Heat pipe

a technology of heat pipe and pipe body, which is applied in the field of heat pipe, can solve the problems of heat conductivity inferior to water, pipe burst, and heat pipe breakage, and achieve the effect of preventing the damage of the pipe body due to the freezing of the working fluid in cold climates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Test for Heat Conductivity

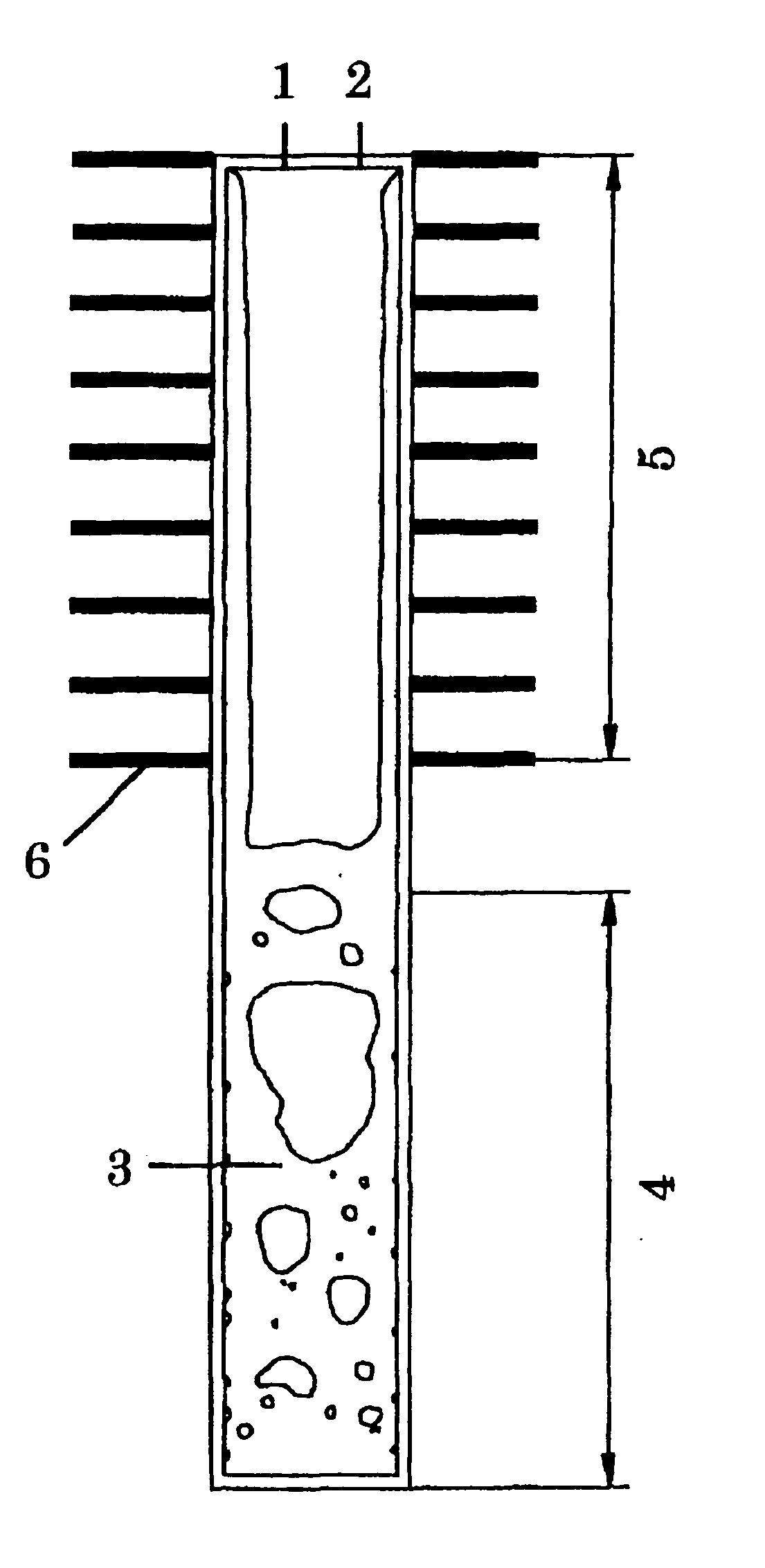

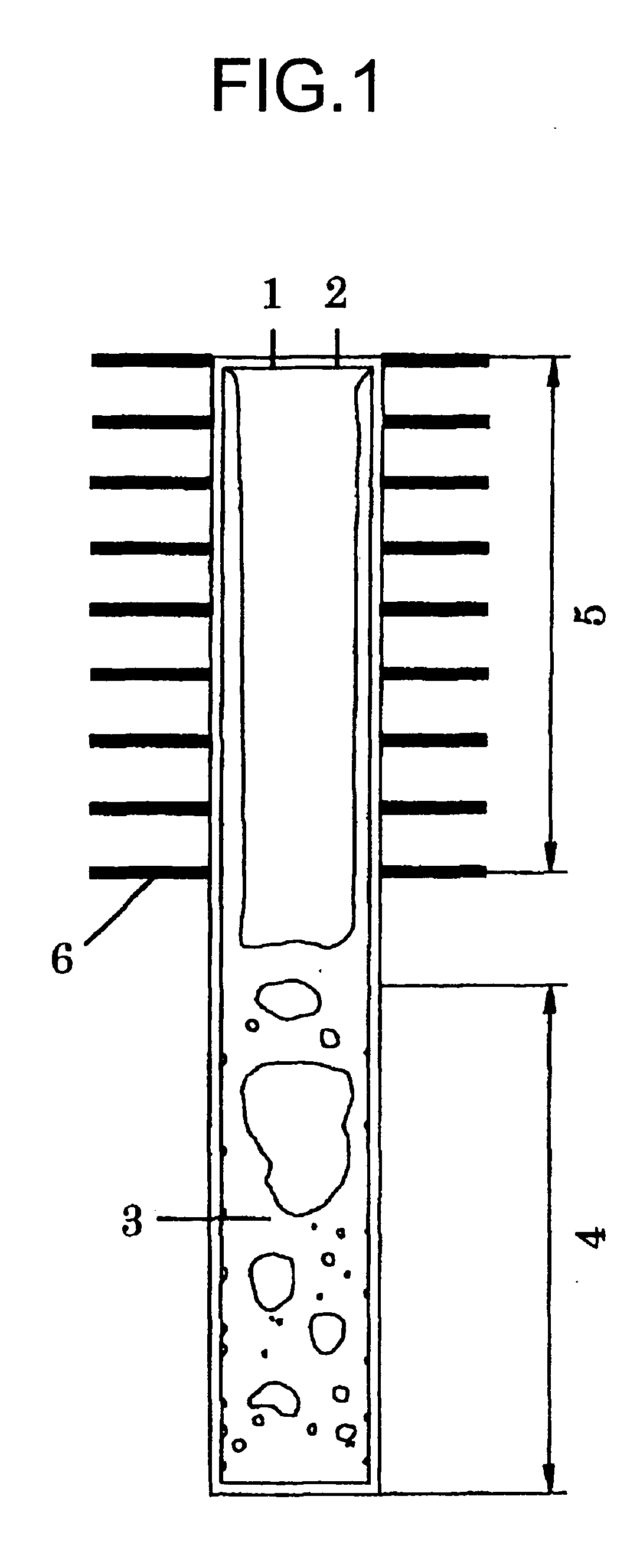

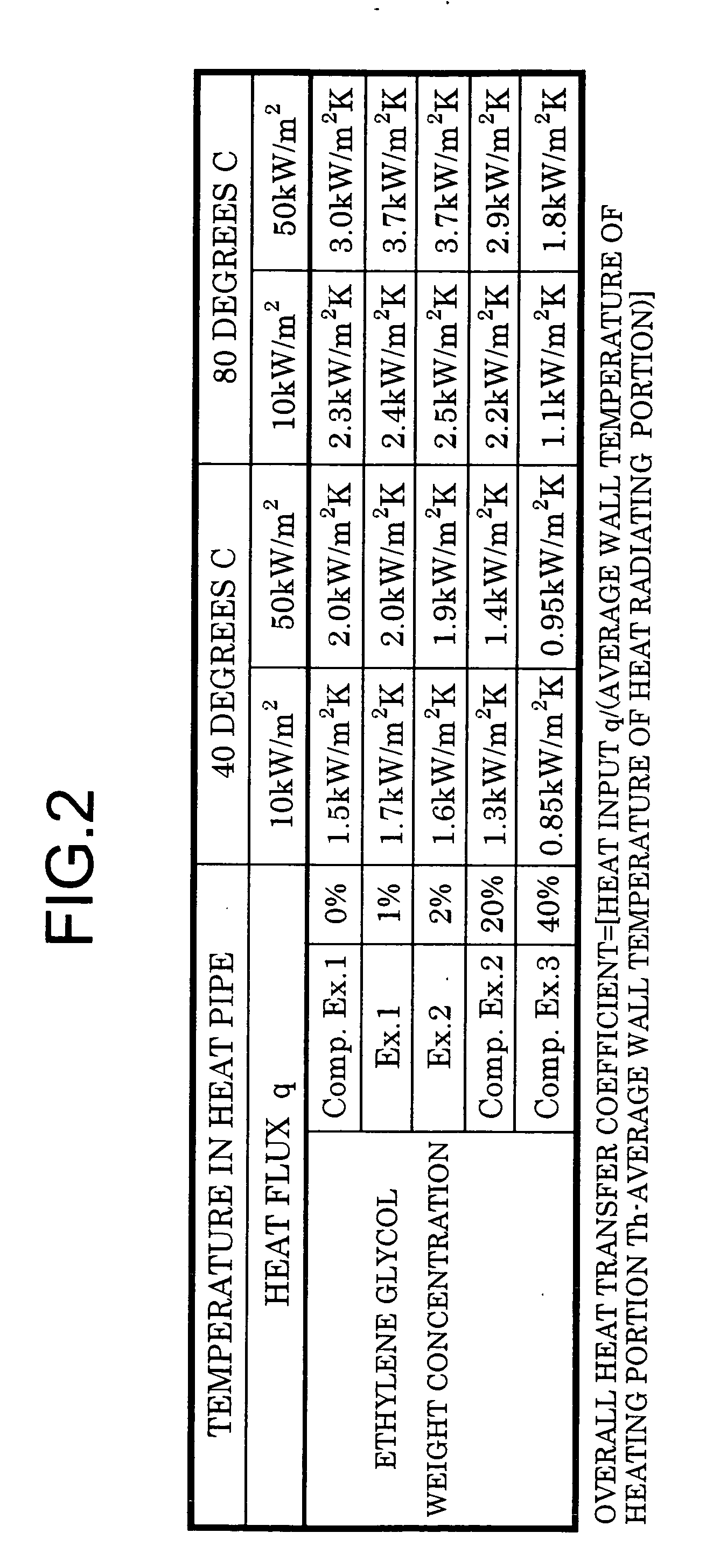

[0026] A device as illustrated in FIG. 1 was used for the tests of heat conductivity. A pipe having a diameter of 16 mm and a length of 1100 mm is provided with double-pipe condensers over 500 mm of an upper portion, and 500 mm of a lower