Method of producing a thermoplastically moldable fiber-reinforced semifinished product

a technology of thermoplastic molds and semi-finished products, which is applied in the direction of coatings, applications, domestic articles, etc., can solve the problems of high standard deviation in mechanical properties, excessive energy consumption, and exceptionally difficult procedures, and achieve excellent and highly reproducible properties, easy re-forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

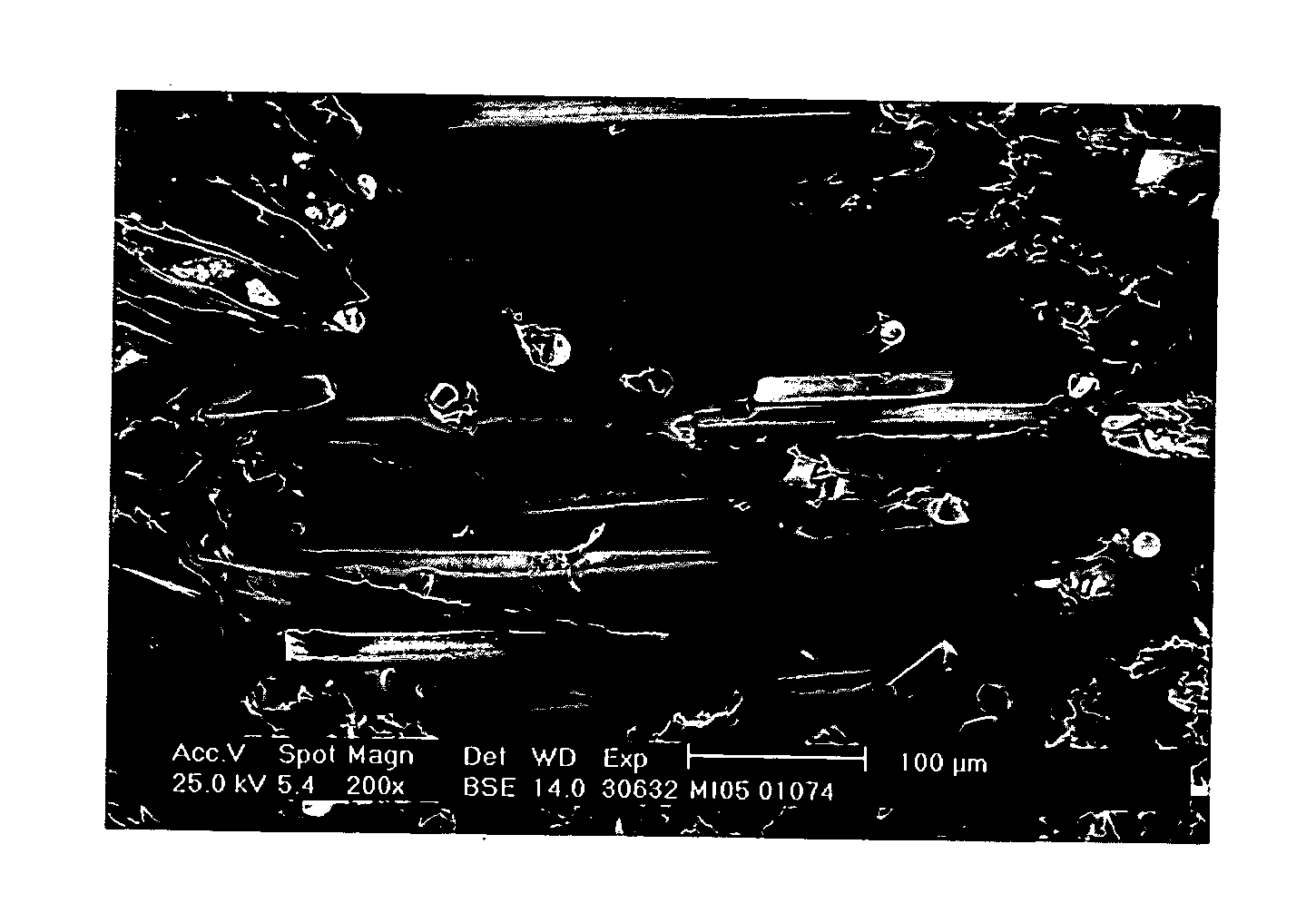

