Dispersant material for mitigating crude oil fouling of process equipment and method for using same

a technology of dispersant material and process equipment, which is applied in the direction of liquid carbonaceous fuels, fuel additives, fuels, etc., can solve the problems of increasing pressure drop characteristics, reducing heat transfer efficiency, and affecting so as to inhibit and/or mitigate the fouling of process equipment, improve the quality of pibsa-pam materials, and facilitate the incorporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example i

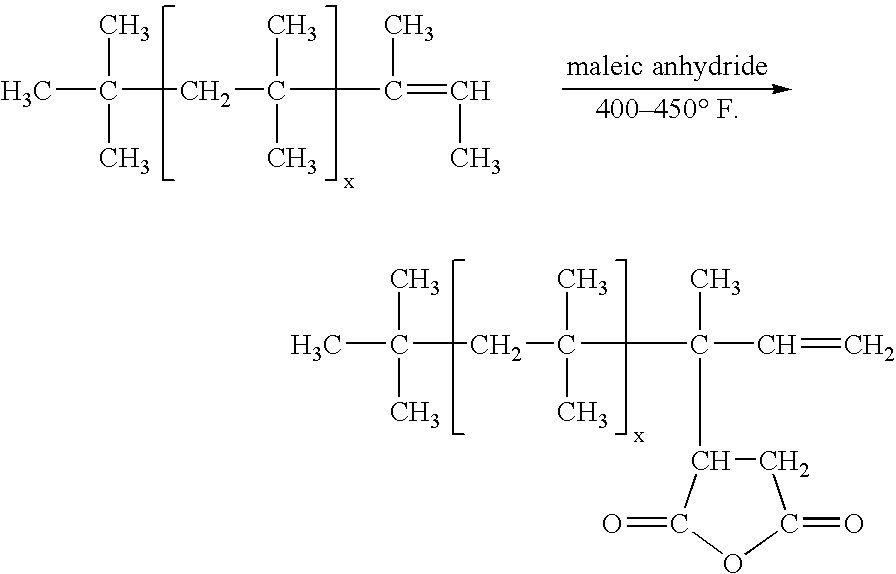

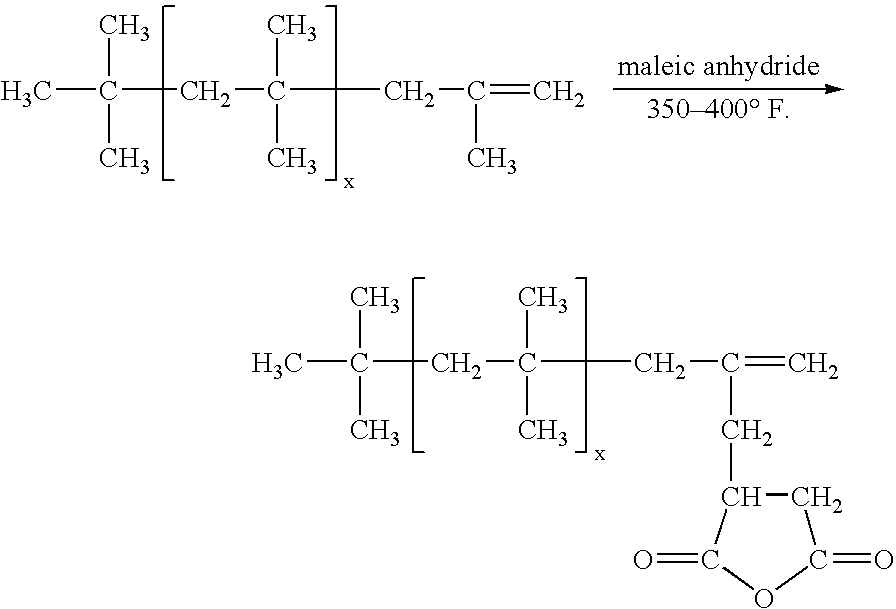

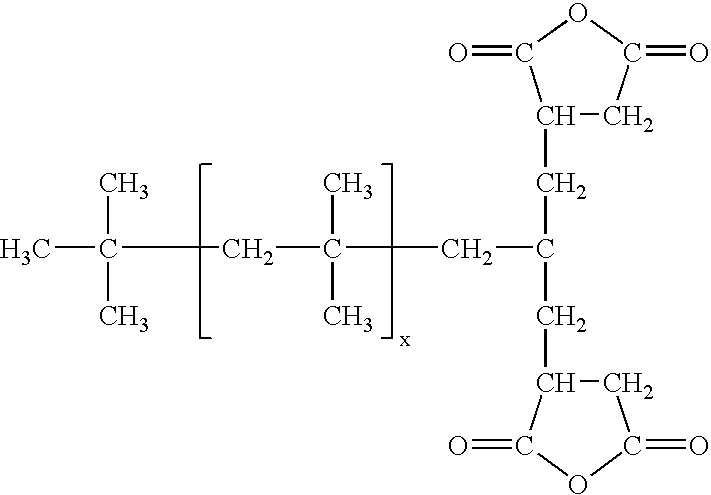

[0030] A preferred embodiment of an improved, high quality PIBSA-PAM material produced from a clean, high quality PIBSA made using a PIB having a significant concentration of vinylidene double bonds is prepared in the following manner: [0031] 1. 433 g of an HR-PIB product having an MN of 950 and an alpha vinylidene content of 83.6% is charged into glass reactor and the reactor is heated to 300° F. for 1 hour while a vacuum and N2 sweep are applied thereto. [0032] 2. 67.04 g of Maleic Anhydride at 300° F. is added to the HR-PIB in the reactor and the reaction mixture is heated to 450° F. [0033] 3. The reaction mixture is maintained at a reaction temperature of 450° F. for 4.5 hours and thereafter a vacuum and N2 sweep are applied to the reactor for 1 hour to strip away any unreacted Maleic Anhydride. [0034] 4. The product is a Polyisobutylene Succinic Anhydride (PIBSA). [0035] 5. 309.3 g of the PIBSA thus prepared is transferred to another glass reactor and heated to 250° F. [0036] 6...

example ii

Thermal Fouling Testing of Untreated Crude Oil

[0044] The thermal fouling characteristics of untreated crude oil is determined using the TFTM described above. The thermal fouling test results show that the crude oil used in connection with these tests is a relatively high fouling crude oil. Test conditions and test fouling results are presented below.

Exchanger heater metal temperature700° F.Liquid outlet temperature510° F.Unit operating pressure800 psigExchanger heater metal typeC / S 1018Oil flow3.0 cc / minTest time180 minutesMeasured fouling 70° F.

example iii

Thermal Fouling Testing of Crude Oil Containing Conventional PIBSA-PAM Antifouling Agent

[0045] A crude oil identical to the crude oil tested in Example I was blended with 100 ppm (wt) of the acquired PIBSA-PAM that was made with conventional PIB. This conventional commercially available PIBSA-PAM had the following characteristics:

Average molecular weight (MN)1300Carbon content82.87 wt %Hydrogen content12.89 wt %Oxygen content 0.90 wt %Nitrogen content 4.8 wt %Carbon / Hydrogen atomic ratio 0.53Total base number114 mg / gm

[0046] The TFTM was used to determine the thermal fouling of the treated crude oil using exactly the same operating conditions as used in Example II. Test results show that the crude oil treated with conventional PIBSA-PAM has reduced fouling characteristics as compared with the untreated crude oil. Test operating conditions and results are presented below.

Exchanger heater metal temperature700° F.Liquid outlet temperature514° F.Unit operating pressure800 psigExcha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com