Method of forming a lead-free bump and a plating apparatus therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

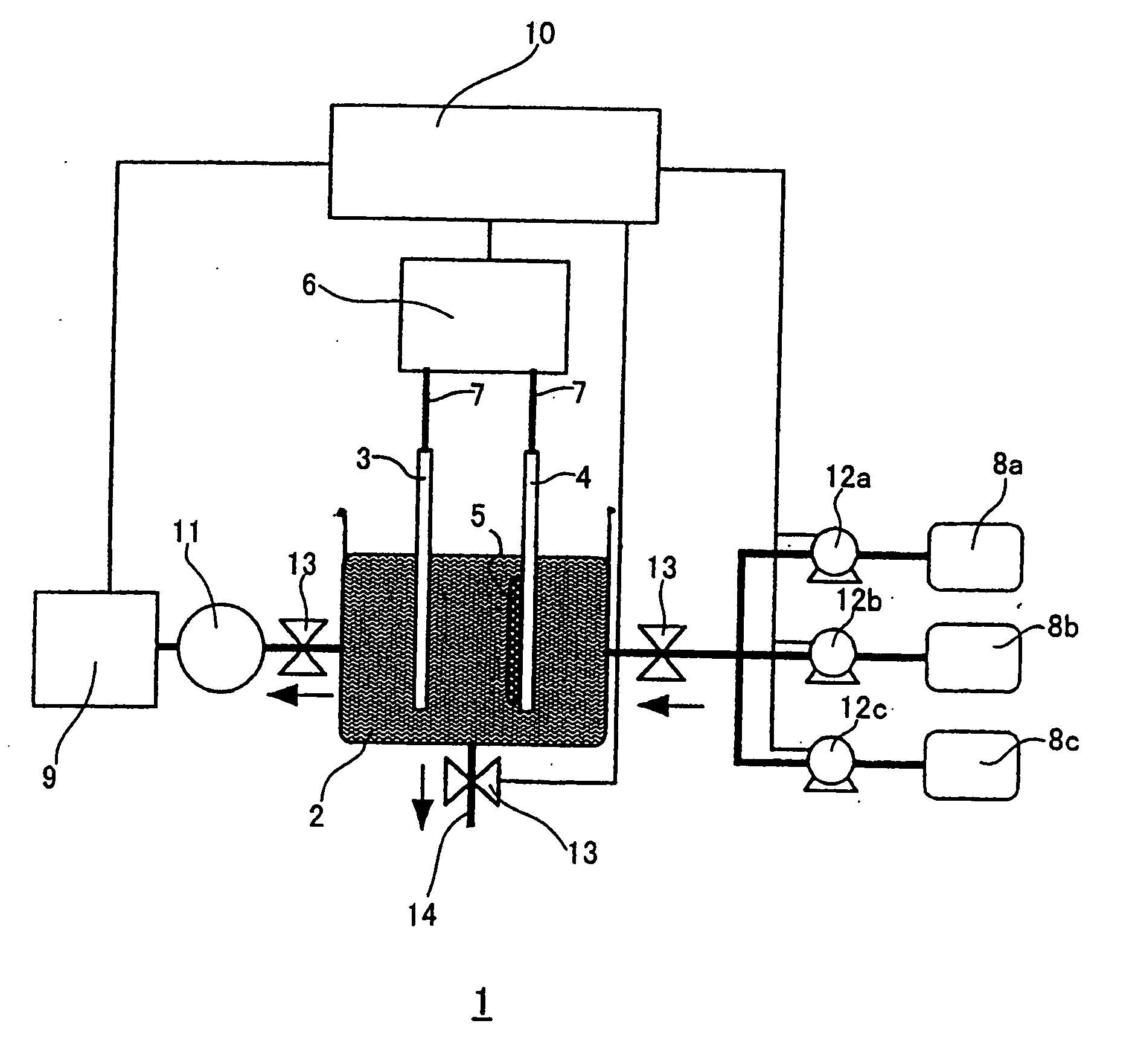

Image

Examples

example 1

(1) Preparation of Sn—Ag Bump:

[0067] A resist was applied to a thickness of 120 μm on a wafer in such a manner that a number of holes having an opening size of 100 μm are formed, thereby preparing a sample. The plating area of the sample was 149.63 cm2. Plating of the sample was carried out by the following steps under the following conditions.

[0068] (Plating Steps)

[0069] Degassing (10 min)→Pre-cleaning with 10% sulfuric acid (1 min)→Copper plating→Water-cleaning→Ni plating Water-cleaning→Sn—Ag alloy plating

[0070] (Plating Conditions)

[0071] (a) Cu Plating

[0072] Plating bath composition:

Cu2+220g / LH2SO4200g / LHCl5mL / LAdditive5mL / L

[0073] Plating temperature: 25° C.

