Organic electro-luminescence device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

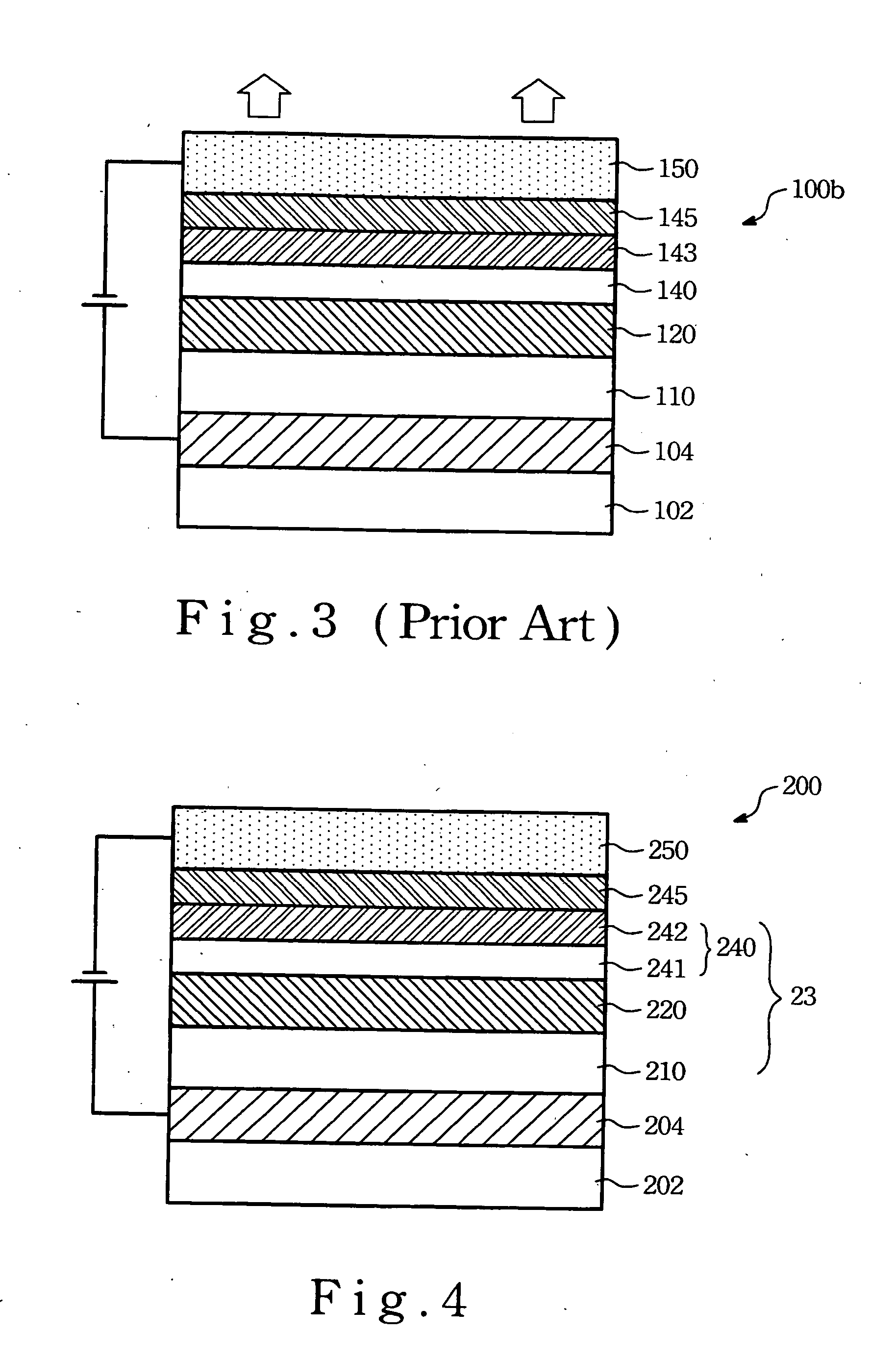

[0023] The invention aims at providing an organic electro-luminescence devices and particularly to a top-emission organic electro-luminescence device, which has high current injection efficiency, relatively loner life time, and can be fabricated with relatively simplified processes.

[0024] Please refer to FIG. 4, which is a cross section view of an organic electro-luminescence device of the present invention. While fabricating the organic electro-luminescence device 200, a substrate 202 is provided first, then a hole injection layer 204 is disposed on the substrate 202. In one embodiment, the substrate 202 is made of light transparent materials or opaque materials with light reflection character. The hole injection layer 204 is made of conductive transparent materials (for instance, ITO, IZO) via sputtering process.

[0025] Next, an organic layer 23 is disposed on the hole injection layer 204. Wherein the organic layer 23 is an multi-layer structure. It at least comprises a light-emi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com