Transport system and dynamo-electric machine

a technology of transport system and dynamo-electric machine, which is applied in the direction of electric motor propulsion transmission, magnetic circuit rotating parts, and shape/form/construction of magnetic circuits, etc., can solve the problems of reduced heat generation efficiency, difficult operation in high-speed range, and complex structure of spring and governor, etc., to achieve simple structure and weakening of magnetic flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

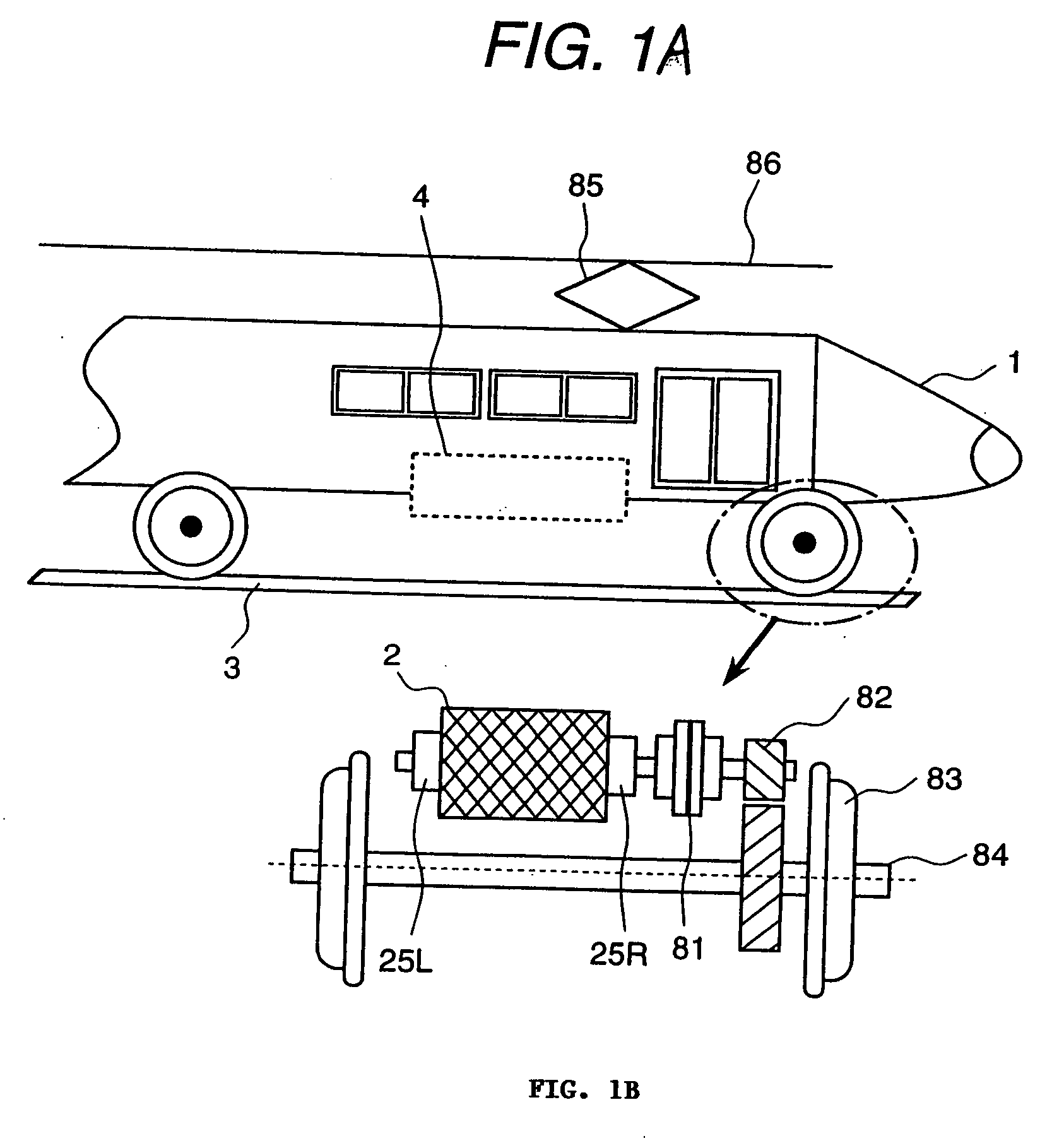

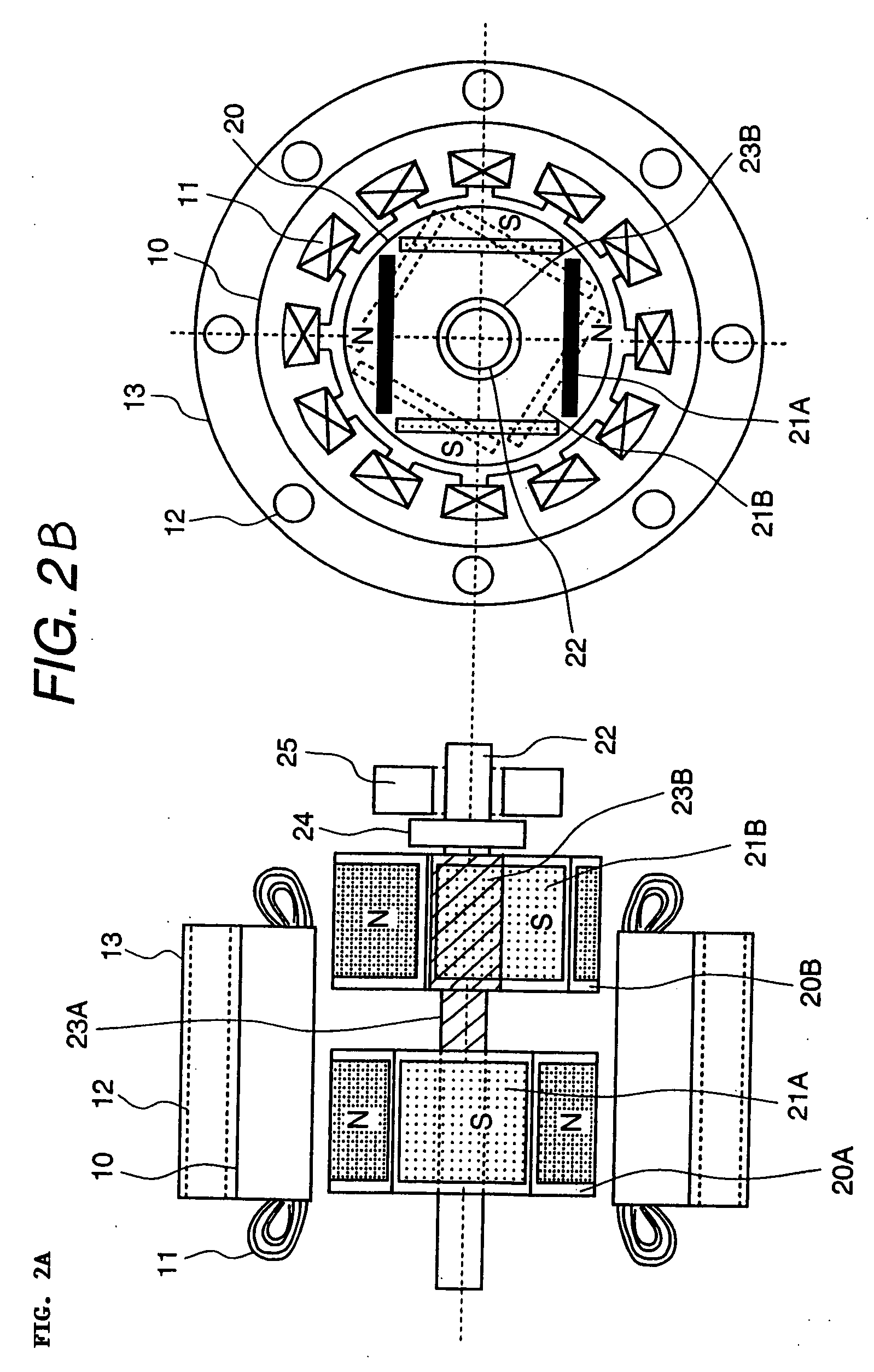

[0033] Embodiments of the present invention will be explained.