[0074] Stirring: mechanical stirring (paddle stirring speed 10 m / min)

[0075] Circulation of plating solution: flow rate 2.5 L / min

[0076] Electrode: copper anode, interpolar distance about 7.5 mm, anode mask ø 250 mm

[0077] Cathode current density (total current): 5 A / dm2 (7.48 A)

[0078] Plating thickness: 2 μm

[0079]...

example 2

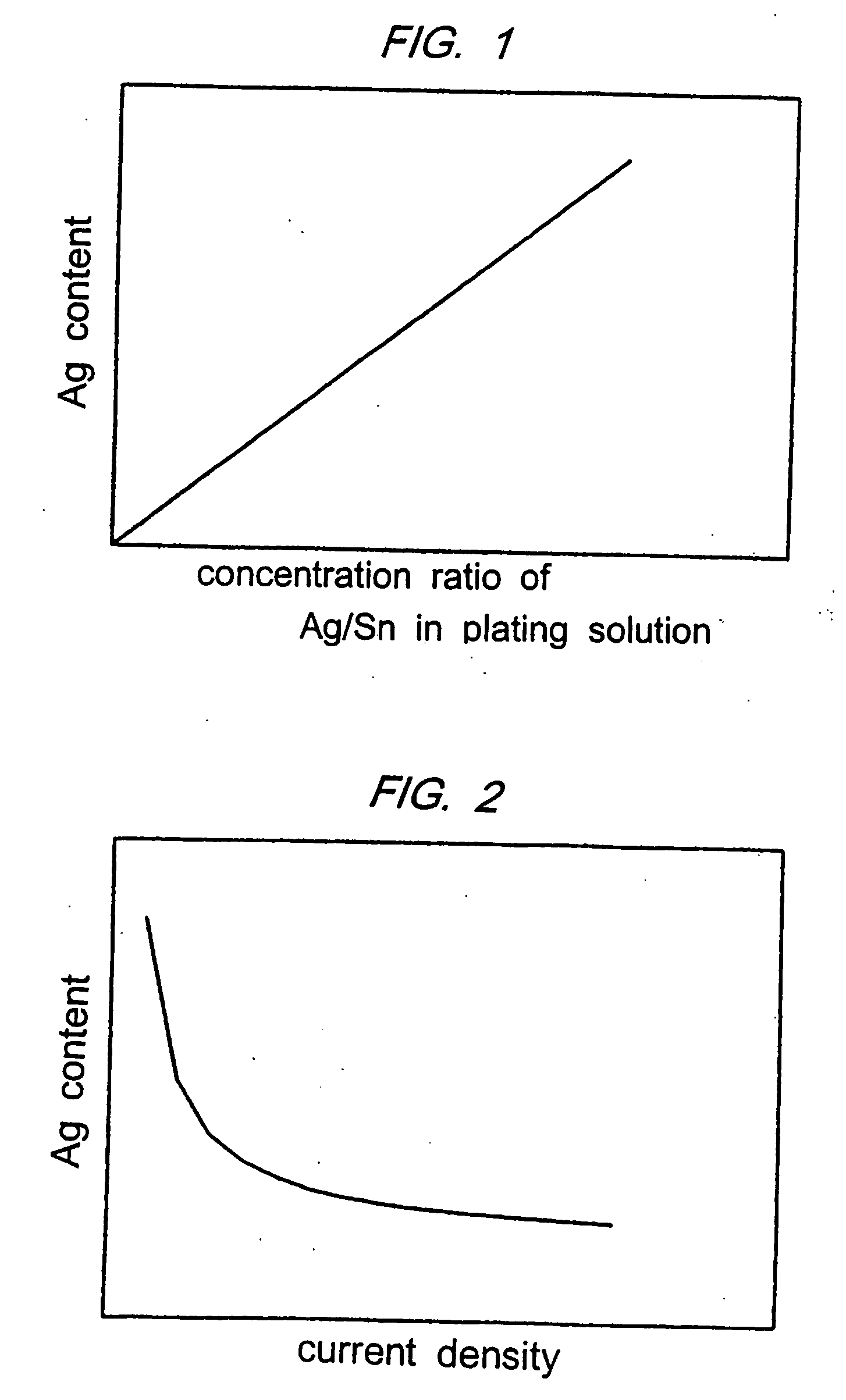

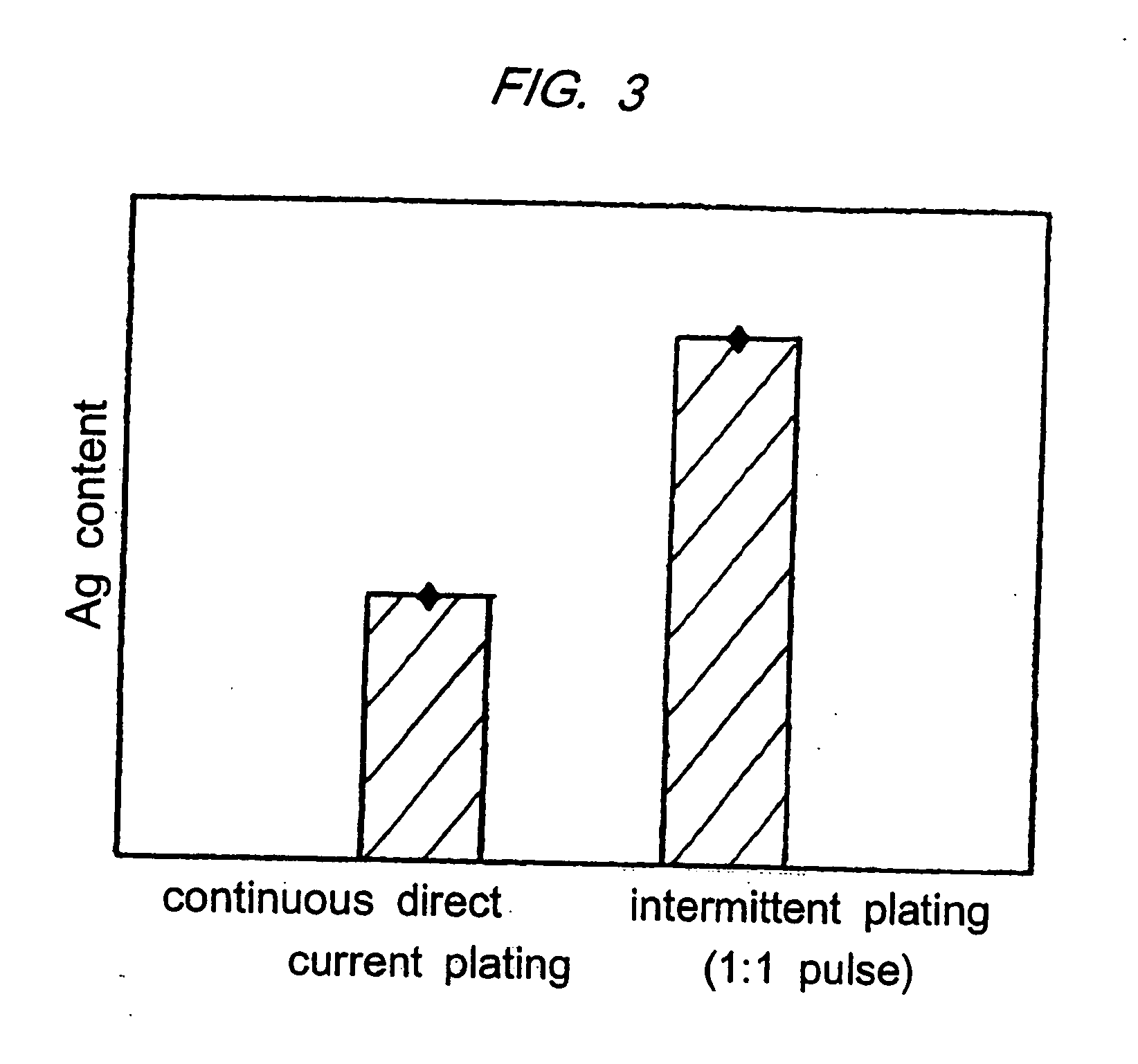

[0102] Alloy plating was carried out with various proportions of Ag to the total metal in an alloy plating solution, various current densities upon plating and various current application methods, and the respective plated alloy films were subjected to reflowing at 238° C. For the bump thus obtained, measurement of the Ag content and observation of the shape of bump and the presence of voids were carried out in the same manner as in Example 1. The results are shown in table 1.

TABLE 1PlatingPlating conditionsVoltageBumpVoidBallsolutionCurrent densityapplicationAg contentpresent (x)formationAg / Sn (%)(A / dm2)method(wt %)absent (∘)at 238° C.4.33DC5.2x∘4.43DC6.4x∘4.420CHOP4.0x∘4.33DC7.7x∘4.320CHOP5.1x∘1.33DC1.8∘∘1.38DC0.9∘x1.320CHOP1.4∘x2.23DC3.4x∘2.220CHOP2.1∘∘4.13DC4.9x∘3.120CHOP2.9∘∘3.110CHOP3.6x∘3.13DC5.0x∘3.23DC5.8x∘3.220CHOP2.7x∘2.33DC3.5x∘2.320CHOP2.6∘∘

Note:

DC denotes direct current plating, and CHOP denotes intermittent plating

[0103] As apparent from the results shown in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com