Short contact time FCC process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

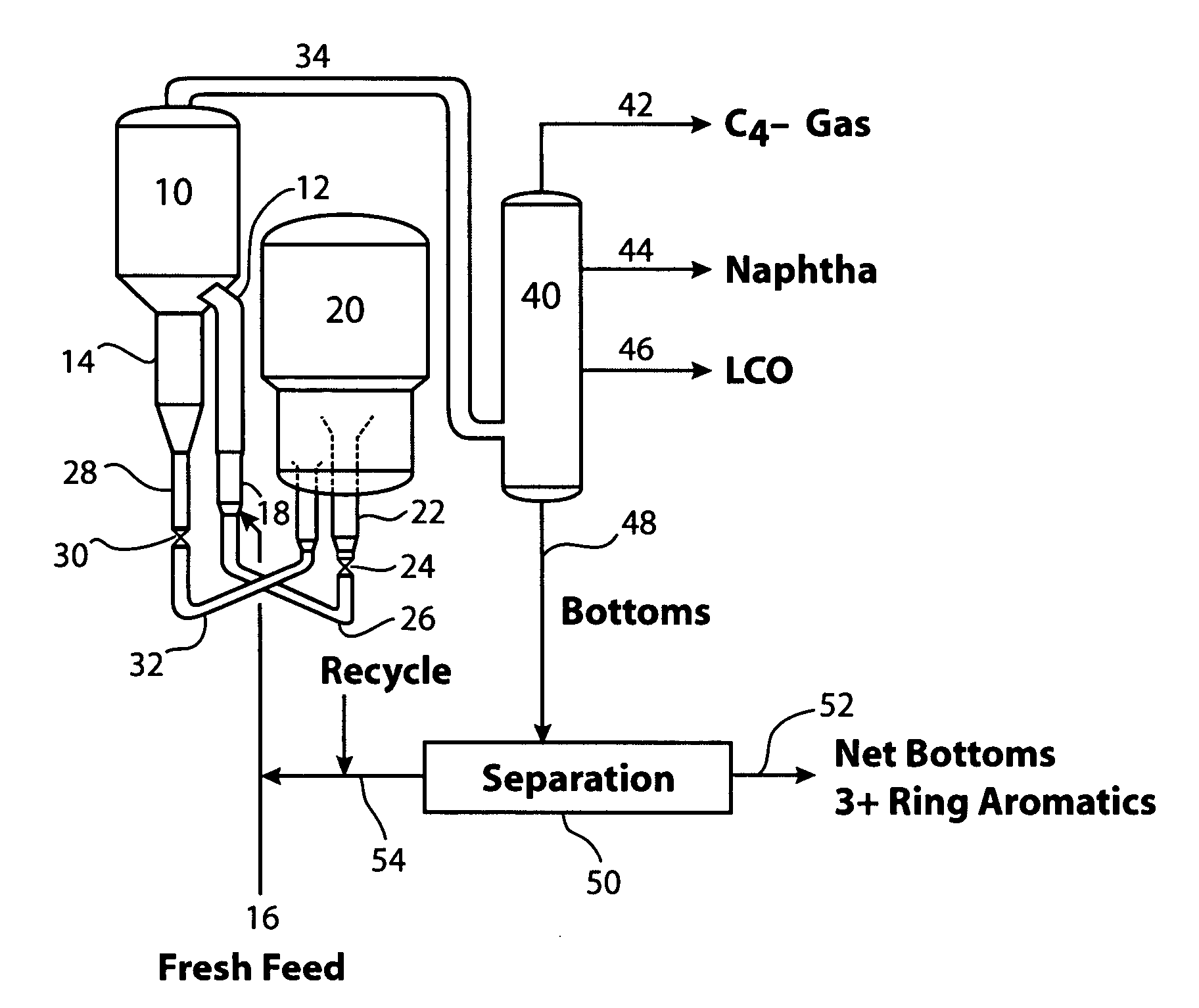

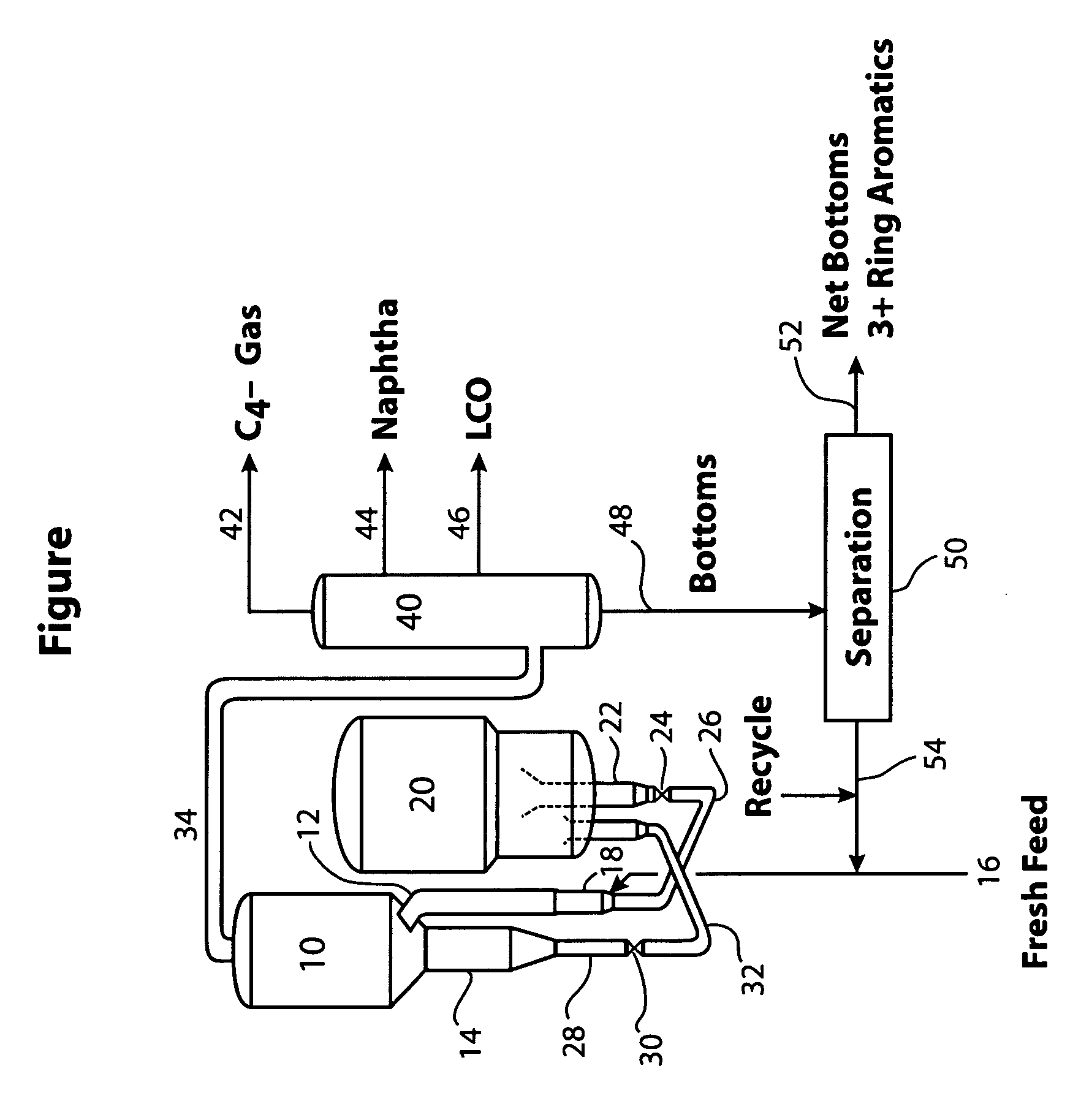

Image

Examples

example

[0040] This example relates to a short contact time FCC riser reactor. Vapor residence times in the riser are in the range of 3 to 4 seconds. Process performance data collected during a commercial monitoring test period were used to tune FCC model software program for representing base case operation. Selected feedstock inspections are listed in Table 1:

TABLE 1Feedstock PropertiesGravityAPI19Aniline PointDEG F.165SulfurWT %2.921NitrogenPPMW1897Basic NitrogenPPMW728Total P / N / AWT %Total Paraffins11.64Total Naphthenes26.46Total Aromatics61.90HPLC-2 AnalysisWT %Saturates38.43Aromatic Ring23.97Class 1Aromatic Ring13.92Class 2Aromatic Ring11.70class 3Aromatic Ring6.78Class 4Polars5.20GC DistillationDEG F.IBP5115% Off62210% Off66830% Off74950% Off81370% Off88290% Off97695% Off1019EP1093

[0041] Commercially available equilibrium catalyst properties are listed in Table 2. Using these feed and catalyst properties, the FCC model software was used to develop a base product yield slate for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com