Process for producing nanoparticle apparatus therefor and method of storing nanoparticle

a nanoparticle and apparatus technology, applied in the direction of grain treatment, chemical/physical/physical/physical-chemical process, energy-based chemical/physical/physical-chemical process, etc., can solve the problem of inadequate efficiency of nanoparticulation and achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

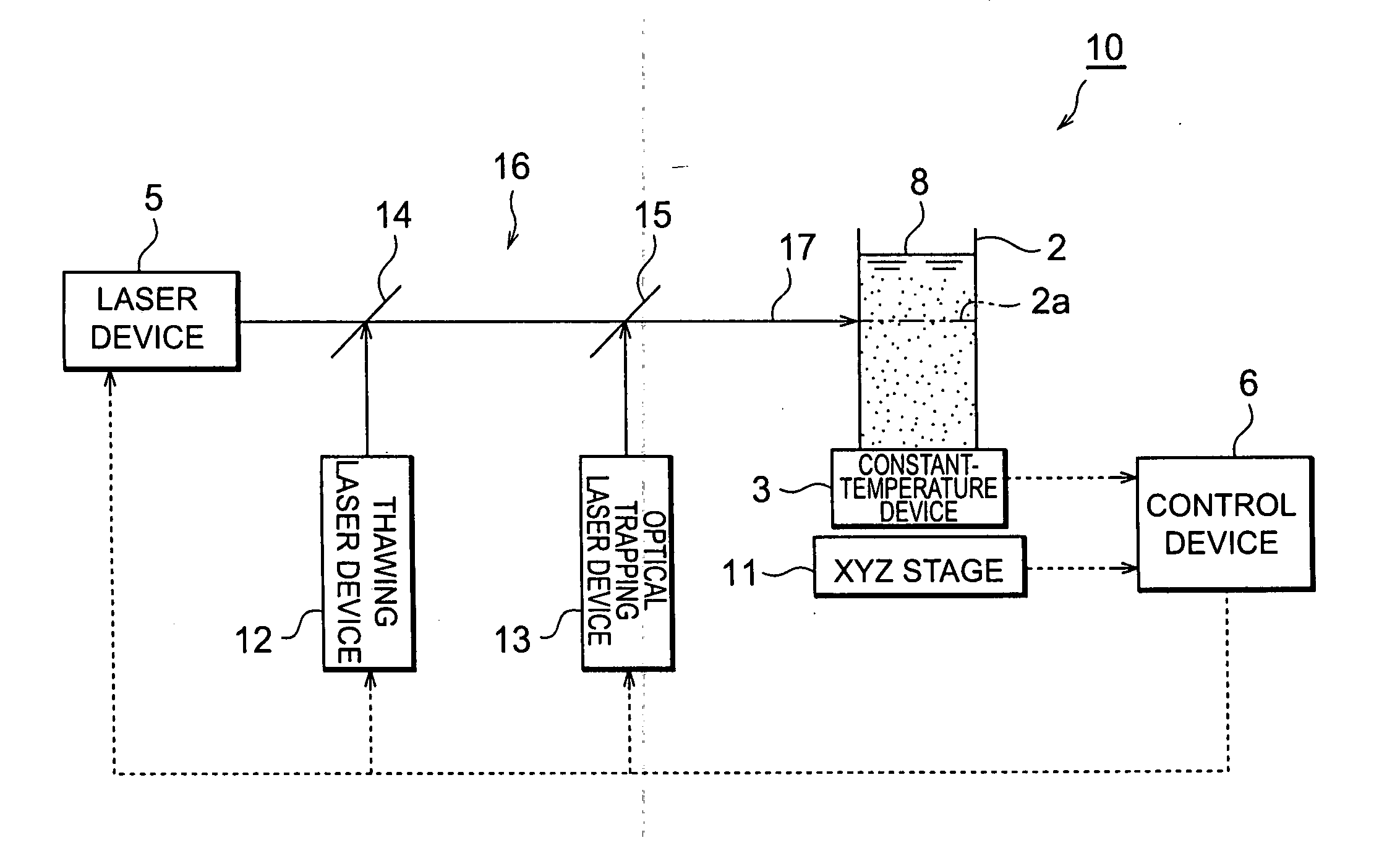

example 1

[0050] 3 ml of a sample solution, prepared by suspending a VOPc powder in water (VOPc: 0.5 mg / ml), were dispensed in a 10 mm×10 mm×40 mm rectangular quartz cell, and thereafter the temperature of the sample solution was lowered to 5° C. using a constant-temperature device (131-0040 Constant-Temperature Cell Holder with Temperature Display, made by Hitachi).

