Time released nutritional product and method of manufacture

- Summary

- Abstract

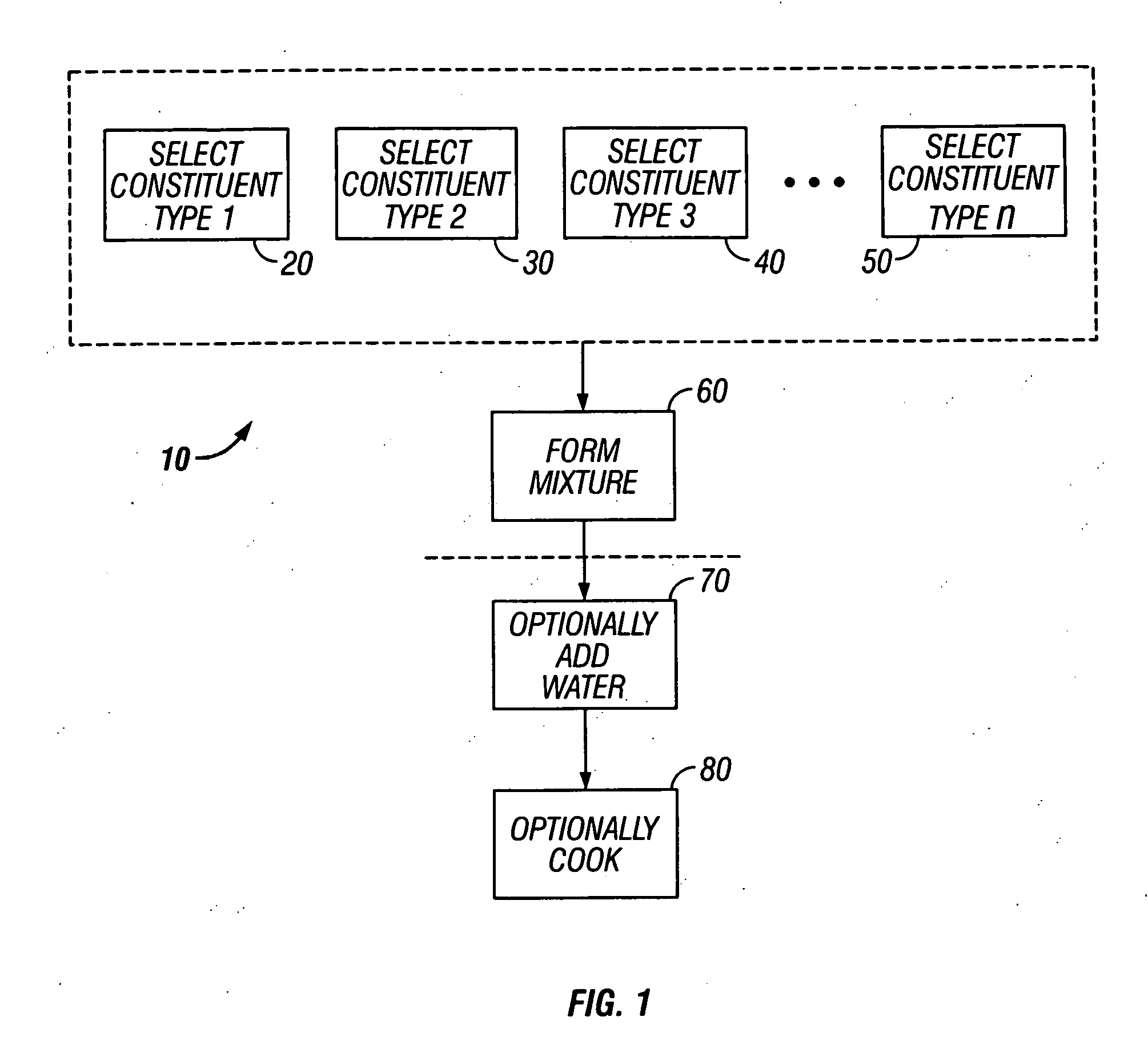

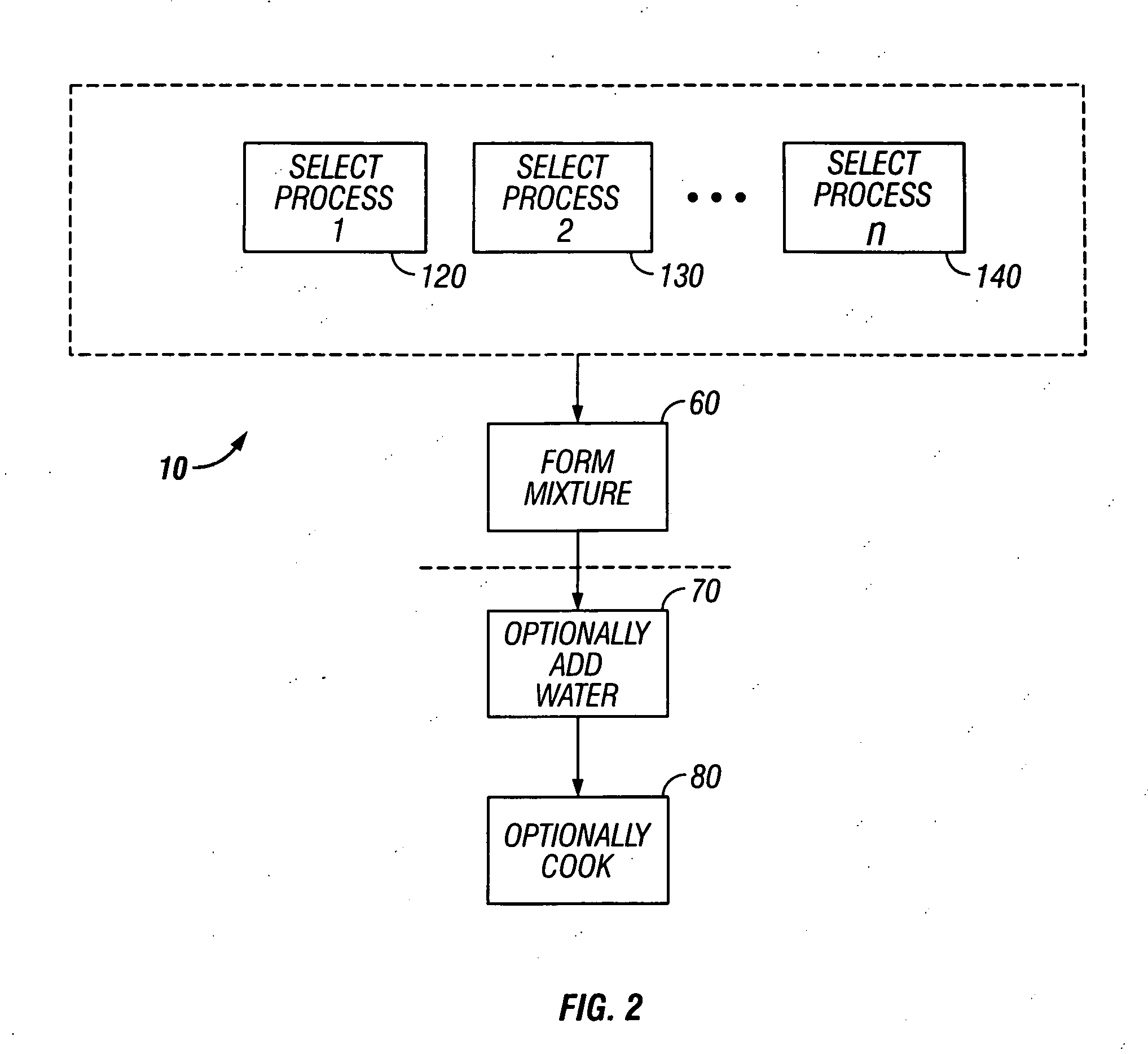

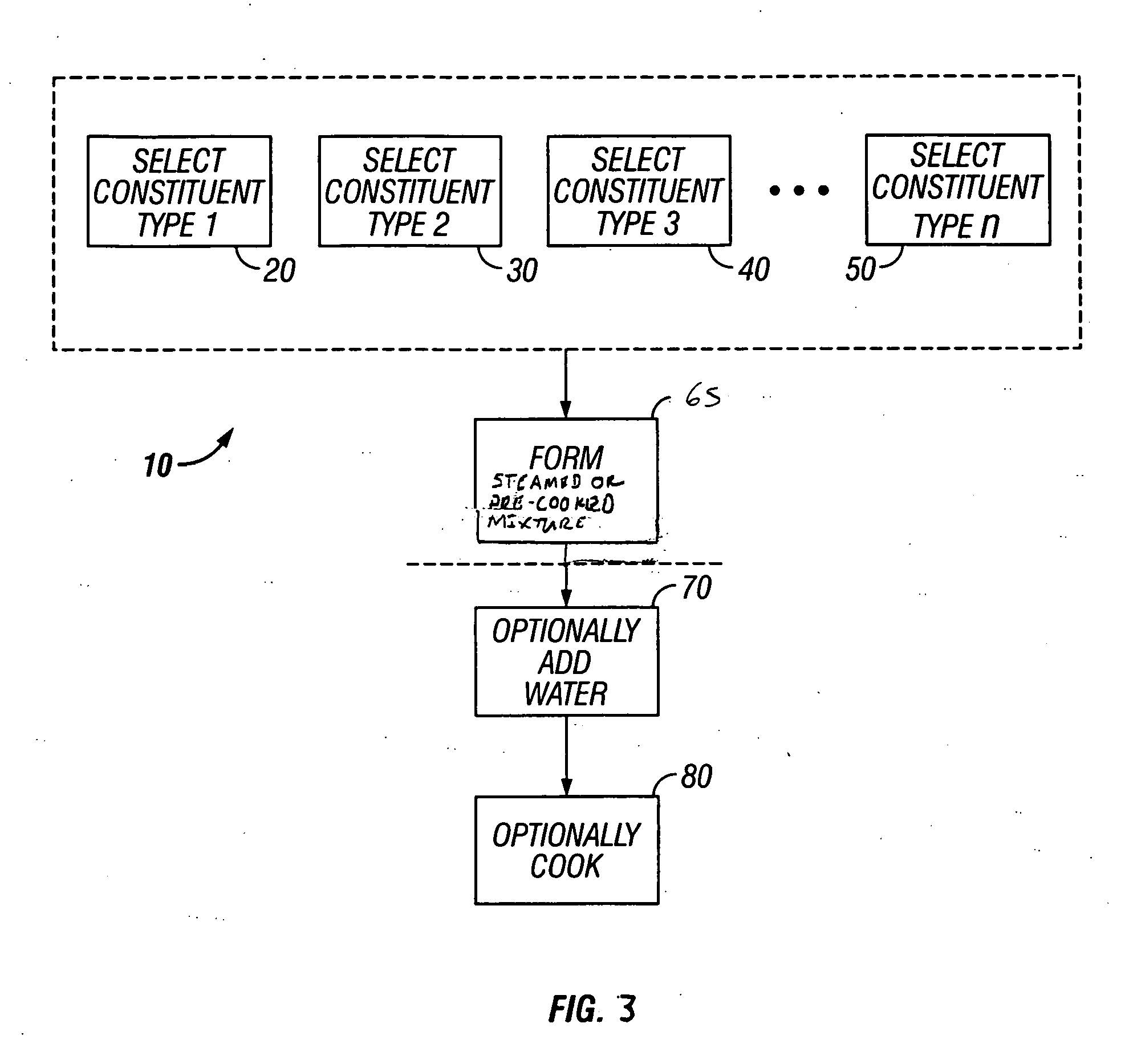

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0043] A formula providing a uniform cooking time of a blend of oats is provided as an illustration of a time released food product. The following constituents are combined to form the food composition. It should be understood the amounts are provided to show proportionality, and not limitation on the batch size. [0044]½ cup of rolled oat flakes [0045] (One half of each mill type: ¼ cup of 0.033″ and ¼ cup of 0.037″ rolled oats) [0046] 3 tablespoons of Steel Cut Oat Groats [0047] 2 tablespoons of Bumped Oat Groats [0048] 2 tablespoons of Whole Oat Groats.

[0049] In order to prepare for eating, about 2¼ cups of water can be added to the mixture and the mixture is brought to a rapid boil in a saucepan and stirred. Optionally it can be allowed to foam froth on top for 1 minute while stirring. Subsequently, optionally it can be covered while cooked, but preferred to be left uncovered. The mixture is allowed to simmer for 17 minutes, and stirred periodically.

