Method and apparatus for in situ inspection of reformer tubes

a technology of reformer tubes and in situ inspection, which is applied in the field of in situ inspection of reformer tubes, can solve the problems of corrosive substances, tube failure, and significant replacement cost of tubes, and achieve the effects of preventing tube failure, huge potential, and optimizing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

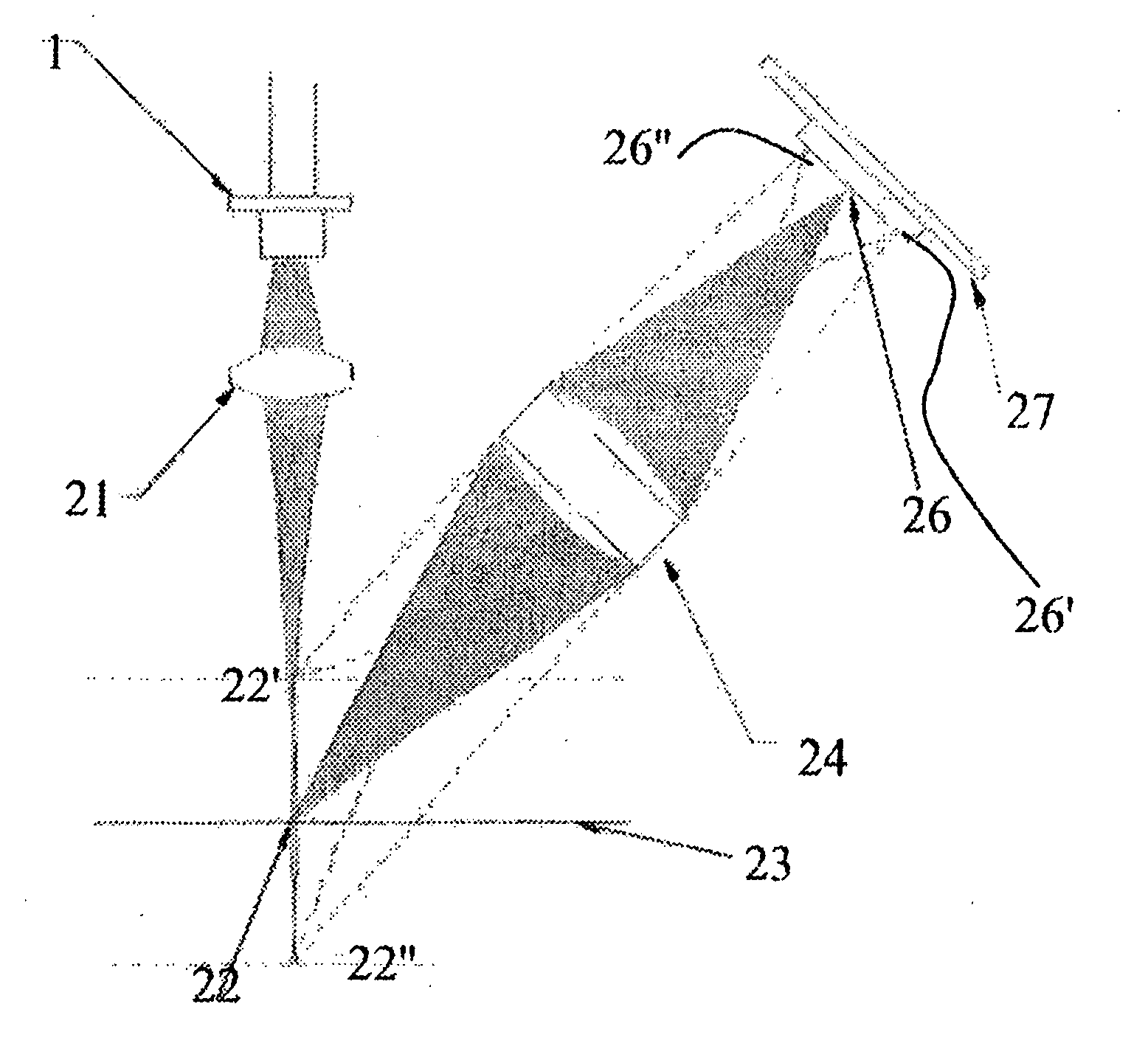

[0030]FIG. 1 is a block diagram of an embodiment of the invention. Components may be either hardware components or software modules as described below. The probe includes a light source 1. The purpose of the light source 1 is to project a spot of light on the surface (not shown) to be inspected. Light source 1 is typically a laser diode or light emitting diode (LED). A light source controller 2 is connected to light source 1. Controller 2 sets and controls the optical power level of light source 1. The power level may either be fixed or varied to produce a preset signal level.

[0031] A position sensitive photo detector (PSD) 3 is situated so as to detect the spot made by light source 1. Photo detector 3 may be a lateral effect photodiode, photodiode array, or charge coupled device (CCD). This description assumes the device chosen for 3 is a lateral effect photodiode. Detector 3 may have either one or two axes, dependant upon the specific measurement geometry. In this description onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com