Piezoelectric Actuator, Ink-Jet Head, Method Of Producing Piezoelectric Actuator, And Method Of Producing Ink-Jet Head

a piezoelectric actuator and actuator technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric/electrostriction/magnetostriction machines, printing, etc., can solve the problems of inability to achieve sufficient piezoelectric characteristics in some cases, exposed substrate to high-temperature environment during calcination, etc., to reduce thermal load, reduce the effect of degradation of piezoelectric characteristics and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

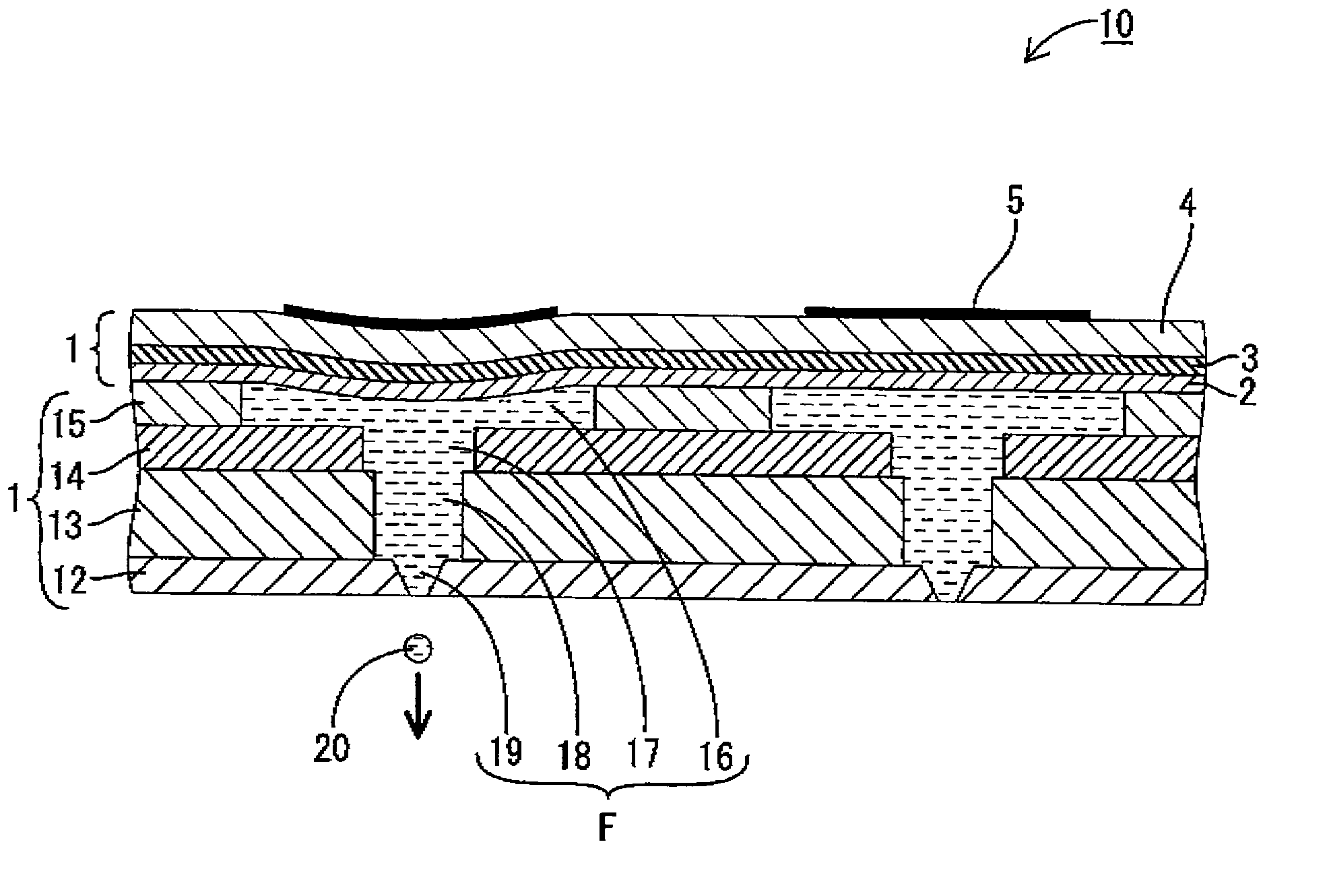

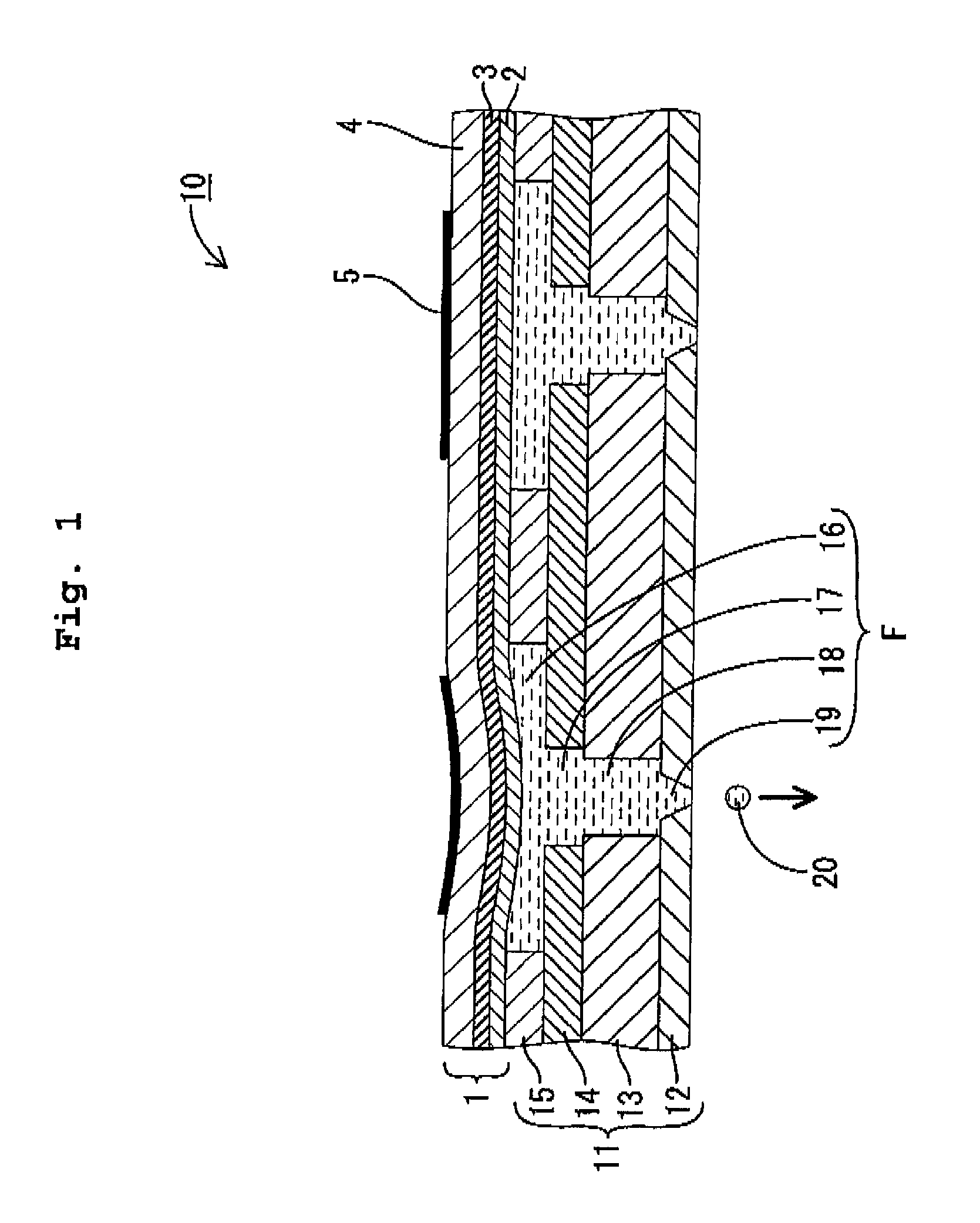

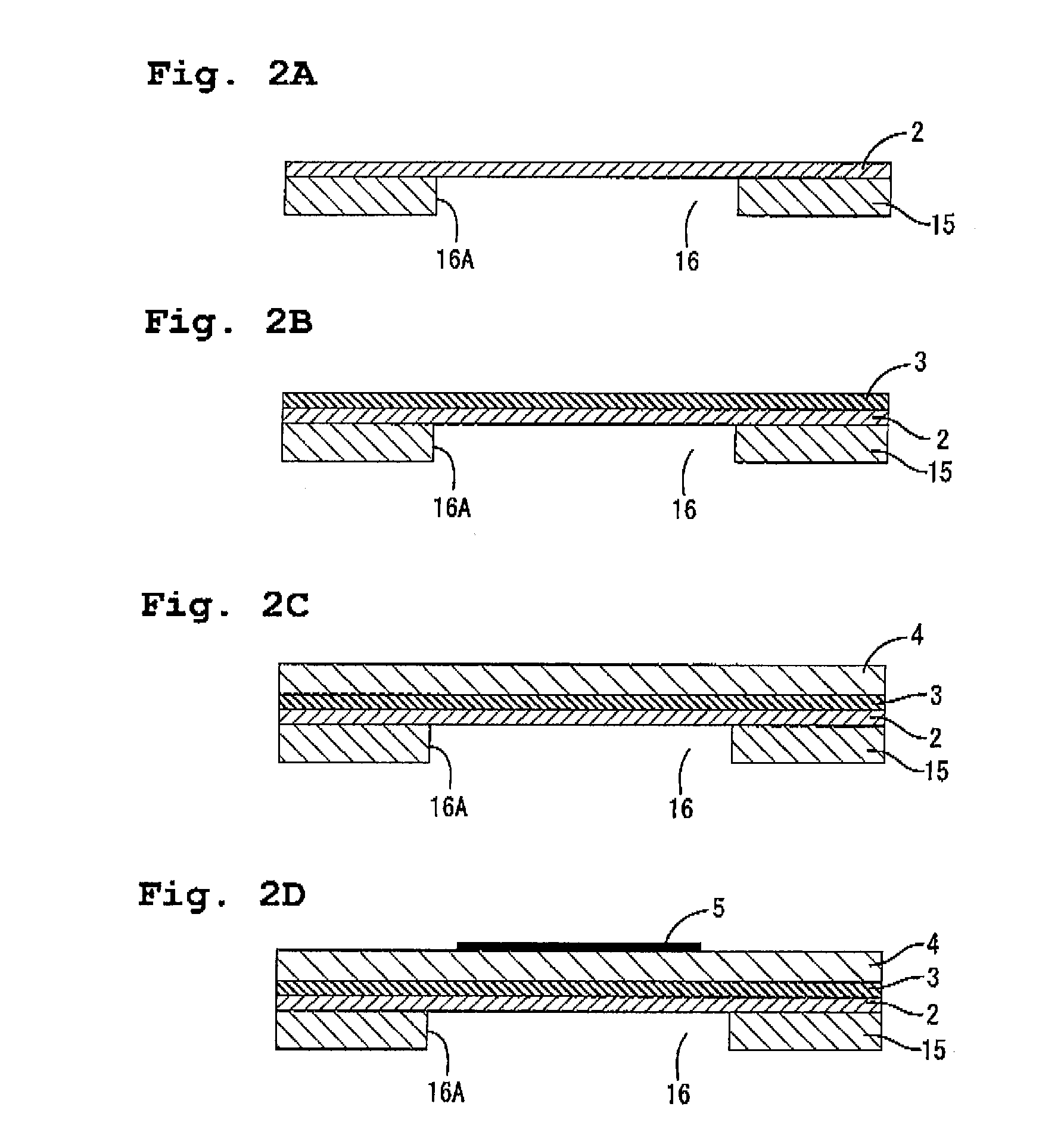

[0023] An embodiment of the present invention will be described with reference to FIGS. 1 to 3.

[0024]FIG. 1 shows an ink-jet head 10 of this embodiment. The ink-jet head 10 includes a channel unit 11 (corresponding to the ink-channel forming body of the present invention) which has a plurality of pressure chambers 16 accommodating an ink 20 and an actuator plate 1 (corresponding to the piezoelectric actuator of the present invention) which is joined to the channel unit 11 so as to close the pressure chambers 16.

[0025] The channel unit 11 as a whole is in the form of a flat plate in which a nozzle plate 12, a manifold plate 13, a channel plate 14, and a pressure-chamber plate 15 are stacked in layers in sequence, and the channel unit 11 has a construction in which the plates 12, 13, 14, and 15 are joined to one another with an epoxy-based thermosetting adhesive.

[0026] The nozzle plate 12 is formed of a polyimide-based synthetic resin material, and a plurality of holes which are to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com