Metal alloy and metal alloy storage product for storing fast neutron emitters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

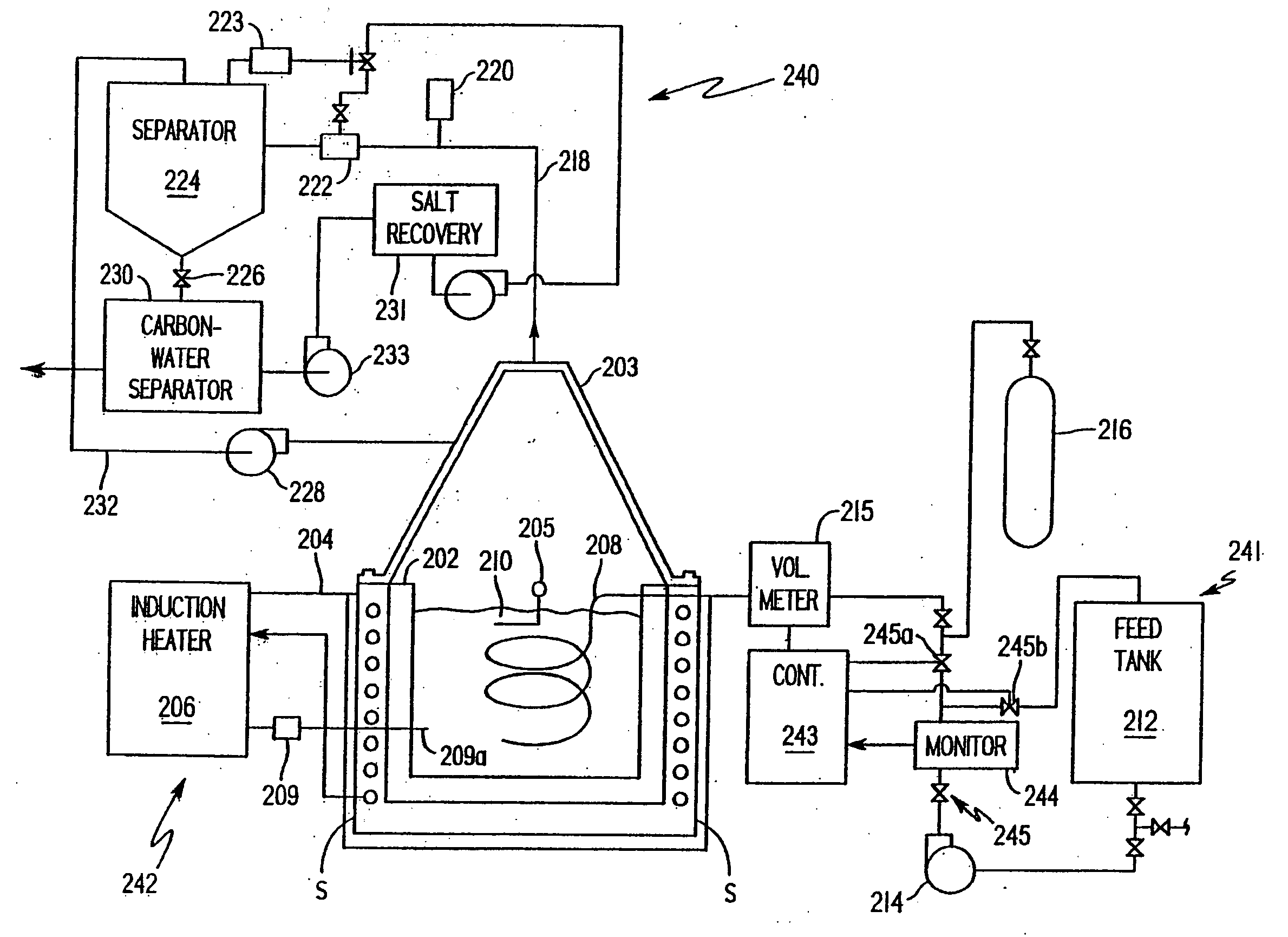

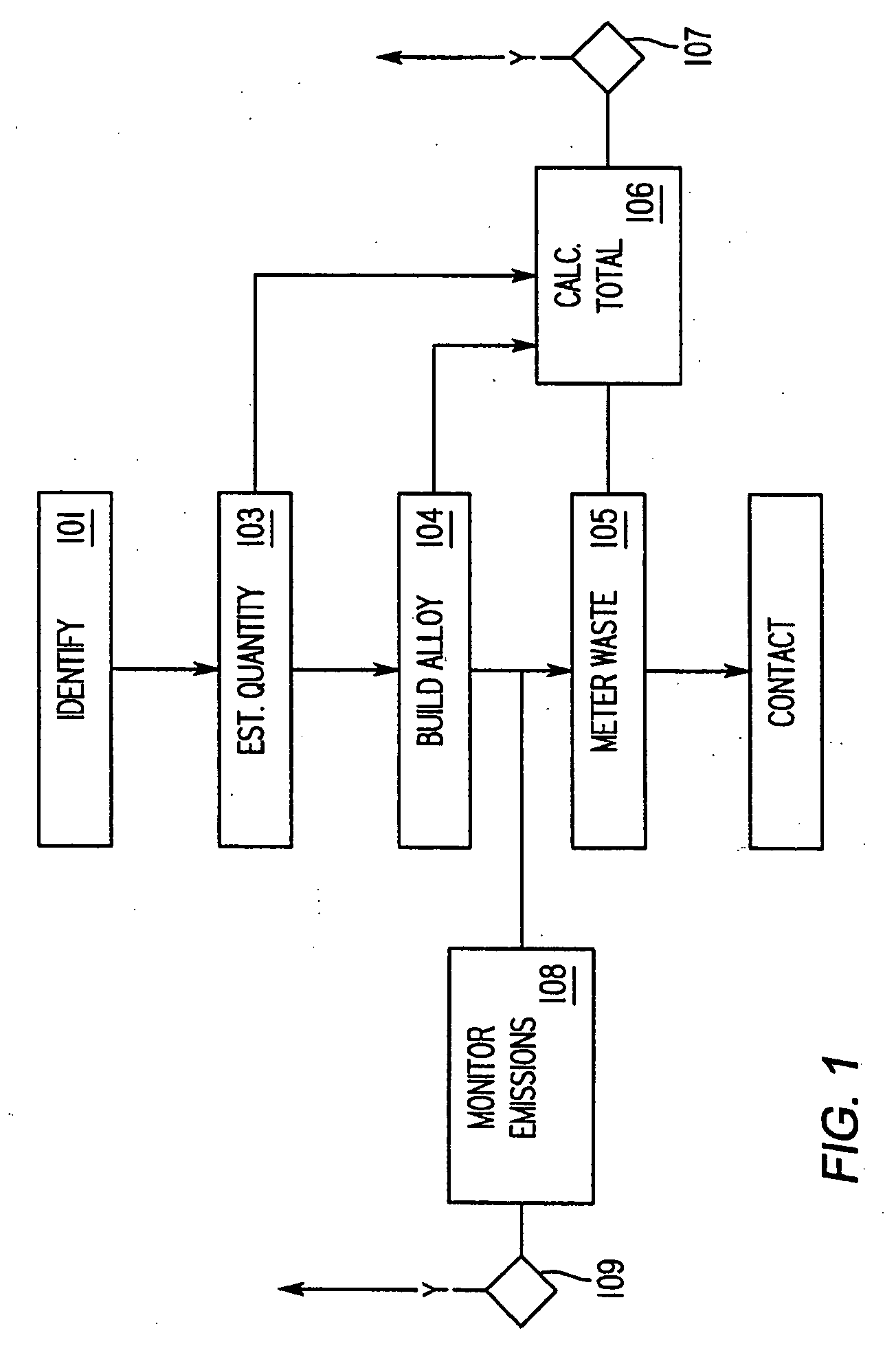

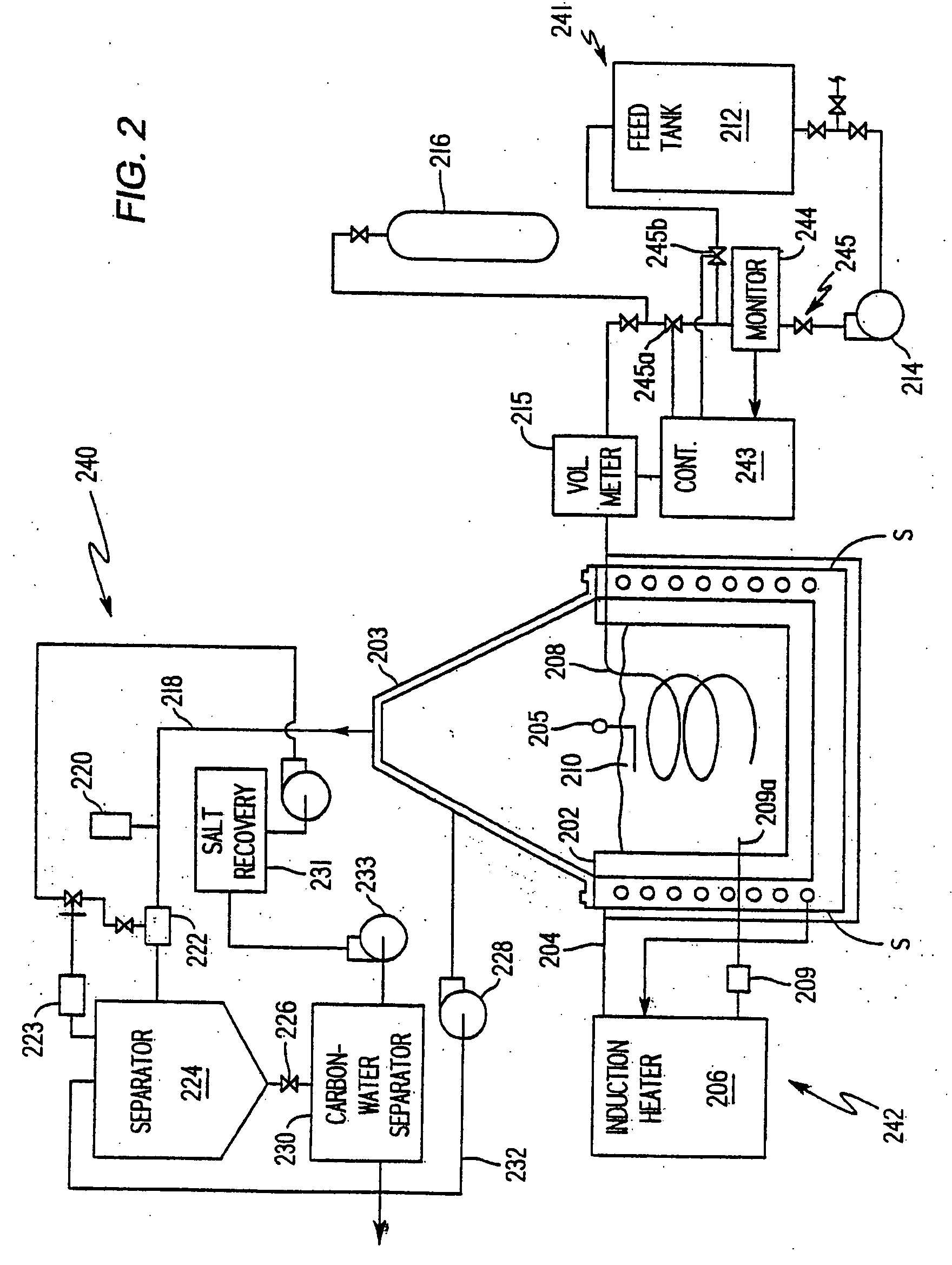

Image

Examples

example i

[0065] A waste material is analyzed with a mass spectrometer and found to comprise thorium 229 at 9 parts per million (ppm), PCBs at 500 ppm, and creosote at 1000 ppm in water. To treat one ton of the waste material, a liquid metal alloy according to the invention may include predominantly aluminum and perhaps small percentages of zinc, iron, copper, and calcium. The primary emissions of thorium 229 include alpha particles at 5.168 MeV. Beryllium 11 is added to the chemically active fraction as a corresponding absorber for the alpha emissions and lead 206 is added to absorb the primary gamma emissions from the thorium 229 and secondary gamma emissions as the alpha particles interact with materials in the bath. The 9 ppm of thorium 229 equates to 6.412 grams of the isotope per ton of the waste material. 6.42 kilograms of beryllium 11 is included in the metal bath to provide a one thousand to one correspondence between the beryllium and the expected alpha emissions. 12.84 kilograms of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Radioactivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com