Bypass controlled regeneration of NOx adsorbers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

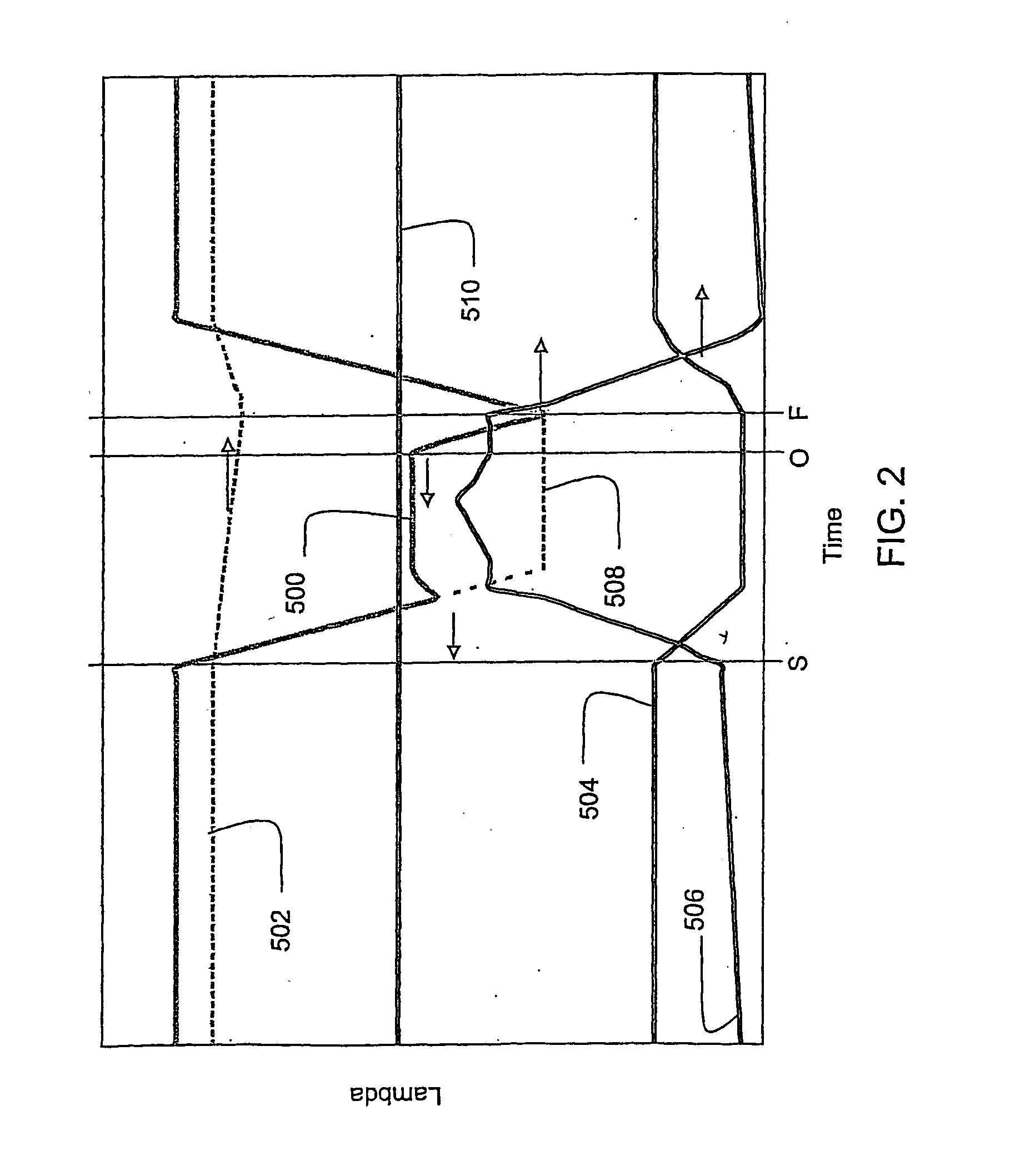

[0090] A method of regenerating a NOx adsorber that is used to treat exhaust gases created during combustion in the combustion chamber is disclosed. A hydrocarbon, preferably methane, is introduced into the exhaust line wherein the hydrocarbon is oxidized and reformed within the exhaust line to generate hydrogen, which is used to regenerate the NOx absorber. CO, as well as hydrogen, is generated during reformation of methane resulting in a regeneration mixture that includes both hydrogen and CO. The aftertreatment system is capable of directing an amount of exhaust gas to by-pass the NOx adsorber during regeneration for the purposes of reducing regeneration flow, hydrocarbon consumption, emissions, and regeneration time. Specific markers, indicative of the properties of the exhaust gas, can be used to identify completion of regeneration.

