Method of fabricating light-emitting semiconductor device

a technology of semiconductor devices and semiconductors, applied in the field of light-emitting diodes, can solve the problems of not contributing to the net efficiency of light-emitting devices, corresponding drop in light production efficiency, and waste of current flowing in this part of the active layer, so as to promote lateral spreading current, low lateral resistivity, and high light production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

of FIG. 4

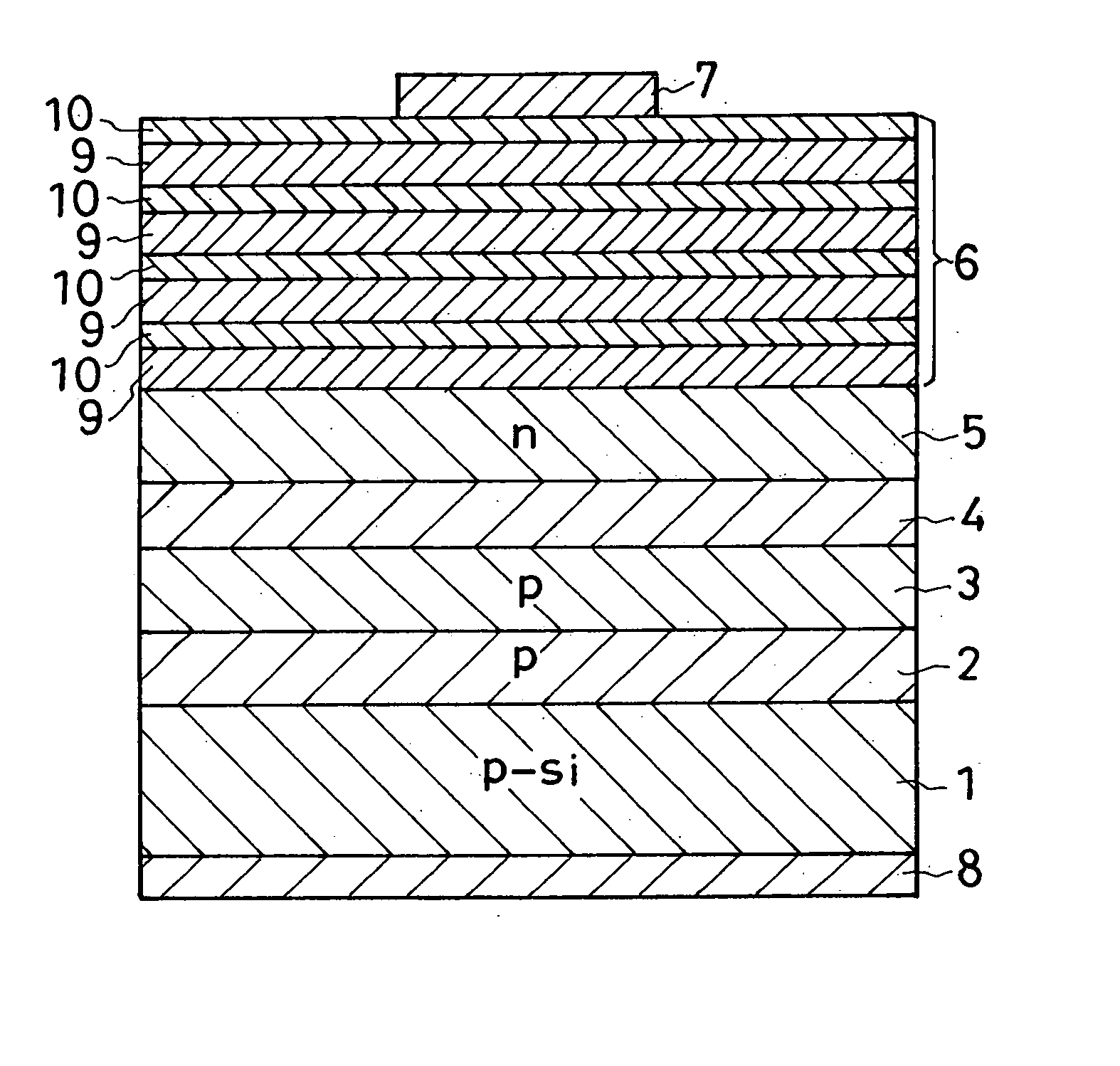

