Contrast coated stent and method of fabrication

a technology of contrast coating and stent, which is applied in the field of contrast coating stent, can solve the problems of significant re-narrowing of treated vessels, damage to the coating, and damage to the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

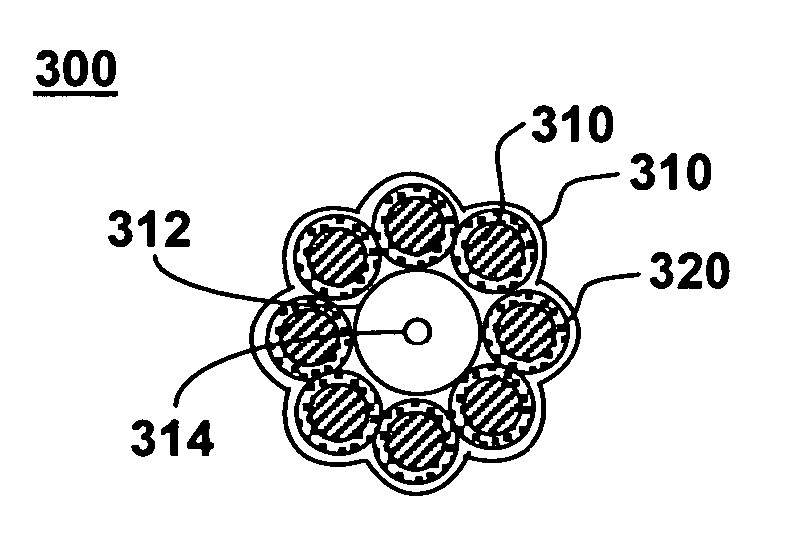

[0019]FIG. 1 illustrates a system for treating a vascular condition, comprising a contrast-drug polymer coated stent coupled to a catheter, in accordance with one embodiment of the present invention at 100. Vascular condition treatment system 100 includes a contrast-drug polymer coated stent 120 coupled to a delivery catheter 110. Coated stent 120 includes a stent framework 130, a drug-polymer coating 140 disposed on at least a portion of stent framework 130 and a contrast coat disposed on drug-polymer coating 140.

[0020] The stent 120 is conventional to stents generally and can be made of a wide variety of medical implantable materials, such as stainless steel (particularly 316-L or 316LS stainless steel), MP35 alloy, nitinol, tantalum, ceramic, nickel, titanium, aluminum, polymeric materials, tantalum, MP35N, titanium ASTM F63-83 Grade 1, niobium, high carat gold K 19-22, and combinations thereof. The stent 120 can be formed through various methods as well. The stent 120 can be we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com