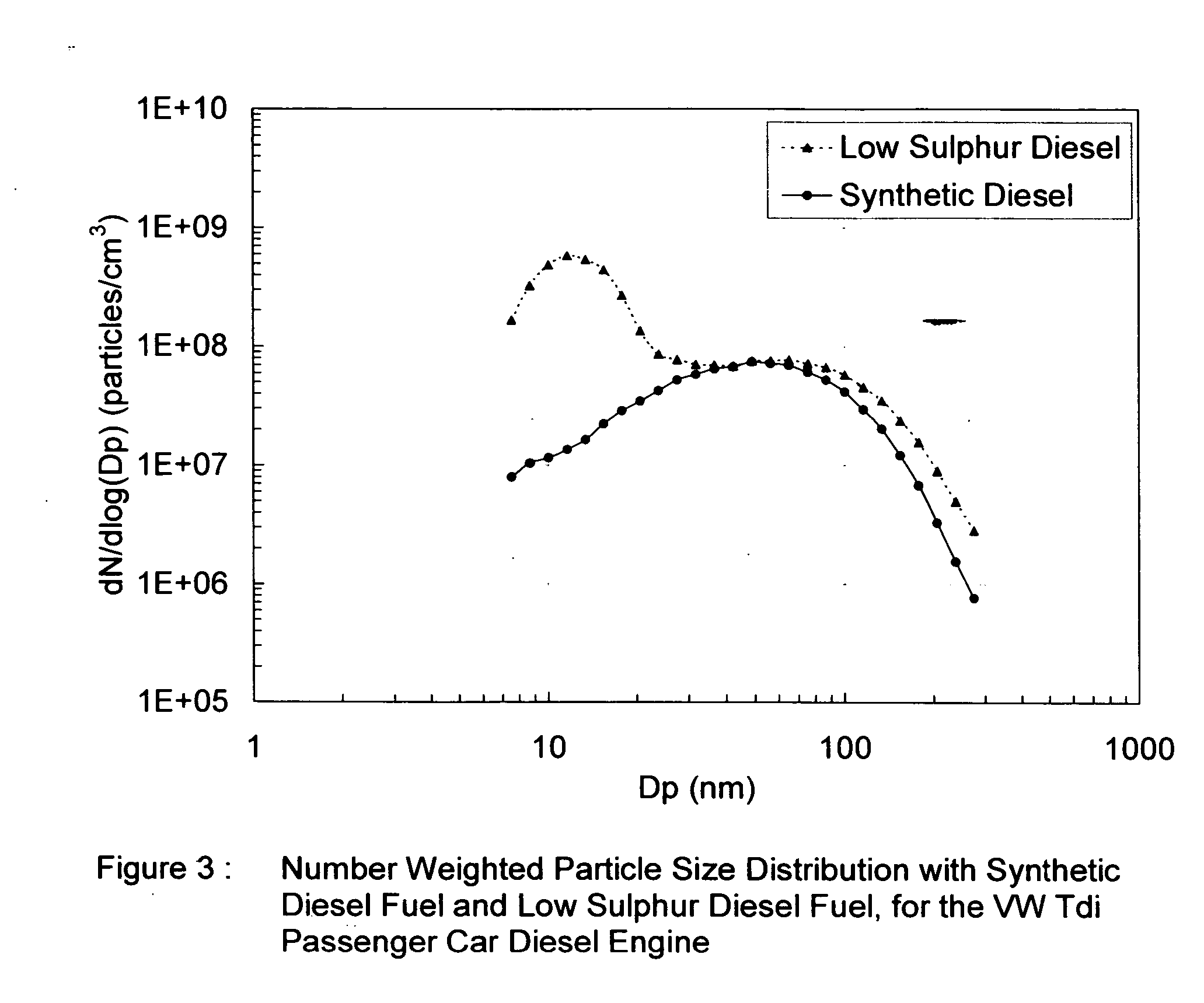

Particle Number Emissions

[0050] For the purposes of comparing particle number emissions and size distributions, a commercially available, low sulphur diesel fuel approved by the US Environmental Protection Agency for on-highway use, was used as the reference fuel. Important characteristics of the two test fuels are presented in Table 3.

TABLE 3Analysis of Test FuelsLow-S DieselSyntheticTestReferenceDieselPropertyMethodFuelFuelSpecific Gravity, 60° F.ASTM D40520.87050.7647Kinematic Viscosity.,ASTM D4453.1992.00740° C. (cSt)Flash Point (° C.)ASTM D938260Cloud Point (° C.)ASTM D2500−19−18Total Sulphur (ppm)ASTM D2622404Distillation (° C.)ASTM D86IBP19616910%22318750%27325190%330312FBP359329Cetane NumberASTM D61341.574.8Total Aromatics (wt. %)ASTM D518638.4Oxygen as Oxygenatesaccording to GC-MSanalysis, (ppm)Oxygen as primaryC12-C24 alcohol (ppm)Oxygen as primaryC7-C12 alcohol (ppm)

[0051] Exhaust particle number emissions and size distributions were measured using two test engines, a ...

example 2

Oxidation Catalyst Performance Tests

[0066] Various exhaust emission tests were carried out to compare a Japanese low sulphur diesel fuel derived from crude oil and GTL diesel fuel, a synthetic compression ignition fuel of the present invention. The tests focused on regulated emissions of hydrocarbons (HC), carbon monoxide (CO), nitrogen oxides (NOx) and particulate matter (PM), as well as carbon dioxide (CO2). The emission tests were performed on a Japanese heavy-duty vehicle, and tests were conducted both with and without an oxidation catalyst fitted in the vehicle exhaust.

[0067] The types of emission tests performed were a Japanese 13 mode steady-state test cycle for heavy-duty engines, and modes 2, 5, and 8 of the Tokyo test cycle, a special test cycle representative of congested traffic patterns encountered in the Tokyo inner city environment.

[0068] The properties of the synthetic diesel fuel used for the tests were typical of diesel produced by low temperature Fischer-Tropsc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com