Oil pump that can be driven by means of an electric motor

a technology of oil pump and electric motor, which is applied in the direction of piston pump, positive displacement liquid engine, liquid fuel engine, etc., can solve the problem that the electric motor cannot be embodied as the high-inertia electric motor of the electric locomotive drive, and achieve the effect of preventing the flow of fluid away, facilitating maneuverability, and facilitating the flow of fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

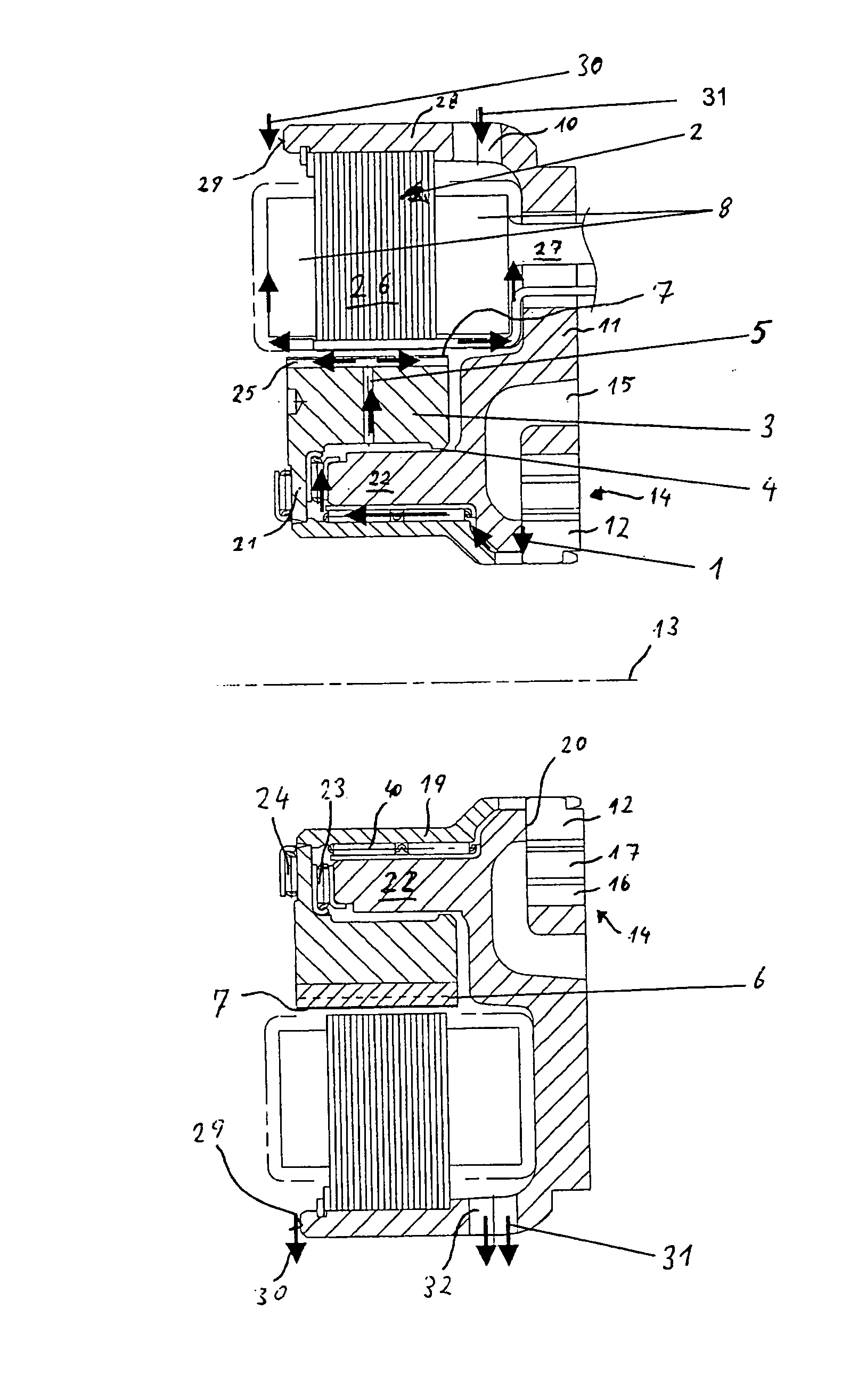

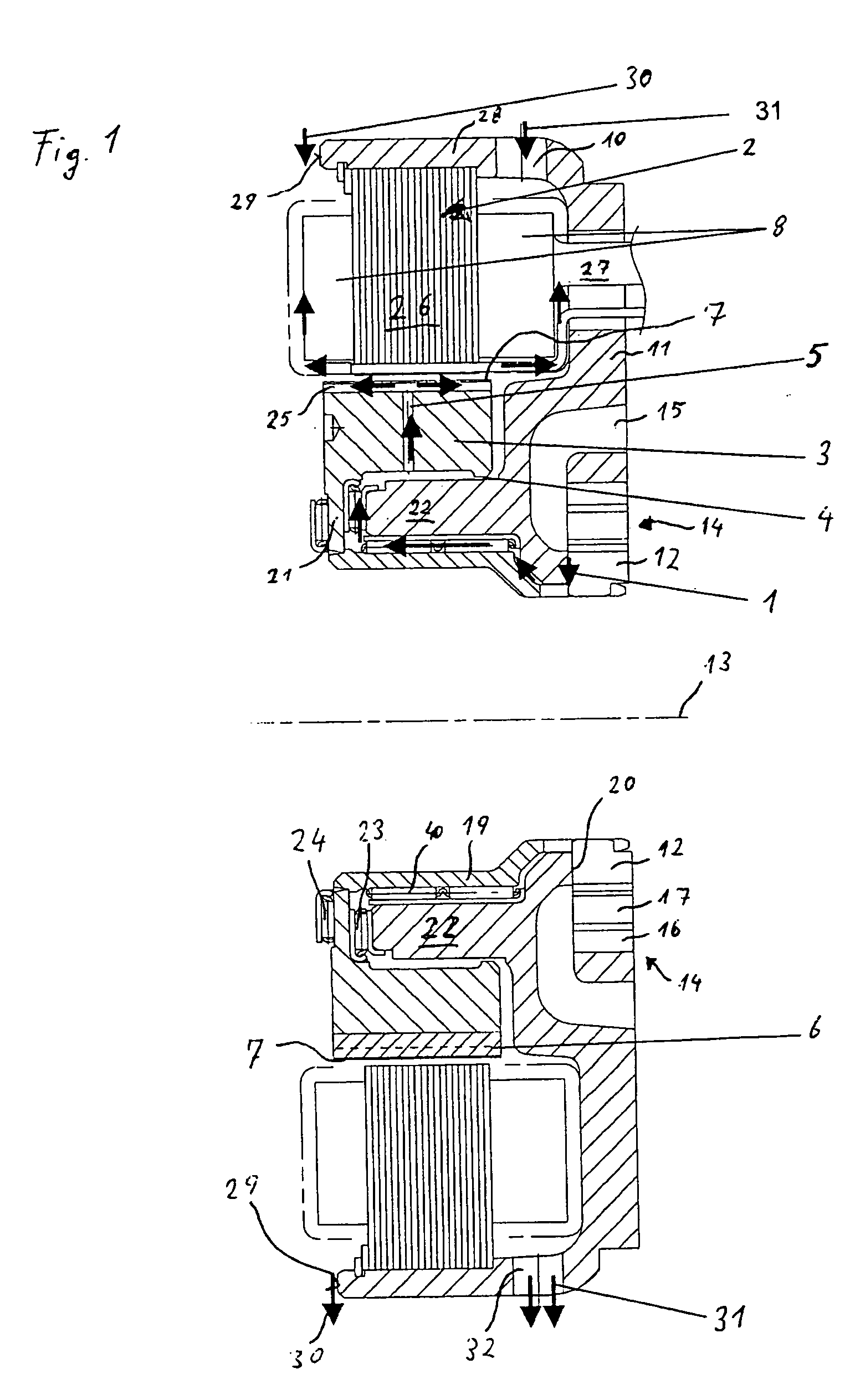

[0028] In the drawing, FIG. 1 shows a detail from a drive train of a hybrid vehicle. Such a drive train comprises an electric machine which is arranged between an internal combustion engine (not illustrated in more detail) and a gearbox of a motor vehicle. The motor vehicle may be driven either by the internal combustion engine or alternatively by the electric machine. The motor vehicle can also be operated in a “boost operating mode”, either with the internal combustion engine or the electric machine, in order to increase the driving-off / acceleration power. Such a drive train is described in PCT / EP03 / 11979, whose content is hereby incorporated by reference.

[0029] The internal combustion engine and the gearbox are arranged coaxially with respect to a central axis 13. This central axis 13 is used below as a reference axis for the expression “axial”. A pressure-regulated oil pump is located inside a gearbox housing of the gearbox. This oil pump is embodied as a crescent pump 14. A wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com