Process for producing molten iron

a technology of molten iron and process, which is applied in the field of producing molten iron, can solve the problems of many problems to be solved, and achieve the effects of improving the metallization ratio of solids, and smooth melting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

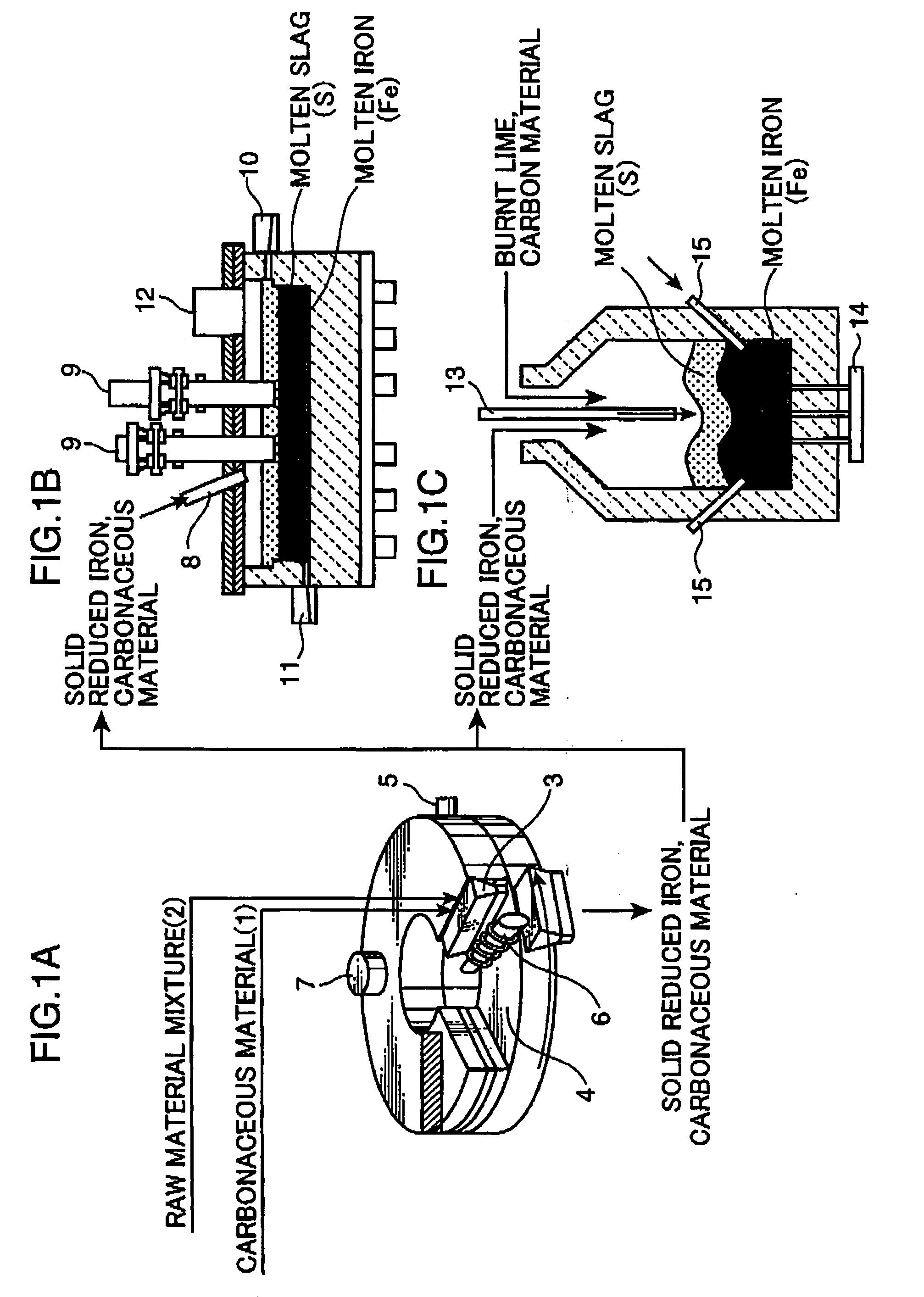

[0063] In this experiment, as shown in the following Tables 1 and 2, two kinds of iron ores as iron oxide sources and one kind of coal as a carbonaceous reducing agent were used, and operational conditions were compared between when burnt line (CaO) was added previously to the raw material mixture (here, that is a compact in a pellet shape) to be fed into a rotary-hearth reducing furnace so that the slag formed in a melting furnace had a basicity of 1.6 respectively and when burnt lime was not added.

