Method and apparatus for resonant wave mixing in closed containers

a technology of resonant wave and closed containers, which is applied in the direction of mixers, mixer accessories, mixing, etc., can solve the problems of significant labor-intensive fluid transfer, inability to mix the ingredients contained in the bag, and difficulty in maintaining sterility during this operation, and achieves a high degree of containment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Mixing in 1000 liter Plastic Bags

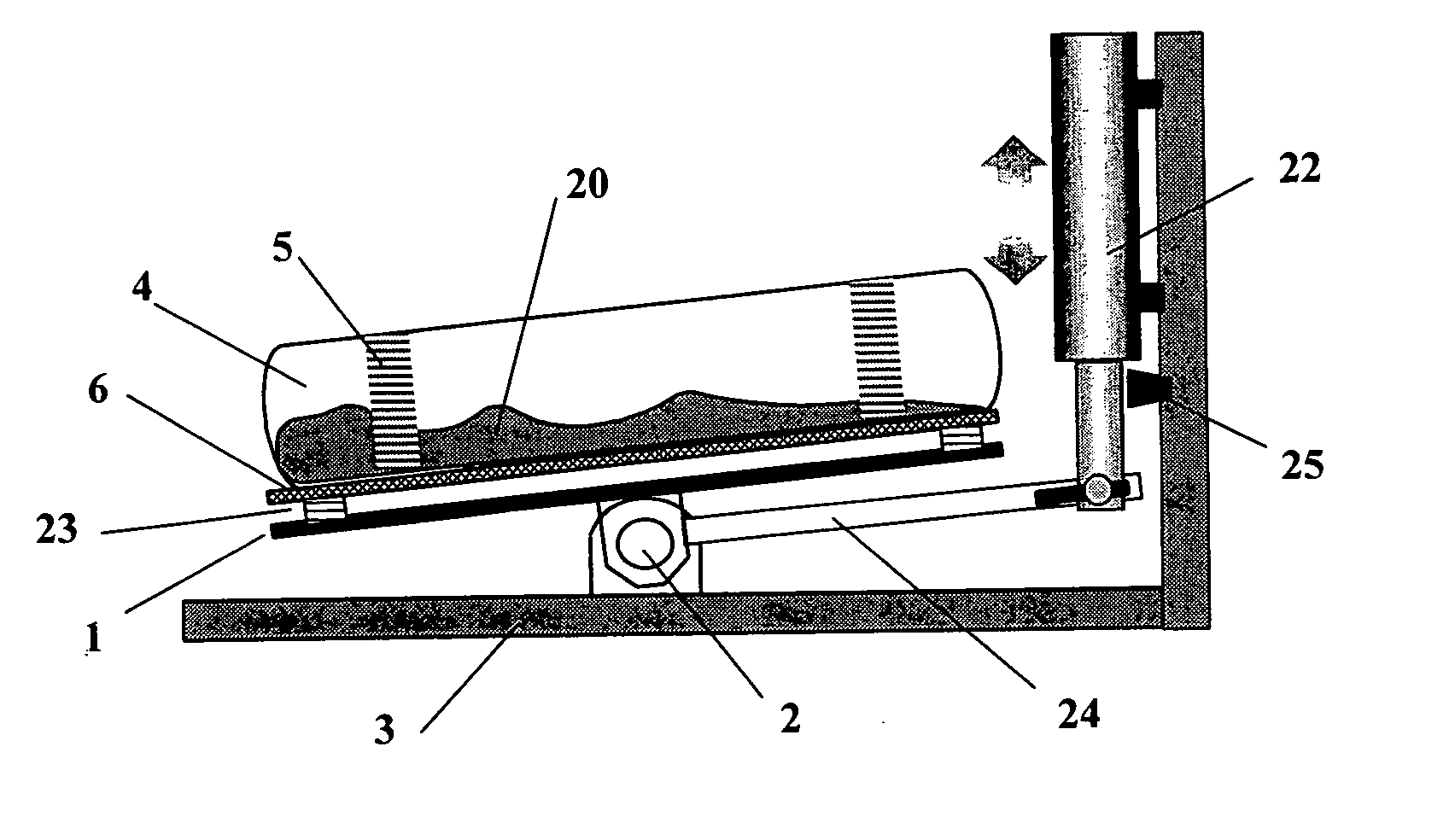

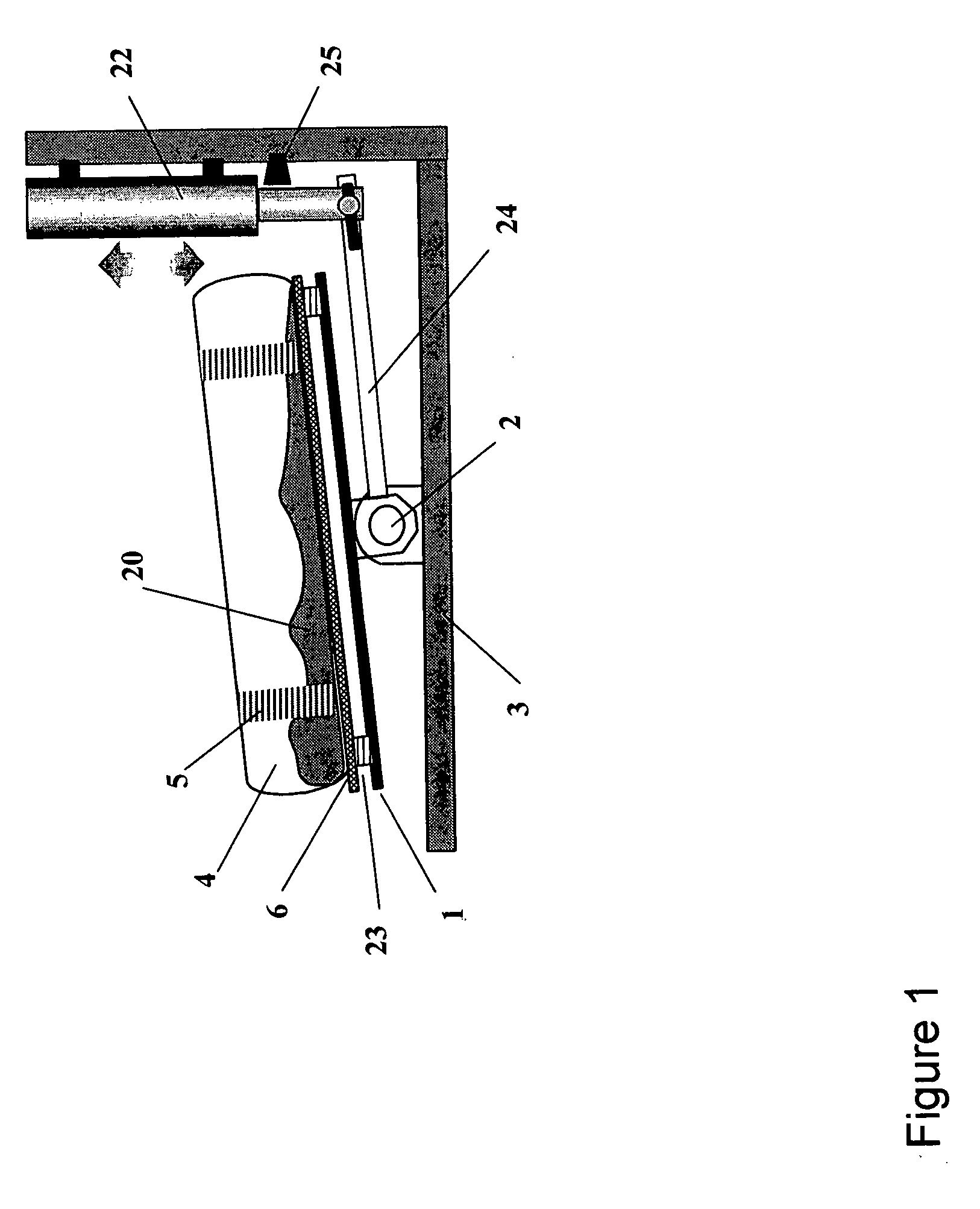

[0062] Mixing performance was evaluated in trials using 1000 liter plastic bags. Bags were of “pillow” design and made of polyethylene. Bags were filled with water to varying percentages (80% maximum) of total volume and placed horizontally on the rocking platform as shown in FIG. 1. Mixing times under different conditions were evaluated by injecting a fluorescent dye into the bag and recording its dispersion by videotape. Mixing time was chosen to be that time after dye injection when the dye first appears to be completely dispersed throughout the contents of the bag.

