Immunosuppressive effects of pteridine derivatives

a technology of pteridine and derivatives, which is applied in the direction of biocide, plant growth regulators, cyclic peptide ingredients, etc., can solve the problems of high turn-over rate, marrow depression and liver damage, and severe toxic effects on normal cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

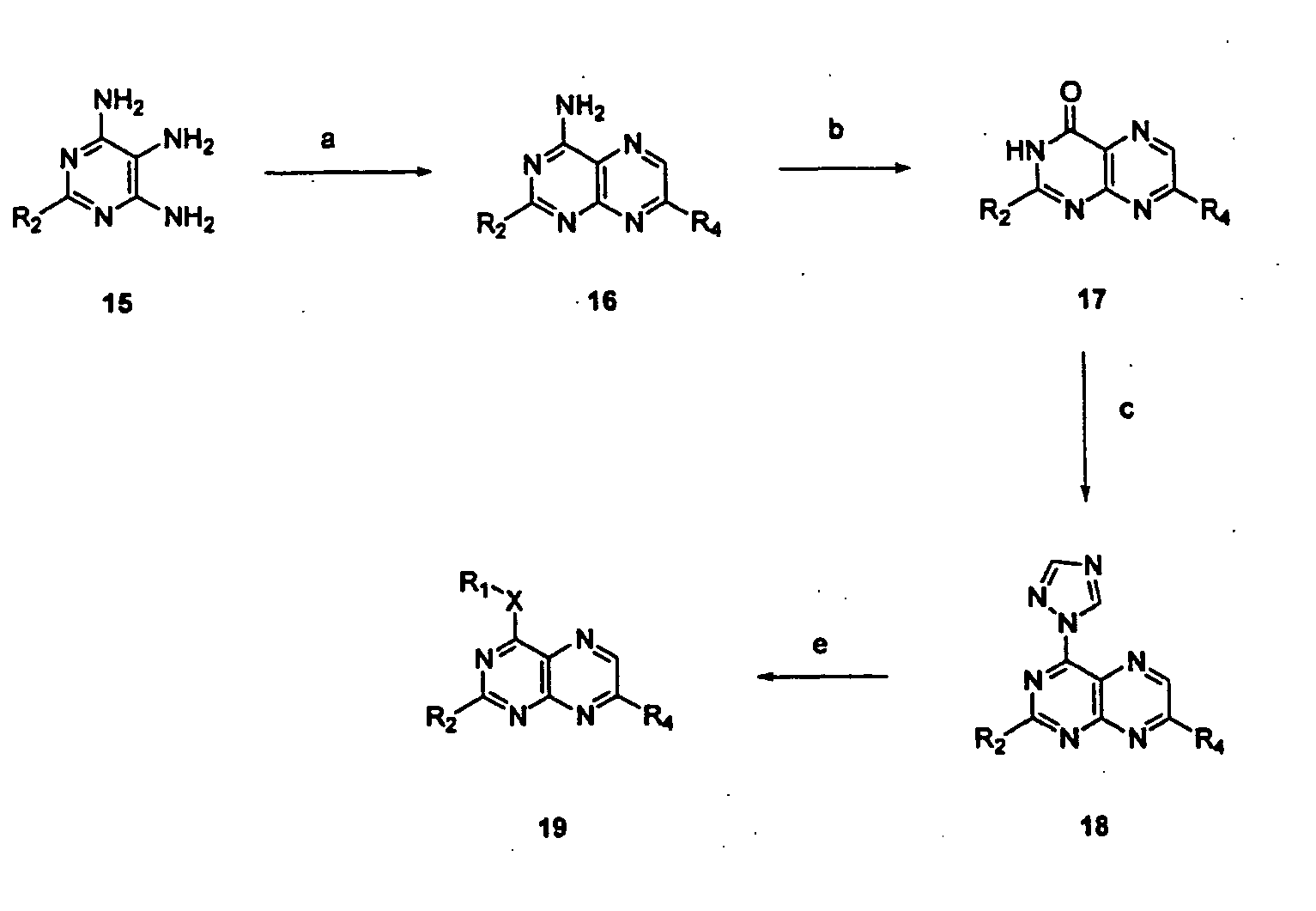

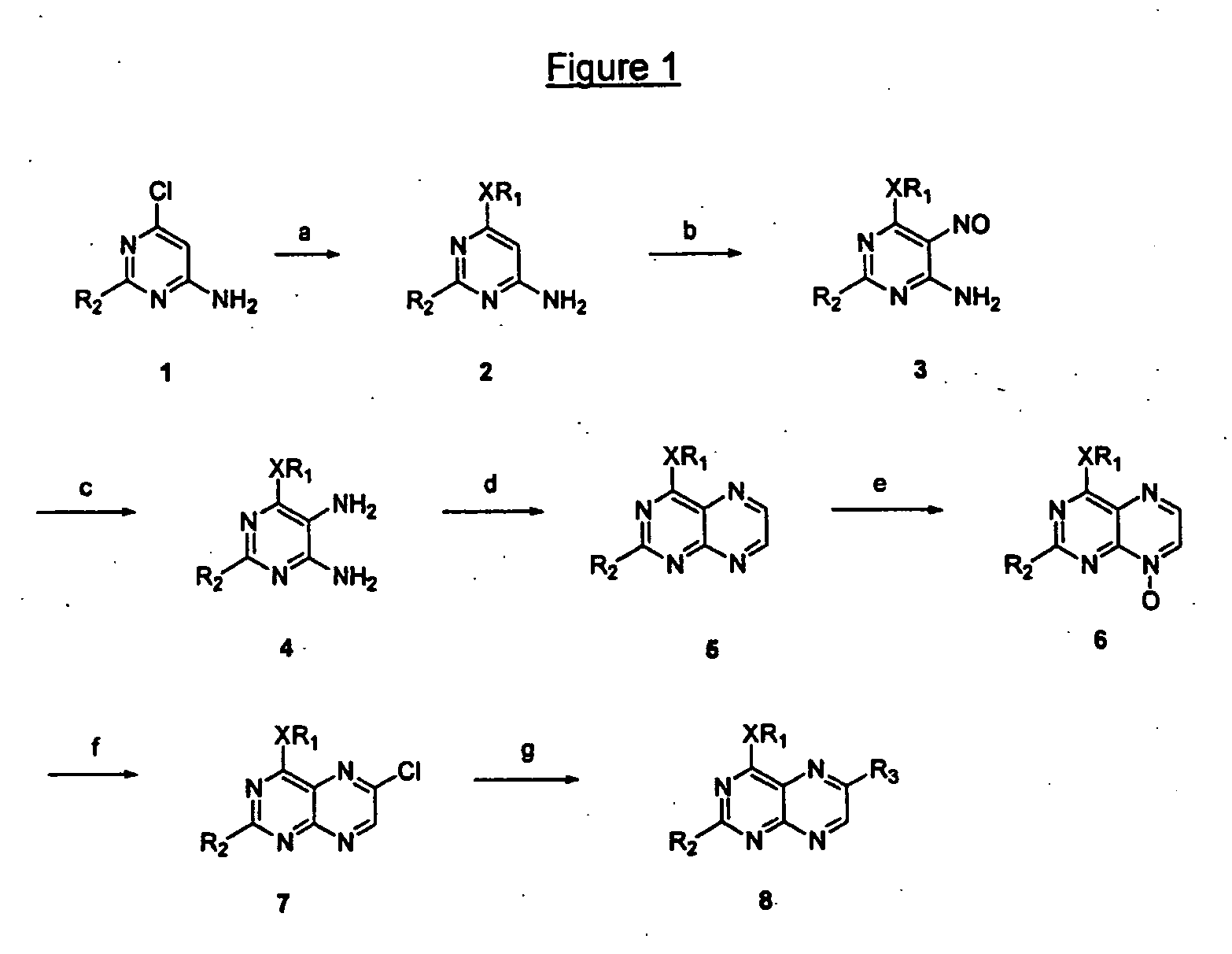

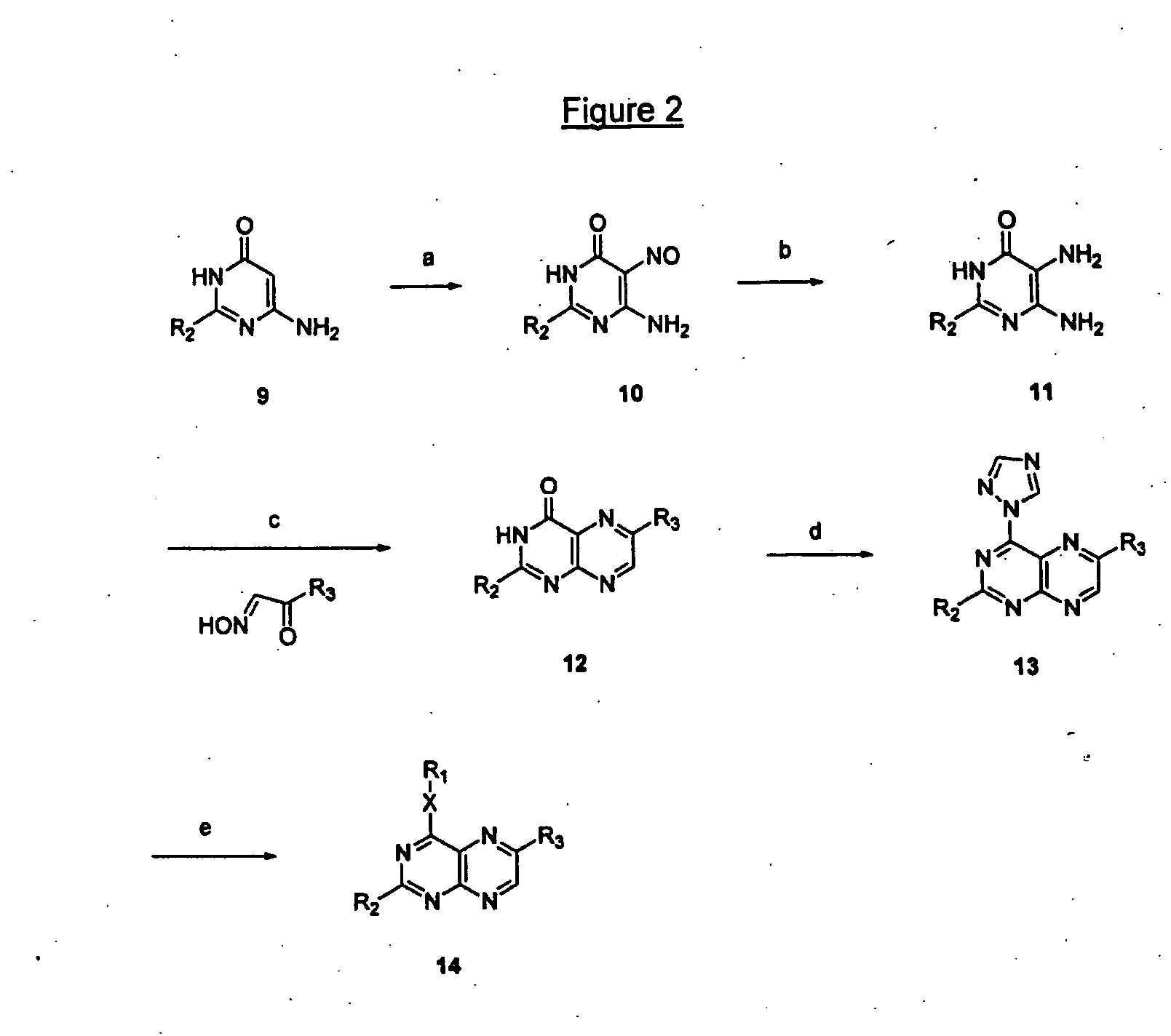

Method used

Image

Examples

example 1

Preparation of 2-amino-4-n-pentyloxy-6-styrylpteridine

[0165] A mixture of 1.5 g (5.6 mmoles) 2-amino-6-chloro-4-n-pentyloxypteridine (e.g. available following the procedure disclosed by Mohr et al. in Helv. Chem. Acta (1992) 75:2317), palladium acetate (63 mg, 0.28 mmoles), tri-o-tolylphosphane (682 mg, 2.24 mmoles), cuprous iodide (53 mg, 0.28 mmoles), styrene (1,3 