[0050] In the above example,...

example 2

[0053] A formula providing a uniform cooking time of a blend of oats is provided. The following constituents are combined to form the food composition. It should be understood the amounts are provided to show proportionality, and not limitation on the batch size. [0054]½ Cup of rolled oats [0055] 3 Tablespoons of whole oat groats [0056] 2 Tablespoons of steel cut oats

In order to prepare for eating, about 2 cups of water can be added to the mixture and the mixture is brought to a rapid boil and stirred. Optionally it could be covered while cooked, but preferred to be left uncovered. The mixture was allowed to simmer for 17 minutes, and stirred periodically.

[0057] In the above example, the cooked cereal optionally could be eaten hot or warm, or allowed to cool. Also optionally, it could be packaged for further distribution after being cooked, such as in jars or cartons. It should be noted that the variations described above with respect to Example 1 apply equally as well to Example...

example 3

[0058] Various other examples of variations of the time release food composition as a constituent of other foods as nutritional food additives have also been considered.

[0059] Examples of such embodiments include the following, added to one cup of the food composition in accordance with the present invention, such as for example, the food composition described above in Examples 1 and 2. It should be noted that depending on the particular recipe or individual taste other amounts of the food composition can be used. [0060] 1. Beef Risotto—Add one 14 oz. can of Swanson Beef Broth (99% Fat Free) or an equivalent thereof to the food composition described in Examples 1 or 2 (Optional: Drain and add one small can or jar of sliced button mushrooms); optionally bring to a boil and simmer for 17 minutes. [0061] 2. Chicken Risotto—Serve as side dish to chicken by adding one 14 oz. can of Chicken Broth (preferably 99% Fat Free) or an equivalent thereof, to the food composition described in Exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com