Clutch plate, friction clutch, and coupling device

a clutch plate and friction technology, applied in the field of friction clutches, can solve the problems of less durability of the clutch plate and significant wear of the sliding surface, and achieve the effect of excellent durability and wear resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

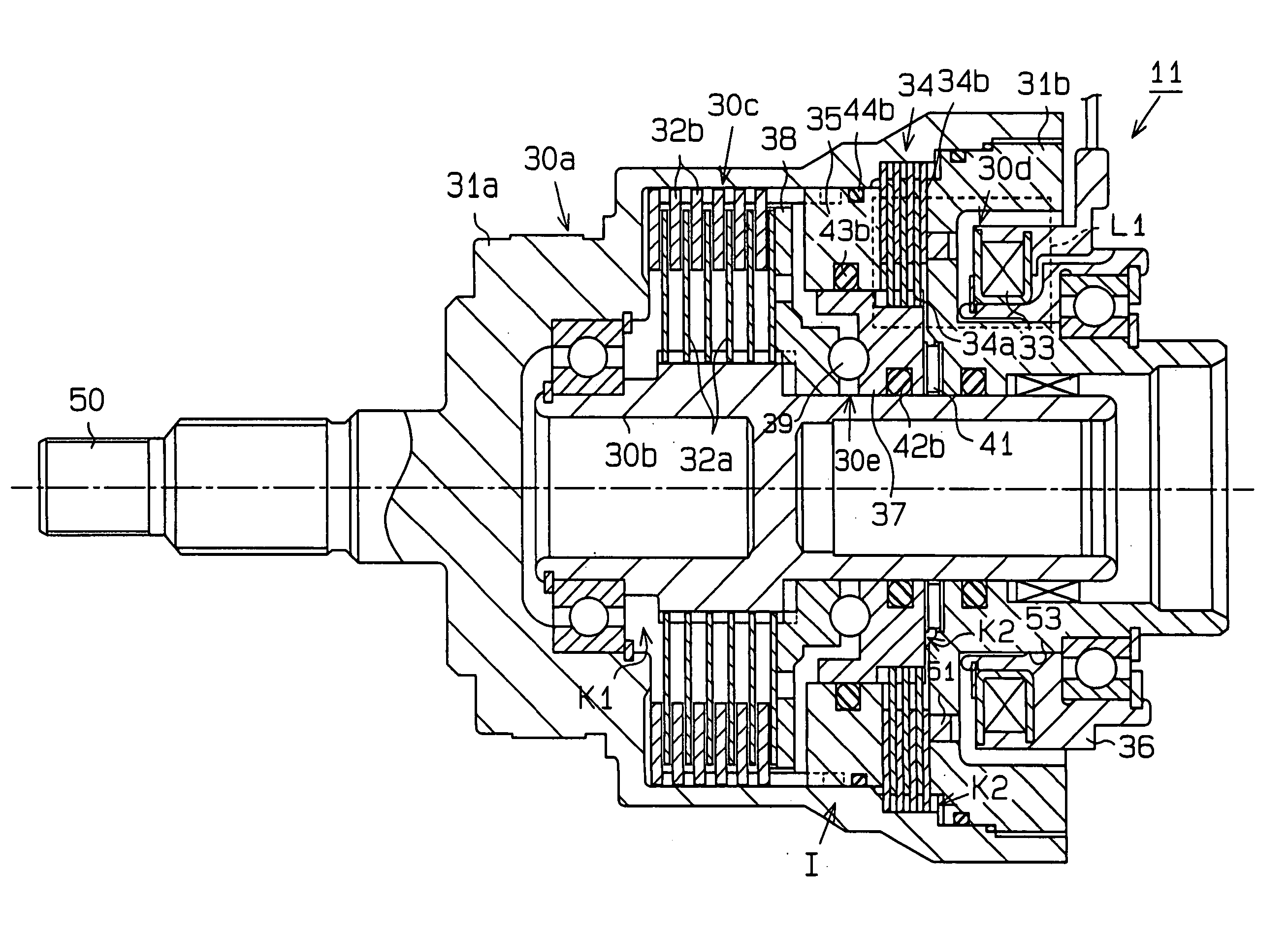

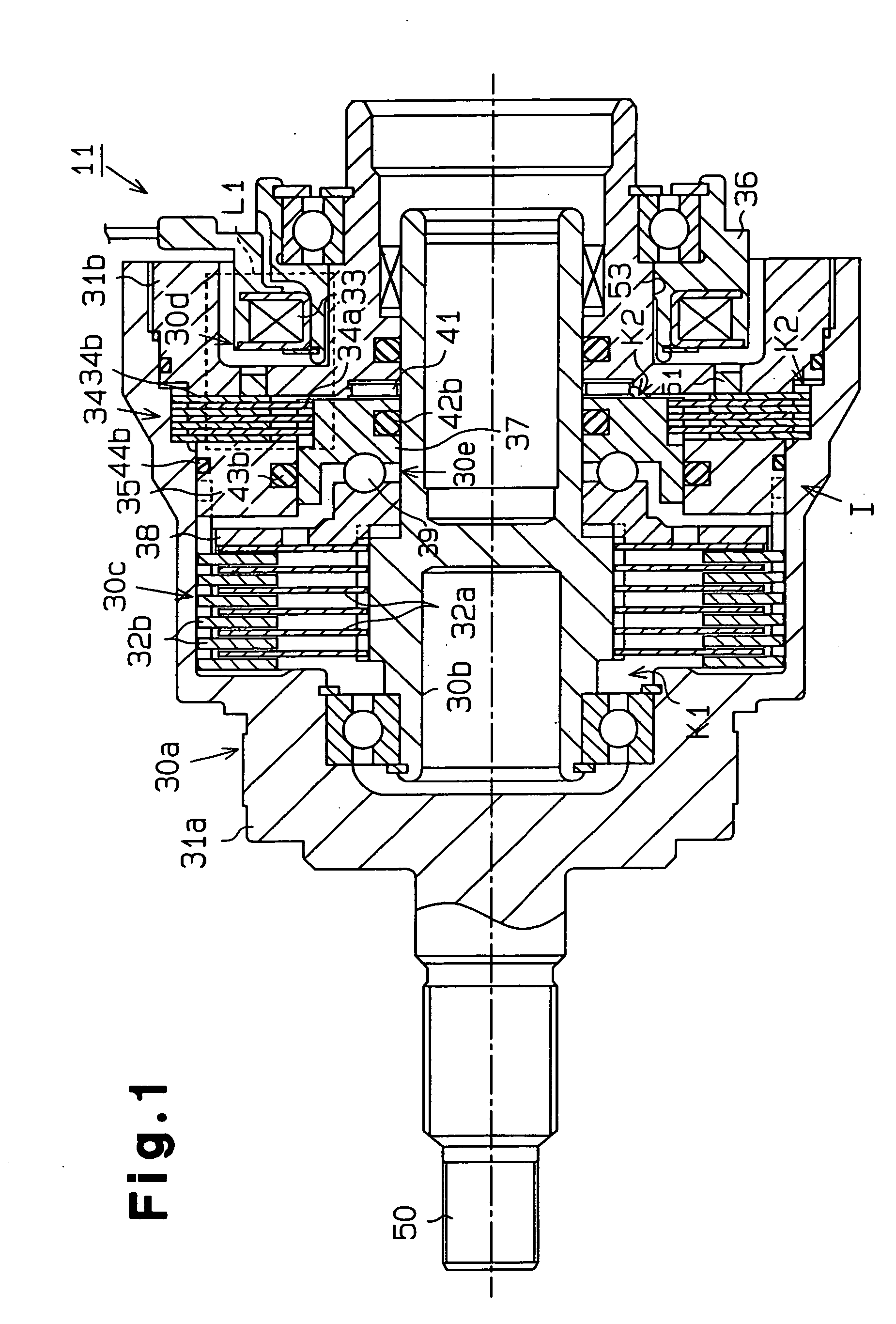

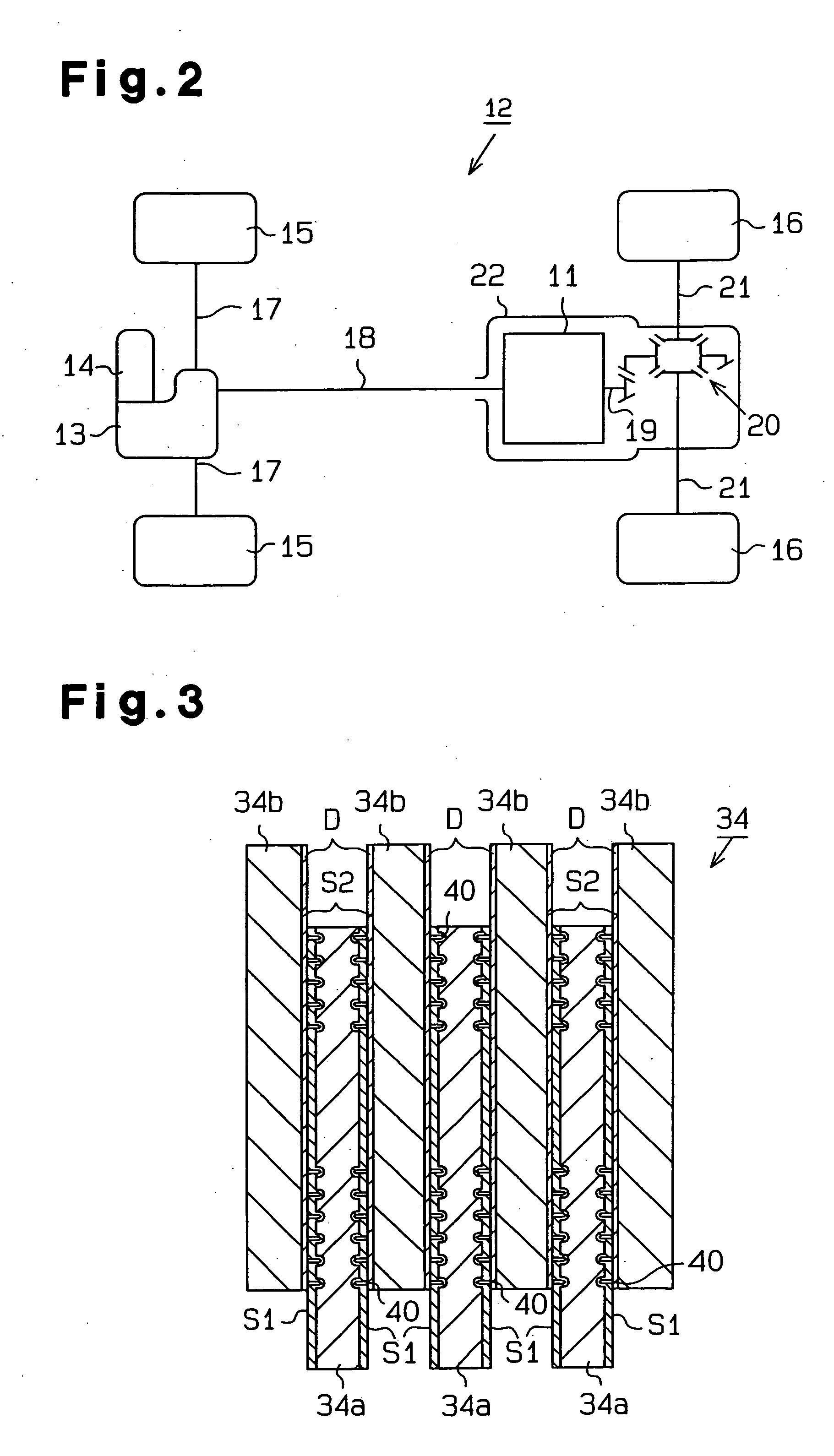

[0024] A first embodiment according to the present invention will be explained below with reference to FIGS. 1 to 8.

[0025] As shown in FIG. 2, a four-wheel drive vehicle 12 includes a coupling device 11, a trans-axle 13, an engine 14, a pair of front wheels 15, and a pair of rear wheels 16. Power of the engine 14 is transmitted to the front wheels 15 via the trans-axle 13 and a pair of axle shafts 17.

[0026] The coupling device 11 is provided on a power transmission route between the engine 14 and the rear wheels 16. Namely, the coupling device 11 is connected to the trans-axle 13 via a propeller shaft 18. A rear differential 20 is connected to the coupling device 11 via a drive pinion shaft 19. The rear wheels 16 are connected to the rear differential 20 via a pair of axle shafts 21. The coupling device 11 selectively permits and shuts off the transmission of torque from the propeller shaft 18 to the drive pinion shaft 19.

[0027] The coupling device 11 and the rear differential 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com