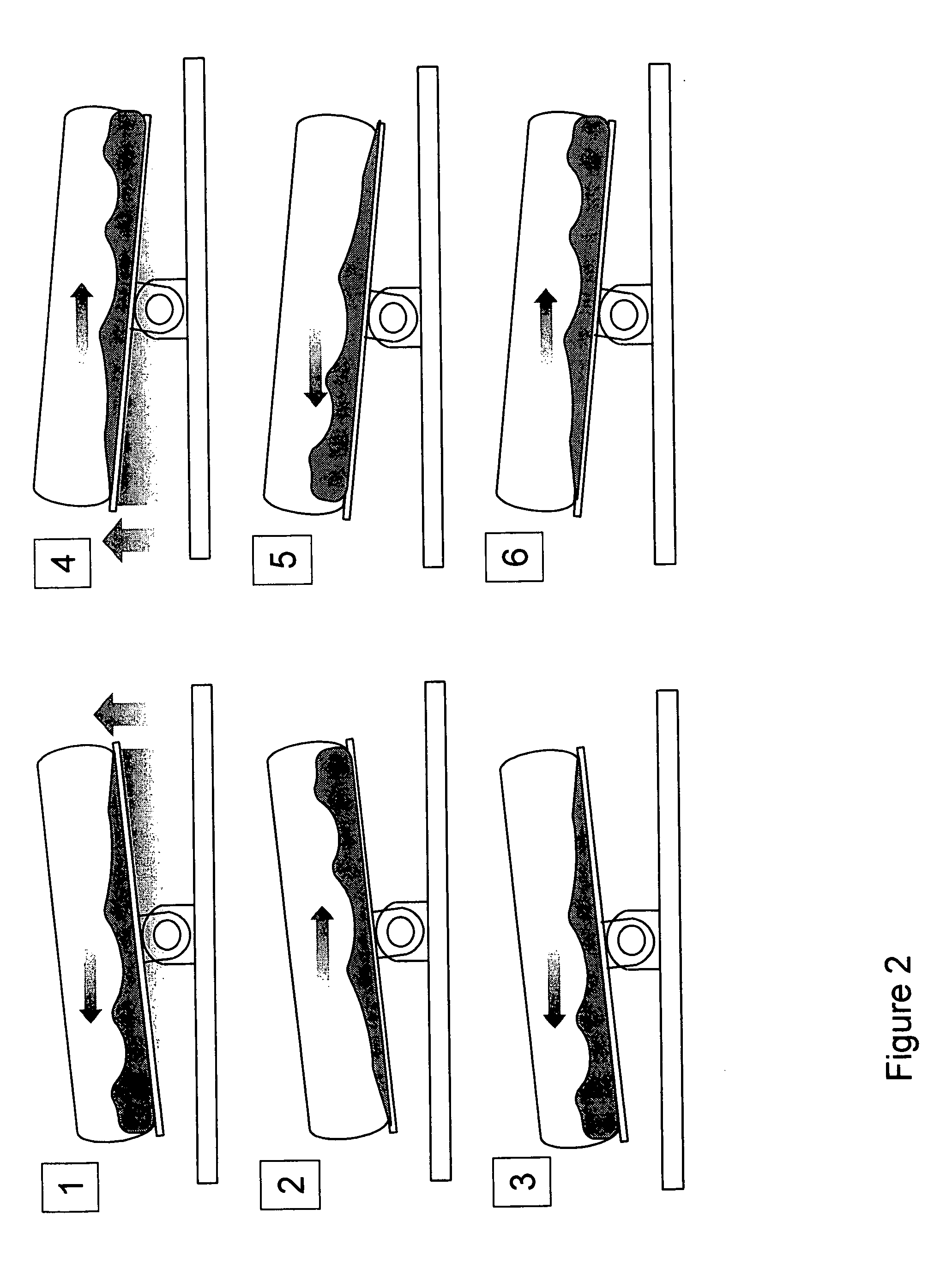

[0063] The resonant frequency for the particular bag holder+bag was found by experiment to be 26.5 cycles per minute (cpm). At this condition, the resonant wave was very pronounced and the load sensors produced a constant sinusoidal output. Mixing experiments were performed at submultiples of this speed—13.25 cpm, 6.6 cpm, 3.2 cpm and 1.6 cpm. Various tilt angles ranging for 1 to 9 de...

example 2

Mixing in 1000 liter Partially Inflated Plastic Bag

[0067] Tests were also performed by partially filling the bags with liquid and inflating the remainder of the bag to rigidity with air. Rocking these bags in the manner described in Example 1 also produced good wave motion and mixing times were slightly faster than reported in Example 1. However, significantly more foam was observed in this mode of operation.

[0068] Inflating the bag made it quite rigid and less creasing was observed during motion. It was apparent that an inflated bag undergoes less stress during motion and would be expected to be less prone to tearing, cracking and leakage during operation.

example 3

Mixing With Rotary Motion

[0069] In the earlier examples the wave motion occurs to and fro. The mixing is very quick in the axis perpendicular to the rocking axis but it much poorer in the parallel axis. By placing suitable baffles (FIG. 3) it is possible to cause the liquid to also rotate as it move to and fro. FIG. 3 shows the fluid circulation patterns in the bag in a top view with the platform tilted to the left. This rotary motion significantly reduces the mixing time and is very useful in applications where the ingredients to be mixed vary greatly in specific density.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com