Solar cells having a transparent composition-graded buffer layer

a technology of composition and buffer layer, which is applied in the field of solar cells having a composition graded buffer layer, can solve the problems of degradation the requirement of nearly perfect lattice matching, and the deterioration of the overall efficiency of the solar cell, so as to improve the performance improve the efficiency of the individual subcell, and reduce internal stresses and strains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

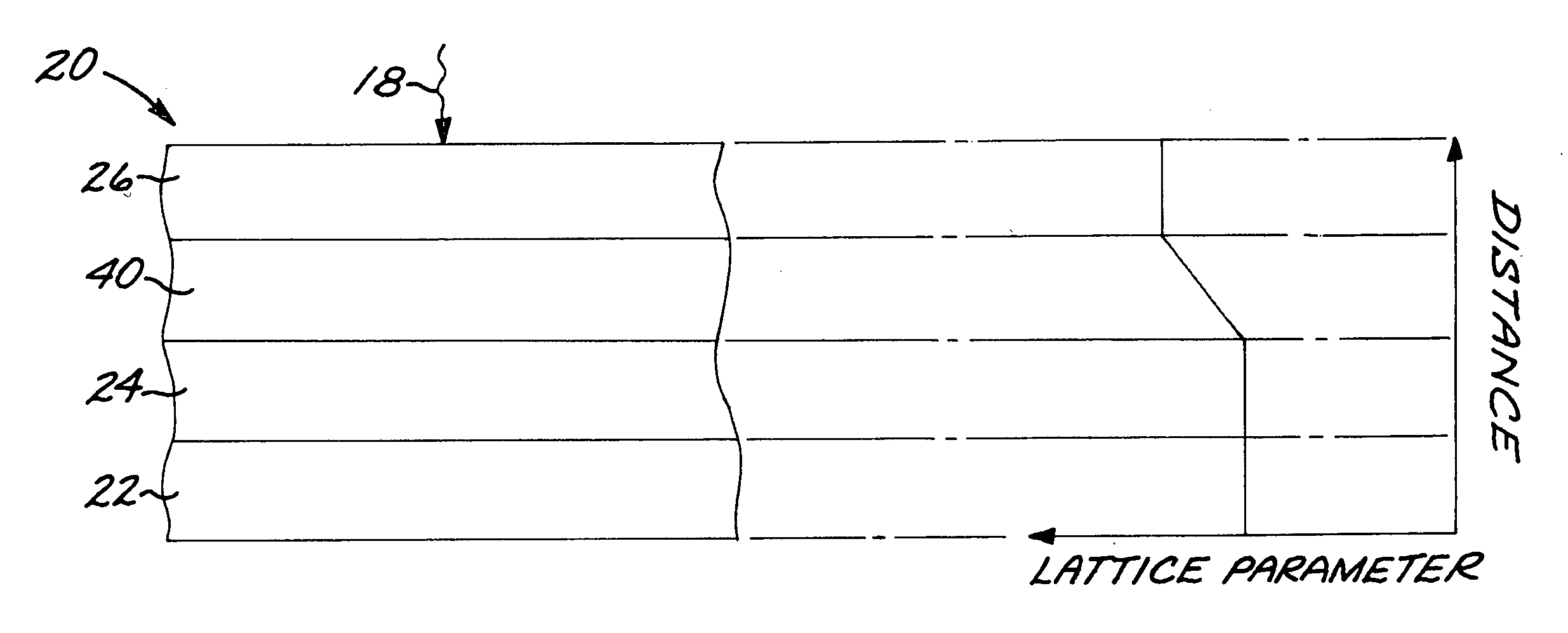