portion is heated by a heater. As the working fluid, an aqueous solution containing 1% weight concentration of ethylene glycol was used and 51 cm3 (i.e., 40% of capacity of the heating portion) thereof was encapsulated in the pipe. The air was adequately removed from the system. FIG. 2 shows a table of overall heat transfer coefficients kw / (m2K) when a heat gauge, which is arranged on a pipe wall at 550 mm from the bottom of the pipe (i.e., a heat insulating portion), indicates 40 degrees C. and 80 degrees C. after 10 kw / m2 and 50 kw / m2 of heat is supplied to the heating portion 4 of the heat pipe.

example 2

[0027] In example 1, an aqueous solution containing 2% weight concentration of ethylene glycol was used for the working fluid instead of the aqueous solution containing 1% weight concentration of ethylene glycol. No alteration was made in the rest of the conditions of example 1. Results are shown in FIG. 2.

example 3

Test for Congelation and Solidification

[0029] Glass test pipes having a diameter of 16 mm, a length of 150 mm and a thickness of 1 mm are used for the test for congelation and solidification. The aqueous solution containing 1% weight concentration of ethylene glycol was filled in each test pipe in the amount of 44 cm3, and stored for 20 hours in a freezer kept at minus 20 degree C. It was found that the aqueous solution of 1% weight concentration of ethylene glycol froze into sherbet-like ice, and the test pipe did not burst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com