[0051] The sample solution was then irradiated with the third harmonic of an Nd:YAG laser (80 mJ / cm2·pulse, FWHM=4 ns, 20 Hz) for 15 minutes. As a result, the entirety of the sample solution became transparent. It is thus considered that nanoparticulation VOPc progressed and pseudo-dissolution of the nanoparticles occurred.

[0052] The absorbance of the sample solution after laser light irradiation was then measured by an absorbance measuring device. The result is shown in FIG. 4. As shown in FIG. 4, the absorbance was found to be significantly high in the vicinity of 500 to 900 nm, which is the absorbance wavelength range of VOPc...

example 2

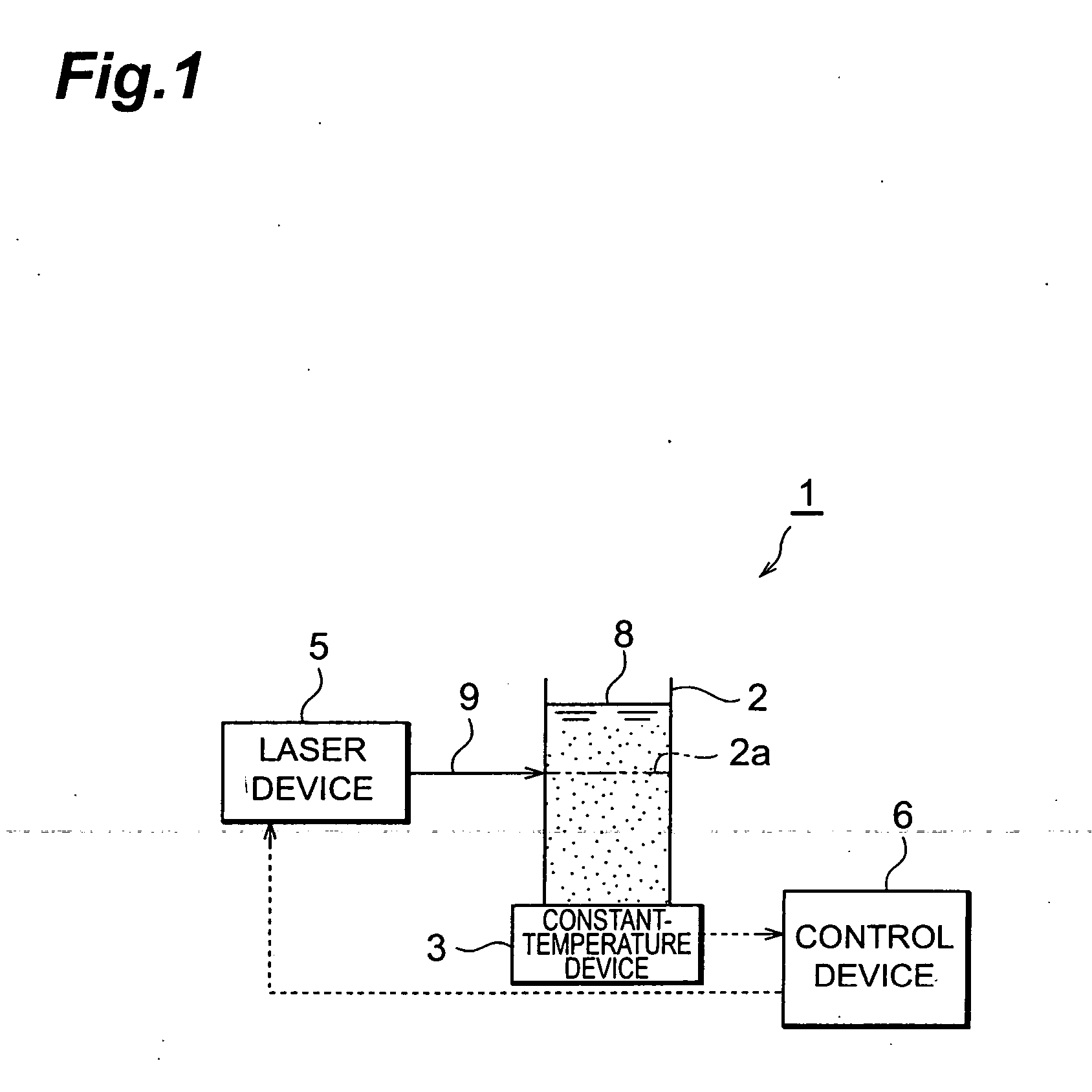

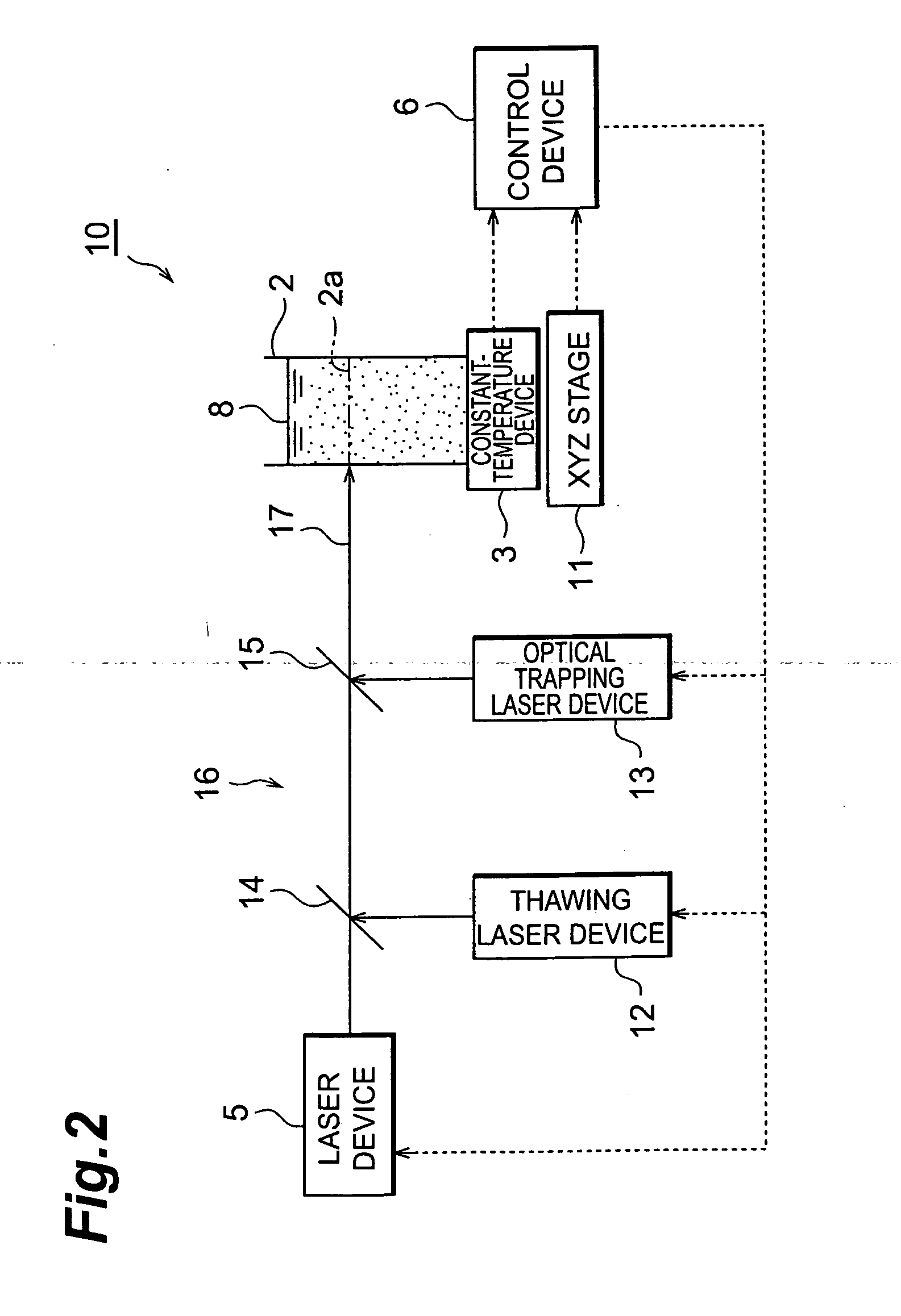

[0057] In this Example, nanoparticulation treatment of VOPc was carried out as follows using the device of FIG. 2.

[0058] First, XYZ stage 11 was moved to set the laser light irradiation portion in the 10 mm×10 mm×40 mm rectangular quartz cell. 3 ml of a sample solution, prepared by suspending VOPc powder in water (VOPc: 0.5 mg / ml), was then dispensed in the rectangular quartz cell. Thereafter, using the same constant-temperature device as in Example 1, the sample solution was cooled to and solidified at −5° C., thereby obtaining a solidified body.

[0059] Then using an argon ion laser (514 nm) as thawing laser device 12, the above-mentioned laser light irradiation portion was irradiated with a thawing laser light.

[0060] Then using a YAG laser (1064 nm) as optical trapping laser device 13, an optical trapping laser light was emitted and the above-mentioned laser light irradiation portion was irradiated with the optical trapping laser light.

[0061] Lastly, using the third harmonic li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com