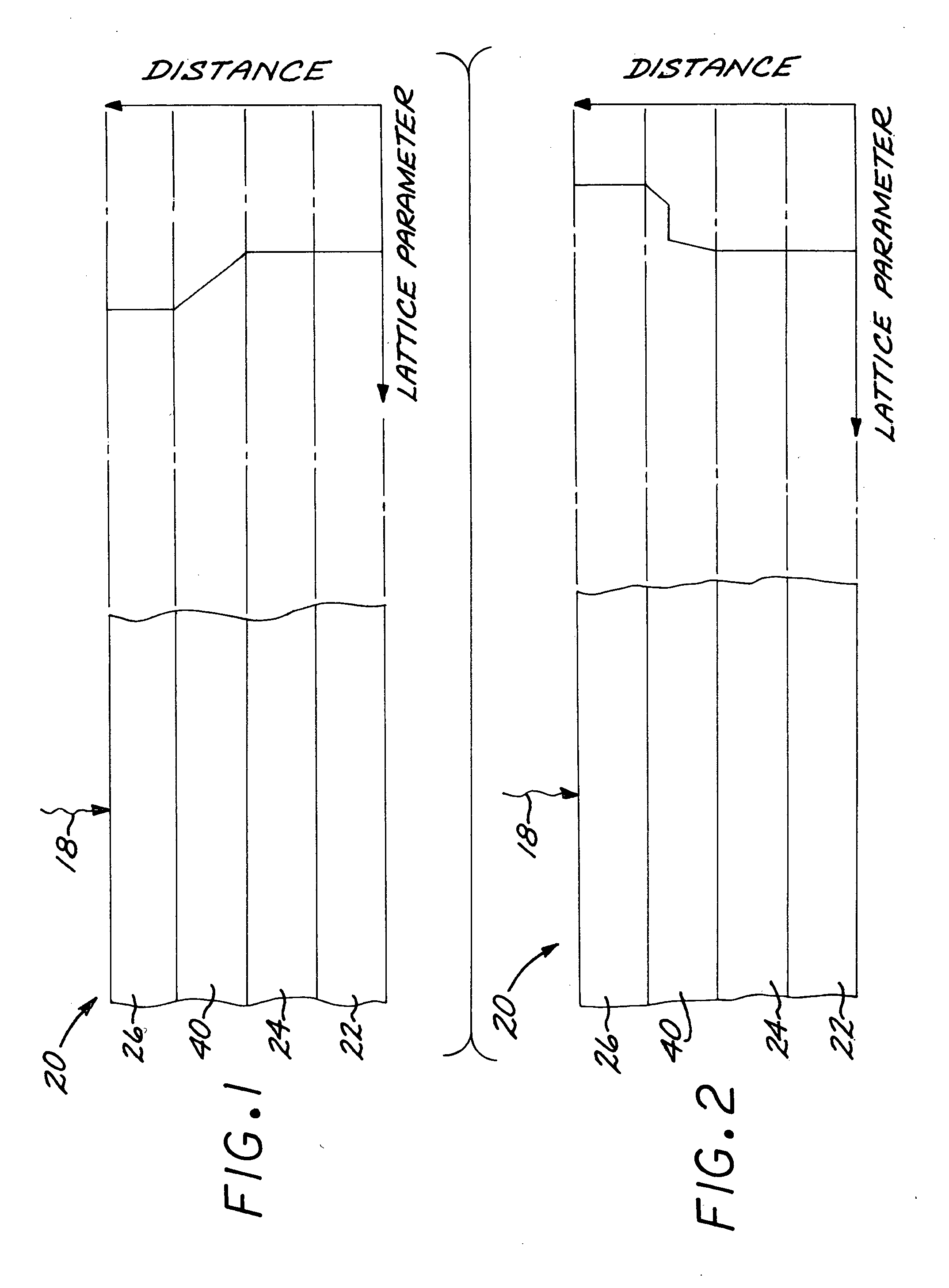

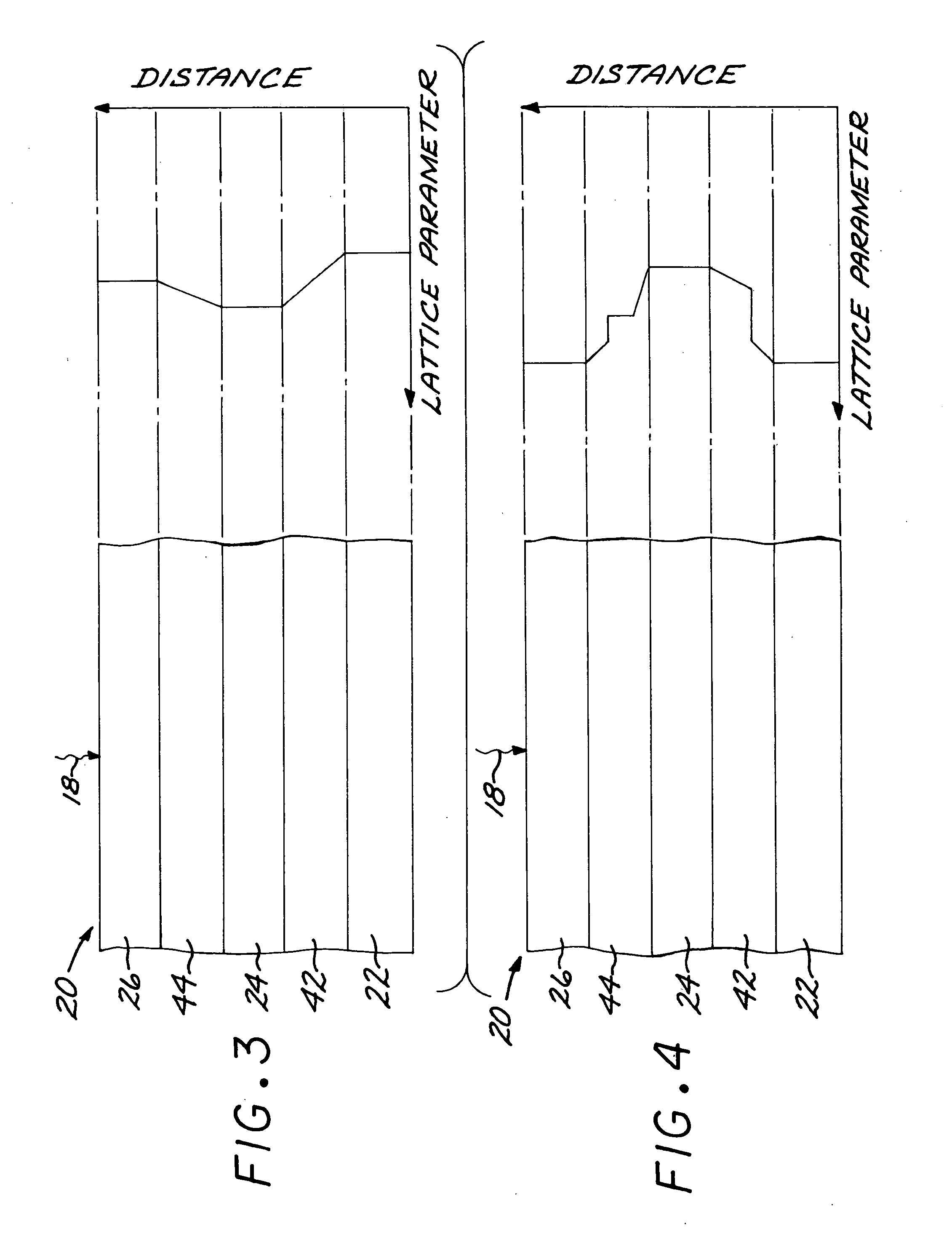

[0039]FIGS. 1-10 depict multijunction solar cells that incorporate the present approach. In each of these multijunction solar cells, sunlight from the sun is incident in a direction 18, and there are electrodes (not shown) to conduct the electrical current generated by the solar cell. When used to compare two layers, “upper” or “above” or “overlying” refers to a layer closer to the sun, and “lower” or “below” or “underlying” refers to a layer further from the sun or other source of illumination.

[0040]FIG. 1 depicts a first embodiment of a multijunction solar cell 20. The multifunction solar cell 20 includes a first layer 22 having a first-layer-lattice parameter. The first layer 22 may be an inert substrate, or it may be a photoactive layer made of a photoactive first-layer material. The multijunction solar cell 20 further includes a second layer 24 having a second-layer lattice parameter different from the first-layer lattice parameter. The second layer 24 includes a photoactive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com