Monocrystalline alloys with controlled partitioning

a monocrystalline alloy and controlled partitioning technology, applied in the field of nickel-based superalloys, can solve the problems of brittle topologically close phase (tcps), degrade mechanical properties, and instabilities of phase, so as to minimize the characteristics of these characteristics, prevent damage and premature failure, and maximize the efficiency of these turbine systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following description of the preferred embodiments is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

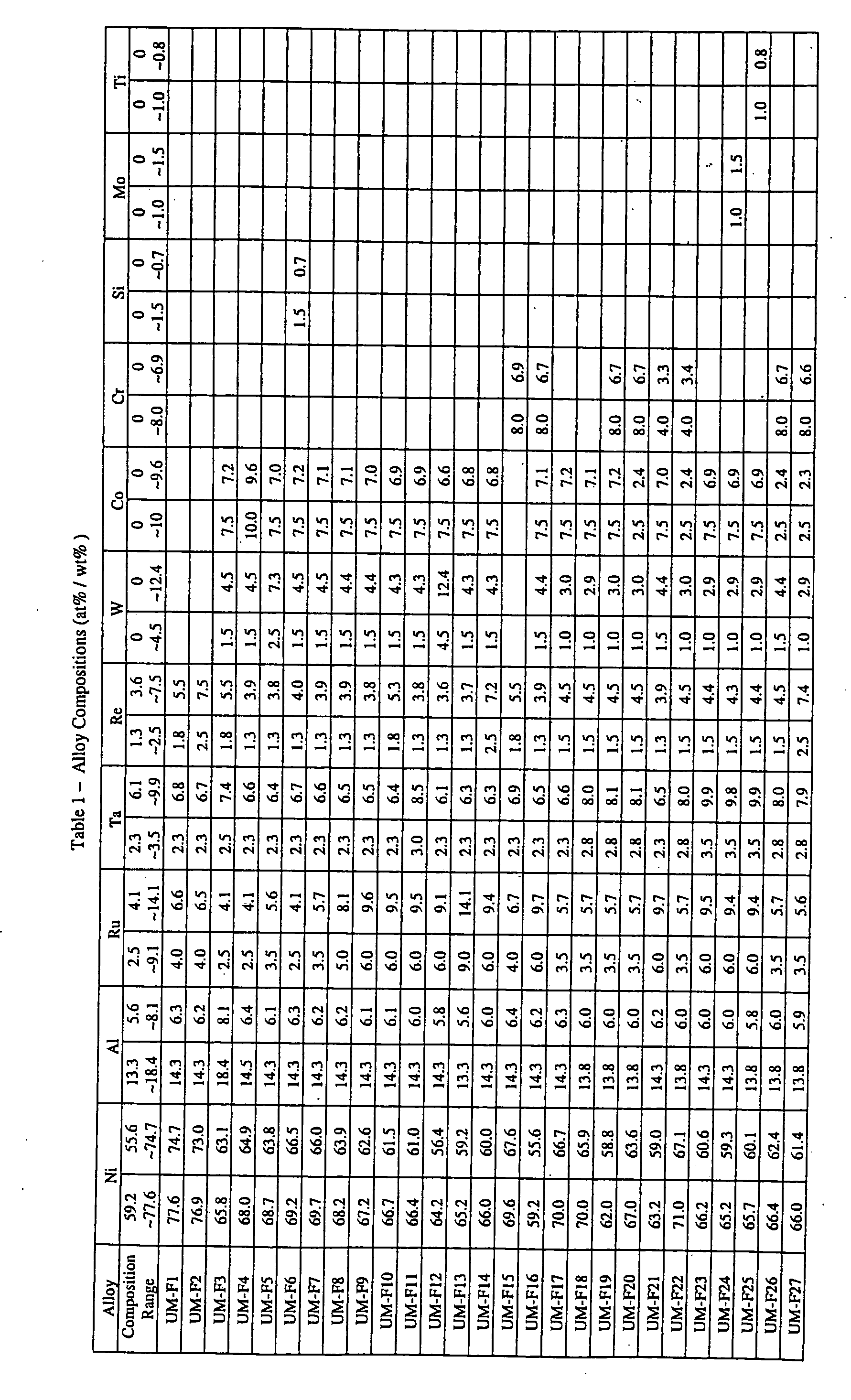

[0032] With initial reference to Table 1, a plurality of embodiments are illustrated that are within the scope of the present invention. However, it should be appreciated that these examples are non-limiting and, thus, additional compositions may be used or the values enumerated modified.