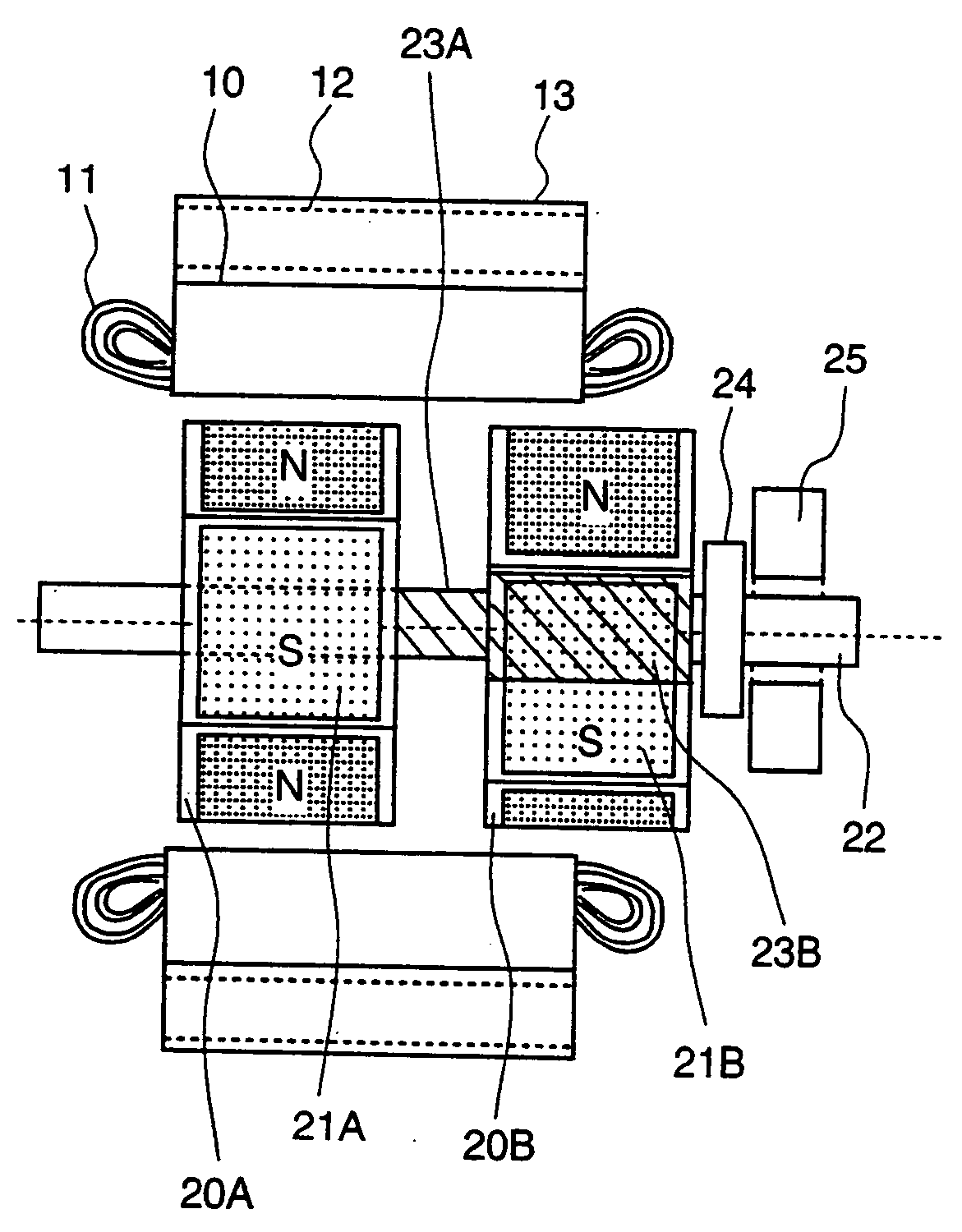

[0034]FIG. 1 shows the arrangement layout of a permanent magnet type synchronous dynamo-electric machine according to an embodiment of the present invention.

[0035] There are various transport systems which use the dynamo-electric machine as a power source. FIG. 1 shows the embodiment of a railway rolling stock system as one example of the transport system.

[0036] The railway rolling stock system shown in FIG. 1 has electric car 1, dynamo-electric machine 2, wheel 83 installed directly or indirectly on the dynamo-electric machine 2, power conversion machine 4 for controlling the electric power of dynamo-electric machine 2, and current collector 85.

[0037] Here, the electric car means the rolling stock which uses electricity as the power. Further, in the transport system including the rolling stock system, the electric car means a truck in a broad sense.

[0038] Further, the current collector is a device for taking the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com