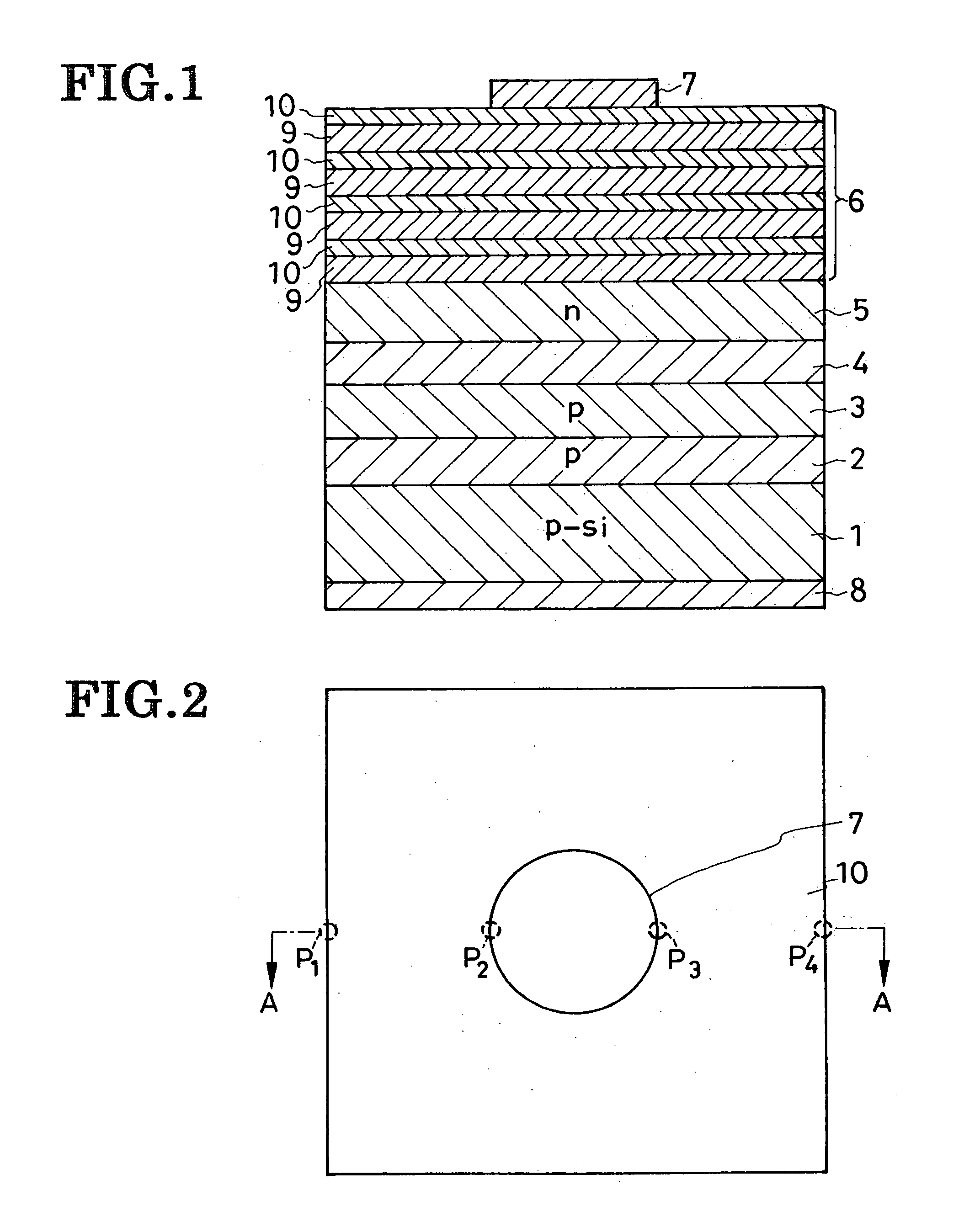

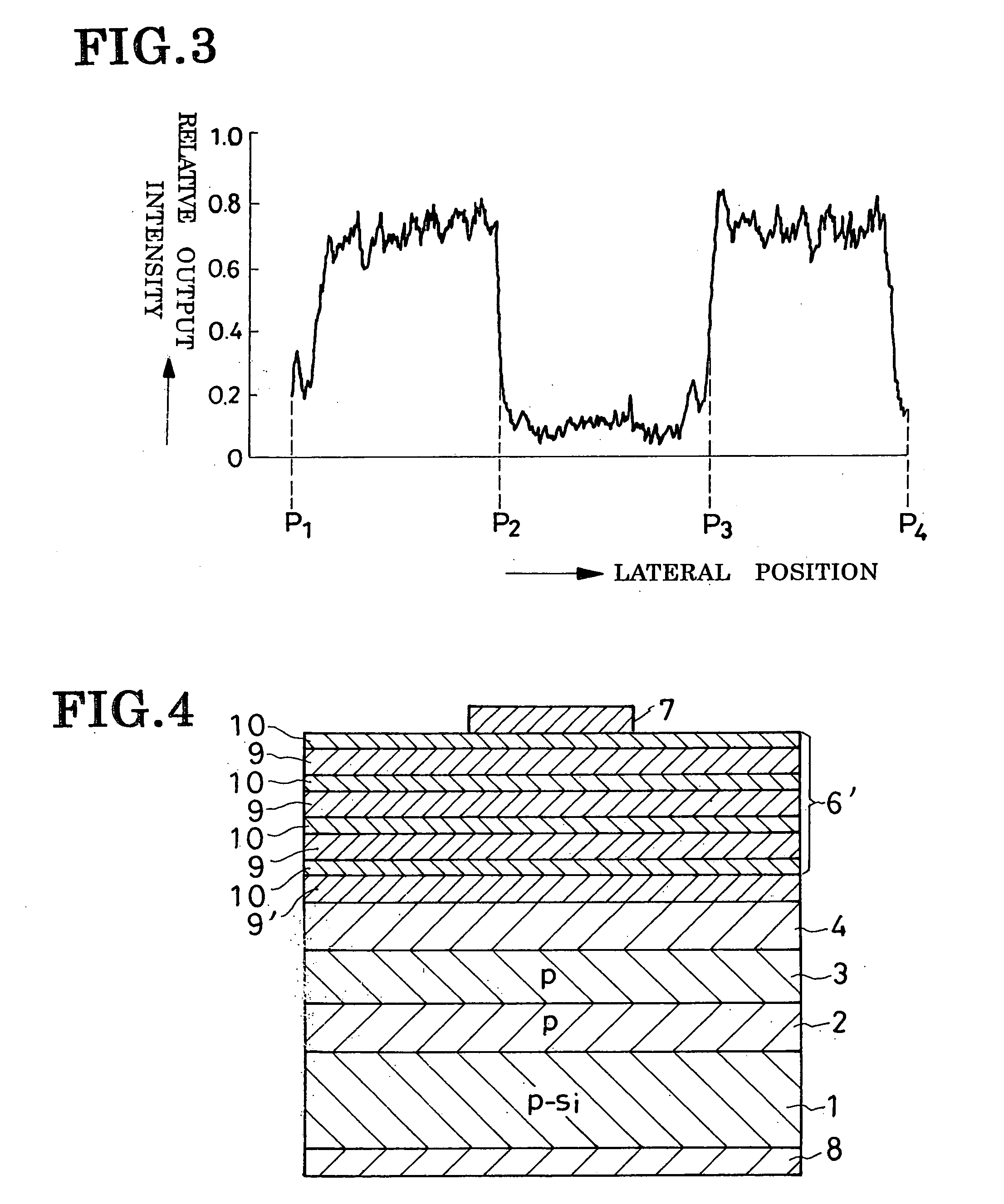

[0068] Another preferred form of LED shown in FIG. 4 is akin to that of FIGS. 1 and 2 except for the absence of the n-type nitride semiconductor layer 5. Formed on the active layer 4 in lieu of the missing n-type nitride semiconductor layer 5 is an n-type nitride semiconductor layer 9′ which is of the same composition as the first sublayers 9 of the current spreading layer. This current spreading layer is generally designated 6′ in FIG. 4 because of the absence of the lowermost first sublayer 9.

[0069] Thus the n-type nitride semiconductor layer 9′ is in contact both with one second sublayer 10 of the current spreading layer 6′ in order to offer the two-dimensional electron gas effect, and with the active layer 4 in order to function as n-type cladding like the n-type nitride semiconductor layer 5 of the FIGS. 1 and 2 embodiment. The current spreading layer 6′ is similar in construction to its FIG. 1 counterpart 6 except for the absence of the lowermost first sublayer 9. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com