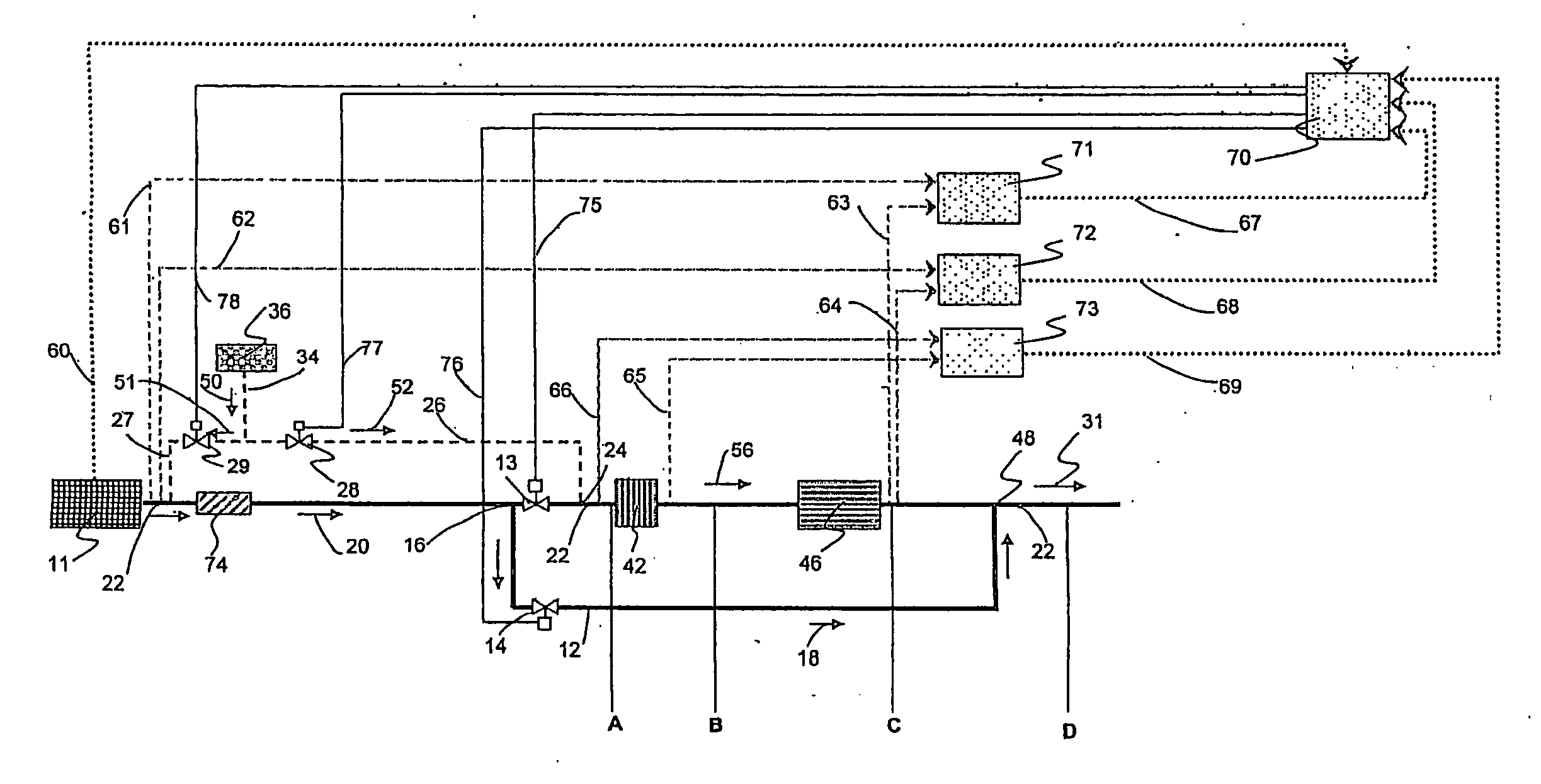

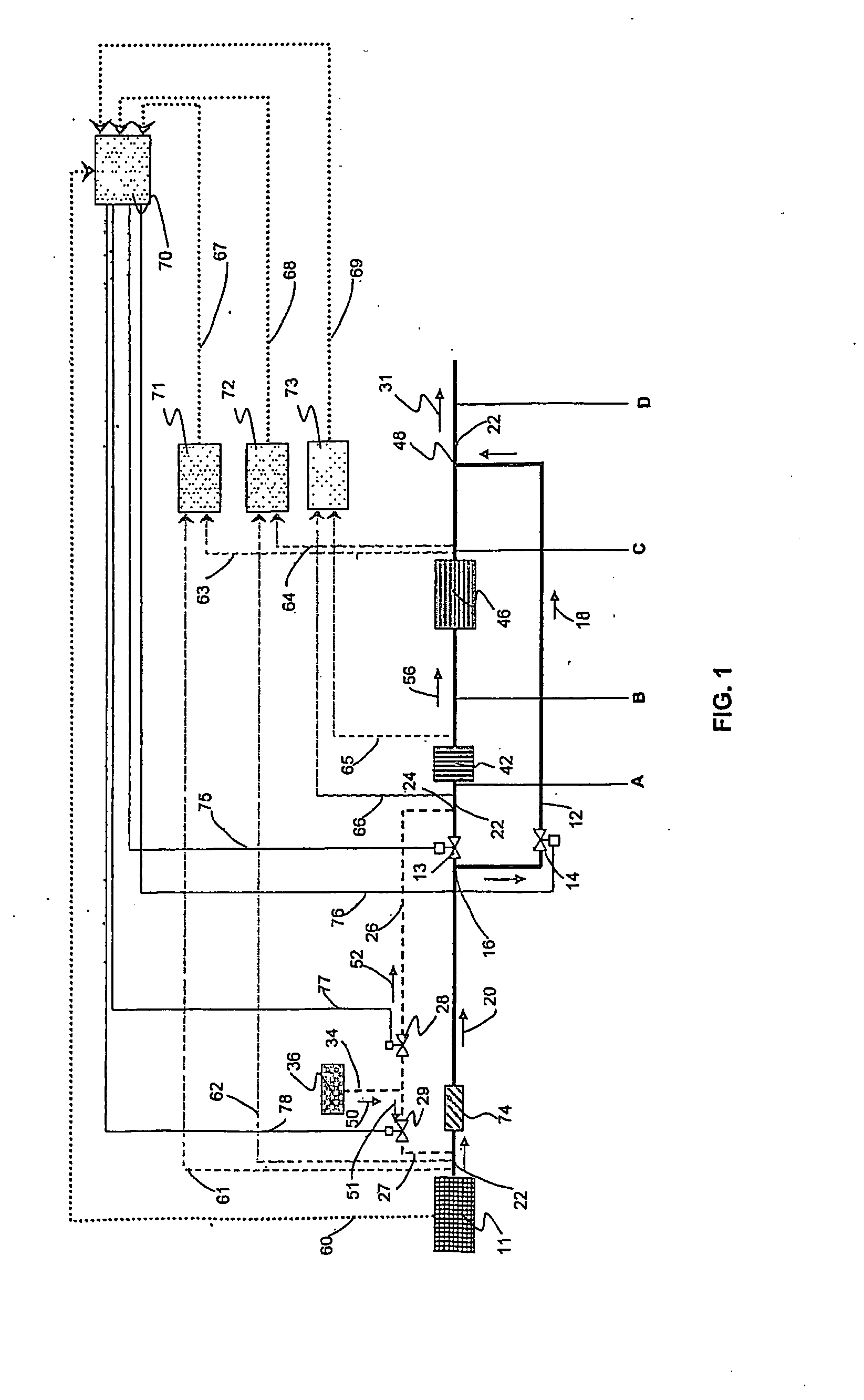

[0091]FIG. 1 is a schematic showing an aftertreatment system according to a preferred embodiment of the invention. An exhaust line 22 carries exha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com