Method to extend the utilization of a catalyst in a multistage reactor system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

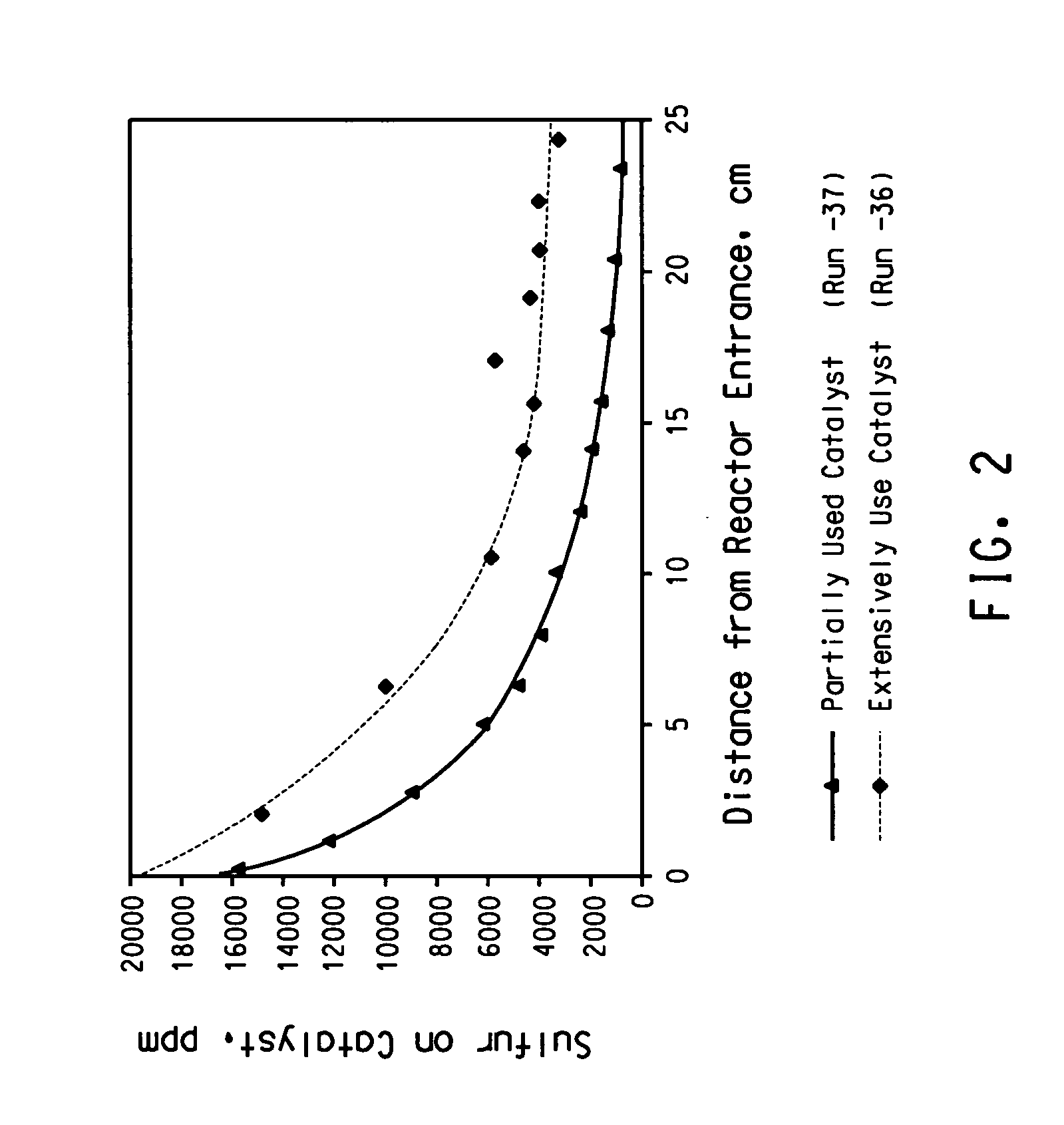

[0053] Run-36 was conducted in a single reactor with 250 mm catalyst packing at various temperatures (80° C., 100° C., and 120° C., but mostly at 100° C.) at 2860 kPa, 0.8 1 / h LHSV with H2 to PDO flow ratio of 6.1 scc / g. The feed had 16 ppm sulfur and the run continued until the catalyst was significantly deactivated. At the end of the run, the catalyst was taken out in segments and analyzed for its sulfur content.

[0054]FIG. 2 shows the sulfur profile in the reactor, indicating that sulfur deposition is predominantly near the reactor entrance.

[0055] Furthermore, this test showed that the desulfurization rate is much faster than the hydrogenation rate to remove color. The following Table 1 shows that at various conditions of operation while the percentage reduction in UV-270 nm varies from 65 to 94%, the sulfur concentration in the PDO exiting the reactor is below the detection limit of 1 ppm.

