Method and apparatus for pumping and diluting a sample

a sample and method technology, applied in the direction of positive displacement liquid engines, instruments, machines/engines, etc., can solve the problems of reducing the reliability of test results and subsequent test results, affecting the accuracy of sample measurement, etc., to achieve high precision dilution, accurate flow rate, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

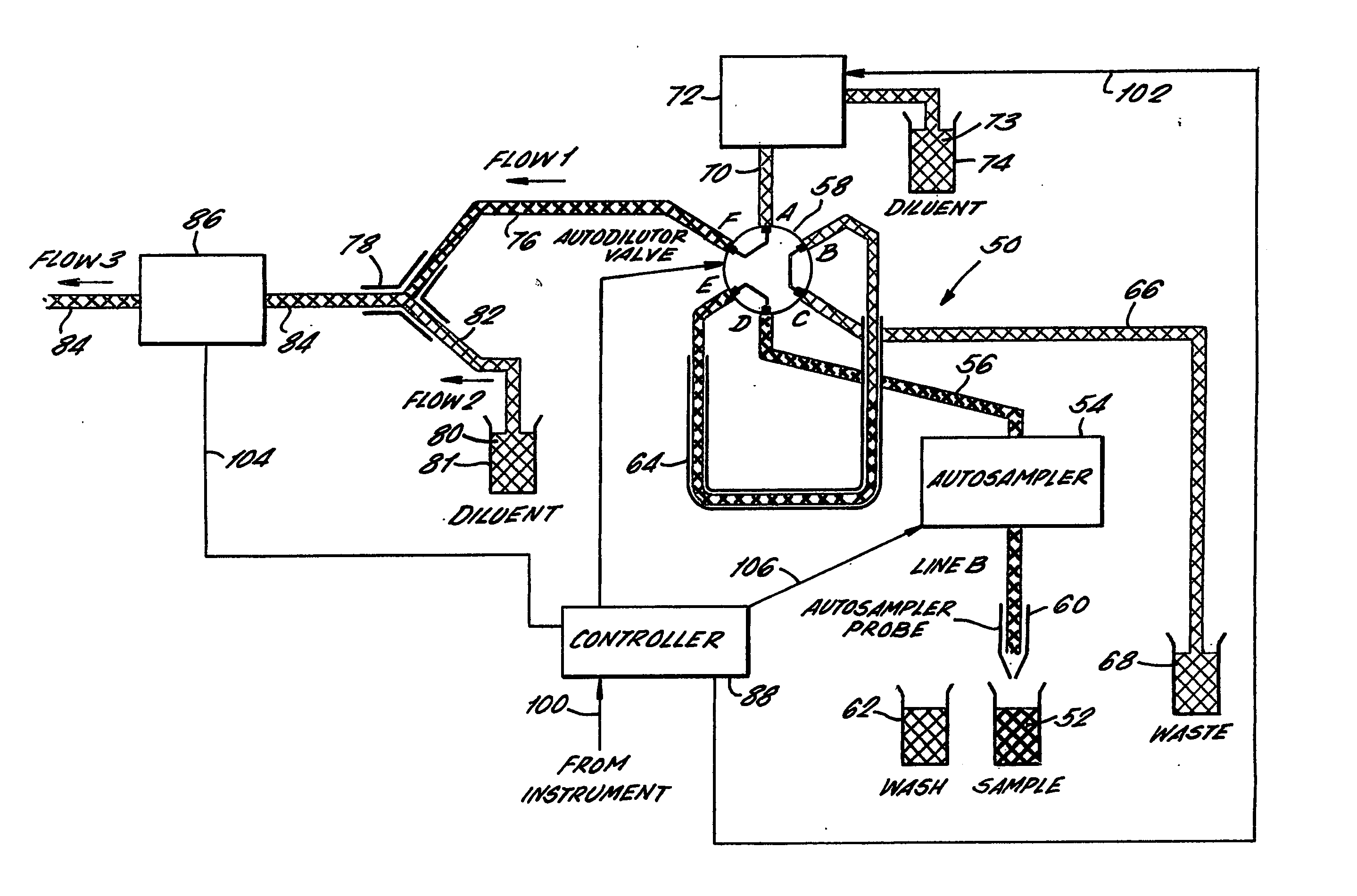

[0039] Referring to FIG. 3, a pump system 50 embodying the present invention is shown in schematic form. A sample 52 to be analysed is drawn from a container by an automatic sampler 54 along a first, or sample uptake pipe 56 to a valve, or pipe flow switch 58. The automatic sampler used in this embodiment is well known in the art and comprises a pump (not shown) and a probe 60. The probe is moveable to be inserted into a fluid in a container placed underneath the probe. Different containers can be placed on a carrousel (not shown) so that different samples or a washing agent 62 can be drawn into the pump system via the probe and automatic sampler pump.

[0040] The switch 58 comprises six input / output ports, A, B, C, D, E and F, and three internal pipes or conduits which each join one port with another. The switch is movable between two positions so that the flow of fluid from one pipe to another pipe can be switched from that pipe to a different pipe when the switch is moved. The swi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| flow rate | aaaaa | aaaaa |

| flow rates | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com