Laser cooling system and method

a cooling system and laser technology, applied in the field of lasers, can solve the problems of significant turbulence, increased cost, and more difficult work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following description of exemplary embodiment(s) is merely illustrative in nature and is in no way intended to limit the invention, its application, or uses.

[0024] Although the discussion herein may not discuss all details associated with the cooling of laser systems, such details, as known by one of ordinary skill, are intended to be included within the scope of embodiments discussed herein.

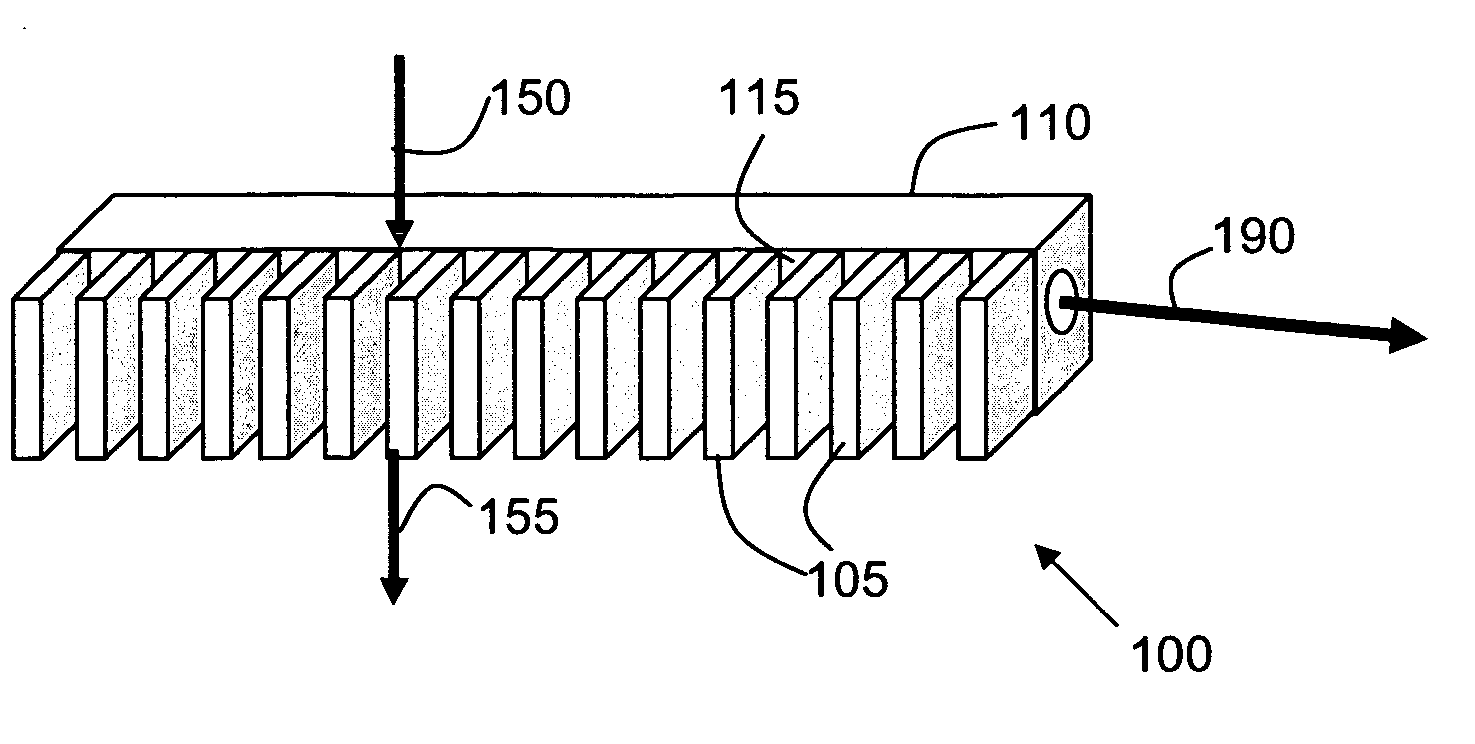

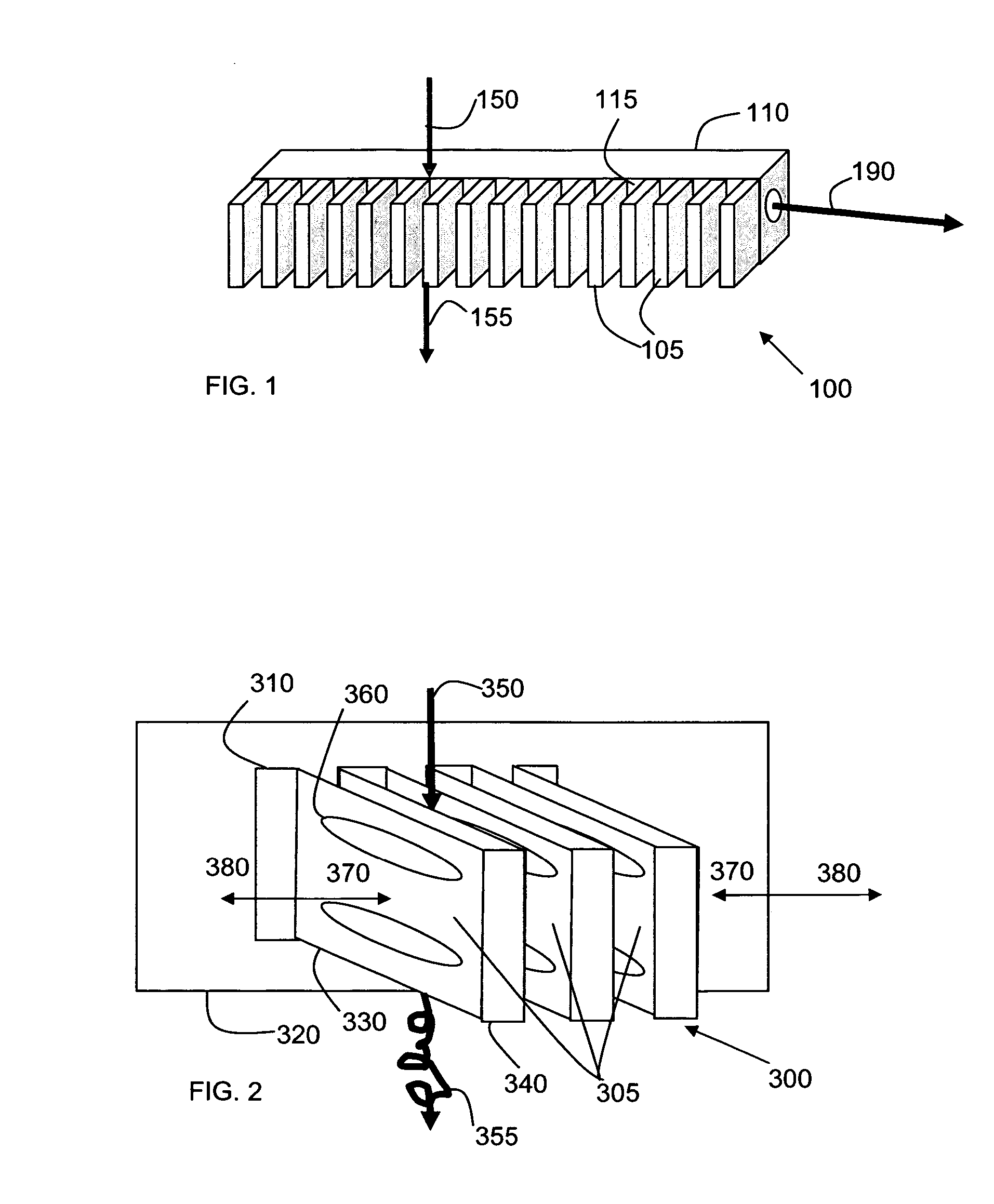

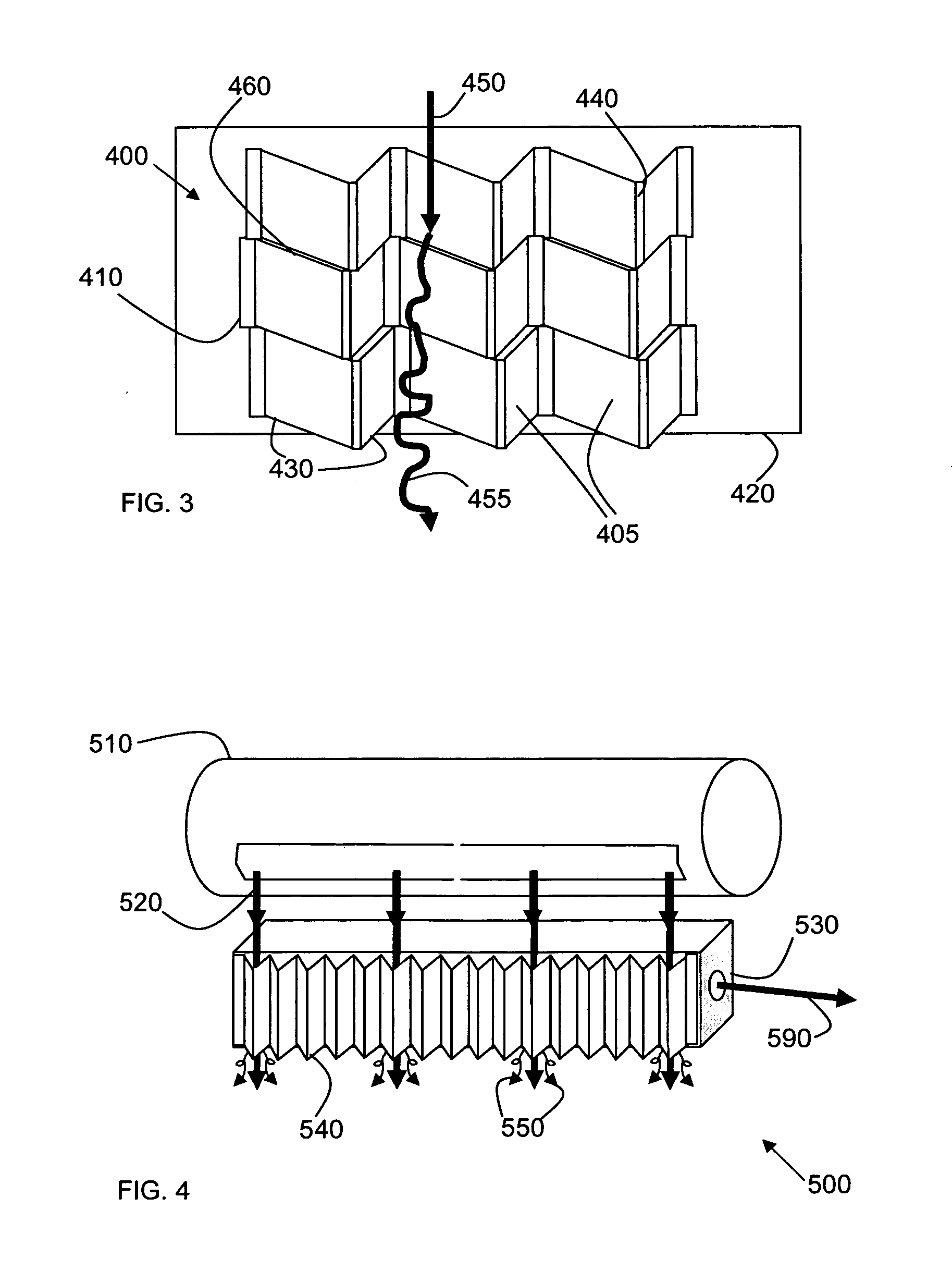

[0025] Fluid cooling of a laser system (e.g. air, gas, water, and other fluids as can be used as determined by one of ordinary skill), can involved flowing the fluid over a fin array, where the fin array conducts heat from the laser. The heated fin array in turn heats the flowing fluid, which convects the heat away from the fin array. The heated portion of the fluid flow depends upon the area of the fin array, the thermal transfer efficiency between the fins and the cooling fluid, and the volume of the fluid passing over the fin array. Laminar fluid flow has a lower heat transfer co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com