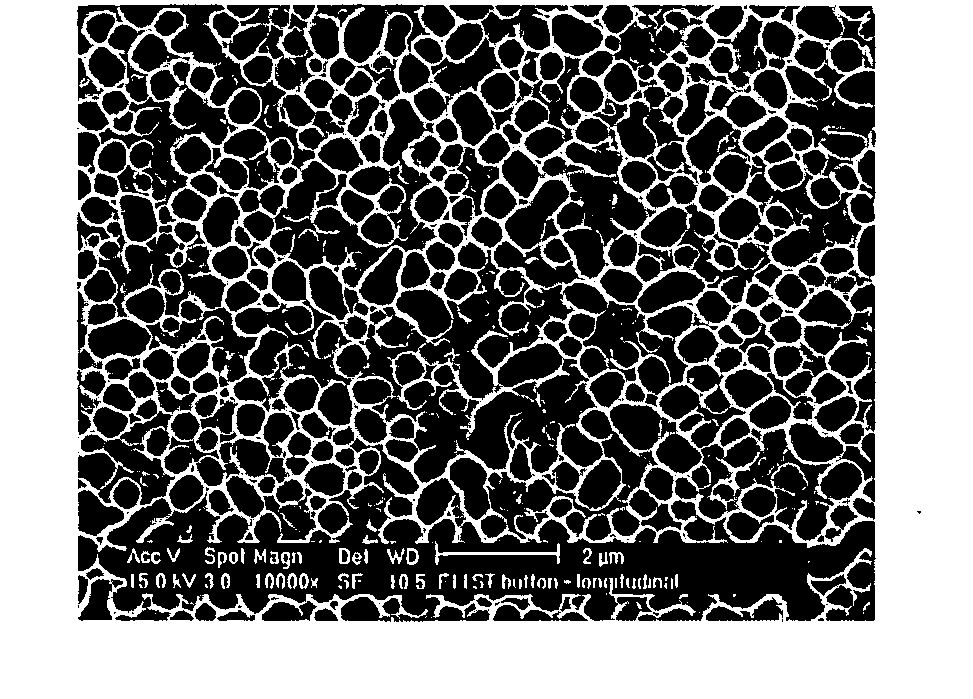

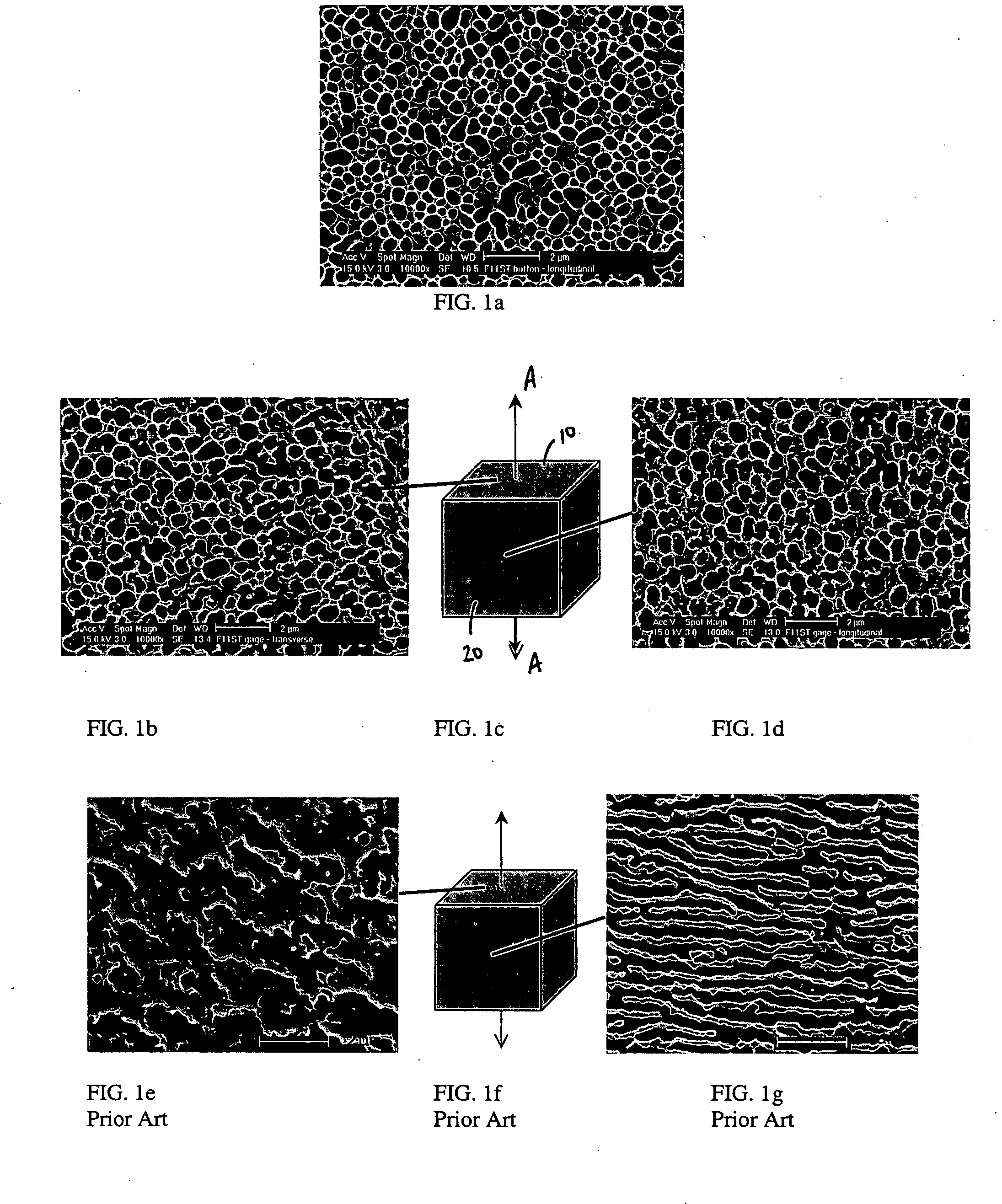

[0033] A first preferred embodiment defined by the principles of the present invention include a class of high refractory content single crystals with spherical precipitates that exhibit no rafting when subjected to external stresses. All current commercial single crystal alloys possess microstructures with γ′ cuboidal precipitates that arise due to lattice misfit between the matrix and precipitates. This misfit occurs due to strong partitioning of the Re and W to the gamma matrix phase. When subjected to tensile stresses along the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength retention | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com