TABLE 1Major compositions and contents of iron ore (mass %)Iron oreTotal FeSiO2Al2O3CaOMgOSPOre (A)68.011.080.470.030.060.0020.041Ore (B)68.673.830.190.380.400.0020.024

[0064]

TABLE 2Composition of reducing agent (mass %)Reducing agentFCVMTATotalCoal71.519.98.6100

(Notes)

FC: Fixed Carbon, VM: Volatile Matter, TA: Total Ash

[0065] Raw material compacts (pellets) having the composition shown in Table 3 were formed by using the two kinds of iron ores and one kind of carbonaceous material sh...

example 2

[0079] In this example, used was an iron-bath melting furnace that uses the combustion heat of carbonaceous material as a heat source for melting a solid reduced iron. A furnace similar to oxygen top-blowing converter was used as the melting furnace, and oxygen for combustion of the carbonaceous material in the melting furnace was blown onto the molten iron from above by using a top-blowing lance. Specifically, conducted were two experiments: by a conventional method of adding into the melting furnace a CaO-containing material needed for controlling the slag basicity not being blended with a raw material compact; and by the present inventive method of blending all of the CaO-containing material with the raw material compact, where each method uses the same ore (A) as that used in Example 1 as an iron oxide source. Results are summarized in Table 5.

[0080] In the conventional method (1), the amount of CaO needed for adjusting the basicity of the slag generated in the melting furnace ...