TABLE 1TemperatureLHSV% Reduction% Reduction° C.1 / hUV-270Sulfur800.865.3approx. 1001000....

example 2

[0056] Run-37 was conducted in a single reactor with 250 mm catalyst packing at various temperatures (80° C., 100° C., and 120° C., but mostly at 100° C.) at 2860 kPa, 0.8 1 / h LHSV with H2 / PDO=6.1 scc / g. The run continued until the reactor bed was partially deactivated but was still able to meet the desired UV specifications. The run was stopped and the catalyst was removed in segments and analyzed for sulfur.

[0057]FIG. 2 shows more distinctly that sulfur deposits predominantly near the entrance of the bed. The partially used bed (Run-37) shows most of the sulfur accumulated in the front one third of the bed. The extensively used catalyst bed (Run-36) shows most of the sulfur accumulated in the first half of the bed.

example 3

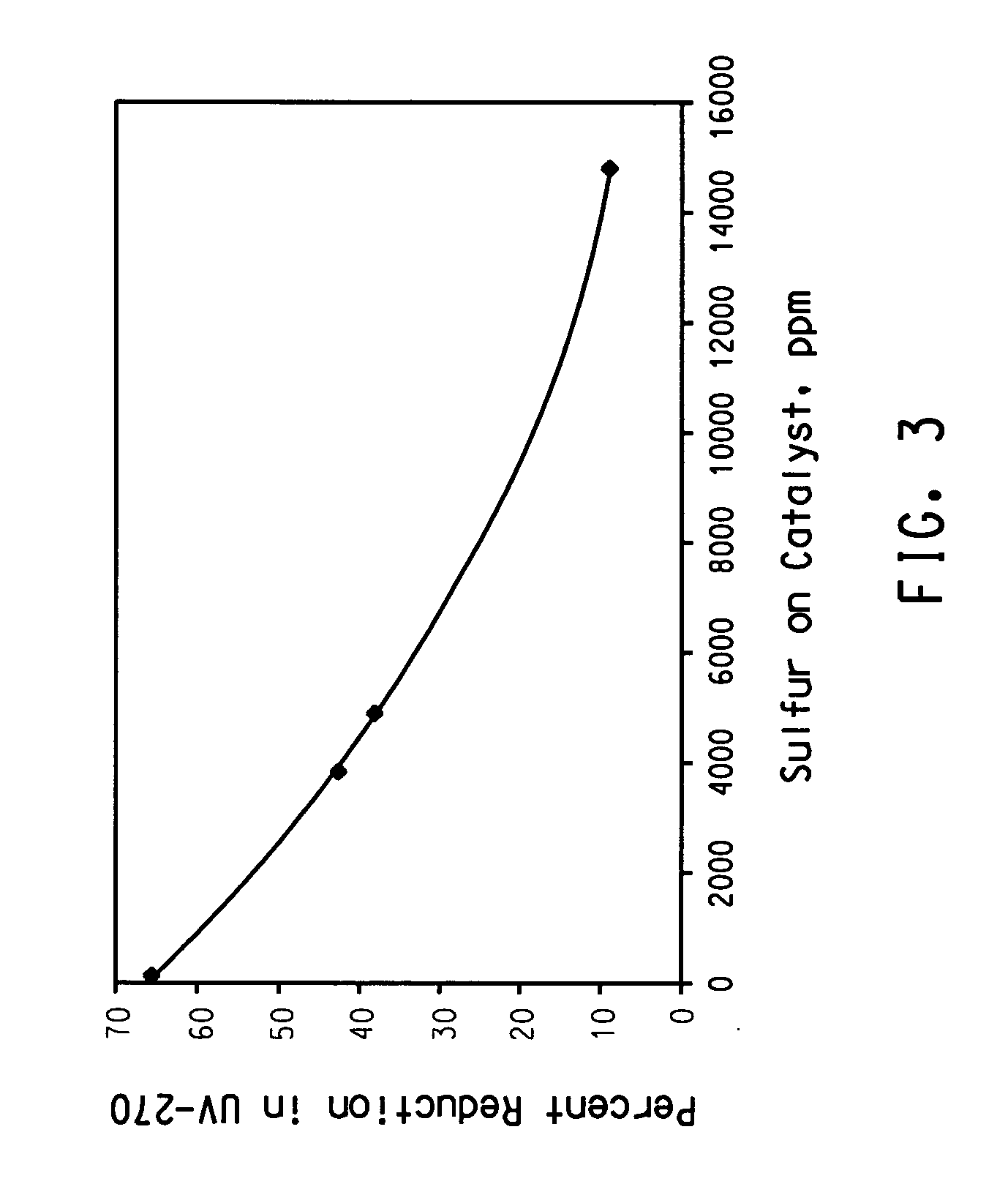

[0058] Three segments of the spent catalyst from Run-36 were sampled to represent poisoned catalysts with different levels of sulfur on the catalyst. The hydrogenation activities of these samples and that of a sample of the fresh catalyst were measured under identical conditions of 3.8 1 / h LHSV, 100° C., and 2860 kPa.

[0059]FIG. 3 shows that the catalyst activity for color removal, as measured by percent reduction in the absorption at UV-270 nm, decreases with increasing level of sulfur accumulated on the catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com