Purification of HBV antigens for use in vaccines

a technology for hbv and antigens, applied in the field of vaccine purification, can solve the problems of enormous dimensions of the global public health problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Production Process of Hepatitis B Surface Antigen in the Presence of Thiomersal

[0049] The Hepatitis B surface antigen (HBsAg) of SB Biologicals hepatitis B monovalent vaccine (Engerix B™) is expressed as a recombinant protein in Saccharomyces cerevisiae (see Harford et. al. loc. cit.). The 24 kD protein is produced intracellularly and accumulated in the recombinant yeast cells. At the end of the fermentation the yeast cells are harvested and disrupted in the presence of a mild surfactant such as Tween 20 to liberate the desired protein. Subsequently the cell homogenate, containing the soluble surface antigen particles, is prepurified in a series of precipitations and then concentrated via ultrafiltration.

[0050] Further purification of the recombinant antigen is performed in subsequent chromatographic separations. In a first step the crude antigen concentrate is subjected to gel permeation chromatography on Sepharose 4B medium. Thiomersal is present in the elution buffer at the 4B...

example 2

Production and Characterization of Yeast-Derived HBsAg by a Thiomersal Free Process.

1. Production and Purification of Yeast-Derived HBsAg

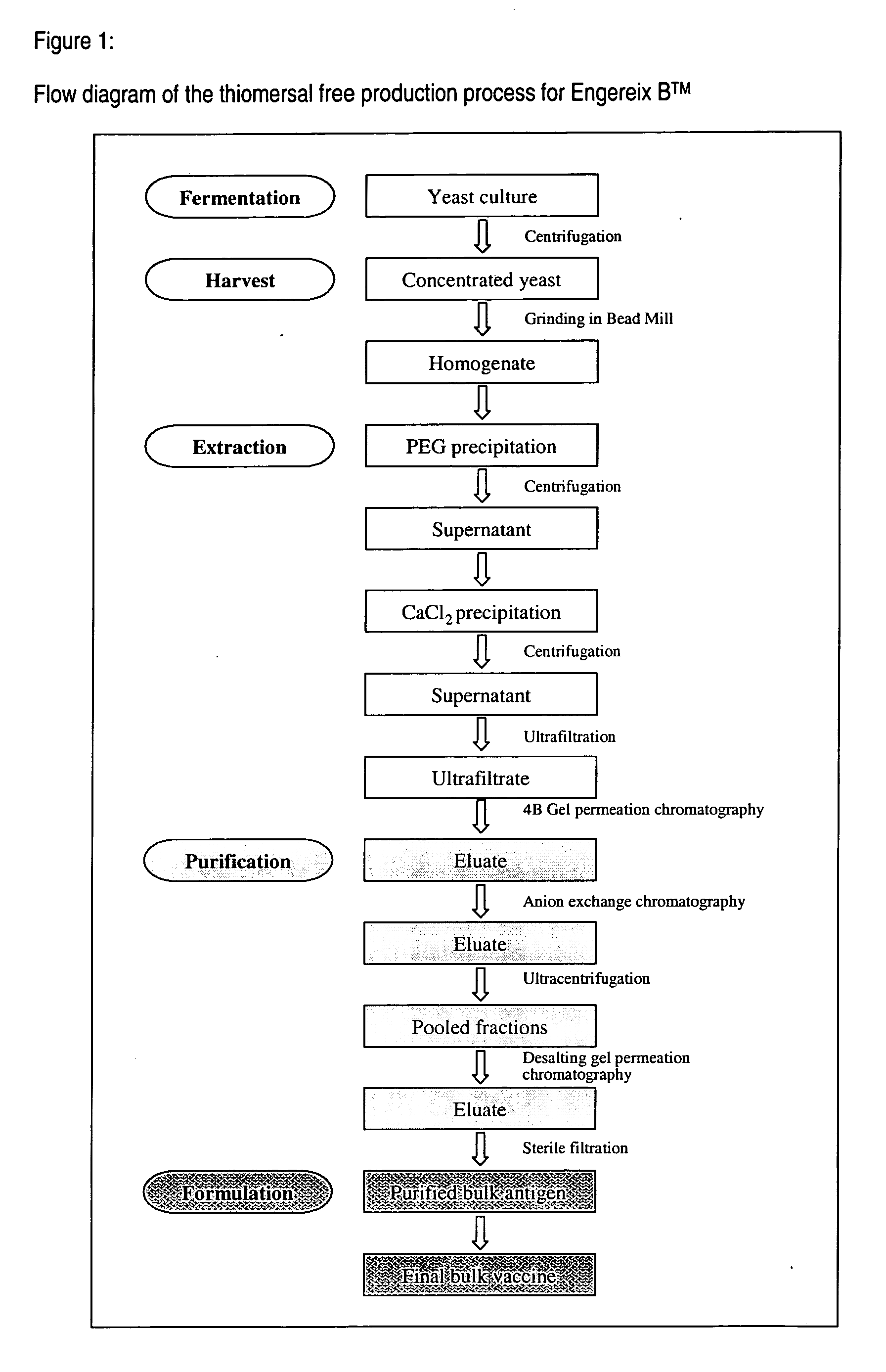

1.1 Outline of the Production Process

[0057] Hepatitis B surface antigen may be produced by fermentation of an appropriate strain of Saccharomyces cerevisiae, for example that described in Harford et. al. (loc. cit.).

[0058] At the end of large-scale fermentation of the recombinant yeast strain, the cells are harvested and broken open in the presence of a mild surfactant such as Tween 20. The surface antigen is then isolated by a multistep extraction and purification procedure exactly as described above in Example 1 up to the step of the first gel permeation on Sepharose 4B.

1.2 Thiomersal-Free Purification Process

[0059] In the thiomersal free process the following two changes have been introduced compared to the process described in Example 1.

1. The elution buffer at the 4B gel permeation chromatography step no longer contains thiomersal....

example 3

Formulation of Combined Vaccines

[0144] The bulk antigen of the invention is particularly suitable for formulation in a combined vaccine comprising IPV.

[0145] Stability studies performed on initial lots of a combined DTPa-HBV-IPV vaccine indicated a decline in potency of the IPV component, particularly of type 1 poliomyelitis antigen, when using an in vitro immunoassay (determination of D-antigen content by ELISA) and an in vivo rat potency test. No potency loss was observed for type 3. For type 2, the potency loss was within the expected range (not more than 10% loss per year of storage).

[0146] Studies were initiated to determine the cause of this loss of potency in the combined DTPa-HBV-IPV vaccine. From the observation that the stability of IPV in SB Biologicals' DTPa-IPV vaccine is satisfactory (not more than 10% antigen content loss per year of storage), it was concluded that the HBV component was likely to be responsible for the instability of IPV in the DTPa-HBV-IPV vaccin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com