example 3

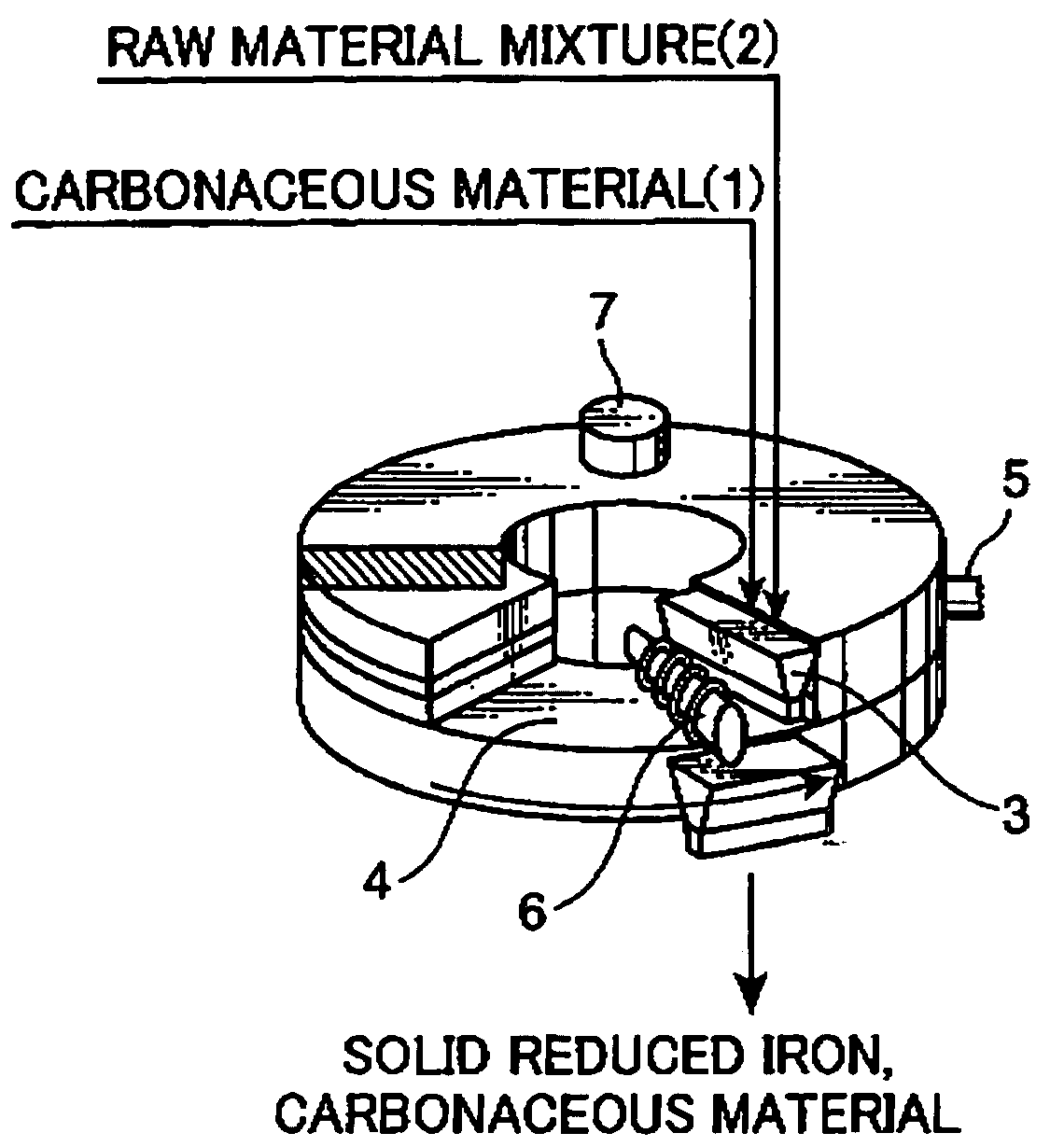

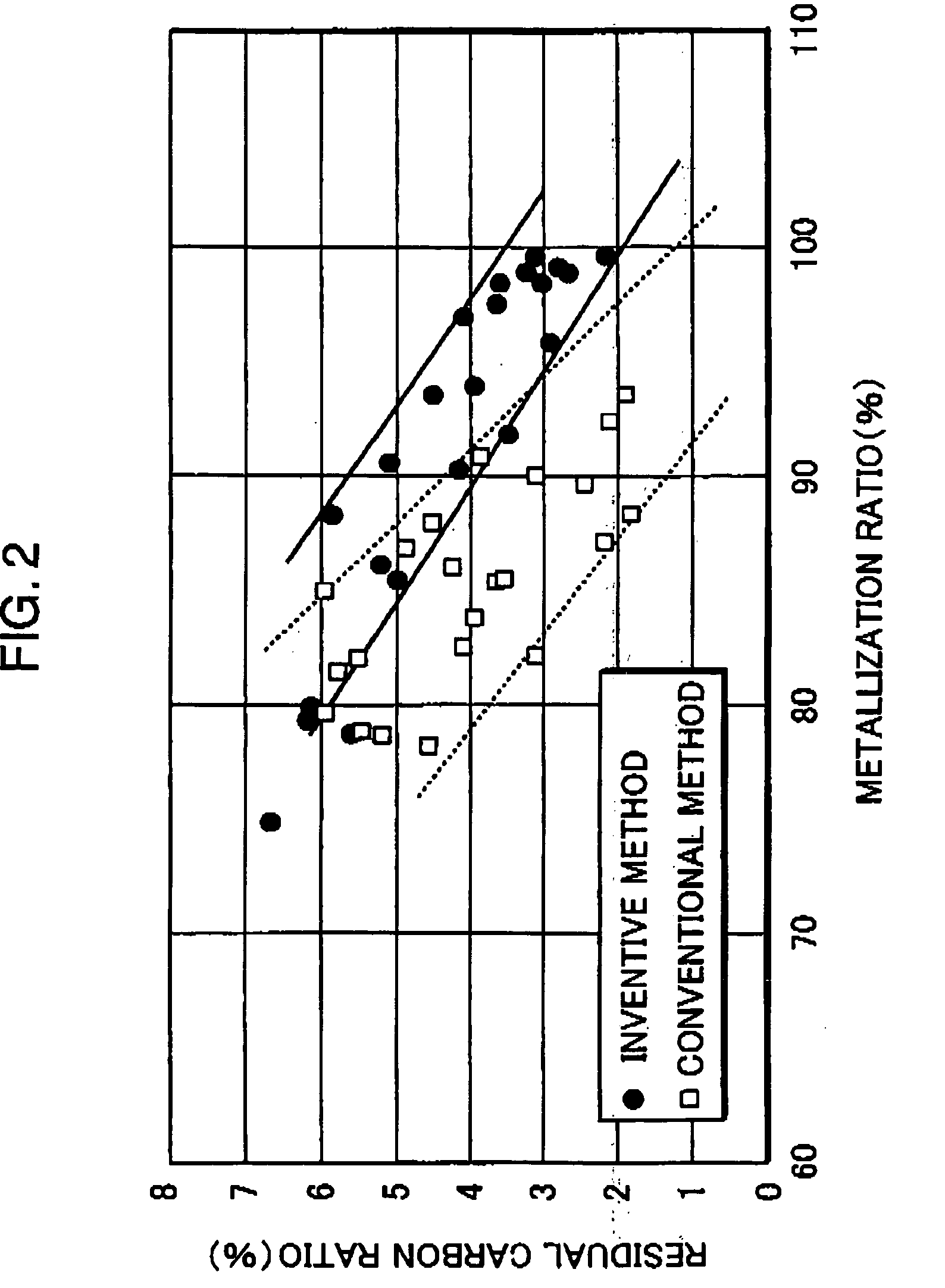

[0084] In this example, shown is a typical method of,producing a solid reduced iron smaller in fluctuation and higher in metallization ratio by using a rotary-hearth reducing furnace. Namely, one case that the heat-reduction carried out by feeding 30 kg or more of a powdery carbonaceous material (per ton of molten iron obtained in the next melting furnace) onto the rotary hearth of a rotary-hearth reducing furnace as a hearth material and then by feeding the raw material pellet over the carbonaceous hearth material layer; and another case that the heat-reduction carried out by feeding only the raw material pellet directly onto the hearth without laying the powdery carbonaceous material onto the rotary-hearth; were compared. In either case, the residual carbon amount of the pellet and the metallization ratio were determined by collecting the raw material pellet under reduction from the sampling holes placed at different sites of the furnace, while maintaining the atmospheric temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com