Methodology of chemical mechanical nanogrinding for ultra precision finishing of workpieces

a technology of nanogrinding and workpieces, applied in the field of nanogrinding and chemical mechanical nanogrinding of workpieces, can solve the problems of sliding abrasive finishing process critically affecting the magnetic, electrical and mechanical performance, and the stability of recording heads, and achieves smooth surface finish (sub-nm ra), the effect of reducing the loss of magnetic space and reducing the smearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

BACKGROUND OF THE INVENTION

[0001] Technical Field

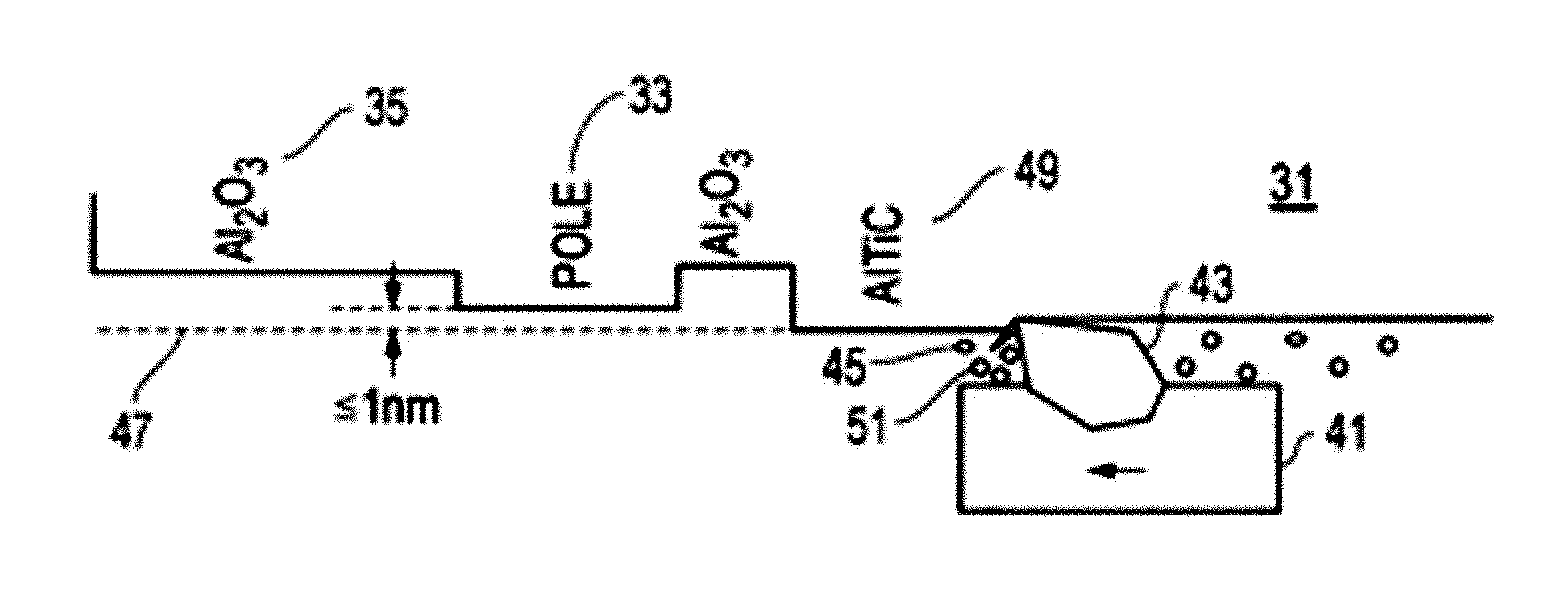

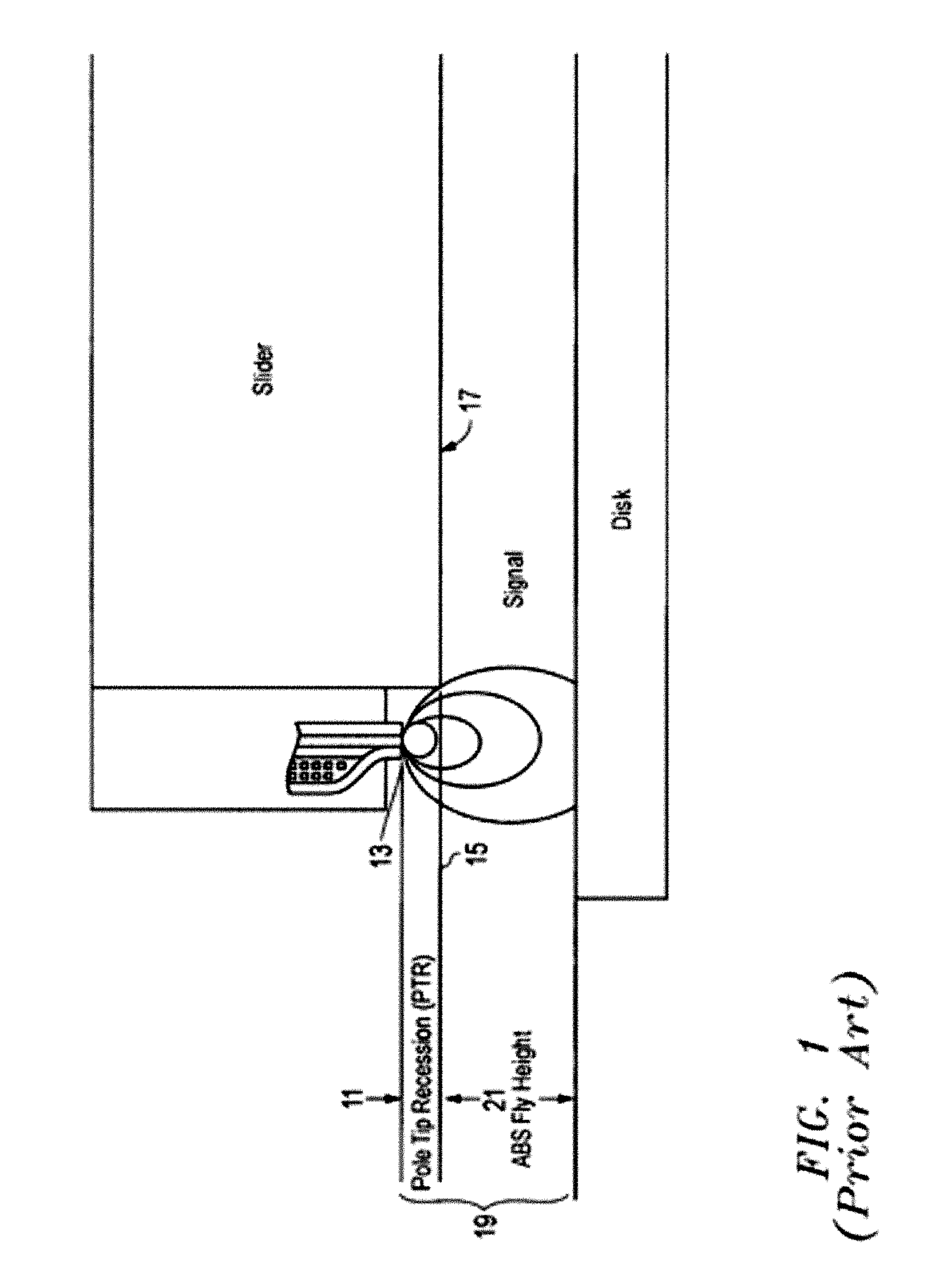

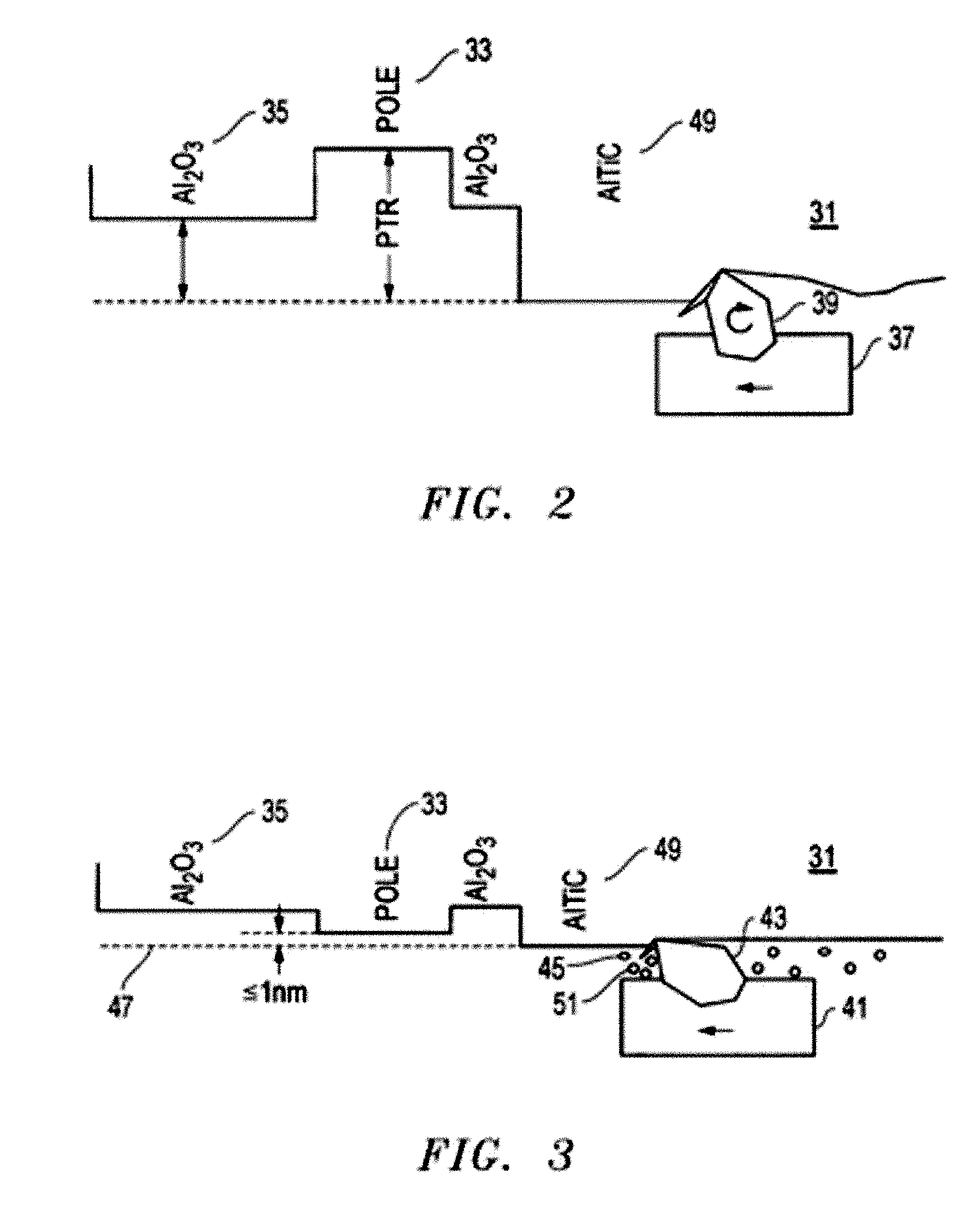

[0002] The present invention relates in general to an improved ultrafine finish for workpieces having various elements with different hardnesses and, in particular, to an improved system, method, and apparatus for nanogrinding and chemical mechanical nanogrinding of workpieces with both chemical and mechanical processes.

[0003] Description of the Related Art

[0004] Data access and storage systems generally comprise one or more storage devices that store data on magnetic or optical storage media. For example, a magnetic storage device is known as a direct access storage device (DASD) or a hard disk drive (HDD) and includes one or more disks and a disk controller to manage local operations concerning the disks. The hard disks themselves are usually made of aluminum alloy or a mixture of glass and ceramic, and are covered with a magnetic coating. Typically, one to five disks are stacked vertically on a common spindle that is turned by a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com