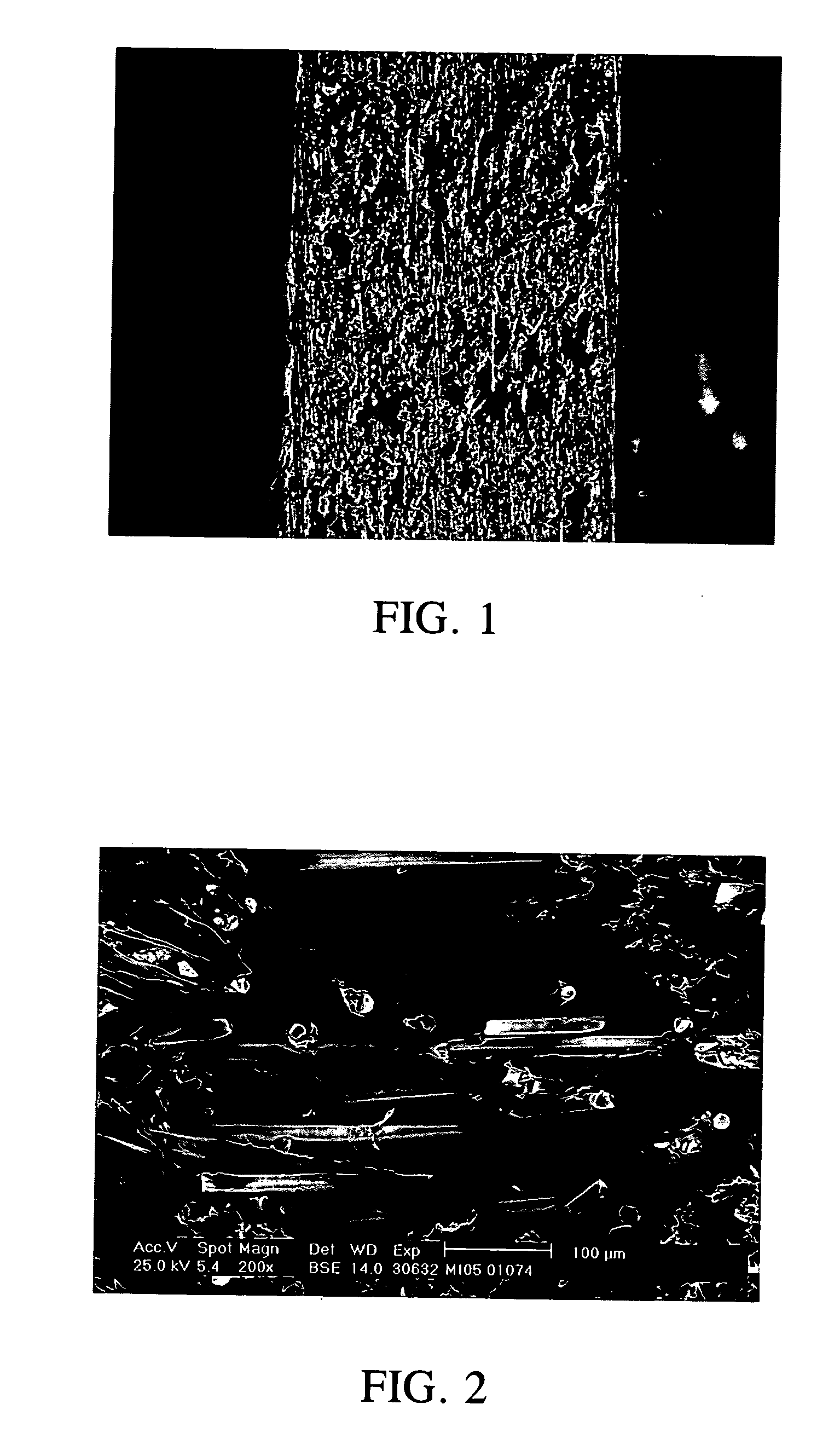

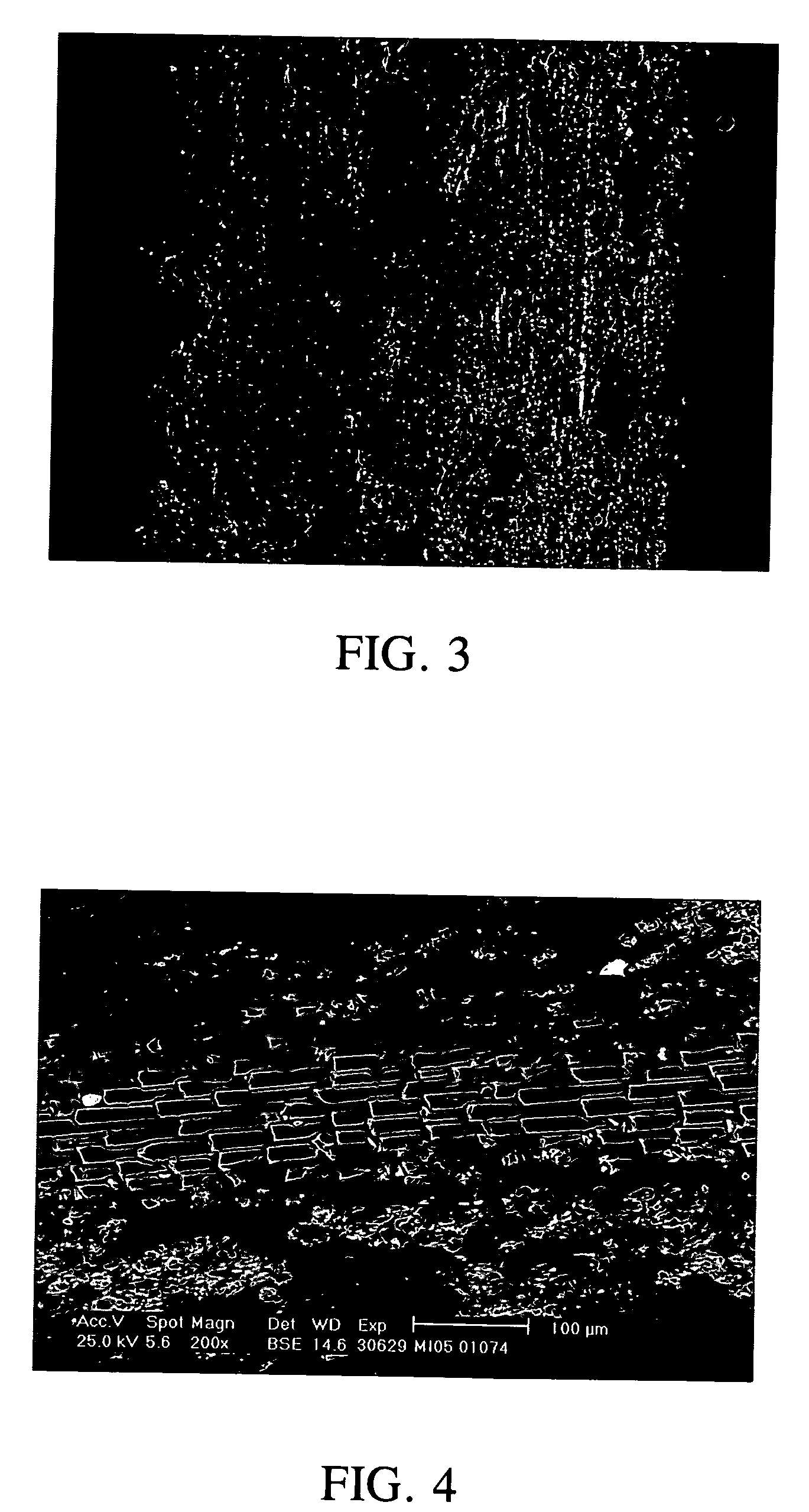

[0041] Staple fibers of PP having a melt flow index (230° C., 2.16 kg) of 25 g / 10 min and a length of about 40 mm are mixed together with chopped glass fibers having a length of 50.8 mm and a water content of about 1%. Mixing is carried out in a blending unit before providing the fibers to a continuous airlay process for further mixing, and the resulting continuous nonwoven fleece, having an areal weight of 1200 g / m2, is needled from one side on a conventional needle loom. The thus preconsolidated fleece is heated in an air flow oven to about 190° C. to melt the PP and thereafter immediately conveyed to a heated double belt laminator. There it is compressed at a pressure of 0.5 bar for about 15 sec. The laminator temperature is about 150° C., to maintain the core of the fleece above the softening point of the PP and to enable it to penetrate the glass fibers homogeneously. On the other hand, due to the relatively low pressure, the three-dimensional randomly oriented glass fibers par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com