ml., 11.3 mmoles) and triethylamine 3.1 ml, 22 mmoles) was stirred in dry acetonitrile (50 ml) under reflux for 90 hours. It was evaporated and the residue purified by silica gel column chromatography with chloroform. The product fraction was evaporated to give 1.37 g (yield: 72%) of an orange powder exhibiting, after recrystallization from a EtOAc / hexane mixture, a melting point (m.p.) range of 127-128° C.

example 2

Preparation of 2-amino-6-(1,2-dibromophenethyl)-4-n-pentyloxy-pteridine

[0166] To a solution of the derivative of example 1 (1.0 g, 2.94 mmoles) in chloroform (50 ml) was added a 2 M bromine solution in chloroform (2.2 ml., 4.4 mmoles) and then the mixture was stirred at room temperature for 7 hours. It was diluted with chloroform (50 ml), washed with a saturated aqueous Na2SO3 solution (100 ml) and dried over sodium sulfate. After evaporation of the solvents, the residue was treated with toluene, filtered, washed with ether and dried in a vacuum desiccator to give 0.84 g (yield: 57%) of a yellow powder.

example 3

Preparation of 2-amino-4,7-dimethoxy-6-styrylpteridine

[0167] A suspension of the derivative of example 2 (0.3 g, 0.6 mmoles) is methanol (10 ml) was treated with 1 M methanolic sodium methoxide (3 ml, 3 mmoles) and then refluxed for 4 hours. It was diluted with chloroform (100 ml), washed with a saturated aqueous ammonium chloride solution and water and then the solution was dried over sodium sulfate. The filtrate was evaporated and the residue was purified by silica gel column chromatography while using chloroform as the eluent. The product fraction was evaporated to give 50 mg (yield: 26%) of a yellow powder with a melting point range of 197-198° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stereoisomer | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com